The injection molding process is a cornerstone of modern manufacturing, producing everything from tiny toy parts to large automotive components. But a common question arises: can one injection molding machine1 fit any mold? The answer is no, and understanding why is crucial for anyone involved in product design, manufacturing, or procurement. This article dives deep into the technical and practical aspects of injection molding machine and mold compatibility2, offering insights for both professionals and those new to the field.

One injection molding machine cannot fit any mold due to differences in size, clamping force3, and design requirements, making specific machine-mold pairings essential for optimal production.

Whether you’re choosing a machine for a new project or optimizing an existing setup, knowing the factors that affect compatibility can save time, reduce costs, and ensure high-quality results. Let’s explore the key reasons why not all molds fit all machines and how to navigate these challenges.

Injection molding machines are universally compatible with all molds.False

Machines and molds must match in size, clamping force, and design to function properly.

Mold size and machine tonnage are critical for compatibility.True

Larger molds require machines with higher clamping force and adequate space.

- 1. What Determines if a Mold Fits an Injection Molding Machine?

- 2. How Does Mold Design Impact Machine Compatibility?

- 3. What Are the Steps in the Injection Molding Process?

- 4. How Do You Choose the Right Injection Molding Machine for Your Mold?

- 5. What Are the Common Applications of Injection Molding?

- 6. How Does Injection Molding Compare to Other Manufacturing Processes?

- 7. Conclusion

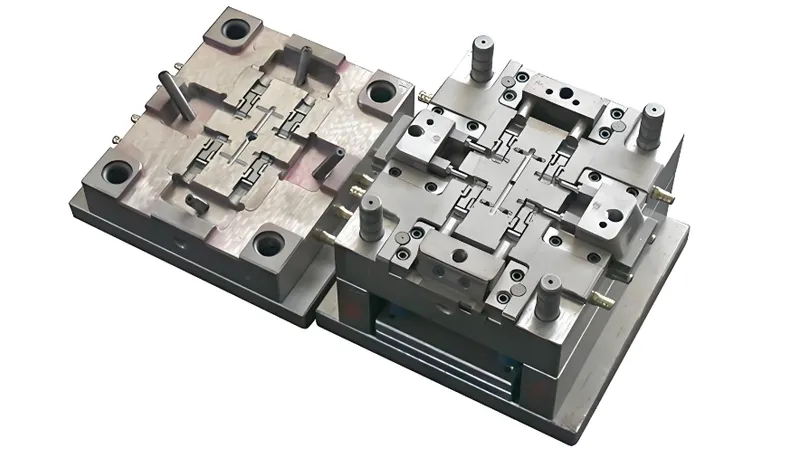

What Determines if a Mold Fits an Injection Molding Machine?

Injection molding machine and mold compatibility hinges on several technical factors that must align for successful production.

A mold fits an injection molding machine if it matches the machine’s clamping force, tie-bar spacing, mold height, and stroke, ensuring proper closure and part ejection.

| Factor | Importance | Notes |

|---|---|---|

| Clamping Force | Must match mold’s pressure requirements | Measured in tons or kilonewtons |

| Tie-bar Spacing4 | Must accommodate mold width and height | Critical for large molds |

| Mold Height5 | Must fit within machine’s min/max limits | Affects vertical space |

| Stroke | Ensures sufficient mold opening for part ejection | Varies by machine type |

Clamping Force (Tonnage)

Clamping force, measured in tons or kilonewtons, is the pressure the machine applies to keep the mold closed during injection. A mismatch can lead to defects like flash (excess material leakage) or incomplete parts. For example, a mold designed for a 500-ton machine won’t function properly on a 100-ton machine due to insufficient force.

Tie-bar Spacing

Tie-bar spacing6 determines the maximum mold size the machine can accommodate. If the mold is too large, it won’t fit between the tie-bars, rendering it incompatible. Standard machines typically handle molds up to 4’ x 4’, but larger molds require specialized equipment with wider spacing.

Mold Height and Stroke

The mold must fit within the machine’s minimum and maximum mold height limits. Additionally, the stroke—the distance the mold can open—must be sufficient for part ejection. A machine with inadequate stroke7 may not fully open, complicating removal of the finished part.

These factors, detailed in A guide to sizing injection molding machines | Plastics Machinery & Manufacturing, highlight why one machine cannot fit all molds.

Clamping force is the only factor determining mold compatibility.False

While critical, tie-bar spacing, mold height, and stroke also play essential roles.

Larger machines can handle any mold size.False

Even large machines have limits on mold dimensions and design complexity.

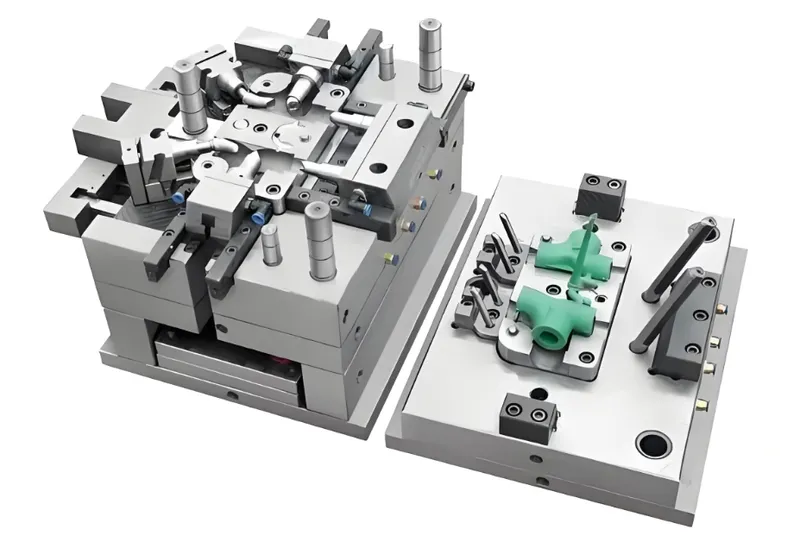

How Does Mold Design Impact Machine Compatibility?

Mold design directly influences whether a mold can be used with a specific injection molding machine, affecting both fit and functionality.

Mold design impacts compatibility through factors like cavity layout, runner type, and material requirements, which must align with the machine’s capabilities.8

Cavity and Runner Design

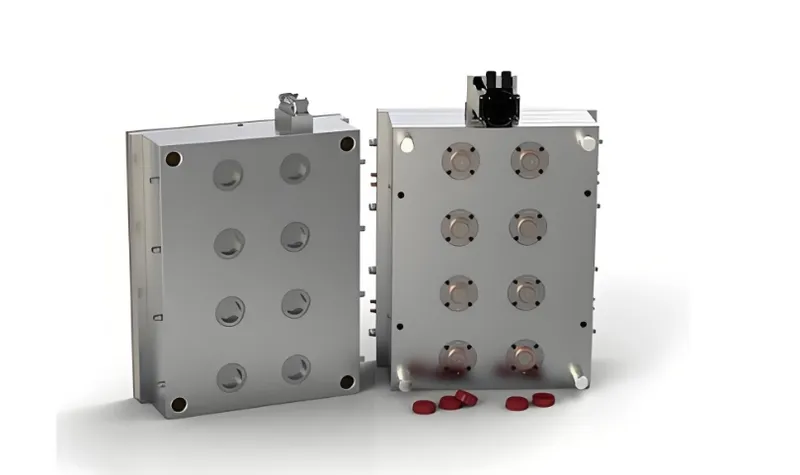

Molds can be single-cavity (producing one part per cycle), multi-cavity (multiple parts), or family molds (different parts). Each type requires different machine capacities. Multi-cavity molds, for instance, demand higher clamping force and precise pressure control, as noted in Injection Molding Molds: Types, Lifespan and Design Tips | Xometry Pro.

Material and Cooling Requirements

Different materials, such as ABS or polypropylene, have unique cooling and shrinkage rates, influencing mold design and machine settings. Machines must be calibrated to handle these variations, as discussed in Everything You Need To Know About Injection Molding.

Complexity and Size

Complex molds with slides, lifters, or inserts require machines with advanced control systems and sufficient space. Larger molds, beyond standard sizes, necessitate machines with extended tie-bar spacing and higher tonnage.

These design elements underscore that mold compatibility extends beyond mere size, involving intricate technical alignments.

All molds are interchangeable across machines with similar tonnage.False

Even with matching tonnage, differences in design and material requirements can prevent compatibility.

Simple molds can be used on any machine.False

Even simple molds must meet the machine’s size and clamping specifications.

What Are the Steps in the Injection Molding Process?

The injection molding process is a precise sequence of steps that transforms raw plastic into finished parts, requiring careful control at each stage.

The injection molding process involves clamping, injection, dwelling, cooling, and ejection, each critical for producing high-quality parts.9

Clamping

The mold is closed and clamped with sufficient force to withstand injection pressure. This step ensures the mold remains sealed during the process.

Injection

Molten plastic is injected into the mold cavity under high pressure. The injection speed and pressure must be carefully controlled to fill the mold completely.

Dwelling

After injection, pressure is maintained to ensure the cavity is fully filled and to compensate for material shrinkage as it cools.

Cooling

The plastic cools and solidifies within the mold. Cooling time varies based on material and part thickness, impacting cycle time and quality.

Ejection

The mold opens, and the part is ejected. Proper ejection prevents damage to the part and prepares the machine for the next cycle.

These steps, outlined in Injection Molding 101 | Molds, Materials, Machines and More | Fictiv, highlight the complexity of the process and why machine-mold compatibility is essential.

The injection molding process is fully automated and requires no human intervention.False

While automation is common, human oversight is often needed for setup, monitoring, and quality control.

Cooling time is the longest phase in the injection molding cycle.True

Cooling typically accounts for the majority of the cycle time, especially for thicker parts.

How Do You Choose the Right Injection Molding Machine for Your Mold?

Selecting the right injection molding machine for a specific mold involves evaluating several technical and practical factors to ensure compatibility and efficiency.

Choose an injection molding machine by matching the mold’s size, clamping force requirements10, and material needs11 with the machine’s specifications.

Assess Clamping Force Needs

Calculate the required clamping force based on the mold’s projected area and the material’s flow characteristics. A general rule is to use 2-5 tons per square inch of projected area.

Check Machine Dimensions

Ensure the mold fits within the machine’s tie-bar spacing, mold height limits, and stroke. For example, a mold that is too tall or wide won’t fit, regardless of other factors.

Consider Material and Process Requirements

Different materials require specific injection pressures, temperatures, and cooling times. Ensure the machine can handle the material’s properties and the mold’s design complexities.

Evaluate Production Volume

For high-volume production, consider machines with faster cycle times and automation capabilities. Low-volume runs may benefit from smaller, more flexible machines.

These considerations, as discussed in Which Injection Molding Machine is Best for Your Project? | KSN Blog, emphasize that selecting the right machine is a nuanced decision.

Higher tonnage machines are always better for larger molds.False

While they provide more clamping force, they may be overkill for smaller molds, increasing costs unnecessarily.

Machine selection impacts production efficiency and cost.True

Choosing the right machine optimizes cycle times, reduces defects, and lowers operational costs.

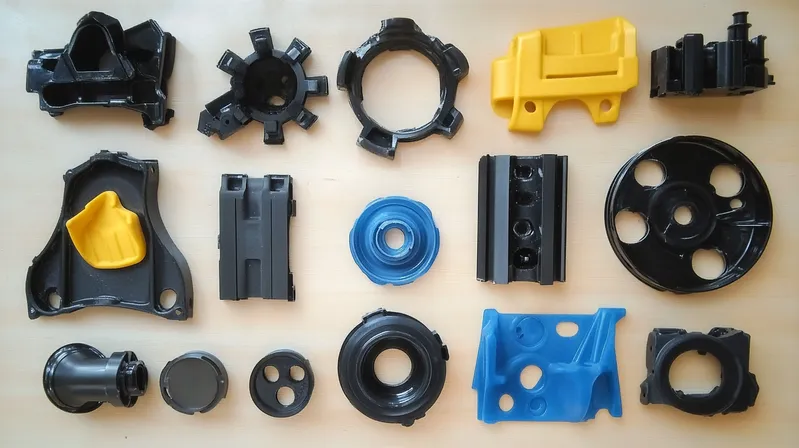

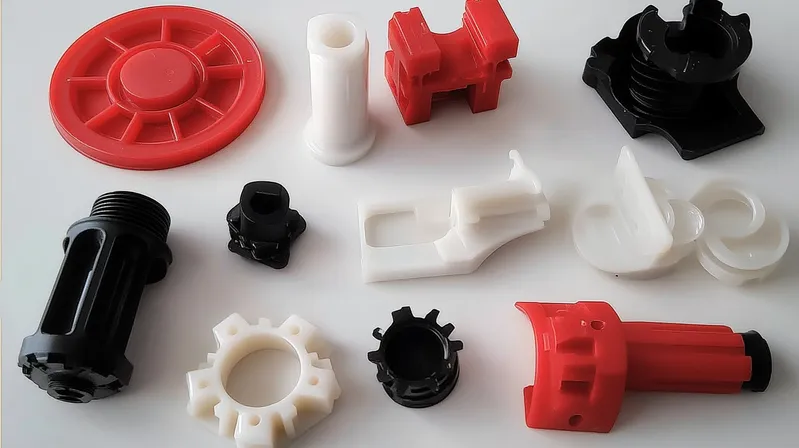

What Are the Common Applications of Injection Molding?

Injection molding is a versatile manufacturing process used across various industries to produce a wide range of products.

Injection molding is commonly used in automotive, consumer goods, packaging, medical devices, and aerospace for its precision and scalability.

Automotive Industry

Produces parts like dashboards, bumpers, and interior components, where durability and precision are critical.

Consumer Goods

Used for items like toys, appliances, and electronics housings, benefiting from high-volume production and design flexibility.

Packaging

Creates containers, caps, and closures with consistent quality and fast production rates.

Medical Devices

Manufactures syringes, housings, and precision components, requiring strict quality control and material compatibility.

Aerospace

Produces lightweight, high-strength components for aircraft, where performance and reliability are paramount.

These applications, highlighted in Everything You Need To Know About Injection Molding, demonstrate the process’s adaptability but also its reliance on specific machine-mold pairings.

Injection molding is only suitable for plastic parts.False

While primarily used for plastics, it can also process metals and composites in specialized applications.

Injection molding is ideal for both prototyping and mass production.True

It offers flexibility for low-volume prototyping and high-volume manufacturing.

How Does Injection Molding Compare to Other Manufacturing Processes?

Injection molding offers distinct advantages and limitations compared to other manufacturing technologies, making it suitable for specific applications.

Injection molding excels in producing complex, high-volume plastic parts but has higher initial costs and longer lead times than processes like 3D printing or thermoforming.

Vs. CNC Machining

Injection molding is faster for large volumes but has higher tooling costs, making it less suitable for low-volume production.

Vs. 3D Printing

Offers better material properties and surface finish for high volumes but is limited to thermoplastics and has high tooling costs.

Vs. Blow Molding

Better for complex, detailed parts but not for hollow parts like bottles.

Vs. Thermoforming

Excels for small, detailed parts but is more expensive for large parts.

These comparisons, drawn from Part Size Impact on Choice Between Injection Molding and Thermoforming | Productive Plastics, highlight that while injection molding is powerful, it’s not universally applicable, reinforcing the need for specific machine-mold compatibility.

Injection molding is always the most cost-effective manufacturing process.False

For low-volume production, processes like 3D printing or CNC machining may be more economical.

Injection molding offers superior part consistency compared to other methods.True

It provides high repeatability and precision, especially for complex geometries.

Conclusion

Injection molding is a powerful manufacturing process, but it’s not a one-size-fits-all solution. One injection molding machine cannot fit any mold due to critical factors like clamping force, mold size, and design complexity. Understanding these constraints is essential for optimizing production and avoiding costly mistakes.

Whether you’re designing a new product or scaling up manufacturing, ensuring the right machine-mold match is key to success. For further insights, explore resources like Injection Molding 101 | Molds, Materials, Machines and More | Fictiv to deepen your knowledge of this versatile process.

-

Understanding the specifications of injection molding machines can help you choose the right one for your molds, ensuring efficiency and quality in production. ↩

-

Exploring mold compatibility can provide insights into optimizing production processes and avoiding costly errors in manufacturing. ↩

-

Learning about clamping force is essential for selecting the right machine and achieving successful molding outcomes. ↩

-

Tie-bar spacing is vital for mold fitting. Learn more about its significance and how it impacts production efficiency. ↩

-

Mold height limits are essential for successful operation. Discover more about these constraints and their implications for production. ↩

-

Exploring tie-bar spacing helps in selecting the right machine for your mold size, ensuring efficient production without compatibility issues. ↩

-

Learning about stroke can help you choose a machine that effectively opens for part ejection, enhancing production efficiency. ↩

-

Understanding these factors can enhance your mold design process and ensure better compatibility with machines, leading to improved production efficiency. ↩

-

Exploring these steps will provide insights into optimizing your injection molding process for better quality and efficiency. ↩

-

This link will provide insights into accurately calculating clamping force, crucial for successful injection molding. ↩

-

Discover the specific material requirements for injection molding to ensure optimal machine compatibility and product quality. ↩