Injection molding machines craft water tanks by transforming molten plastic into precise, durable shapes through a series of sophisticated steps. This process involves melting plastic resin, injecting it into a meticulously designed mold, cooling it to solidify, and ejecting the finished tank. While typically suited for smaller to medium-sized tanks, advancements in technology now enable the production of larger tanks with specialized equipment. Common materials like polyethylene1 and polypropylene are selected for their strength and chemical resistance, making injection molding a preferred method for high-precision, efficient mass production.

Injection molding produces water tanks by melting plastic, injecting it into a mold, cooling it, and ejecting the tank, offering precision and efficiency for various applications.

Understanding the details of this process—from material selection to technical execution—unlocks its potential for industries needing reliable water storage solutions. Read on to discover how injection molding shapes water tanks2, its advantages, and how it fits into broader manufacturing ecosystems.

Injection molding is the most common method for producing large water tanks.False

While effective for smaller tanks and components, rotational molding is more common for large tanks due to cost and equipment constraints.

Injection molding offers higher precision than rotational molding.True

Injection molding ensures better control over wall thickness and dimensions, resulting in superior precision.

- 1. What is Injection Molding and How Does it Apply to Water Tank Production?

- 2. How Are Water Tanks Classified in Injection Molding?

- 3. What Are the Typical Applications of Injection-Molded Water Tanks?

- 4. How Does Injection Molding Compare to Other Technologies for Water Tank Production?

- 5. What Are the Steps in the Injection Molding Process for Water Tanks?

- 6. How Do Different Materials Affect Injection Molding for Water Tanks?

- 7. What Are the Practical Tools for Designing and Selecting Injection-Molded Water Tanks?

- 8. How Does Injection Molding Connect to Other Technologies in Water Tank Production?

- 9. Conclusion

What is Injection Molding and How Does it Apply to Water Tank Production?

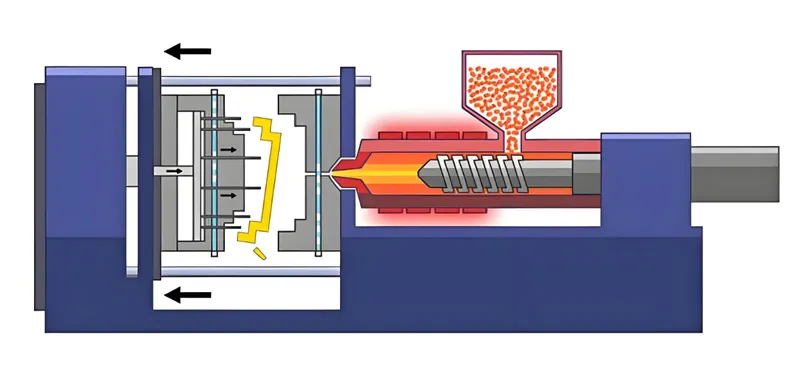

Injection molding is a manufacturing technique where molten plastic is forced into a mold cavity under high pressure to create a specific shape. In water tank production, this process begins with designing a mold tailored to the tank’s specifications, selecting a suitable plastic resin, melting it, injecting it into the mold, cooling it to harden, and finishing the tank with additional features if needed. Renowned for its precision and consistency, injection molding is ideal for water tanks requiring exact dimensions and robust structural integrity.

Water tanks made via injection molding3 use plastics like polyethylene (PE) or polypropylene (PP) for durability and are efficient for mass production despite higher initial costs.

Common materials include polyethylene—especially high-density polyethylene (HDPE)—and polypropylene, valued for their durability, chemical resistance, and ability to form large, reliable structures. While the initial setup costs are significant due to mold complexity, the process becomes cost-effective for large production runs.

Injection molding is only used for small plastic parts.False

Though historically used for smaller items, modern advancements allow injection molding to produce larger products like water tanks.

Polyethylene is the most common material for injection-molded water tanks.True

HDPE is widely used for its strength, durability, and chemical resistance, making it a top choice.

How Are Water Tanks Classified in Injection Molding?

Water tanks produced through injection molding are categorized by size, material, and application, each factor influencing design and production decisions.

Injection-molded water tanks are classified by size (small to medium), material (e.g., PE, PP), and application (residential, industrial), guiding manufacturing choices.

| Classification Type | Categories | Notes |

|---|---|---|

| Size | Small (up to 100 gallons), Medium (100-1,000 gallons) | Larger tanks need specialized equipment |

| Material | Polyethylene (HDPE, LDPE), Polypropylene (PP), PVC | Selected for strength and resistance |

| Application | Residential, Agricultural, Industrial, Emergency | Dictates design and compliance requirements |

Size Classification

-

Small Tanks (up to 100 gallons): Perfect for residential or small-scale uses, easily produced with standard machines.

-

Medium Tanks (100-1,000 gallons): Require larger or specialized injection molding equipment, such as those used by Infiltrator Water Technologies for their IM-Series tanks, capable of holding up to 1,787 gallons Infiltrator Water Tanks.

Material Classification

-

Polyethylene (PE): HDPE offers strength and durability; LDPE provides flexibility.

-

Polypropylene (PP): Known for chemical resistance and suitability for food-safe applications.

-

Polyvinyl Chloride (PVC): Less common but used for rigid tank needs.

Application Classification

-

Residential: For potable water or household use, often requiring FDA approval.

-

Agricultural: For irrigation or livestock,needing weather resistance.

-

Industrial: For process water or chemicals, requiring material compatibility.

-

Emergency: For disaster preparedness, prioritizing reliability.

These classifications ensure tanks meet specific needs efficiently.

Injection molding is suitable for all sizes of water tanks.False

It excels for smaller to medium tanks, but rotational molding is more practical for very large capacities.

Material selection impacts the tank’s durability and application suitability.True

Materials determine strength, resistance, and compliance with standards.

What Are the Typical Applications of Injection-Molded Water Tanks?

Injection-molded water tanks serve a wide range of industries due to their precision and durability.

These tanks support residential drinking water4, agricultural irrigation5, industrial processes, and emergency supplies, showcasing their versatility.

Residential Water Storage

Ideal for drinking water or household backups, these tanks are lightweight and easy to install, especially in areas with unreliable water supply.

Agricultural Use

Used for irrigation or livestock watering, they withstand environmental challenges, ensuring long-term reliability.

Industrial Use

Perfect for storing process water or chemicals, designed to match the stored substance’s requirements.

Emergency Water Supply

Critical for disaster readiness, providing dependable water storage when needed most.

This adaptability makes injection-molded tanks invaluable across sectors.

Injection-molded water tanks are primarily used in residential settings.False

They’re also prevalent in agricultural, industrial, and emergency contexts.

Injection molding allows for tanks with integrated features like fittings.True

Its precision enables complex designs to be molded directly into the tank.

How Does Injection Molding Compare to Other Technologies for Water Tank Production?

Injection molding stands out against alternatives like rotational and blow molding, each with unique strengths and trade-offs.

Injection molding excels in precision and strength but is costlier for large tanks compared to rotational molding, which suits bigger capacities.

| Technology | Precision | Production Speed | Initial Cost | Size Suitability | Material Options | Durability |

|---|---|---|---|---|---|---|

| Injection Molding | High | Fast for large runs | High | Small to medium | Wide (PE, PP, PVC) | High |

| Rotational Molding6 | Moderate | Slower | Lower | Large tanks | Limited (PE, PP) | High |

| Blow Molding7 | Moderate | Moderate | Moderate | Medium hollow parts | Limited (PE, PP) | Moderate |

Pros of Injection Molding

-

High Precision: Superior control over dimensions and wall thickness.

-

Efficiency: Fast cycle times for mass production.

-

Versatility: Broad material options, including UV-resistant plastics.

Cons of Injection Molding

-

Cost: High initial mold and equipment expenses.

-

Size Limits: Best for smaller tanks, though larger ones are possible with advanced machines.

Rotational Molding Comparison

-

Cost: Lower startup costs with simpler molds.

-

Size: Ideal for tanks over 10,000 gallons.

-

Finish: Less precise than injection molding.

Blow Molding Comparison

-

Use: Suited for smaller hollow items, not large tanks.

-

Speed: Moderate, less efficient for complex parts.

This analysis aids in selecting the right method for specific needs.

Rotational molding is always cheaper than injection molding.False

Injection molding can be more economical for large runs due to faster cycles.

Injection molding offers better surface finish than rotational molding.True

High-pressure injection yields smoother surfaces.

What Are the Steps in the Injection Molding Process for Water Tanks?

The production of water tanks via injection molding follows a precise sequence of steps.

The process includes mold design, material selection, melting and injection, cooling, and finishing, each vital for quality.

Mold Design and Creation

- Craft a mold withconsiderations for wall thickness and gating, often using steel for durability. Large tanks require complex molds Innovative Wastewater Treatment Solutions.

Material Selection and Preparation

- Select resins like HDPE or PP, drying them to eliminate moisture and prevent defects.

Melting and Injection

- Melt the resin and inject it into the mold under high pressure to ensure complete cavity fill.

Cooling

- Cool the plastic to solidify it, controlling the process to avoid warping or shrinkage.

Ejection and Finishing

- Eject the tank and add finishing touches like trimming or fittings.

Key Parameters

-

Injection Pressure8: Measured in tons (e.g., up to 16,000 tons for large tanks, per Plastics News.

-

Cooling Time9: Optimized for efficiency and quality.

-

Cycle Time: Critical for high-volume output.

These steps ensure consistent, high-quality tanks.

The injection molding process is fully automated with no human input.False

Automation is high, but human oversight ensures quality and setup accuracy.

Cooling time is the most critical factor in injection molding.False

It’s important, but mold design and pressure are equally vital.

How Do Different Materials Affect Injection Molding for Water Tanks?

Material choice shapes both the process and the tank’s final properties.

HDPE and PP10 are favored for strength and resistance, influencing molding and performance.

High-Density Polyethylene (HDPE)

-

Properties: Strong, durable, chemically resistant—ideal for water storage.

-

Process Impact: Needs precise temperature control to avoid defects.

Polypropylene (PP)

- Properties: Chemically resistant, food-safe, heat-tolerant.

- Process Impact: Requires adjusted molding conditions for optimal results.

Polyvinyl Chloride (PVC)

-

Properties: Rigid and durable for specific uses.

-

Process Impact: Demands careful pressure management due to rigidity.

Material selection ensures compliance and performance Plastic Infiltrator Tanks.

All plastics are interchangeable in injection molding for tanks.False

Each plastic has unique properties requiring specific processing.

HDPE is preferred for its strength and cost-effectiveness.True

It balances durability and affordability effectively.

What Are the Practical Tools for Designing and Selecting Injection-Molded Water Tanks?

Effective design and process selection rely on practical tools.

Use mold design checklists and process guides to optimize production choices.

Design Checklist for Water Tank Molds

-

Wall Thickness: Uniform for strength and cooling.

-

Draft Angles: 1-2 degrees for easy ejection.

-

Gating: Positioned to minimize defects.

-

Venting: Ensures air escape to prevent voids.

Process Selection Guide

-

Choose Injection Molding When: Precision, complexity, or large quantities are needed.

-

Consider Alternatives When: Large size or low cost is prioritized.

These tools streamline decision-making and enhance outcomes.

Injection molding is always the best choice for tank production.False

It depends on size, quantity, and design needs.

A well-designed mold reduces costs and defects.True

Good design boosts efficiency and quality.

How Does Injection Molding Connect to Other Technologies in Water Tank Production?

Injection molding integrates with complementary technologies.

It pairs with rotational molding for large tanks, blow molding for parts, and extrusion for fittings, forming a robust manufacturing network.

-

Rotational Molding: Best for large tanks, complementing injection molding’s smaller focus.

-

Blow Molding: Produces smaller components for tank systems.

-

Extrusion: Supplies pipes and fittings for complete solutions.

This synergy enhances water tank production flexibility.

Injection molding works with other methods for complete systems.True

It integrates with extrusion and blow molding for full solutions.

Conclusion

Injection molding delivers precision and efficiency for water tank production, excelling in small to medium sizes with potential for larger capacities. By mastering its process, materials, and applications, industries can optimize water storage solutions effectively.

-

Learn about polyethylene’s unique properties and why it’s a preferred material in manufacturing, especially for durable products like water tanks. ↩

-

Discover the various types of water tanks available, their uses, and how they can meet different storage needs effectively. ↩

-

Explore this link to understand the fundamentals of injection molding and its applications in various industries, including water tank production. ↩

-

Learn how these tanks ensure safe and reliable drinking water storage for households, especially in emergencies. ↩

-

Discover how these tanks enhance irrigation efficiency and support sustainable farming practices. ↩

-

Discover the benefits of Rotational Molding, especially for large capacities, and how it compares to other methods. ↩

-

Learn about Blow Molding and its specific applications, particularly for smaller hollow items, to see if it fits your needs. ↩

-

Understanding injection pressure is crucial for optimizing the molding process and ensuring product quality. Explore this link for in-depth insights. ↩

-

Cooling time is vital for preventing defects and ensuring product integrity. Learn more about its role in the molding process here. ↩

-

Explore the benefits of HDPE and PP to understand their impact on strength and performance in manufacturing processes. ↩