Injection moulding

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Most Effective Ways to Reduce Part Weight in Injection Molding?

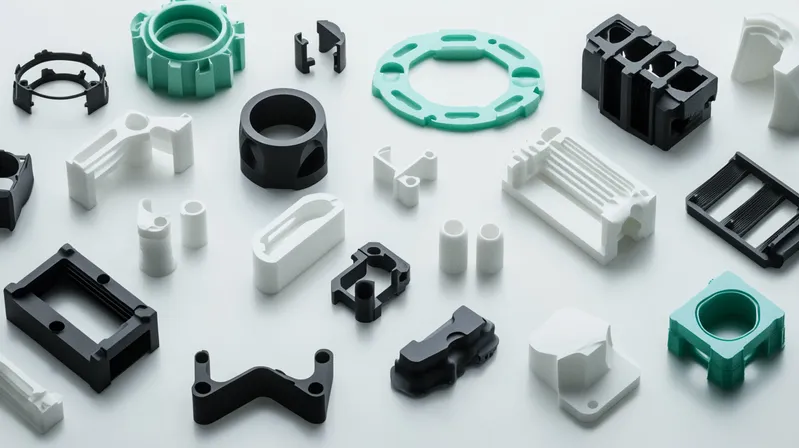

Injection molding is a versatile manufacturing process, but part weight can be a significant concern, especially in industries like automotive and aerospace where every gram counts. Reducing part weight can lead to cost savings, improved performance, and environmental benefits. In ...

Injection moulding

Injection Molding UHMWPE: A Comprehensive Guide

Imagine a plastic so tough it can outlast steel in harsh conditions, yet so versatile it can be shaped into intricate parts for medical devices or industrial machinery. That’s Ultra High Molecular Weight Polyethylene1, or UHMWPE. Molding this super-plastic isn’t ...

Injection moulding

Optimal Rib-to-Wall Thickness Ratio in Injection Molding

In the world of injection molding, achieving a perfect balance between strength, weight, cost, and aesthetics is paramount. One critical design feature that significantly impacts this balance is the rib. Ribs add structural integrity1 to plastic parts without dramatically increasing ...

Injection moulding

Is Bakelite Suitable for Injection Molding?

Bakelite, the world’s first synthetic plastic, has a storied history and unique properties that continue to make it relevant in modern manufacturing. But is it suitable for injection molding1—a process typically associated with thermoplastics? This blog post dives into Bakelite’s ...

Injection moulding

How Does Desktop Injection Molding Work?

Desktop injection molding enables cost-effective, small-scale production of plastic parts, ideal for prototyping and low-volume manufacturing. Desktop injection molding is a compact manufacturing process that utilizes small, benchtop machines to create precise plastic parts. It’s an excellent choice for prototyping, ...

Injection moulding

What Are the Best Strategies to Reduce Costs in Injection Molding?

Injection molding is a cornerstone of modern manufacturing, enabling the mass production of precise, high-quality plastic parts1 across industries like automotive, medical, and consumer goods. However, the process can be resource-intensive, making cost reduction2 a critical focus for manufacturers aiming ...

Injection moulding

How Can You Texture Injection Molded Surfaces Effectively?

Injection molding is a cornerstone of modern manufacturing, producing precise plastic parts for industries ranging from automotive to medical devices. However, achieving the desired surface finish often requires more than just molding the shape—texturing injection molded surfaces1 can enhance both ...

Injection moulding

Balancing Quality and Cost in Injection Molding: A Comprehensive Guide

Injection molding is a cornerstone of modern manufacturing, enabling the mass production of high-quality plastic parts with remarkable precision and efficiency. From automotive components to medical devices, this process is integral to industries that demand both consistency and cost-effectiveness. However, ...

Injection moulding