Injection mold

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Best Practices for Storing Injection Molds to Extend Their Life?

Injection molds are the backbone of plastic manufacturing, shaping everything from automotive parts to medical devices. These precision tools represent a significant investment, often costing thousands to millions of dollars. However, their longevity and performance hinge on one critical factor: ...

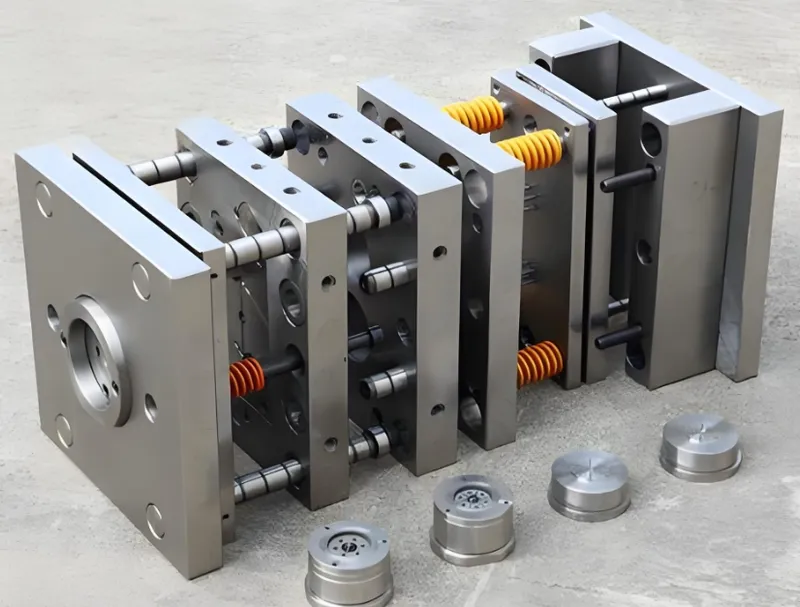

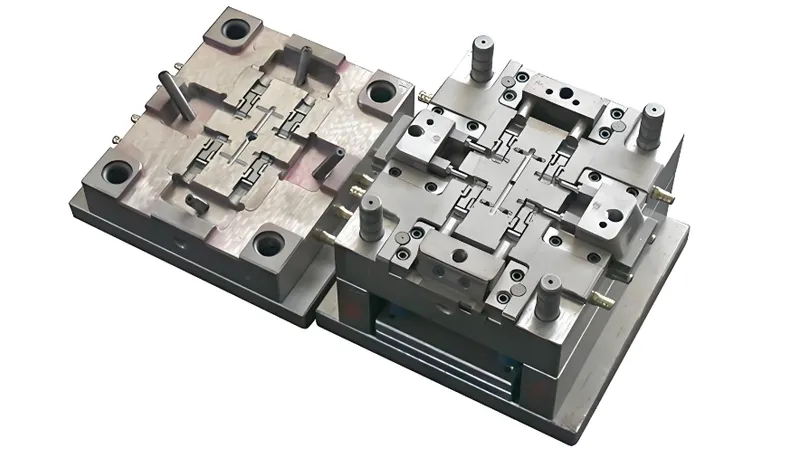

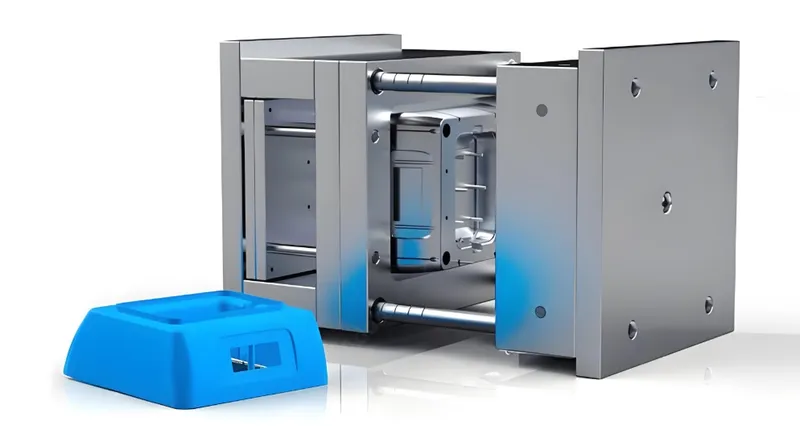

Injection mold

What Are the Most Effective Rapid Prototyping Techniques for Mold Making?

Rapid prototyping1 techniques for mold making have transformed manufacturing by enabling faster, more cost-effective mold production. These methods are vital for industries like automotive, medical devices, and consumer goods, where precision and speed are paramount. Rapid prototyping for mold making2 ...

Injection mold

How Can You Design Effective Molds for Thin-Wall Injection Molding?

Thin-wall injection molding1 is a specialized manufacturing process that produces lightweight plastic parts with walls often less than 1mm thick, making it ideal for industries like packaging, automotive, and consumer electronics. However, designing molds for this process requires precision to ...

Injection mold

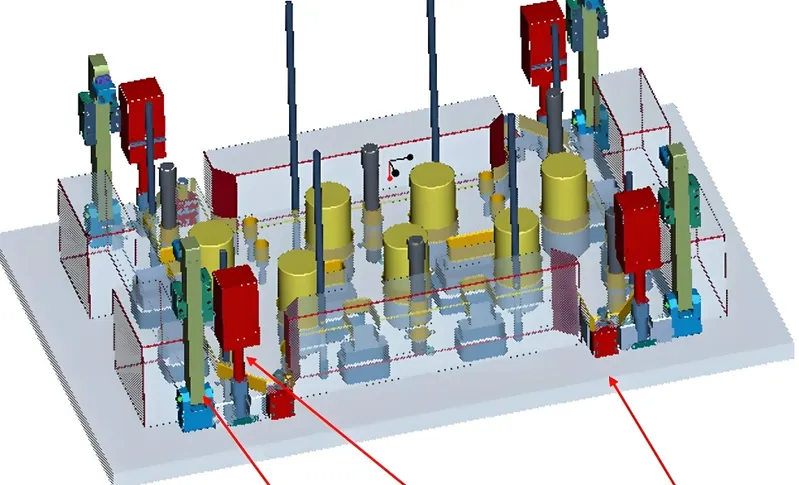

Designing Multi-Cavity Molds: A Comprehensive Guide

In the world of injection molding, efficiency is everything. Manufacturers constantly seek ways to produce more parts in less time without compromising quality. Enter multi-cavity molds1—these specialized tools allow the creation of multiple identical parts in a single cycle, slashing ...

Injection mold

Balancing Runners in Multi-Cavity Molds: A Comprehensive Guide

Balancing runners in multi-cavity molds1 is a critical aspect of injection molding that ensures each cavity fills uniformly, producing consistent, high-quality parts. In multi-cavity molds, which are designed to produce multiple identical parts in a single cycle, the runner system—the ...

Injection mold

What Are the Top Mold Testing Practices for Efficient Injection Molding?

Injection molding is a cornerstone of modern manufacturing, enabling the mass production of plastic parts with high precision and efficiency. However, the success of this process hinges on the quality of the mold used. Mold testing is a critical step ...

Injection mold

What Are the Essential Tips for Effective Mold Design?

Mold design is a critical process in manufacturing that shapes materials like plastics, metals, or glass into precise parts used across industries such as automotive, medical, and consumer goods. A well-designed mold ensures high-quality parts1, reduces waste, and speeds up ...

Injection mold

What Are the Essential Tools for Injection Mold Making?

Injection mold making1 is a critical process in manufacturing, enabling the production of precise plastic parts for industries like automotive, electronics, and medical devices. The essential tools2 for this process include software for design, machines for shaping, and components for ...

Injection mold

How Do You Choose the Right Ejection System for Your Mold?

The ejection system is a critical component in injection molding1, responsible for removing the solidified part from the mold cavity2. Choosing the right ejection system ensures efficient production, minimizes part damage, and extends the mold's lifespan. This guide provides a ...

Injection mold

How Can Venting Enhance the Efficiency of Injection Mold Designs?

In the fast-paced world of injection molding1, precision and efficiency are paramount. One often-overlooked but critical aspect of mold design is venting. Proper venting ensures that air and gases escape smoothly during the injection process, preventing defects like burn marks, ...

Injection mold

Understanding the Cavity in Injection Molding: A Comprehensive Guide

Injection molding is a cornerstone of modern manufacturing, producing precise plastic parts1 for industries ranging from automotive to consumer goods. At the heart of this process lies the cavity, a critical component that shapes the external form of the molded ...

Injection mold

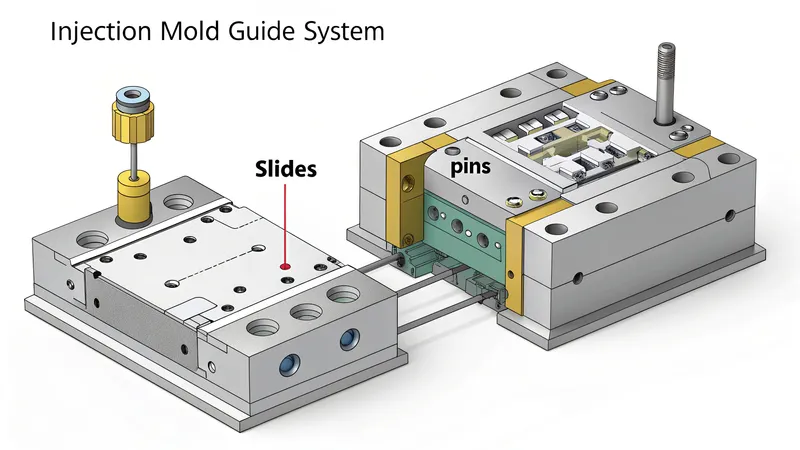

How Does the Injection Mold Guide System Work?

The injection mold guide system1 ensures precise alignment of mold halves during production, reducing defects and wear while maintaining high-quality plastic parts. The injection mold guide system uses guide pins and bushings2 to align mold halves accurately, ensuring consistent part ...

Injection mold

Can One Injection Molding Machine Fit Any Mold?

The injection molding process is a cornerstone of modern manufacturing, producing everything from tiny toy parts to large automotive components. But a common question arises: can one injection molding machine1 fit any mold? The answer is no, and understanding why ...

Injection mold

How Does an Injection Molding Machine Create Button Molds?

Injection molding is a cornerstone of modern manufacturing, renowned for its ability to produce precise, high-quality plastic parts in large volumes. Among its many applications, creating button molds stands out due to the demand for durable, consistent buttons across industries ...

Injection mold

How Does a Two-Plate Mold Function in Injection Molding?

Two-plate molds are the backbone of injection molding1, offering a straightforward and cost-effective solution for producing a wide range of plastic parts2. In this blog post, we’ll explore how these molds work, their applications, and why they remain a popular ...

Injection mold

What Are the Mechanics Behind a Three-Plate Mold?

The three-plate mold is a cornerstone in injection molding, enabling manufacturers to produce complex plastic parts with precision and efficiency. By using a unique three-plate design, this mold type offers flexible gate placement and automatic degating1, making it ideal for ...

Injection mold

How Can You Identify Signs of Wear and Tear in Injection Molds?

Injection molding is a vital manufacturing process used to create precise components for industries like automotive, electronics, and consumer goods. However, the molds at the heart of this process endure significant stress, leading to wear and tear over time. Recognizing ...

Injection mold

Essential Guide to Troubleshooting & Repairing Injection Molds for Peak Performance

Injection molding is a cornerstone of modern manufacturing, enabling the mass production of precise plastic parts for industries ranging from automotive to medical devices. However, even the most well-designed molds can encounter issues, leading to defects like incomplete parts, excess ...

Injection mold