Injection molding is a versatile and efficient manufacturing process that has transformed the production of plastic products, including flower pots. This technique involves injecting molten plastic into a precisely designed mold cavity, where it cools and solidifies into the desired shape. For flower pots, injection molding offers significant advantages, such as high production efficiency1, consistent quality, and the ability to create intricate designs with functional features like drainage holes.

In this blog post, we will explore how injection molding2 machines are used to manufacture flower pots. We’ll cover the process steps, common materials, key parameters, applications, and differences from other methods. Whether you’re a manufacturer, gardener, or simply curious about production techniques, this guide will provide a comprehensive understanding of why injection molding is a preferred choice for creating plastic flower pots.

Injection molding machines manufacture flower pots3 by injecting molten plastic into a mold, creating durable, consistent products ideal for mass production, especially in retail and gardening industries.

Understanding this process can help optimize production, reduce costs, and meet the demand for high-quality flower pots in various markets.

Injection molding is the most efficient method for producing plastic flower pots.True

Injection molding allows for high-volume production with consistent quality and minimal waste, making it highly efficient for manufacturing plastic flower pots.

Injection molding cannot be used for small production runs.False

While injection molding excels in large-scale production, it can be adapted for smaller runs with appropriate mold design and machine adjustments.

- 1. What is the Injection Molding Process for Flower Pots?

- 2. What are the Common Materials Used in Injection Molding for Flower Pots?

- 3. What are the Key Parameters in the Injection Molding Process for Flower Pots?

- 4. What are the Applications of Injection Molding in Flower Pot Manufacturing?

- 5. What are the Differences Between Injection Molding and Other Manufacturing Methods for Flower Pots?

- 6. Conclusion

What is the Injection Molding Process for Flower Pots?

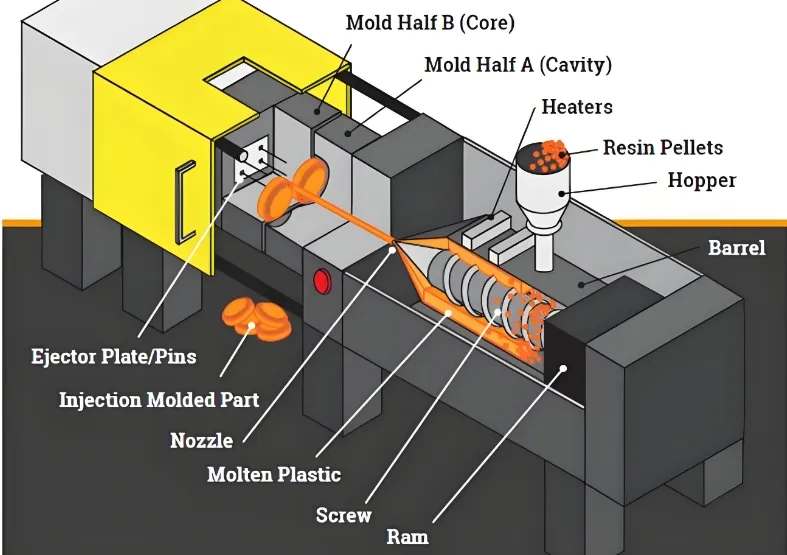

The injection molding process for flower pots consists of several key steps, each essential for producing a high-quality final product.

The injection molding process4 for flower pots includes designing the mold, selecting materials, melting plastic, injecting it into the mold, cooling, ejecting, and finishing the pot.

Designing the Mold

The process begins with designing a mold that matches the desired flower pot shape, including features like wall thickness, drainage holes, and decorative elements. Precision in mold design ensures the pot meets both functional and aesthetic requirements.

Material Selection

Choosing the right plastic is critical. Common materials include High-Density Polyethylene (HDPE)5 and Polypropylene (PP)6, selected for their durability and resistance to outdoor conditions. The material must align with the pot’s intended use and the molding process.

Melting the Plastic

Plastic pellets are fed into the injection molding machine’s barrel, where they are heated until molten. Temperature control is vital to achieve a uniform melt without degrading the material.

Injecting the Plastic

The molten plastic is injected into the mold cavity under high pressure, filling every detail of the design. Injection speed and pressure are adjusted based on the pot’s size and complexity to avoid defects.

Cooling and Solidification

The plastic cools and hardens inside the mold, taking on the flower pot’s final shape. Cooling systems, such as water channels, regulate the cooling rate to prevent warping and ensure dimensional stability.

Ejecting the Pot

Once solidified, the mold opens, and the flower pot is ejected using pins or other mechanisms. The ejection process7 is designed to preserve the pot’s integrity, especially for delicate features.

Finishing Touches

Excess material, like sprues or runners, is trimmed off, and the pot may undergo additional steps such as painting or labeling to enhance its appearance or functionality.

Each step requires precise control of variables like temperature, pressure, and cooling time to ensure consistent quality.

The design of the mold is the most critical factor in injection molding.True

A well-designed mold ensures the flower pot has accurate dimensions, features, and surface finish, directly impacting its quality and functionality.

Any plastic material can be used for injection molding flower pots.False

Not all plastics are suitable; materials must be selected for durability, UV resistance, and compatibility with outdoor use.

What are the Common Materials Used in Injection Molding for Flower Pots?

The choice of material significantly affects the performance and longevity of injection-molded flower pots. Here are the most commonly used plastics:

Common materials for injection molding flower pots include HDPE for durability, PP for lightweight and chemical resistance, and PVC for transparency.

| Material Type | Properties | Applications |

|---|---|---|

| HDPE | Durable, UV-resistant, strong | Outdoor flower pots |

| Polypropylene (PP) | Lightweight, chemical-resistant | Pots for fertilizers |

| Polyvinyl Chloride (PVC) | Transparent, rigid | Decorative/transparent pots |

High-Density Polyethylene (HDPE)

HDPE is prized for its strength and UV resistance, making it perfect for outdoor flower pots. It withstands harsh weather and resists degradation, ensuring long-lasting performance.

Polypropylene (PP)

PP is lightweight and chemically resistant8, ideal for pots exposed to fertilizers or sunlight. Its higher melting point enhances durability in warm climates.

Polyvinyl Chloride (PVC)

PVC is used for transparent or semi-transparent pots, offering unique design options. However, it requires careful processing to avoid warping and may not match HDPE or PP in outdoor durability.

Material selection depends on the pot’s intended use—whether for indoor decoration or outdoor gardening9—and specific design needs.

HDPE is the best material for all types of flower pots.False

While HDPE excels outdoors, PP or PVC may be better for lightweight or transparent designs.

Material selection affects the injection molding process.True

Materials vary in melting points, flow characteristics, and cooling needs, requiring tailored machine settings.

What are the Key Parameters in the Injection Molding Process for Flower Pots?

Success in injection molding flower pots hinges on controlling several critical parameters:

Key parameters in injection molding for flower pots include production cycle time10, injection pressure11, mold temperature, and cooling system design12.

| Parameter | Details |

|---|---|

| Production Cycle | 12-35 seconds, depending on size and complexity |

| Injection Pressure | Adjusted based on pot size and wall thickness |

| Mold Temperature | Controlled to prevent warping and ensure uniform cooling |

| Cooling System | Essential for maintaining shape and preventing deformation |

Production Cycle Time

Cycle time, ranging from 12 to 35 seconds, varies with the pot’s size and complexity. Shorter cycles boost efficiency but must not compromise quality.

Injection Pressure

Pressure is tailored to the pot’s design, ensuring complete mold filling. Larger or thicker pots may require higher pressure to avoid voids.

Mold Temperature

Maintaining optimal mold temperature prevents defects like warping and ensures a smooth finish. It’s a delicate balance to achieve uniform cooling.

Cooling System

Effective cooling, often via water channels, preserves the pot’s shape and speeds up production by reducing solidification time.

Optimizing these parameters ensures high-quality flower pots tailored to specific designs.

Longer cooling times always improve the quality of the flower pot.False

Excessive cooling can slow production without enhancing quality, if sufficient solidification is already achieved.

Injection pressure is the same for all flower pot designs.False

Pressure varies with design specifics like wall thickness and material flow requirements.

What are the Applications of Injection Molding in Flower Pot Manufacturing?

Injection molding shines in flower pot production due to its versatility and efficiency.

Injection molding is used for mass-producing flower pots13 with consistent quality, complex designs, and cost-effectiveness14, ideal for retail and custom applications.

Mass Production

The process enables rapid production of large quantities, perfect for supplying retail stores and greenhouses with consistent stock.

Consistent Quality

Every pot is identical in shape, size, and quality, meeting industry standards and customer expectations reliably.

Design Flexibility

From simple shapes to intricate patterns with drainage holes, injection molding accommodates a wide range of designs.

Cost-Effectiveness

After the initial mold investment, per-unit costs drop significantly with higher volumes, making it economical for large runs.

These benefits position injection molding as a top choice for commercial flower pot manufacturing.

Injection molding is only suitable for standard flower pot designs.False

It supports both simple and complex designs, including custom shapes and features.

Injection molding reduces production costs for flower pots.True

High-volume production with minimal waste lowers the cost per unit.

What are the Differences Between Injection Molding and Other Manufacturing Methods for Flower Pots?

While injection molding dominates, other methods exist, each with distinct characteristics:

Injection molding differs from blow molding, rotational molding, and vacuum forming in production speed, design complexity, and cost-effectiveness.

Blow Molding

Best for hollow objects like bottles, blow molding lacks the precision and flexibility of injection molding for solid flower pots.

Rotational Molding

Used for large, hollow items, rotational molding is slower and less precise, making it less suitable for mass-producing flower pots.

Vacuum Forming

Ideal for prototyping or small runs, vacuum forming can’t match injection molding’s speed and consistency for large-scale production.

Injection molding excels in balancing speed, quality, and design versatility for flower pots.

Injection molding is the only method for manufacturing plastic flower pots.False

Other methods like blow molding and rotational molding are used, depending on specific needs.

Injection molding offers the best balance of cost, speed, and quality for flower pot production.True

It combines high production rates, consistent quality, and design flexibility effectively.

Conclusion

Injection molding is a powerful method for manufacturing plastic flower pots, offering unmatched efficiency, quality, and design possibilities. By mastering the process steps, material choices, and key parameters, manufacturers can produce durable, attractive pots to meet diverse market needs.

-

Learn about the advantages of production efficiency in injection molding, which can significantly impact manufacturing success. ↩

-

Explore this link to gain a deeper understanding of injection molding, its applications, and benefits in manufacturing processes. ↩

-

Discover the detailed process of manufacturing flower pots through injection molding, enhancing your knowledge of production techniques. ↩

-

Learn about the injection molding process to gain insights into its steps and importance in manufacturing high-quality products. ↩

-

Explore the advantages of HDPE in injection molding to understand its durability and suitability for outdoor use. ↩

-

Discover the properties of Polypropylene (PP) to see why it’s a popular choice in various manufacturing applications. ↩

-

The ejection process is vital for preserving the quality of molded items. Learn about its techniques and importance in manufacturing. ↩

-

Exploring chemical resistance can guide you in selecting pots that withstand fertilizers and harsh conditions, enhancing plant health. ↩

-

Discovering the best materials for outdoor gardening can improve your gardening experience and plant growth, ensuring success in your garden. ↩

-

Understanding production cycle time is crucial for optimizing efficiency and quality in injection molding processes. Explore this link to learn more. ↩

-

Injection pressure is vital for achieving complete mold filling and preventing defects. Discover more about its impact on quality here. ↩

-

A well-designed cooling system is essential for maintaining product shape and speeding up production. Learn best practices to enhance your process. ↩

-

Discover the techniques and advantages of mass-producing flower pots, ensuring consistent quality and design flexibility. ↩

-

Learn about the cost benefits of injection molding, especially for large-scale manufacturing, and how it impacts overall production costs. ↩