All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

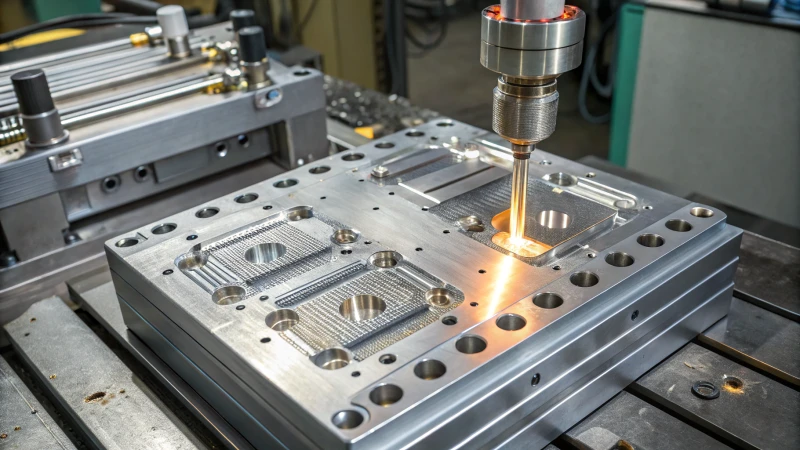

How Does the Injection Mold Manufacturing Process Work?

Injection mold manufacturing is a detailed process that transforms raw materials into precision plastic components. It encompasses several key stages: mold design, manufacturing preparation, parts processing, assembly, debugging, optimization, and acceptance. Each stage is crucial for ensuring the final product ...

MANUFACTURING

How Can You Produce Transparent Products Using Injection Molding?

This blog post explores techniques for producing transparent products through injection molding. It covers essential material selection, precise mold design, and control of temperature and pressure to achieve optimal clarity. Key materials like polycarbonate, acrylic, and PMMA are discussed along ...

MANUFACTURING

How Can You Optimize Acoustic Properties in Injection Molding?

This blog post explores how to optimize the acoustic properties of molded products through careful material selection, innovative mold design, and precise processing adjustments. It highlights the importance of using sound-dampening materials like polypropylene, ABS, and nylon while considering factors ...

OPTIMIZATION

What Key Factors Should You Consider When Designing Molds for Overmolding Applications?

Designing molds for overmolding applications requires careful consideration of several key factors. Material compatibility is crucial to ensure proper bonding and prevent delamination. Precise mold design enhances product quality by ensuring accurate dimensions and effective venting. Additionally, optimizing process parameters ...

DESIGN

How Can Injection Molded Products Achieve Antimicrobial Properties?

As cleanliness becomes increasingly important, industries are turning to antimicrobial plastics. By integrating additives like silver and copper ions during the injection molding process, these materials can effectively disrupt microbial cell functions. This innovation is crucial in sectors such as ...

MANUFACTURING

How Can You Enhance Material Flame Retardancy in Injection Molding?

This article explores methods to enhance material flame retardancy in injection molding. It discusses the use of various flame retardant additives—halogenated, phosphorus-based, and metal hydroxide—and their impacts on safety and performance. The importance of understanding each additive's properties is emphasized ...

Materials Recommendations

How Are Plastic Gears Manufactured Through Injection Molding?

This blog post explores the fascinating process of manufacturing plastic gears through injection molding. It details the steps involved in the injection molding cycle, highlights key material choices such as acetal, nylon, and polycarbonate, and discusses the advantages of this ...

MANUFACTURING

What Impact Do UV Stabilizers Have on Injection-Molded Products?

UV stabilizers are essential additives in injection-molded products, safeguarding them against the damaging effects of ultraviolet radiation. By absorbing or reflecting harmful UV rays, these stabilizers help maintain the physical properties of plastics, ensuring longevity and vibrant colors. Understanding the ...

MANUFACTURING

What Are the Best Techniques for Creating Complex Structures in Injection Molding?

This blog post delves into the best techniques for creating intricate structures in injection molding. Key methods discussed include mold flow analysis to optimize material usage and reduce defects, the use of advanced materials for enhanced performance and durability, 3D ...

DESIGN

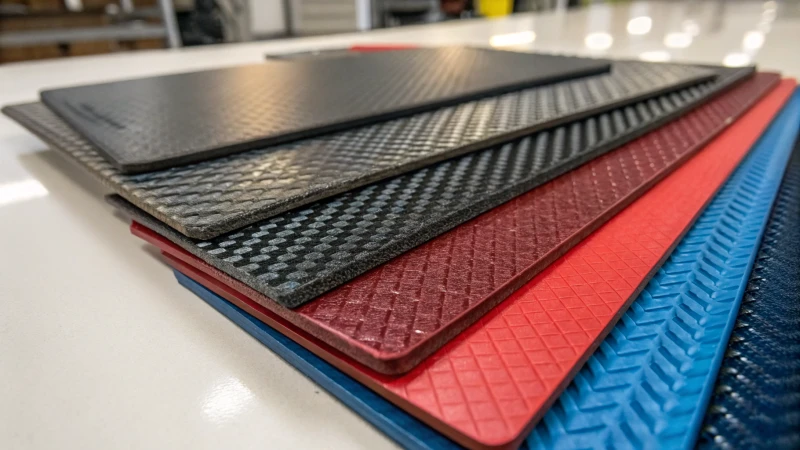

What Impact Do Colorants and Pigments Have on the Injection Molding Process?

Colorants and pigments play a crucial role in the injection molding process by altering the physical properties of plastics such as flexibility, hardness, and durability. The right selection enhances visual appeal while optimizing performance for large-scale manufacturing. Understanding how different ...

MANUFACTURING

What Impact Do Plasticizers Have on the Flexibility of Injection-Molded Parts?

Plasticizers are essential additives that improve the flexibility and durability of injection-molded plastics by inserting themselves between polymer chains. This process reduces intermolecular forces, allowing for greater mobility and adaptability in various applications. While plasticizers like phthalates have been widely ...

MANUFACTURING

What Challenges Arise When Molding High-Impact Resistant Materials?

Molding high-impact resistant materials involves navigating various challenges such as selecting appropriate materials, designing effective molds, and preventing defects like warping and sink marks. Each challenge requires a blend of technical skill and creativity to ensure product durability and manufacturing ...

Materials Recommendations

What Impact Do Crystallinity Levels in Polymers Have on Injection Molding Outcomes?

This article explores how crystallinity levels in polymers impact injection molding processes. It discusses the relationship between crystallinity and mechanical properties such as strength, brittleness, and thermal stability. Understanding these factors is essential for optimizing product designs in various applications, ...

MANUFACTURING

How Do You Design Molds for Achieving High-Gloss Surface Finishes?

Creating high-gloss finishes in molded parts is an intricate process that combines art and engineering. Key factors include choosing the right materials like stainless steel or aluminum, employing advanced polishing techniques, and adhering to industry standards such as SPI. Mold ...

DESIGN

What Are the Differences in Injection Molding for Thin-Wall vs. Thick-Wall Parts?

This article explores the key differences between thin-wall and thick-wall injection molding processes. Thin-wall molding typically requires higher pressure and faster cooling times, enhancing production speed but potentially compromising structural integrity. In contrast, thick-wall molding allows for more leeway in ...

MANUFACTURING

How Can Gas-Assisted Injection Molding Enhance Mold Design?

Gas-assisted injection molding revolutionizes traditional manufacturing by optimizing mold designs. This innovative technique reduces material usage, enhances surface finish, minimizes shrinkage, and allows for intricate geometries. It significantly improves production efficiency while maintaining product integrity. Designers can achieve lightweight components ...

DESIGN

How Do Biopolymers Enhance the Sustainability of Injection Molding?

Biopolymers are revolutionizing the injection molding industry by providing eco-friendly, biodegradable alternatives to conventional plastics. Derived from renewable resources, they help reduce carbon footprints and align with sustainable production practices. However, integrating biopolymers into existing manufacturing processes presents challenges such ...

MANUFACTURING

How Can Venting Enhance the Efficiency of Injection Mold Designs?

Venting plays a vital role in injection mold design by facilitating the escape of trapped air and gases during the injection process. This essential step helps reduce defects such as burn marks and voids, improves material flow, and optimizes cycle ...

DESIGN

How Can Mold Design Strategies Effectively Minimize Material Waste?

This article explores how effective mold design strategies can minimize material waste in manufacturing. By focusing on techniques such as precise gate placement, optimizing runner systems, and utilizing advanced CAD tools, manufacturers can enhance production efficiency while promoting sustainability. The ...

DEVELOPMENT

Why Choose Family Molds for Injection Molding: What Are the Benefits?

Family molds are a game-changer in injection molding, allowing manufacturers to produce various components in one cycle. This method significantly cuts production costs and time while optimizing material usage. Ideal for projects requiring diverse parts, family molds streamline operations and ...

MANUFACTURING

What Impact Do Glass Fiber and Carbon Fiber Fillers Have on the Mechanical Properties of Injection-Molded Parts?

This article explores the impact of glass fiber and carbon fiber fillers on the mechanical properties of injection-molded parts. It highlights how these materials enhance strength, stiffness, thermal stability, and weight reduction. Glass fibers improve durability and thermal resistance, while ...

Materials Recommendations

How Can You Identify Signs of Wear and Tear in Injection Molds?

Injection molding is a vital manufacturing process used to create precise components for industries like automotive, electronics, and consumer goods. However, the molds at the heart of this process endure significant stress, leading to wear and tear over time. Recognizing ...

Injection mold

What Are the Best Practices for Choosing Materials in Medical-Grade Injection Molding?

Selecting the right materials for medical-grade injection molding is crucial for developing safe and reliable medical devices. Key factors include sterilization compatibility, mechanical properties like tensile strength and elasticity, biocompatibility to prevent adverse reactions, and adherence to regulatory standards. Understanding ...

Materials Recommendations

What Are the Challenges of Injection Molding Large-Scale Parts?

This blog explores the complexities of injection molding large-scale parts, highlighting challenges such as managing material volumes, ensuring consistent quality, and dealing with extended cooling times. It emphasizes the importance of selecting appropriate materials to balance cost and performance while ...

MANUFACTURING

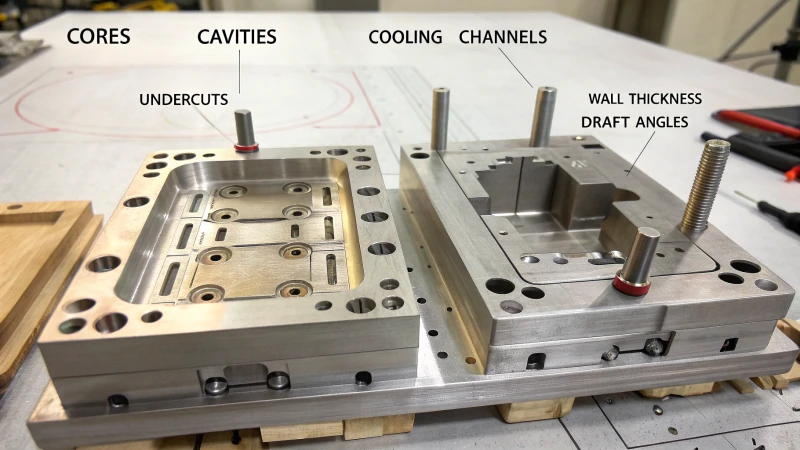

How Does Part Geometry Influence Mold Design in Injection Molding?

This article explores how part geometry affects mold design in injection molding. Key factors such as wall thickness, mold size, core shapes, and undercuts are discussed to highlight their influence on manufacturability and product quality. The importance of draft angles ...

MANUFACTURING

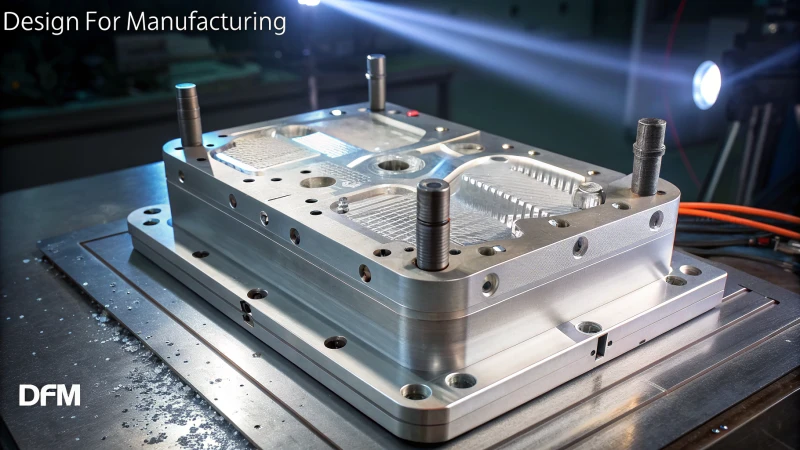

How Can DFM Principles Enhance Injection Mold Design?

Design for Manufacturing (DFM) principles significantly improve injection mold design by streamlining production processes, minimizing costs, and enhancing product quality. By focusing on simplicity, standardization, and ease of assembly, DFM helps designers create molds that are not only functional but ...

DESIGN

How Effectively Do Flame-Retardant Materials Perform in Injection Molding Applications?

This article explores the effectiveness of flame-retardant materials in injection molding applications, highlighting their crucial role in enhancing fire safety for consumer electronics. It discusses various types of flame-retardants, including halogenated compounds, phosphorous-based additives, and nitrogen-based synergists, each with unique ...

Materials Recommendations

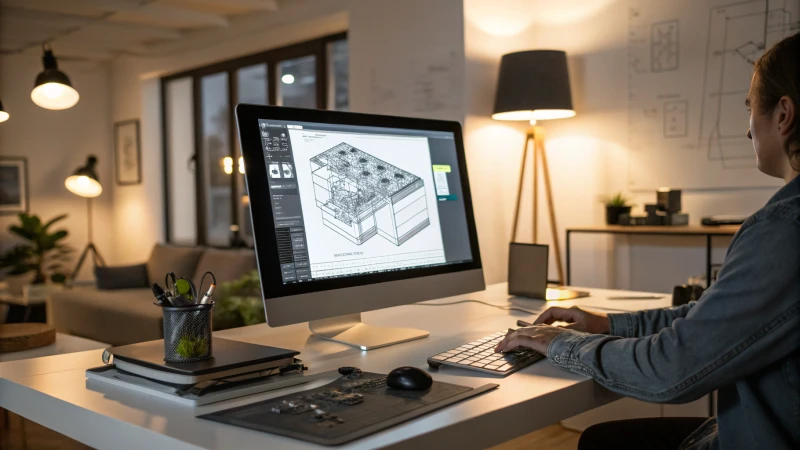

How Does CAD Software Enhance the Design of Injection Molds?

CAD software significantly enhances the design of injection molds by improving precision and efficiency. Key features include 3D modeling for accurate visualization, simulation tools to predict performance, and automated documentation that streamlines communication. These capabilities not only reduce design time ...

DESIGN

What Are the Essential Factors in Designing Injection Molds for High-Volume Production?

Designing injection molds for high-volume production involves a blend of art and science. Essential factors include careful material selection, optimizing cooling systems, ensuring uniform wall thickness, and precise construction. Utilizing advanced technologies like CAD software streamlines the design process by ...

DESIGN

What Are the Latest Advancements in Thermoplastic Elastomers for Injection Molding?

Thermoplastic elastomers (TPEs) are transforming manufacturing with their unique blend of flexibility and durability. Recent advancements have led to enhanced material properties, new formulations, and innovative processing techniques that improve efficiency and reduce costs. TPEs allow for intricate designs, reduced ...

Materials Recommendations