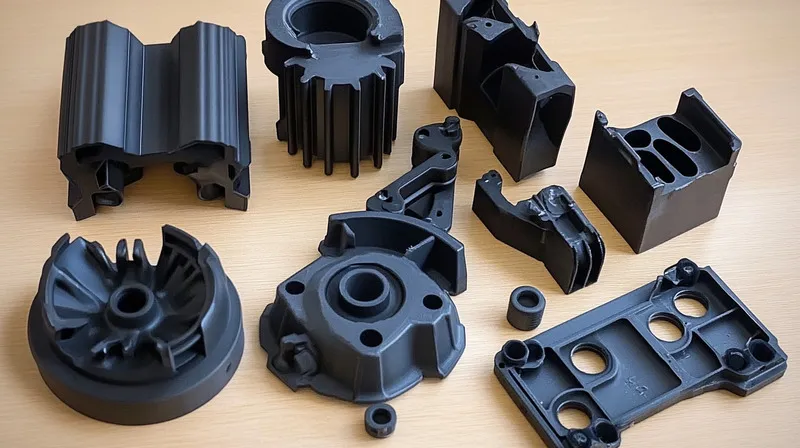

Injection Molded Products

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

How Do Additives Impact the Properties of Injection-Molded Parts?

Additives play a crucial role in enhancing the properties of injection-molded parts1, allowing manufacturers to tailor materials for specific applications. From improving strength and durability to enhancing aesthetics and environmental resistance, additives can transform the performance of molded components. However, ...

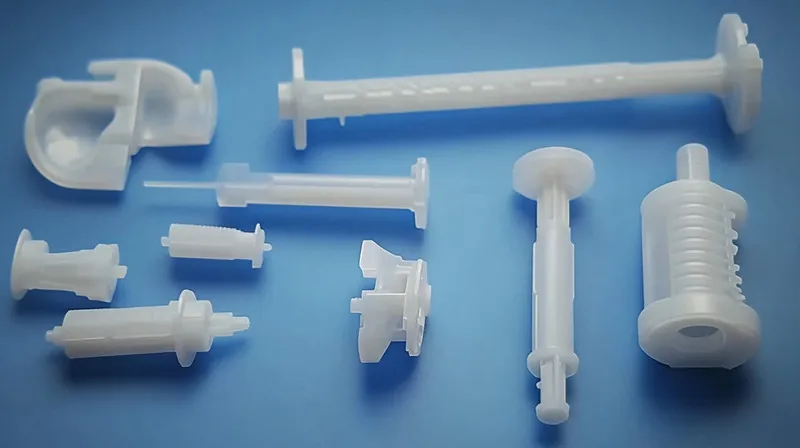

Injection Molded Products

How to Design Injection Molded Parts for Seamless Assembly

Designing injection molded parts1 for seamless assembly is essential for efficient manufacturing and high-quality products. It ensures that parts fit together perfectly, reducing assembly time and costs while improving overall product reliability. This guide will walk you through the key ...

Injection Molded Products

How Biopolymers Enhance the Sustainability of Injection Molding

Biopolymers are transforming the injection molding1 industry by offering a sustainable alternative to traditional petroleum-based plastics. Derived from renewable resources like plants and microorganisms, biopolymers are often biodegradable or compostable, making them an eco-friendly choice for manufacturers looking to reduce ...

Injection Molded Products

Achieving Perfect Color Consistency in Injection Molded Parts

Achieving perfect color consistency1 in injection molded parts is a critical aspect of manufacturing that ensures every part produced has the same color, with no noticeable variations. This uniformity is essential for maintaining product quality, brand identity, and compliance with ...

Injection Molded Products

What Impact Do Plasticizers Have on the Flexibility of Injection-Molded Parts?

Plasticizers play a crucial role in enhancing the flexibility of injection-molded parts1 by modifying the physical properties of polymers. This blog post explores the definitions, classifications, applications, advantages, disadvantages, and technical considerations of using plasticizers in injection molding. Plasticizers are ...

Injection Molded Products

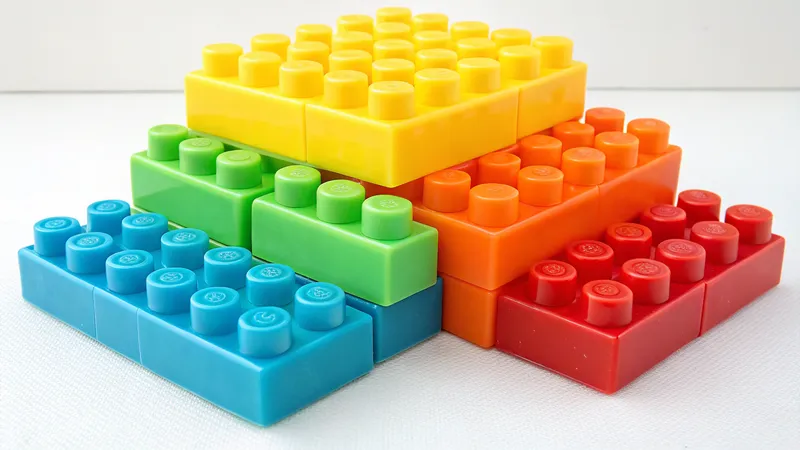

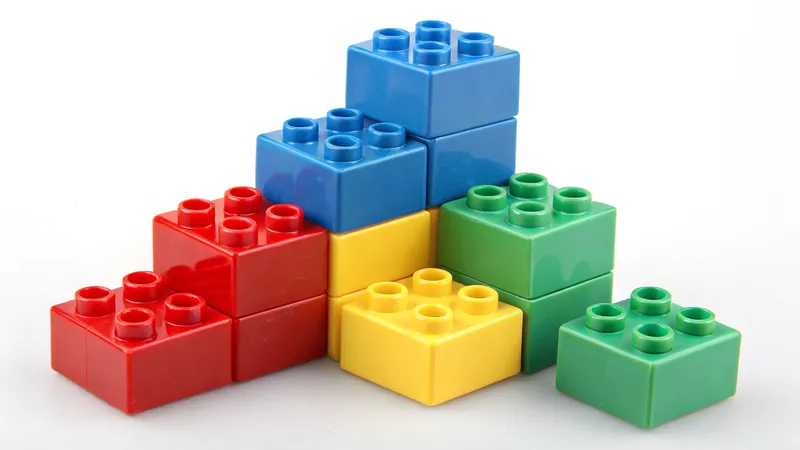

How Legos Are Made: Are They Injection Molded?

The manufacturing of Lego bricks involves a precise and highly automated process called injection molding1, where molten plastic is injected into molds to create the iconic, interlocking bricks. This method ensures each brick meets strict quality standards for durability, precision, ...

Injection Molded Products

How Can You Texture Injection Molded Surfaces Effectively?

Texturing injection molded surfaces involves applying patterns or finishes to molds, which transfer to plastic parts during molding, enhancing aesthetics, functionality, and defect concealment. Understanding how to texture injection molded surfaces effectively is crucial for industries seeking to improve product ...

Injection Molded Products

How Can You Produce an Egg Tray Using an Injection Molding Machine?

Injection molding is a highly efficient manufacturing process1 used to create durable, lightweight egg trays for the poultry and food packaging industries. This guide provides a comprehensive overview, from the basics of injection molding to advanced technical details, helping you ...

Injection Molded Products

How Are Toothbrushes Made Using Injection Molding Machines?

Ever wondered how the toothbrush you use every day is crafted? Behind its simple design lies a sophisticated manufacturing process that ensures durability, effectiveness, and safety. At the core of this process is injection molding, a technique that enables the ...

Injection Molded Products

How Can an Injection Molding Machine Produce Plastic Spoons?

Injection molding is a widely adopted manufacturing process for producing plastic spoons, especially in large quantities. This method involves melting plastic pellets, injecting the molten plastic into a mold shaped like a spoon, cooling it to solidify, and then ejecting ...

Injection Molded Products

How Can Injection Molded Parts Be Recycled Effectively?

Injection molded parts, widely used in industries like automotive, packaging, and consumer goods, are typically crafted from plastics such as PET, HDPE, and PP. With growing concerns over plastic waste, recycling these components has become a vital practice. Fortunately, many ...

Injection Molded Products

How Does an Injection Molding Machine Create a Keyboard?

Injection molding is a cornerstone of modern manufacturing, particularly in producing the plastic components of keyboards, such as keycaps and bases. This process involves melting plastic pellets, injecting them into a mold under high pressure, and cooling them to form ...

Injection Molded Products

How Do Injection Molding Machines Manufacture Rulers?

Injection molding is a cornerstone of modern manufacturing, widely employed to produce precise plastic parts, including everyday tools like rulers. This process involves melting plastic materials, injecting them into a mold, and allowing them to cool and solidify into the ...

Injection Molded Products

What Are the Key Standards for Injection Molded Electronic Casings?

Injection molded electronic casings1 are plastic housings that protect and support electronic components in devices like smartphones, laptops, and industrial control panels. They are created by injecting molten plastic into a mold, which cools to form precise, durable shapes. These ...

Injection Molded Products

What Size Injection Molding Machine is Needed for an Air Conditioning Shell?

Selecting the right size of an injection molding machine1 is essential for producing high-quality air conditioning (AC) shells efficiently and cost-effectively. The machine size impacts production capacity, part quality, and operational costs, making it critical to align the machine’s capabilities ...

Injection Molded Products

How Do Plastic Injection Molding Machines Create Eyeglasses?

Plastic injection molding is a cornerstone of modern eyeglass manufacturing, enabling the efficient production of lightweight, durable, and stylish frames. This process involves melting thermoplastic materials1 and injecting them into precision molds to create intricate designs with consistent quality. While ...

Injection Molded Products

How Do Injection Molding Machines Create Plastic Flowers?

Injection molding is a widely used manufacturing process1 that produces precise plastic parts by injecting molten plastic into a mold. When it comes to creating plastic flowers, this technique is employed to craft detailed components such as petals, stems, and ...

Injection Molded Products

How Efficiently Can an Injection Molding Machine Produce PVC Fittings?

Injection molding is a manufacturing process where molten plastic, such as polyvinyl chloride (PVC), is injected into a mold to create precise, complex shapes like PVC fittings. These fittings are vital components in plumbing, construction, and irrigation systems. Known for ...

Injection Molded Products

How Can an Injection Molding Machine Create a Toy Car?

Injection molding is a cornerstone of modern manufacturing, especially in the production of plastic toys1 like toy cars. This process enables the mass production of detailed, durable parts with high efficiency and consistency, making it an ideal choice for creating ...

Injection Molded Products

How Can Injection Molding Machines Be Used to Manufacture Flower Pots?

Injection molding is a versatile and efficient manufacturing process that has transformed the production of plastic products, including flower pots. This technique involves injecting molten plastic into a precisely designed mold cavity, where it cools and solidifies into the desired ...

Injection Molded Products

How Can an Injection Molding Machine Be Used to Make Helmets?

Injection molding is a manufacturing powerhouse, transforming molten plastic into precise, durable shapes by injecting it into a mold under high pressure. When it comes to helmets, this process is the go-to method for crafting the hard outer shells that ...

Injection Molded Products

How Do Injection Molding Machines Produce Water Tanks?

Injection molding machines craft water tanks by transforming molten plastic into precise, durable shapes through a series of sophisticated steps. This process involves melting plastic resin, injecting it into a meticulously designed mold, cooling it to solidify, and ejecting the ...

Injection Molded Products

How Can Injection Molding Revolutionize the Production of Food Containers?

Injection molding1 is a transformative manufacturing process poised to revolutionize food container production2. By injecting molten plastic into precisely engineered molds, this technique creates containers with intricate shapes, tight tolerances, and consistent quality—features critical for ensuring food safety, extending shelf ...

Injection Molded Products

Can Injection Molding Machines Produce Both PPR and PVC Fittings?

Injection molding machines can produce both PPR and PVC fittings1 with proper adjustments, but the distinct properties of each material necessitate specific temperature settings, cleaning protocols, and maintenance to ensure quality and machine longevity. Understanding these nuances is essential for ...

Injection Molded Products

How to Calculate the Cost Per Part in Injection Molding

Injection molding is a cornerstone of modern manufacturing, enabling the mass production of precise plastic parts across industries like automotive, medical, and consumer goods. However, for businesses, understanding the cost per part1 is crucial—it directly impacts profitability, pricing, and production ...

Injection Molded Products

Injection Molding vs. Rotational Molding: A Comprehensive Comparison

Injection Molding1 and Rotational Molding are two distinct plastic manufacturing processes, each with unique advantages and applications. While both are used to create plastic parts, they differ significantly in their methods, materials, and ideal use cases. This article provides a ...

Injection Molded Products

How Can Injection Molding Machines Be Used to Manufacture Phone Cases?

Injection molding machines are essential for producing phone cases, offering precision and efficiency for mass production of protective, aesthetically pleasing smartphone covers. Injection molding is a manufacturing process where molten plastic is injected into a mold to create detailed, form-fitting ...

Injection Molded Products

Surface Finishing Techniques for Injection Molded Parts: A Comprehensive Guide

Surface finishing techniques are vital in injection molding, transforming raw molded parts into polished, functional, and visually appealing products. Whether it’s achieving a high-gloss finish for consumer electronics or a textured surface for automotive grips, these techniques enhance both aesthetics ...

Injection Molded Products

A Guide to Plating Injection Molded Parts: Process, Materials, and Applications

Plating injection molded parts is a fascinating process that marries the lightweight versatility of plastic with the durability and shine of metal. By coating plastic components with a thin metal layer—think chrome, nickel, or gold—manufacturers can create parts that look ...

Injection Molded Products

How Efficiently Can Injection Molding Machines Produce Toolboxes?

Injection molding is a cornerstone of modern manufacturing, renowned for its efficiency, precision, and ability to produce complex plastic parts like toolboxes. This article delves into the efficiency of injection molding machines1 in toolbox production2, exploring the process, materials, applications, ...

Injection Molded Products