Injection moulding

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Advantages of Using Recycled Materials in Injection Molding?

Did you know that the plastic bottle you recycled last week could become part of your next car or favorite toy? Thanks to advances in injection molding1, recycled materials are transforming the manufacturing landscape2, offering a win-win for both the ...

Injection moulding

How Do Plastic Ribs Enhance Injection-Molding Design?

Plastic ribs enhance injection-molding design by adding strength and stiffness to parts while minimizing material usage and preventing defects like warpage or sink marks. Understanding how to properly design and implement ribs is key to optimizing your injection-molding projects. In ...

Injection moulding

Cutting-Edge Trends in Injection Molding Technology: A Comprehensive Guide

Injection molding, a cornerstone of modern manufacturing, involves injecting molten material into a mold to produce precise, high-quality parts. This process is undergoing a transformation driven by cutting-edge trends such as sustainability1, automation, miniaturization, advanced materials, and on-demand production. These ...

Injection moulding

Achieving Tight Tolerances in Injection Molding: A Comprehensive Guide

Achieving tight tolerances in injection molding1 is critical for producing high-quality, precise parts that meet stringent industry standards, such as those in medical, automotive, and aerospace applications. Injection molding with tight tolerances involves optimizing design, materials, tooling, and processes to ...

Injection moulding

Comprehensive Report on ISO 9001 Certification Benefits for Injection Molding Operations

ISO 9001 certification, a globally recognized standard for quality management systems1 (QMS), provides a structured framework for organizations to ensure consistent quality, meet customer expectations, and drive continuous improvement. For injection molding operations—a manufacturing process that produces precise plastic parts ...

Injection moulding

How Does Automation Lower Labor Costs in Injection Molding?

Automation in injection molding significantly reduces labor costs by replacing manual tasks with efficient, machine-driven processes, enabling manufacturers to produce more with fewer workers while maintaining high quality and consistency. Automation in injection molding lowers labor costs by automating repetitive ...

Injection moulding

What Are the Types and Causes of Waste in Injection Molding?

Injection molding is a widely used manufacturing process for producing precise plastic parts, but it often generates various forms of waste that can increase costs and impact sustainability. Understanding the types and causes of waste in injection molding is essential ...

Injection moulding

What Impact Do RoHS Directives Have on Injection Molding Materials?

The Restriction of Hazardous Substances (RoHS) directives significantly impact injection molding materials by enforcing strict limits on hazardous substances, driving manufacturers to adopt safer, eco-friendly alternatives1. This shift affects material selection, production costs, and market access, particularly for electronics sold ...

Injection moulding

What Impact Do Crystallinity Levels in Polymers Have on Injection Molding Outcomes?

Crystallinity in polymers plays a crucial role in determining the mechanical properties1, dimensional stability, and overall performance of injection-molded parts. Understanding how crystallinity affects the injection molding process2 is essential for engineers, designers, and manufacturers aiming to optimize product quality ...

Injection moulding

Understanding Side Actions in Injection Molding: A Comprehensive Guide

Side actions in injection molding are specialized mechanisms that enable the creation of complex part features, such as undercuts1, which cannot be achieved with standard molds. These features, like snap-fits or threaded holes, are essential for many industries but would ...

Injection moulding

How Injection Molding Companies Achieve FDA Compliance

Injection molding is a cornerstone of modern manufacturing, producing everything from food packaging to life-saving medical devices. However, when these products come into contact with food or the human body, they must meet strict safety standards set by the U.S. ...

Injection moulding

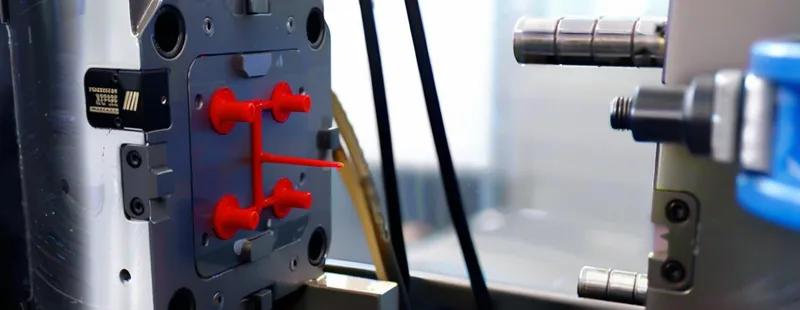

How Does the Ejector System Work in Injection Molding?

The ejector system in injection molding is a crucial mechanism that ensures the efficient removal of molded parts from the mold cavity. This system plays a vital role in maintaining production speed and part quality1, making it essential for manufacturers ...

Injection moulding

How Does Insert Molding Enhance Injection Processes?

Insert molding is a specialized injection molding technique1 that integrates pre-formed inserts—typically metal components2—into plastic parts during the molding process. This method enhances traditional injection molding by producing stronger, more functional, and cost-effective products. By embedding inserts directly into the ...

Injection moulding

What Are the Best Practices for Managing Post-Processing in Injection Molding?

Injection molding is a cornerstone of modern manufacturing, producing plastic parts for industries ranging from automotive to medical devices. However, the molded parts often require additional operations—known as post-processing1—to meet the desired quality, appearance, and functionality. These steps, which include ...

Injection moulding

How Do Biodegradable Plastics Benefit Injection Molding?

Biodegradable plastics are revolutionizing the injection molding1 industry by offering a sustainable alternative to traditional plastics. These materials, derived from renewable resources, decompose naturally, reducing environmental impact. In injection molding, they provide versatility, consumer appeal, and eco-friendly solutions across various ...

Injection moulding

How Can You Apply Lean Manufacturing Principles to Enhance Injection Molding?

Applying Lean Manufacturing1 principles to injection molding optimizes production by eliminating waste2, reducing costs, and improving efficiency, making it ideal for industries like automotive and consumer goods. Lean Manufacturing enhances injection molding by streamlining processes, cutting waste, and boosting productivity3, ...

Injection moulding

How Can You Achieve a High-Gloss Finish in Injection Molding?

The high-gloss injection molding1 process creates premium, shiny plastic parts by using polished molds and specific materials, enhancing aesthetics and durability for various industries. High-gloss injection molding uses polished molds2 and materials like ABS or polycarbonate to produce reflective surfaces3, ...

Injection moulding

What Are the Key Steps to Designing an Effective Screw Boss?

In plastic part design, screw bosses1 are essential features that provide secure fastening points for screws, ensuring sturdy and reliable assemblies. These cylindrical protrusions are widely used in industries like electronics, automotive, and consumer goods. A screw boss is a ...

Injection moulding

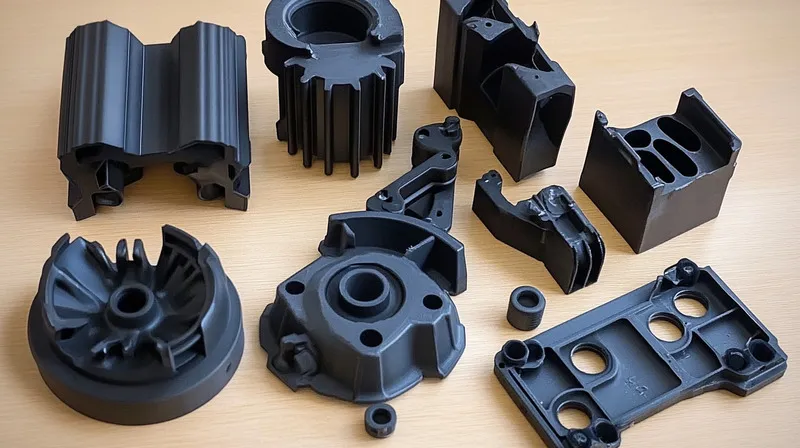

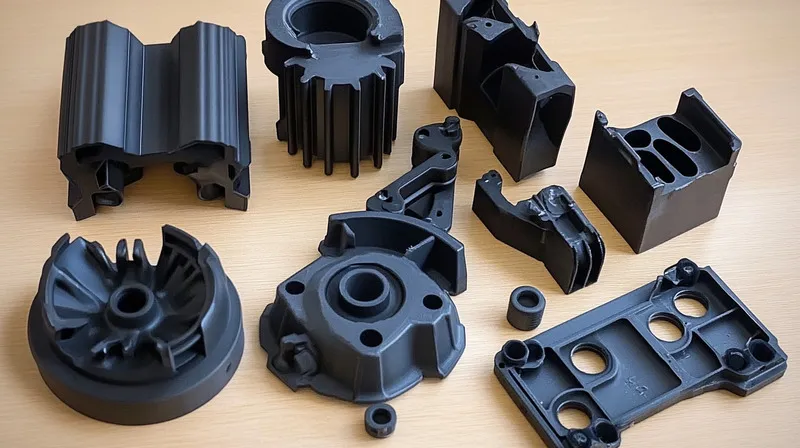

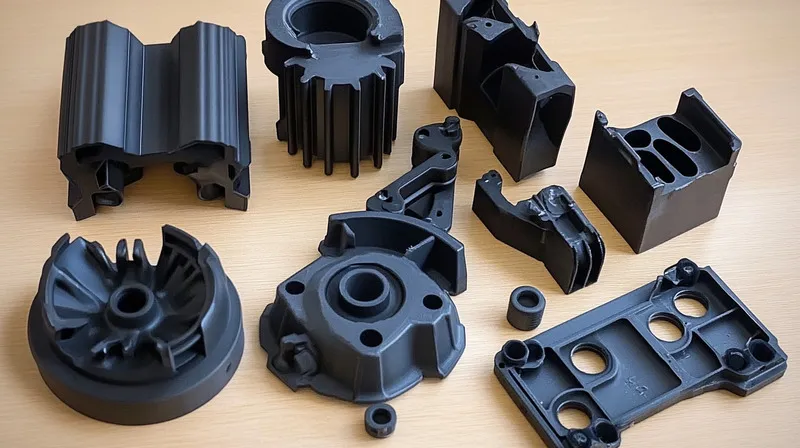

What Are the Best Techniques for Creating Complex Structures in Injection Molding?

Injection molding is a cornerstone of modern manufacturing, enabling the production of intricate plastic parts with high precision and efficiency. When it comes to creating complex structures1—such as parts with undercuts, thin walls, or integrated components—specialized techniques are essential to ...

Injection moulding

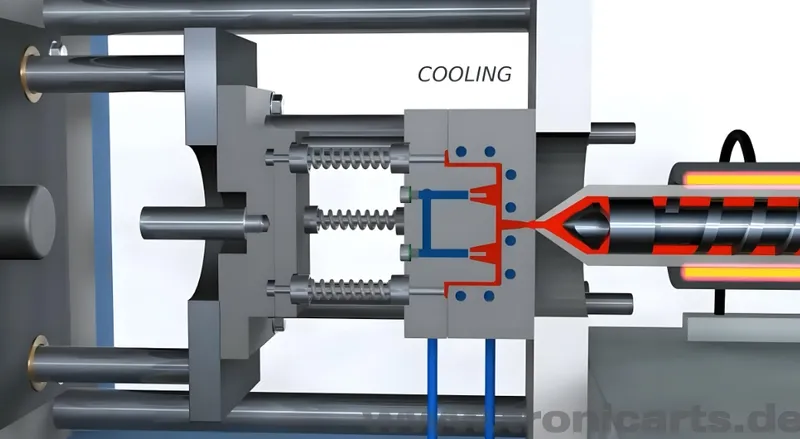

The Essential Guide to Cooling Time in Injection Molding

Injection molding is a cornerstone of modern manufacturing, enabling the production of complex plastic parts with high precision and efficiency. However, one of the most critical yet often overlooked aspects of this process is cooling time—the period during which the ...

Injection moulding

Texturing Injection Molded Surfaces Effectively

I. Basic Cognitive Level: Establishing Conceptual Framework Clear Definitions: Texture Injection Molding1: A process applying patterns to injection-molded parts via the mold surface, enhancing aesthetics or functionality. Aliases include mold texturing or surface texturing. Core Principles: Texture is mold-derived, leveraging ...

Injection moulding

Injection Molding vs. Compression Molding: Key Differences and Applications

Injection molding and compression molding are two widely used manufacturing processes1 for producing plastic parts, each with its own strengths and ideal applications. Understanding the key differences between them is crucial for selecting the right method for your project. Injection ...

Injection moulding

Demystifying Injection Molding Cooling Time: A ZetarMold Guide to Efficiency and Quality

I. Basic Cognitive Level: Establishing Conceptual Framework Before we optimize, we must understand. Clear Definitions Injection Molding Cooling Time: Full Technical Name: Cooling Phase Duration in Injection Molding Cycle. Common Aliases: Cooling time1, solidification time2, cure time (less common for ...

Injection moulding

Key Design Considerations for Injection Molding High-Temperature Parts : A Comprehensive Guide

Injection molding is a versatile manufacturing process, but when it comes to producing parts that must withstand extreme heat, the stakes are higher. High-temperature plastics like PEEK, PEI, and PPS are essential in industries such as aerospace, automotive, and electronics, ...

Injection moulding

Bakelite Injection Molding vs. Other Plastic Injection Molding: A Comprehensive Comparison

Bakelite injection molding1 and other plastic injection molding are two widely used manufacturing processes, each with its unique characteristics and applications. In this blog post, we'll explore the differences between these two processes, from their basic principles to their practical ...

Injection moulding

What is the Maximum Wall Thickness Allowed for Injection Molding?

Injection molding is a widely used manufacturing process for producing precise plastic parts, from small consumer goods to large industrial components. A critical factor in designing these parts is wall thickness1, which impacts the part’s strength, functionality, and the efficiency ...

Injection moulding

Die Casting vs. Injection Molding: What Are the Key Differences?

Die casting and injection molding1 are two powerhouse manufacturing processes that shape the world around us, from the cars we drive to the gadgets we use daily. But what sets them apart? In this deep dive, we’ll explore the key ...

Injection moulding

When Should You Use Clean Room Injection Molding?

Clean room injection molding is a specialized manufacturing process where plastic parts are produced in a controlled, sterile environment1 to prevent contamination. This method is vital for industries where even microscopic particles can compromise product safety, functionality, or compliance with ...

Injection moulding

What Challenges Do Startups Face in Injection Molding?

Injection molding is a powerful manufacturing process that allows for the mass production of complex plastic parts with high precision. However, for startups, entering this space comes with a unique set of challenges that can make the journey seem daunting. ...

Injection moulding

Navigating the Future: How Global Market Trends Are Shaping the Injection Molding Industry

Injection molding has long been a cornerstone of modern manufacturing, enabling the mass production of complex plastic parts with precision and efficiency. However, as global market trends evolve, the injection molding industry faces new challenges and opportunities. From the rise ...

Injection moulding