Injection molding is a manufacturing powerhouse, transforming molten plastic into precise, durable shapes by injecting it into a mold under high pressure. When it comes to helmets, this process is the go-to method for crafting the hard outer shells that protect wearers in activities ranging from motorcycling to industrial work. Its ability to produce uniform, complex designs efficiently makes it a cornerstone of modern helmet production1.

Injection molding machines create helmet shells by melting thermoplastics2 like ABS or polycarbonate, injecting them into a mold, cooling, and finishing the part, offering cost-effective mass production with high precision.

Whether you’re a manufacturer optimizing production or a curious reader exploring how safety gear is made, understanding injection molding3’s role in helmet creation reveals its technical brilliance and practical benefits. This article explores the materials, process steps, applications, and how injection molding stacks up against other methods.

Injection molding is the most cost-effective method for producing helmets in large quantities.True

Due to its high automation and fast cycle times, injection molding significantly reduces per-unit costs for large production runs.

Injection molding can only be used for simple helmet designs.False

Injection molding can handle complex shapes, including vents and visor attachments, making it suitable for intricate helmet designs.

- 1. What are the Common Materials Used in Injection Molding for Helmets?

- 2. What are the Steps in the Injection Molding Process for Helmets?

- 3. What are the Applications of Injection Molding in Helmet Production?

- 4. What are the Differences Between Injection Molding and Other Methods for Helmet Production?

- 5. Conclusion

What are the Common Materials Used in Injection Molding for Helmets?

The choice of material in helmet production isn’t just a detail—it’s a game-changer. It determines the helmet’s strength, weight, and cost, directly affecting its performance and safety. Injection molding relies on thermoplastics, prized for their moldability and resilience.

Common materials for injection-molded helmets include ABS4, polycarbonate5, PC/ABS alloy, and polypropylene, selected for their impact resistance, lightweight properties, and cost-effectiveness.

| Material | Key Properties | Typical Applications |

|---|---|---|

| ABS | Good impact resistance, easy to process, cost-effective | Urban and sports helmets |

| Polycarbonate | High impact strength, transparent, durable | Motorcycle and high-performance helmets |

| PC/ABS Alloy | Balanced strength and processability | Versatile use across helmet types |

| Polypropylene | Lightweight, lower impact resistance | Children’s helmets, low-impact use |

Acrylonitrile Butadiene Styrene (ABS)

ABS strikes a sweet spot with its affordability and solid impact resistance. It’s a favorite for urban and sports helmets, where ease of processing keeps production costs down without skimping on protection.

Polycarbonate

For helmets needing top-tier toughness—like those shielding motorcyclists—polycarbonate shines. Its high impact strength and potential for transparency make it perfect for premium designs, often featuring integrated visors.

PC/ABS Alloy

Blending polycarbonate’s strength with ABS’s versatility, this alloy offers a middle ground. It’s adaptable across helmet types, delivering reliable performance at a competitive price point.

Polypropylene

Light and budget-friendly, polypropylene suits helmets for kids or low-impact scenarios. While it doesn’t match the heavy hitters in strength, its featherweight nature keeps it in the game.

ABS is the most commonly used material for helmet shells.True

ABS is favored for its balance of cost, impact resistance, and ease of molding, making it ideal for mass production.

All helmet materials are equally suitable for all applications.False

Different materials offer varying levels of impact resistance and weight, making them suitable for specific helmet types and uses.

What are the Steps in the Injection Molding Process for Helmets?

Crafting a helmet shell via injection molding is a precise dance of engineering and timing. Each step builds toward a final product that’s both protective and polished, meeting rigorous safety standards.

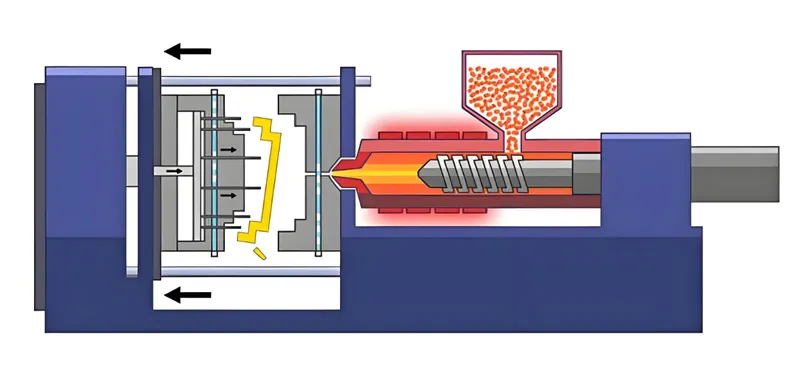

The injection molding process6 for helmets includes design and mold creation, material selection, machine setup, melting and injection, cooling, part ejection, and post-processing.

1. Design and Mold Creation

It all starts with a vision—translated into a digital design using CAD software. This blueprint guides the crafting of a mold, typically steel or aluminum, built to exact specifications for the helmet’s shape.

2. Material Selection

Picking the right thermoplastic is critical. Will it be ABS for cost savings or polycarbonate for extra durability? The choice hinges on the helmet’s purpose.

3. Machine Setup

The injection molding machine gets prepped: the mold is mounted, and settings like temperature and pressure are dialed in. Machines for helmets often wield clamping forces from 50 to 3000 tons, tailored to the part’s size.

4. Melting and Injection

Plastic pellets melt into a molten flow inside the machine’s barrel, then get shot into the mold under intense pressure. This fills every nook, shaping the helmet shell.

5. Cooling and Solidification

Cooling kicks in—often via water channels in the mold—to harden the plastic. Timing here is key; too fast or too slow, and the shell’s integrity could falter.

6. Part Ejection

Once solid, the shell pops out, often with help from automated ejectors or robotic arms, streamlining the process for high-volume runs.

7. Post-Processing

The rough edges get smoothed—trimming excess plastic, sanding, and adding finishes like paint or decals. A final quality check ensures it’s ready to protect.

| Material | Melting Temperature (°C) | Injection Pressure (MPa) | Cooling Time (s) |

|---|---|---|---|

| ABS | 200-250 | 50-100 | 30-60 |

| Polycarbonate | 280-320 | 70-120 | 40-80 |

| PC/ABS Alloy | 240-280 | 60-110 | 35-70 |

The injection molding process for helmets is fully automated.False

While many steps are automated, post-processing often requires manual intervention for finishing touches like painting and quality checks.

Cooling time is the most critical factor in the injection molding process.False

While cooling is important, other factors like injection pressure and mold design also significantly impact the final product.

What are the Applications of Injection Molding in Helmet Production?

Injection molding’s versatility shines in the diverse world of helmets, tailoring shells to meet specific demands—from high-speed thrills to workplace safety.

Injection molding is used to produce motorcycle, bicycle, sports, and industrial safety helmets7, offering customization in design and material to meet specific safety and performance requirements.

Bicycle Helmets

Lightweight and breathable, bike helmets use injection molding to craft thin shells packed with ventilation, balancing protection with comfort on the road.

Motorcycle Helmets

Built for speed and impact, these helmets lean on injection molding for tough shells with intricate features like vents and visor mounts, ensuring rider safety.

Sports Helmets

From skiing to skateboarding, sports helmets need custom fits and shock absorption. Injection molding delivers, shaping shells that prioritize both style and safety.

Industrial Safety Helmets

In rugged settings like construction sites, these helmets demand durability. Injection molding produces consistent, strong shells to guard against workplace hazards.

Injection molding is only used for consumer helmets, not industrial ones.False

Injection molding is widely used for both consumer and industrial helmets due to its efficiency and ability to meet safety standards.

What are the Differences Between Injection Molding and Other Methods for Helmet Production?

Injection molding isn’t the only player in helmet manufacturing—compression molding and vacuum forming vie for attention too. Each method brings its own strengths to the table.

Injection molding is best for high-volume production of thermoplastic helmets, while compression molding suits composite materials, and vacuum forming is cost-effective for low volumes.

| Method | Material Compatibility | Production Speed | Initial Cost | Complexity Handling |

|---|---|---|---|---|

| Injection Molding | Thermoplastics (ABS, PC, etc.) | Fast | High | High |

| Compression Molding | Composites (fiberglass, carbon fiber) | Slow | Moderate | Moderate |

| Vacuum Forming | Thermoplastics | Moderate | Low | Low |

Injection Molding

-

Pros: Lightning-fast for big runs, handles complex designs with ease, cost-effective at scale.

-

Cons: Steep upfront mold costs, sticks to thermoplastics.

Compression Molding

-

Pros: Excels with composites like fiberglass, boosting strength for niche helmets.

-

Cons: Slower pace, more hands-on effort required.

Vacuum Forming

-

Pros: Wallet-friendly startup, great for small batches.

-

Cons: Lacks precision and strength for demanding applications.

Injection molding is the only method used for helmet production.False

Other methods like compression molding and vacuum forming are also used, depending on material and production requirements.

Compression molding is faster than injection molding for helmet production.False

Compression molding is generally slower due to longer cycle times and more manual processes.

Conclusion

Injection molding stands tall as a linchpin in helmet production, blending speed, precision, and affordability for large-scale manufacturing. From the tough ABS shells of sports helmets to the sleek polycarbonate shields for motorcyclists, this process delivers safety and style in equal measure. While alternatives like compression molding8 and vacuum forming have their niches, injection molding’s efficiency and adaptability make it a top pick for thermoplastic helmets9. Dive into its materials, steps, and applications, and you’ll see why it’s a manufacturing marvel.

-

Discover the detailed process of helmet production and the advantages of using injection molding for safety gear. ↩

-

Learn about thermoplastics and their vital role in creating durable products like helmet shells through injection molding. ↩

-

Explore this link to understand the intricacies of injection molding and its significance in various manufacturing processes. ↩

-

Learn about ABS’s properties and why it’s a go-to material for affordable and effective helmet designs. ↩

-

Explore the advantages of polycarbonate to see why it’s favored for high-performance helmets and safety gear. ↩

-

Learn about the intricate steps of the injection molding process, crucial for producing safe and effective helmet shells. ↩

-

Learn about the manufacturing process of industrial safety helmets and the importance of injection molding in ensuring durability and safety. ↩

-

Investigate the differences between compression molding and injection molding to see why the latter is often preferred in manufacturing. ↩

-

Learn about thermoplastic helmets to discover their benefits in safety and design, enhancing your understanding of modern helmet technology. ↩