Injection molding machines are essential for producing phone cases, offering precision and efficiency for mass production of protective, aesthetically pleasing smartphone covers.

Injection molding is a manufacturing process where molten plastic is injected into a mold to create detailed, form-fitting phone cases. This method is ideal for producing large quantities of cases with consistent quality, ensuring each case perfectly fits the smartphone model it’s designed for. Below, we explore the process, materials, and strategic considerations for using injection molding1 in phone case manufacturing.

Injection molding is the most cost-effective method for producing phone cases.True

For large production runs, injection molding reduces per-unit costs significantly after the initial mold investment.

Injection molding can only produce simple phone case designs.False

Injection molding can create complex designs with intricate details, such as precise cutouts and textured surfaces.

- 1. What are the Common Materials Used in Injection Molding for Phone Cases?

- 2. What are the Steps in the Injection Molding Process for Phone Cases?

- 3. What are the Key Factors in the Injection Molding Process for Phone Cases?

- 4. What are the Applications of Injection Molding in Phone Case Manufacturing?

- 5. What are the Differences Between Injection Molding and Other Manufacturing Methods for Phone Cases?

- 6. Conclusion

What are the Common Materials Used in Injection Molding for Phone Cases?

Materials used in injection molding for phone cases are selected for their durability, flexibility, and aesthetic appeal, ensuring the cases provide protection and style.

Common materials include polycarbonate (PC)2, acrylonitrile butadiene styrene (ABS), polypropylene (PP), and thermoplastic polyurethane (TPU)3, chosen for their strength, flexibility, and impact resistance.

| Material Type | Recommended Wall Thickness | Notes |

|---|---|---|

| Polycarbonate (PC) | 1.0 – 2.0 mm | Ideal for clear, impact-resistant cases |

| ABS4 | 1.5 – 2.5 mm | Suitable for colorful, durable cases |

| Polypropylene (PP) | 1.2 – 2.0 mm | Used for flexible, lightweight cases |

| Thermoplastic Polyurethane (TPU) | 1.5 – 3.0 mm | Best for shock-absorbing, soft cases |

Polycarbonate (PC)

PC is a strong, transparent plastic often used for clear phone cases that showcase the phone’s design while providing impact resistance. Its high strength-to-weight ratio makes it ideal for protective cases.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a versatile plastic known for its durability and ease of coloring, making it popular for phone cases with vibrant designs. It offers good impact resistance and is cost-effective for mass production.

Polypropylene (PP)

PP is a lightweight, flexible plastic used for thin, snap-on cases. Its resistance to moisture and chemicals makes it suitable for cases that need to withstand environmental exposure.

Thermoplastic Polyurethane (TPU)

TPU is a soft, flexible material that provides excellent shock absorption, making it ideal for protective cases. It can be molded into various textures and is often used for cases with a grippy feel.

These materials are selected based on the desired properties of the phone case, such as protection level, appearance, and tactile feel.

Polycarbonate is the most commonly used material for phone cases.True

PC’s combination of strength, transparency, and impact resistance makes it a top choice for many manufacturers.

All phone cases are made from the same material.False

Different materials are used based on the specific requirements of the case, such as flexibility, transparency, or shock absorption.

What are the Steps in the Injection Molding Process for Phone Cases?

The injection molding process for phone cases involves several key steps to ensure precision and quality in mass production.

The process includes designing the mold, selecting materials, setting up the machine, injecting molten plastic, cooling, and ejecting the finished case.

Mold Design

A detailed 3D model of the phone case is created using CAD software, ensuring precise fitment and functionality, including cutouts for buttons and ports. The mold is then designed to match this model, considering factors like gate locations and draft angles.

Material Selection

The appropriate plastic material is chosen based on the desired properties of the phone case, such as strength, flexibility, or transparency.

Machine Setup

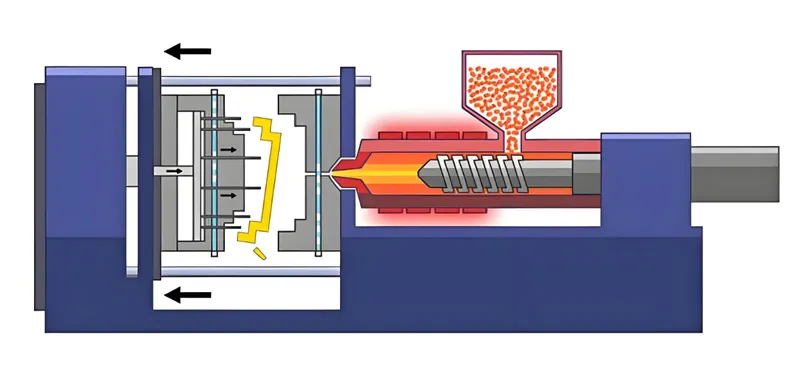

The injection molding machine is configured with specific parameters, including temperature, pressure, and injection speed, to optimize the process for the selected material.

Injection

The plastic is melted in the machine’s barrel and injected into the mold cavity under high pressure, filling the space to form the case shape.

Cooling

The mold is cooled to solidify the plastic, typically taking 10-20 seconds for thin-walled phone cases.

Ejection

Once cooled, the mold opens, and the finished phone case is ejected using an automated system.

Post-processing

Secondary operations may include trimming excess material, polishing, or adding logos through printing or engraving.

This workflow ensures efficient production of high-quality phone cases, with each step critical to the final product’s performance and appearance.

The injection molding process for phone cases is fully automated.True

Modern injection molding machines are highly automated, reducing labor costs and ensuring consistency.

Injection molding cannot produce phone cases with intricate designs.False

Injection molding can create complex shapes and detailed features, such as textured surfaces and precise cutouts.

What are the Key Factors in the Injection Molding Process for Phone Cases?

Several factors influence the success of the injection molding process for phone cases, impacting the quality and performance of the final product.

Key factors include mold design5, material selection6, machine parameters7, and cooling time, which determine the case’s fit, finish, and durability.

Mold Design

The mold must be precisely designed to match the phone’s dimensions and include features like draft angles for easy ejection and gate locations to minimize visible marks.

Material Selection

Choosing the right plastic8 is crucial for achieving the desired properties, such as impact resistance, flexibility, or transparency.

Machine Parameters

Settings like temperature, pressure, and injection speed must be optimized for the specific material to ensure proper flow and filling of the mold.

Cooling Time

Adequate cooling9 is necessary to solidify the plastic without warping or defects, with cycle times typically around 20-30 seconds for phone cases.

These factors must be carefully controlled to produce high-quality phone cases that meet design specifications and performance standards.

Mold design is the most critical factor in injection molding for phone cases.True

A well-designed mold ensures precise fitment and minimizes defects, directly impacting the case’s quality.

All injection molding machines use the same parameters for different materials.False

Each material requires specific temperature, pressure, and speed settings to achieve optimal results.

What are the Applications of Injection Molding in Phone Case Manufacturing?

Injection molding is widely used in phone case manufacturing for its ability to produce large volumes of precise, durable cases.

Applications include protective cases10, aesthetic designs, and functional cases with added features like card holders or kickstands.

Protective Cases

Injection molding produces cases that provide excellent protection against drops, scratches, and impacts, using materials like PC and TPU.

Aesthetic Designs

The process allows for a wide range of colors, textures, and finishes, enabling manufacturers to create visually appealing cases that cater to consumer preferences.

Functional Cases

Injection molding can incorporate additional features, such as card slots, kickstands, or battery compartments, enhancing the case’s utility.

These applications demonstrate the versatility of injection molding in meeting diverse market demands for phone cases.

Injection molding is only used for basic phone case designs.False

Injection molding can produce complex, multi-functional cases with integrated features.

Injection molding reduces production costs for phone cases.True

For large production runs, injection molding significantly lowers per-unit costs compared to other methods.

What are the Differences Between Injection Molding and Other Manufacturing Methods for Phone Cases?

Injection molding offers distinct advantages and challenges compared to other manufacturing methods for phone cases.

Injection molding excels in precision and efficiency for mass production, while other methods like 3D printing11 are better for prototyping and small runs.

Injection Molding vs. 3D Printing

-

Precision: Injection molding provides higher precision and consistency, essential for form-fitting phone cases.

-

Speed: Injection molding is faster for large volumes, with cycle times of seconds per part.

-

Cost: Injection molding has higher initial costs due to mold creation but lower per-unit costs for mass production.

-

Flexibility: 3D printing allows for rapid prototyping and design changes without mold modifications.

Injection Molding vs. Vacuum Forming

-

Complexity: Injection molding can produce more complex shapes and detailed features.

-

Material Use: Vacuum forming is limited to simpler designs and may use more material for similar strength.

-

Production Volume: Injection molding is more cost-effective for large volumes, while vacuum forming can be cheaper for small runs.

These comparisons highlight injection molding’s strengths in high-volume, precision manufacturing, though it requires careful consideration of initial costs and production scale.

Injection molding is always the best choice for phone case manufacturing.False

While excellent for mass production, other methods may be more suitable for small runs or prototyping.

Injection molding produces higher quality phone cases than other methods.True

Injection molding ensures consistent quality and precise fitment, crucial for protective cases.

Conclusion

Injection molding is a powerful method for manufacturing phone cases12, offering precision, efficiency, and versatility for mass production. By understanding the process, materials, and key factors involved, manufacturers can leverage this technology to meet market demands and produce high-quality, protective, and aesthetically pleasing phone cases. The detailed workflow, material compatibility, and decision-making tools provided here ensure a comprehensive approach to using injection molding for phone case manufacturing13.

-

Understanding injection molding can enhance your knowledge of efficient manufacturing processes, especially for products like phone cases. ↩

-

Exploring polycarbonate’s advantages will help you appreciate its role in creating durable and stylish phone cases. ↩

-

Learning about TPU will reveal how it enhances the protective features and user experience of phone cases. ↩

-

Discover why ABS is favored for its durability and vibrant design options in phone cases. ↩

-

Understanding mold design is essential for creating high-quality phone cases. Explore this link to learn best practices and improve your designs. ↩

-

Material selection greatly affects the durability and performance of phone cases. Discover expert tips on choosing the right materials. ↩

-

Optimizing machine parameters is key to successful injection molding. Learn how to adjust these settings for better results. ↩

-

Discover the various plastics used in phone cases and their unique properties to make informed choices for your needs. ↩

-

Learn about the critical role of cooling in injection molding to ensure quality and prevent defects in phone cases. ↩

-

Learn about the effectiveness of injection molded protective cases in safeguarding devices against damage and their market relevance. ↩

-

Discover the key differences between these two manufacturing methods, especially in terms of cost, speed, and flexibility. ↩

-

Discover the latest trends and materials used in phone case manufacturing to enhance quality and design. ↩

-

Learn about the essential factors that contribute to efficient manufacturing, which can help optimize production in various sectors. ↩