Bakelite, the world’s first synthetic plastic, has a storied history and unique properties that continue to make it relevant in modern manufacturing. But is it suitable for injection molding1—a process typically associated with thermoplastics? This blog post dives into Bakelite’s characteristics, the injection molding process, its applications, and the practical considerations to answer this question comprehensively.

Bakelite is suitable for injection molding, particularly for producing heat-resistant and electrically insulating parts, but it requires specialized equipment and processing conditions due to its thermosetting nature.

Understanding whether Bakelite2 fits your injection molding needs involves exploring its properties, the technical process, and its advantages and challenges. Let’s break it down.

Bakelite can be used in injection molding.True

Despite being a thermosetting plastic, Bakelite can be injection molded with the right equipment and process adjustments.

Bakelite is not suitable for any molding process.False

Bakelite can be molded using various processes, including injection molding, compression molding, and transfer molding.

- 1. What is Bakelite and How is it Classified?

- 2. What are the Applications of Bakelite in Injection Molding?

- 3. What is the Process of Injection Molding Bakelite?

- 4. What are the Practical Considerations for Bakelite Injection Molding?

- 5. How Does Bakelite Injection Molding Relate to Other Technologies?

- 6. Conclusion

What is Bakelite and How is it Classified?

Bakelite, also known as phenolic resin, was invented in 1907 by Leo Baekeland, marking a revolutionary moment in materials science as the first fully synthetic plastic. Formed through the condensation reaction of phenol and formaldehyde, Bakelite is a thermosetting plastic3, meaning it hardens irreversibly when cured. This gives it exceptional heat resistance (up to 356°F) and electrical insulation properties, distinguishing it from thermoplastics that can be melted and reshaped.

Bakelite is a thermosetting plastic made from phenol and formaldehyde, classified by its process, material type, and applications in industries like electronics and automotive.

| Classification Type | Details |

|---|---|

| Process | Injection, compression, transfer molding; injection requires 302–356°F cure. |

| Materials | Paper (cheaper, high insulation), fabric (stronger, mechanical focus). |

| Applications | Electrical, automotive, historical consumer goods. |

Bakelite’s thermosetting nature results in a three-dimensional mesh structure, making it ideal for applications requiring durability and stability under heat. It comes in variants like paper Bakelite, which is lightweight and highly insulating, and fabric Bakelite, which offers greater mechanical strength.

Bakelite is a thermoplastic material.False

Bakelite is a thermosetting plastic, meaning it cannot be remelted or reshaped once cured.

Bakelite is used in electrical applications due to its insulating properties.True

Its excellent electrical insulation makes it ideal for circuit boards and switchboards.

What are the Applications of Bakelite in Injection Molding?

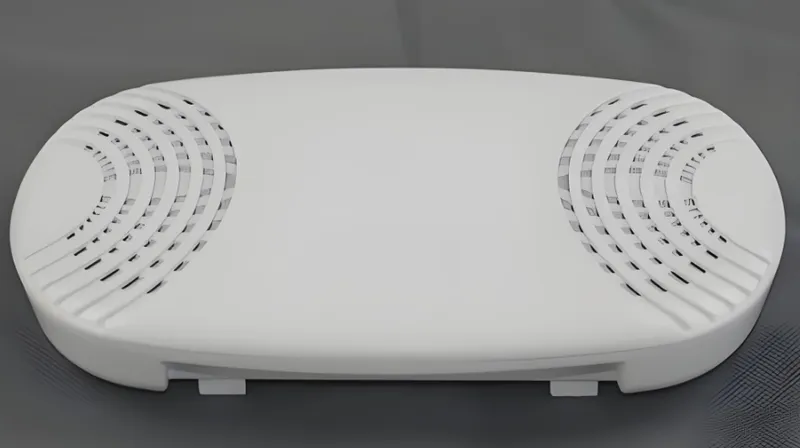

Bakelite’s unique properties make it a go-to material for specific injection molding applications, especially where heat resistance and electrical insulation are paramount.

Bakelite is used in injection molding for electrical insulators, automotive components, and kitchenware handles due to its heat resistance and electrical insulation properties.

Typical Application Scenarios

-

Electrical Industry: Bakelite shines in producing circuit boards, switchboards, and insulators, leveraging its non-conductive nature. Its use in vintage radio casings highlights its historical significance.

-

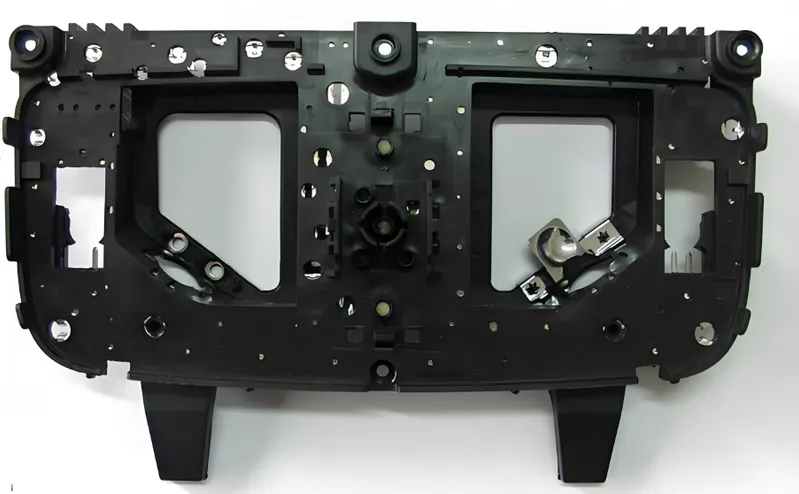

Automotive Sector: It’s employed for handles and components that need to withstand heat and wear, making it a durable choice for car parts.

-

Consumer Goods: Historically, Bakelite was molded into kitchenware handles and jewelry, showcasing its versatility and aesthetic appeal.

These applications capitalize on Bakelite’s ability to resist heat and chemicals, though its high water absorption can limit its use in humid environments.

Pros and Cons Comparison

Compared to thermoplastic injection molding or compression molding, Bakelite offers distinct advantages and challenges:

-

Pros:

-

High heat resistance (up to 356°F), perfect for high-temperature settings.

-

Superior electrical insulation, critical for electronics.

-

Dimensional stability, ensuring parts maintain their shape.

-

Higher precision and lower labor costs compared to compression molding.

-

-

Cons:

-

Difficult to recycle due to its thermoset nature.

-

High water absorption in laminates, limiting use in wet conditions.

-

Higher initial costs for molds and specialized machinery.

-

| Aspect | Bakelite Injection Molding | Comparison (Thermoplastics/Compression) |

|---|---|---|

| Heat Resistance | High (up to 356°F) | Lower for thermoplastics, variable for compression. |

| Electrical Insulation | Excellent, ideal for electronics | Poor for many thermoplastics, variable for compression. |

| Recycling | Difficult, thermoset, cannot remelt | Easier for thermoplastics, limited for compression. |

| Initial Costs | High for molds/machines | Lower for compression, variable for thermoplastics. |

| Precision | High, lower labor costs | Lower for compression, high for thermoplastics. |

Bakelite injection molding is cost-effective for all applications.False

While it offers high precision and lower labor costs, the initial investment in molds and machines is higher compared to other methods.

Bakelite is ideal for applications requiring heat resistance.True

Its ability to withstand temperatures up to 356°F makes it suitable for high-temperature environments.

What is the Process of Injection Molding Bakelite?

Injection molding Bakelite differs from thermoplastic processes due to its thermosetting properties4, requiring precise control and specialized equipment.

The process includes heating Bakelite to 122°F, injecting it into a mold, curing at 302–356°F, and using specialized equipment like a 1:1 screw compression ratio5.

Process Full Workflow Breakdown

-

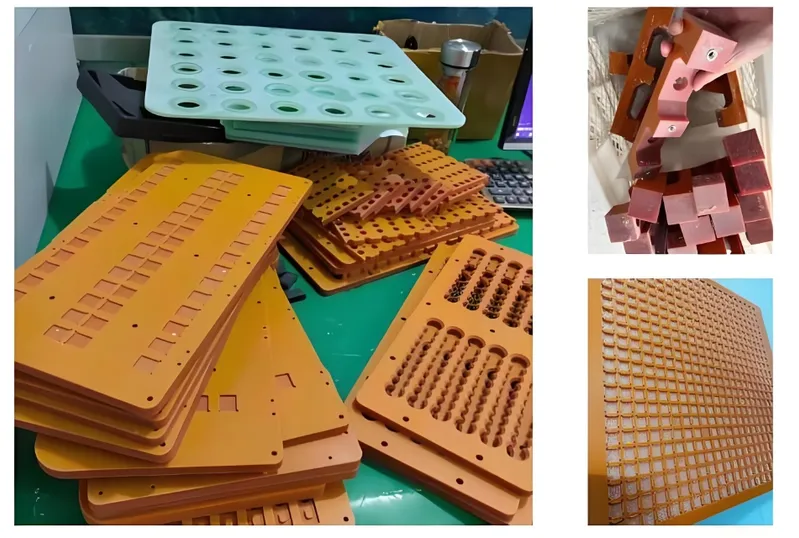

Material Preparation: Bakelite starts as a powder (Novolac or Resole resin), often mixed with fillers like cellulose or minerals to enhance properties.

-

Heating and Plasticizing: A screw with a 1:1 compression ratio melts the powder at multi-stage temperatures: front (90–100°C), middle (80–90°C), and rear (70–80°C).

-

Injection: The molten Bakelite, heated to around 122°F, is injected into the mold cavity.

-

Curing and Cooling: The material cures at 302–356°F under pressure, hardening irreversibly, then cools to solidify.

-

Ejection: The finished part is ejected, ready for use or assembly.

This process demands precise temperature control and a unique screw configuration to handle Bakelite’s thermosetting behavior.

Material Compatibility Explanation

-

Novolac6: Requires a catalyst (e.g., hexamethylenetetramine) for crosslinking, commonly used with fillers for strength and insulation.

-

Resole: Self-cures with heat, simplifying the process for some applications.

Fillers like wood flour boost insulation but may weaken mechanical strength, while laminates increase water absorption, affecting suitability.

Bakelite injection molding uses the same equipment as thermoplastics.False

It requires specialized equipment, such as a screw with a 1:1 compression ratio, unlike the 1:3–1:4.5 ratio for thermoplastics.

The curing temperature for Bakelite is between 302–356°F.True

This temperature range is necessary to harden the thermosetting plastic.

What are the Practical Considerations for Bakelite Injection Molding?

Successfully molding Bakelite requires attention to several practical factors.

Key considerations include specialized equipment, mold design7, material type, and environmental conditions, as they impact the process’s efficiency and the final product’s quality.

Design Checklist

-

Ensure mold temperature control supports 302–356°F curing.

-

Use a screw with a 1:1 compression ratio, distinct from thermoplastic standards.

-

Match material type (Novolac or Resole) to the process requirements.

-

Assess part design for humidity exposure due to water absorption risks.

-

Verify mold dimensions align with technical specifications.

Process Selection Decision-Making

-

Cost: Injection molding has higher initial costs but offers precision and lower labor expenses compared to compression molding.

-

Precision: Ideal for complex, high-precision parts.

-

Decision Tip: Choose injection molding for precision needs if budget allows; opt for compression molding if cost is a priority and precision is less critical.

Bakelite injection molding is always the best choice for cost-sensitive projects.False

While it offers precision, the higher initial costs may not suit all budgets.

Specialized equipment is necessary for Bakelite injection molding.True

The process requires specific machinery, such as a screw with a 1:1 compression ratio.

How Does Bakelite Injection Molding Relate to Other Technologies?

Bakelite injection molding8 connects to a network of processes.

It involves upstream phenolic resin production9 and downstream assembly in industries like electronics and automotive, with challenges in recycling due to its thermoset nature.

-

Upstream: Phenolic resin synthesis and compounding with fillers.

-

Downstream: Assembly into electrical systems or automotive parts, with limited recycling options due to its inability to remelt.

Bakelite injection molding is an isolated process with no connections to other technologies.False

It is part of a larger network, involving resin production and downstream assembly and machining.

Conclusion

Bakelite is indeed suitable for injection molding, excelling in applications needing heat resistance and electrical insulation10, such as electronics and automotive components. Its thermosetting nature requires specialized equipment—like a 1:1 screw ratio and precise curing at 302–356°F—making it distinct from thermoplastic processes. While it offers high precision and durability, challenges include high initial costs and recycling difficulties. For industries valuing its unique properties, Bakelite remains a viable choice.

-

Discover the intricacies of the injection molding process for thermosetting plastics to enhance your manufacturing knowledge. ↩

-

Explore the unique properties and applications of Bakelite to understand its relevance in today’s manufacturing processes. ↩

-

Learn about thermosetting plastics and their characteristics to see how they compare to thermoplastics in various applications. ↩

-

Understanding thermosetting properties is crucial for selecting materials in engineering and manufacturing processes. ↩

-

Learning about screw compression ratios can improve your knowledge of injection molding efficiency and product quality. ↩

-

Learn about Novolac resin’s role in Bakelite production and its benefits, which can help you in material selection for projects. ↩

-

Learn how mold design influences the quality of Bakelite products, ensuring efficiency and superior outcomes. ↩

-

Explore this link to understand the intricacies and best practices of Bakelite injection molding for optimal results. ↩

-

Discover the detailed process of phenolic resin production, crucial for understanding Bakelite manufacturing. ↩

-

Discover various materials that offer heat resistance and electrical insulation, including Bakelite, to enhance your knowledge in manufacturing. ↩