All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

How Can You Avoid Short Shots by Adjusting Injection Pressure?

Short shots in injection molding can lead to incomplete products and manufacturing frustrations. To avoid this issue, manufacturers must adjust injection pressure based on product structure and material properties. Key factors include wall thickness, melt flow complexity, and the viscosity ...

MANUFACTURING

What Are the Best Injection Molding Process Adjustments to Enhance Product Strength?

This article explores effective adjustments in the injection molding process to enhance product strength. Key factors include optimizing injection pressure and speed, managing mold temperature, and extending cooling time. By carefully balancing these parameters, manufacturers can significantly improve the density ...

MANUFACTURING

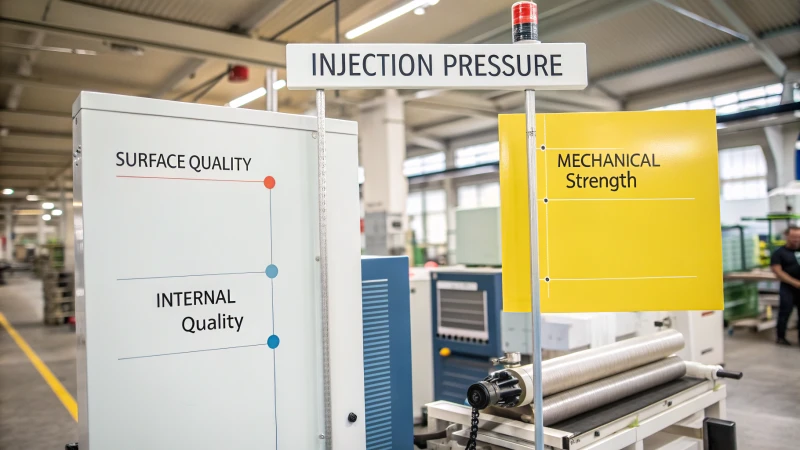

How Does Injection Pressure Affect the Quality of Injection Molded Products?

Injection pressure is a critical factor in injection molding that directly impacts the quality of molded products. High pressure can lead to defects such as flash formation, surface imperfections, oversized items, and internal stress issues. Conversely, low pressure may result ...

MANUFACTURING

How Does Injection Pressure Influence the Properties of Plastic Products?

This article explores how injection pressure impacts the properties of plastic products, including surface quality, dimensional accuracy, mechanical strength, and internal stress. Properly managed injection pressure is crucial for achieving high-quality results in molded plastics. High pressures can lead to ...

MANUFACTURING

What Are the Best Strategies for Finding Top Injection Mold Manufacturers in China?

Finding the right injection mold manufacturer in China is essential for production success. Key regions such as Guangdong and the Yangtze River Delta are known for advanced technology and competitive pricing. This article explores these areas' strengths, including quality levels, ...

MANUFACTURING

How Can You Enhance the Strength of Plastic Products with Excessive Shrinkage?

This article explores strategies to enhance the strength of plastic products suffering from excessive shrinkage. Key methods include selecting appropriate materials like glass fiber-reinforced plastics, adjusting process parameters such as injection pressure and mold temperature, and optimizing mold designs with ...

MANUFACTURING

What Are the Most Effective Surface Treatments for Plastic Products?

This article delves into the most effective surface treatments for plastic products. It covers various methods such as In-Mold Decoration (IMD), Outside Membrane Decoration (OMD), Non-Conductive Vacuum Metallization (NCVM), and spraying techniques. Each method is analyzed for its advantages in ...

MANUFACTURING

How Can You Enhance the Production Efficiency of Injection Molds?

This article explores various strategies to enhance the production efficiency of injection molds. Key methods include optimizing mold design with balanced runner systems and conformal cooling channels, selecting appropriate materials, and implementing advanced technologies such as gas-assisted and multi-color injection ...

OPTIMIZATION

How Can You Improve Production Efficiency in Injection Molding?

Improving production efficiency in injection molding involves several strategies. Key actions include optimizing mold design with balanced runner systems and efficient cooling channels, selecting appropriate materials like P20 or H13 steel for durability, and standardizing molds to facilitate quick replacements. ...

OPTIMIZATION

What Are the Key Applications of Multi-Stage Injection in Injection Molding Machines?

Multi-stage injection molding is a transformative technology widely used in various sectors such as automotive, electronics, medical devices, packaging, household goods, and toy manufacturing. This advanced process allows for precise control over injection speed and pressure, resulting in improved product ...

MANUFACTURING

How Can You Overcome Technical Challenges in Multi-Stage Injection Molding Machines?

Overcoming technical challenges in multi-stage injection molding machines requires a multifaceted approach. Key strategies include conducting detailed product and mold analyses, utilizing simulation tools for predictive modeling, implementing advanced control systems for precise adjustments, and maintaining equipment regularly to prevent ...

DEVELOPMENT

What Technical Challenges Arise with Multi-Stage Injection Functions in Injection Molding Machines?

This article explores the technical challenges of multi-stage injection molding, including complex parameter settings for injection speed and pressure matching. It emphasizes the importance of adapting to material properties and mold structures while maintaining equipment performance. Key factors such as ...

DEVELOPMENT

What Are the Key Application Scenarios for Multi-Stage Injection Molding Machines?

Multi-stage injection molding machines are revolutionizing the manufacturing of intricate plastic components. By adjusting speed and pressure throughout the process, these machines excel in creating products with varying wall thicknesses, detailed internal structures, and high precision. This method is particularly ...

MANUFACTURING

What Benefits Does the Multi-Stage Injection Function Offer in Injection Molding Machines?

Multi-stage injection molding is a transformative technique in manufacturing that significantly improves product quality. By allowing precise control over the injection process, it reduces surface defects like flow marks and silver streaks while enhancing internal integrity by minimizing residual stress. ...

MANUFACTURING

How Does Multi-Stage Injection Work in Injection Molding Machines?

This article explores multi-stage injection molding, detailing its process divided into initial injection, fast filling, slow filling, and holding pressure. Each stage requires specific settings for speed and pressure tailored to material characteristics. Understanding product structure is crucial for optimizing ...

MANUFACTURING

How Can You Minimize the Negative Impact of Injection Speed on the Tensile Strength of Plastic Products?

This article explores how to minimize the negative impact of injection speed on the tensile strength of plastic products. Key strategies include optimizing injection speed parameters, adjusting mold structure, and implementing effective material pretreatment and post-treatment processes. By fine-tuning injection ...

OPTIMIZATION

How Does Injection Speed Impact the Tensile Strength of Plastic Products?

This article explores how injection speed affects the tensile strength of plastic products. Moderate speeds (80-120mm/s for polyamide) improve material density and molecular chain orientation, enhancing strength. Conversely, excessive speeds create internal residual stress and surface defects, while low speeds ...

DEVELOPMENT

How Can You Adjust Injection Speed to Optimize Impact Strength?

This article explores how adjusting injection speed in the molding process can optimize impact strength. It emphasizes the importance of understanding material properties—differentiating between crystalline and non-crystalline plastics—and adapting speeds accordingly. For crystalline plastics like polypropylene, a controlled speed of ...

OPTIMIZATION

How Does Injection Speed Influence the Mechanical Properties of Plastic Products?

This article explores how injection speed affects the mechanical properties of plastic products, including tensile strength, impact resistance, and bending strength. It emphasizes the importance of maintaining optimal injection speeds for different materials to ensure even filling and proper crystallization. ...

DEVELOPMENT

What is the Best Way to Determine the Most Suitable Injection Speed?

This article explores how to determine the most suitable injection speed in plastic molding. It emphasizes the importance of material properties such as viscosity, thermal conductivity, and density in setting initial speed ranges. The piece discusses trial molds and adjustments ...

DEVELOPMENT

How Does Reducing Injection Mold Speed Enhance Product Quality?

Lowering the speed of injection molding significantly improves product quality. It reduces surface defects like flow marks and silver streaks while enhancing internal stability and density. Slower speeds allow for better replication of intricate textures and patterns, ensuring a smooth ...

MANUFACTURING

What Factors Determine the Best Injection Speed?

Choosing the right injection speed is crucial for optimizing plastic molding processes. Factors such as material characteristics (fluidity and heat sensitivity), mold design (gate size and runner system), and specific product requirements all influence the ideal injection speed. For instance, ...

MANUFACTURING

How Does Injection Pressure Impact the Quality of Injection Molds?

This article explores the critical role of injection pressure in molding processes, highlighting its impact on product quality, internal structure, and mold longevity. Properly adjusted pressure ensures complete filling of molds, enhances material properties, and extends the service life of ...

Quality Inspection

How is Injection Mold Injection Pressure Determined?

This article explores how injection mold pressure is determined by various factors including material characteristics, mold structure, and product requirements. Key aspects such as fluidity of plastics like polyethylene (PE) and polycarbonate (PC), gate size, runner system design, and the ...

MANUFACTURING

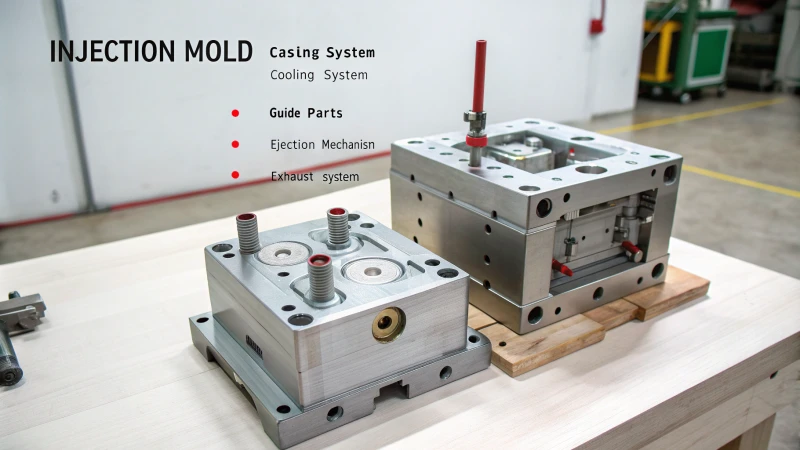

What Are the Functions of Each Part of an Injection Mold?

Injection molds consist of various critical components that work together to produce high-quality plastic parts. This article delves into the functions of each part: the casting system guides melted plastic; molded parts shape products; guide parts ensure precise alignment; ejection ...

DESIGN

What Key Details Should You Consider When Installing a Heating Ring?

Installing a heating ring on machinery demands precision and attention to detail. Key steps include inspecting the heating coil and barrel for damage, ensuring specifications match, achieving a snug fit for optimal heat transfer, securing electrical connections properly, and conducting ...

OPTIMIZATION

How Can Product Design Optimization Solve Warpage Defects in Injection Molded Parts?

This article explores how product design optimization can address warpage defects in injection molded parts. Key strategies include maintaining uniform wall thickness to ensure even cooling, strategically designing ribs to enhance strength without increasing thickness, and simplifying complex shapes to ...

OPTIMIZATION

How Do Warpage Defects Affect the Performance of Injection Molded Parts?

Warpage defects significantly impact the performance of injection molded parts by altering their dimensional accuracy, mechanical properties, and appearance. These issues arise from uneven cooling, material shrinkage, and poor mold design. Warped components can lead to assembly challenges and functional ...

OPTIMIZATION

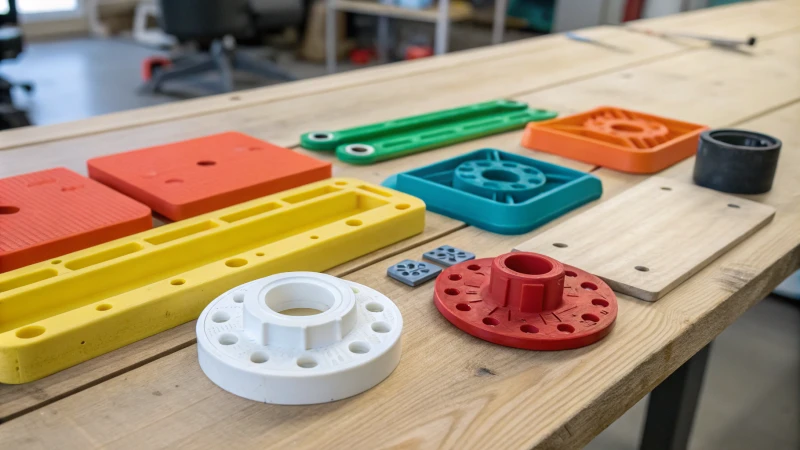

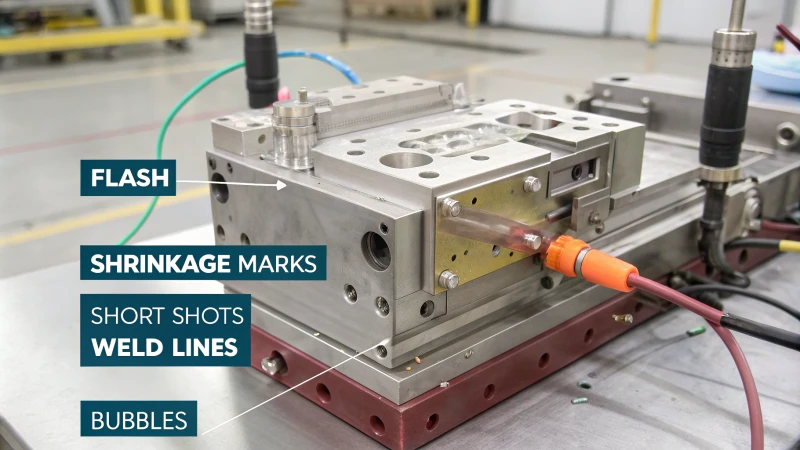

What Are the Most Common Defects in Injection Molding?

Injection molding can lead to various defects that affect product quality and efficiency. Common issues include flash caused by excessive pressure, shrinkage marks from uneven cooling, weld marks from flow convergence, bubbles due to moisture or poor venting, and short ...

Quality Inspection

How Can You Integrate Mold Design Standardization with Personalized Design?

This article explores how to effectively integrate mold design standardization with personalized elements. It emphasizes the importance of understanding product demand, developing a strategic design plan, and utilizing parametric design software to achieve a balance between creativity and efficiency. By ...

DESIGN