All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

How Does Insert Molding Enhance Injection Processes?

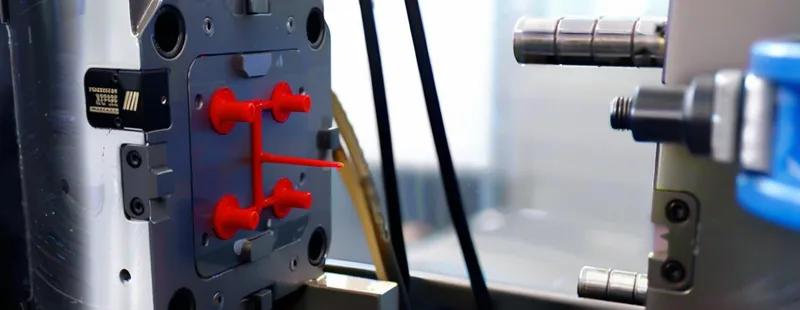

Insert molding is a specialized injection molding technique1 that integrates pre-formed inserts—typically metal components2—into plastic parts during the molding process. This method enhances traditional injection molding by producing stronger, more functional, and cost-effective products. By embedding inserts directly into the ...

Injection moulding

Choosing the Right Plastic B Side Features: A Comprehensive Guide

When designing plastic parts for injection molding, one of the critical aspects to consider is the selection of B side features1. These features, located on the non-visible side of the part, play a vital role in the functionality and assembly ...

Injection molding raw materials

How Biopolymers Enhance the Sustainability of Injection Molding

Biopolymers are transforming the injection molding1 industry by offering a sustainable alternative to traditional petroleum-based plastics. Derived from renewable resources like plants and microorganisms, biopolymers are often biodegradable or compostable, making them an eco-friendly choice for manufacturers looking to reduce ...

Injection Molded Products

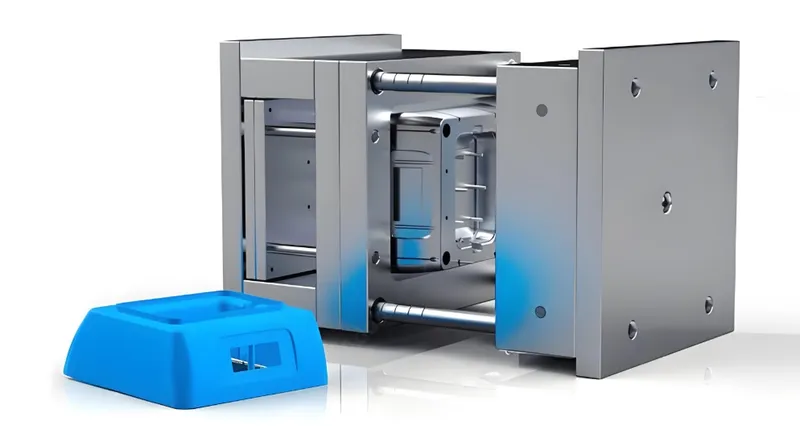

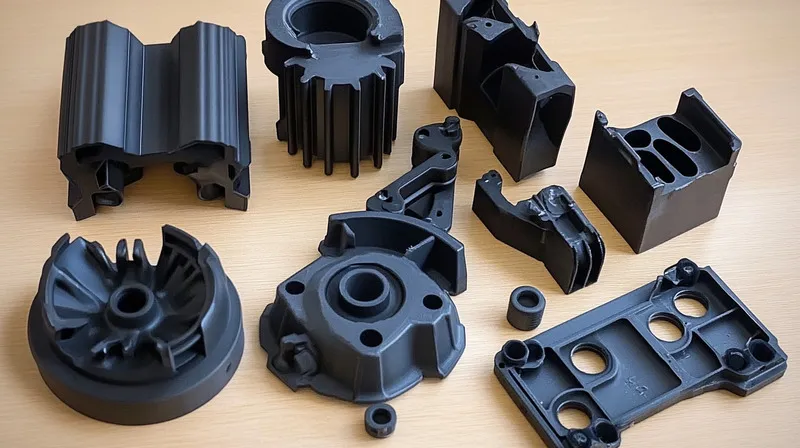

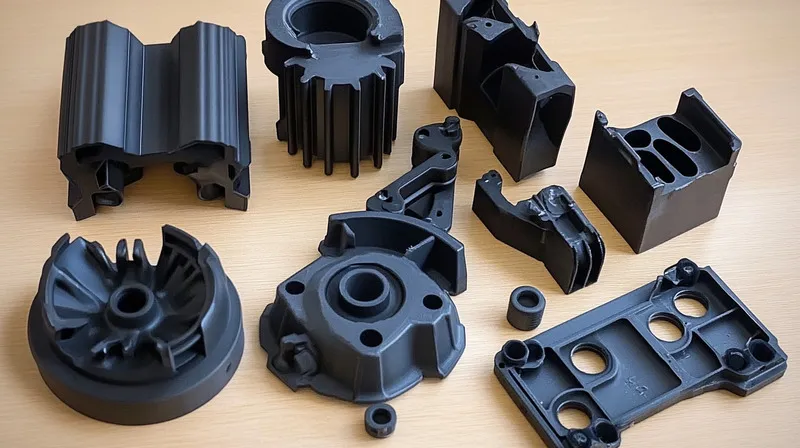

What Are the Essential Tools for Injection Mold Making?

Injection mold making1 is a critical process in manufacturing, enabling the production of precise plastic parts for industries like automotive, electronics, and medical devices. The essential tools2 for this process include software for design, machines for shaping, and components for ...

Injection mold

What Are the Best Practices for Managing Post-Processing in Injection Molding?

Injection molding is a cornerstone of modern manufacturing, producing plastic parts for industries ranging from automotive to medical devices. However, the molded parts often require additional operations—known as post-processing1—to meet the desired quality, appearance, and functionality. These steps, which include ...

Injection moulding

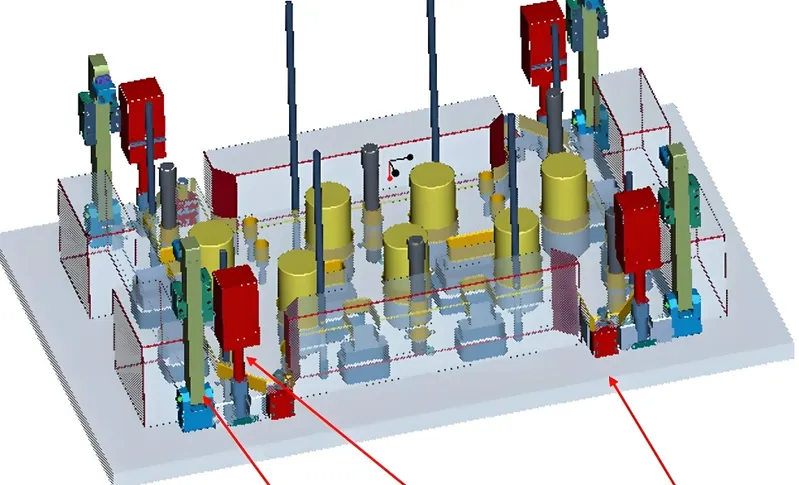

How Do You Choose the Right Ejection System for Your Mold?

The ejection system is a critical component in injection molding1, responsible for removing the solidified part from the mold cavity2. Choosing the right ejection system ensures efficient production, minimizes part damage, and extends the mold's lifespan. This guide provides a ...

Injection mold

How Do Biodegradable Plastics Benefit Injection Molding?

Biodegradable plastics are revolutionizing the injection molding1 industry by offering a sustainable alternative to traditional plastics. These materials, derived from renewable resources, decompose naturally, reducing environmental impact. In injection molding, they provide versatility, consumer appeal, and eco-friendly solutions across various ...

Injection moulding

How Can You Apply Lean Manufacturing Principles to Enhance Injection Molding?

Applying Lean Manufacturing1 principles to injection molding optimizes production by eliminating waste2, reducing costs, and improving efficiency, making it ideal for industries like automotive and consumer goods. Lean Manufacturing enhances injection molding by streamlining processes, cutting waste, and boosting productivity3, ...

Injection moulding

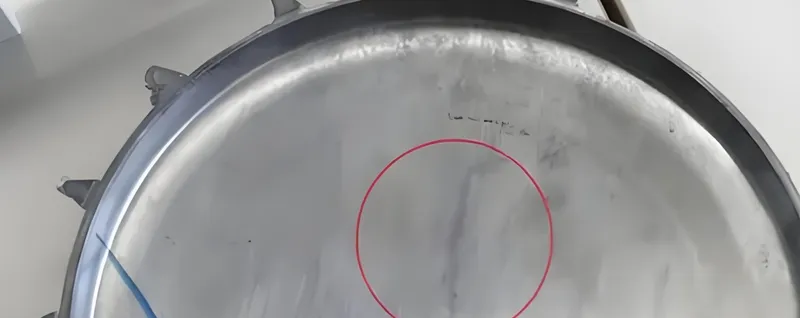

How Can You Achieve a High-Gloss Finish in Injection Molding?

The high-gloss injection molding1 process creates premium, shiny plastic parts by using polished molds and specific materials, enhancing aesthetics and durability for various industries. High-gloss injection molding uses polished molds2 and materials like ABS or polycarbonate to produce reflective surfaces3, ...

Injection moulding

Achieving Perfect Color Consistency in Injection Molded Parts

Achieving perfect color consistency1 in injection molded parts is a critical aspect of manufacturing that ensures every part produced has the same color, with no noticeable variations. This uniformity is essential for maintaining product quality, brand identity, and compliance with ...

Injection Molded Products

What Impact Do Plasticizers Have on the Flexibility of Injection-Molded Parts?

Plasticizers play a crucial role in enhancing the flexibility of injection-molded parts1 by modifying the physical properties of polymers. This blog post explores the definitions, classifications, applications, advantages, disadvantages, and technical considerations of using plasticizers in injection molding. Plasticizers are ...

Injection Molded Products

What Are the Key Steps to Designing an Effective Screw Boss?

In plastic part design, screw bosses1 are essential features that provide secure fastening points for screws, ensuring sturdy and reliable assemblies. These cylindrical protrusions are widely used in industries like electronics, automotive, and consumer goods. A screw boss is a ...

Injection moulding

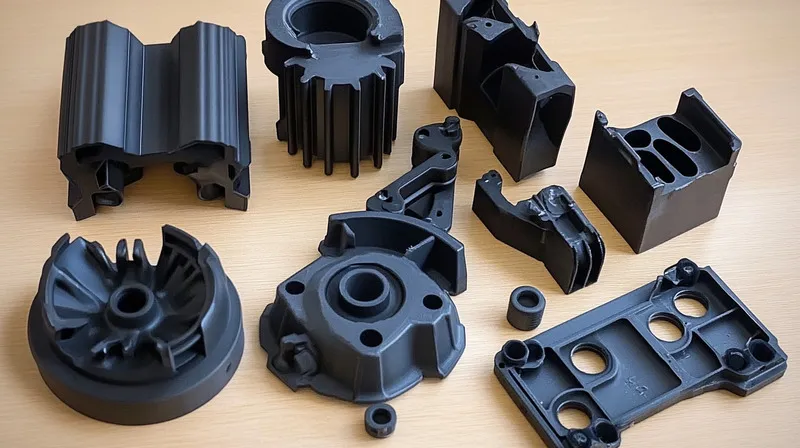

What Are the Best Techniques for Creating Complex Structures in Injection Molding?

Injection molding is a cornerstone of modern manufacturing, enabling the production of intricate plastic parts with high precision and efficiency. When it comes to creating complex structures1—such as parts with undercuts, thin walls, or integrated components—specialized techniques are essential to ...

Injection moulding

The Essential Guide to Cooling Time in Injection Molding

Injection molding is a cornerstone of modern manufacturing, enabling the production of complex plastic parts with high precision and efficiency. However, one of the most critical yet often overlooked aspects of this process is cooling time—the period during which the ...

Injection moulding

Texturing Injection Molded Surfaces Effectively

I. Basic Cognitive Level: Establishing Conceptual Framework Clear Definitions: Texture Injection Molding1: A process applying patterns to injection-molded parts via the mold surface, enhancing aesthetics or functionality. Aliases include mold texturing or surface texturing. Core Principles: Texture is mold-derived, leveraging ...

Injection moulding

Injection Molding vs. Compression Molding: Key Differences and Applications

Injection molding and compression molding are two widely used manufacturing processes1 for producing plastic parts, each with its own strengths and ideal applications. Understanding the key differences between them is crucial for selecting the right method for your project. Injection ...

Injection moulding

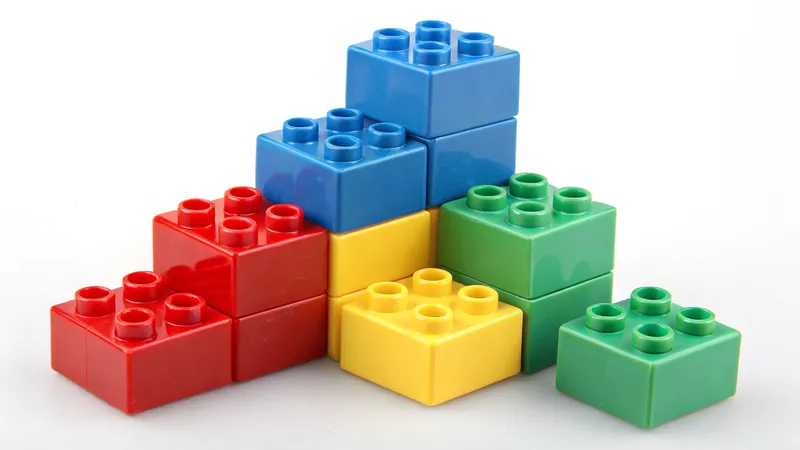

How Legos Are Made: Are They Injection Molded?

The manufacturing of Lego bricks involves a precise and highly automated process called injection molding1, where molten plastic is injected into molds to create the iconic, interlocking bricks. This method ensures each brick meets strict quality standards for durability, precision, ...

Injection Molded Products

How Do Gas Marks Affect the Injection Molding Process?

Gas marks are a prevalent defect in injection molding, manifesting as streaks, burns, or focal points on the surface of molded parts. These defects arise from trapped gases—such as air, water vapor, or decomposition gases—that fail to escape the mold ...

Injection Molding Defects

Demystifying Injection Molding Cooling Time: A ZetarMold Guide to Efficiency and Quality

I. Basic Cognitive Level: Establishing Conceptual Framework Before we optimize, we must understand. Clear Definitions Injection Molding Cooling Time: Full Technical Name: Cooling Phase Duration in Injection Molding Cycle. Common Aliases: Cooling time1, solidification time2, cure time (less common for ...

Injection moulding

How Can You Texture Injection Molded Surfaces Effectively?

Texturing injection molded surfaces involves applying patterns or finishes to molds, which transfer to plastic parts during molding, enhancing aesthetics, functionality, and defect concealment. Understanding how to texture injection molded surfaces effectively is crucial for industries seeking to improve product ...

Injection Molded Products

How Can Venting Enhance the Efficiency of Injection Mold Designs?

In the fast-paced world of injection molding1, precision and efficiency are paramount. One often-overlooked but critical aspect of mold design is venting. Proper venting ensures that air and gases escape smoothly during the injection process, preventing defects like burn marks, ...

Injection mold

Key Design Considerations for Injection Molding High-Temperature Parts : A Comprehensive Guide

Injection molding is a versatile manufacturing process, but when it comes to producing parts that must withstand extreme heat, the stakes are higher. High-temperature plastics like PEEK, PEI, and PPS are essential in industries such as aerospace, automotive, and electronics, ...

Injection moulding

Bakelite Injection Molding vs. Other Plastic Injection Molding: A Comprehensive Comparison

Bakelite injection molding1 and other plastic injection molding are two widely used manufacturing processes, each with its unique characteristics and applications. In this blog post, we'll explore the differences between these two processes, from their basic principles to their practical ...

Injection moulding

How Can You Produce an Egg Tray Using an Injection Molding Machine?

Injection molding is a highly efficient manufacturing process1 used to create durable, lightweight egg trays for the poultry and food packaging industries. This guide provides a comprehensive overview, from the basics of injection molding to advanced technical details, helping you ...

Injection Molded Products

Understanding the Cavity in Injection Molding: A Comprehensive Guide

Injection molding is a cornerstone of modern manufacturing, producing precise plastic parts1 for industries ranging from automotive to consumer goods. At the heart of this process lies the cavity, a critical component that shapes the external form of the molded ...

Injection mold

How Are Toothbrushes Made Using Injection Molding Machines?

Ever wondered how the toothbrush you use every day is crafted? Behind its simple design lies a sophisticated manufacturing process that ensures durability, effectiveness, and safety. At the core of this process is injection molding, a technique that enables the ...

Injection Molded Products

How Can You Ensure Quality Consistency from Suppliers in Injection Molding?

Injection molding is a versatile manufacturing process that produces precise, high-volume parts by injecting molten material into a mold. Ensuring quality consistency from suppliers is critical to minimizing defects, maintaining production efficiency, and meeting industry standards across applications like automotive, ...

Find Suppliers

How Can an Injection Molding Machine Produce Plastic Spoons?

Injection molding is a widely adopted manufacturing process for producing plastic spoons, especially in large quantities. This method involves melting plastic pellets, injecting the molten plastic into a mold shaped like a spoon, cooling it to solidify, and then ejecting ...

Injection Molded Products

How Can Injection Molded Parts Be Recycled Effectively?

Injection molded parts, widely used in industries like automotive, packaging, and consumer goods, are typically crafted from plastics such as PET, HDPE, and PP. With growing concerns over plastic waste, recycling these components has become a vital practice. Fortunately, many ...

Injection Molded Products

What is the Maximum Wall Thickness Allowed for Injection Molding?

Injection molding is a widely used manufacturing process for producing precise plastic parts, from small consumer goods to large industrial components. A critical factor in designing these parts is wall thickness1, which impacts the part’s strength, functionality, and the efficiency ...

Injection moulding