All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Key Four Elements of Injection Molding Processing?

Injection molding is a pivotal process in manufacturing, where precision and quality are paramount. In this article, we'll explore the four key elements that define injection molding: plastic materials, injection molding machines, molds, and process parameters. Understanding these components is ...

MANUFACTURING

What Are the Steps to Create High-Quality Injection Molding?

Creating high-quality injection molded parts involves several critical steps, including careful selection of raw materials, meticulous mold design, precise process control, effective post-processing, and stringent quality management. Each phase plays a crucial role in ensuring that the final products meet ...

MANUFACTURING

What Are the Seven Essential Components of Injection Molding?

Injection molding is a fascinating and complex process that shapes our everyday lives. From the toys we play with to the containers we use, this manufacturing technique is everywhere. Understanding the seven essential components—molding parts, gating system, guide mechanism, ejector ...

MANUFACTURING

What Causes Burrs in Injection Molded Products?

Burrs in injection molded products can be a manufacturer’s nightmare, affecting product quality and performance. By understanding the root causes—from mold design to material properties—manufacturers can tackle these challenges head-on and improve their processes. This article dives deep into the ...

OPTIMIZATION

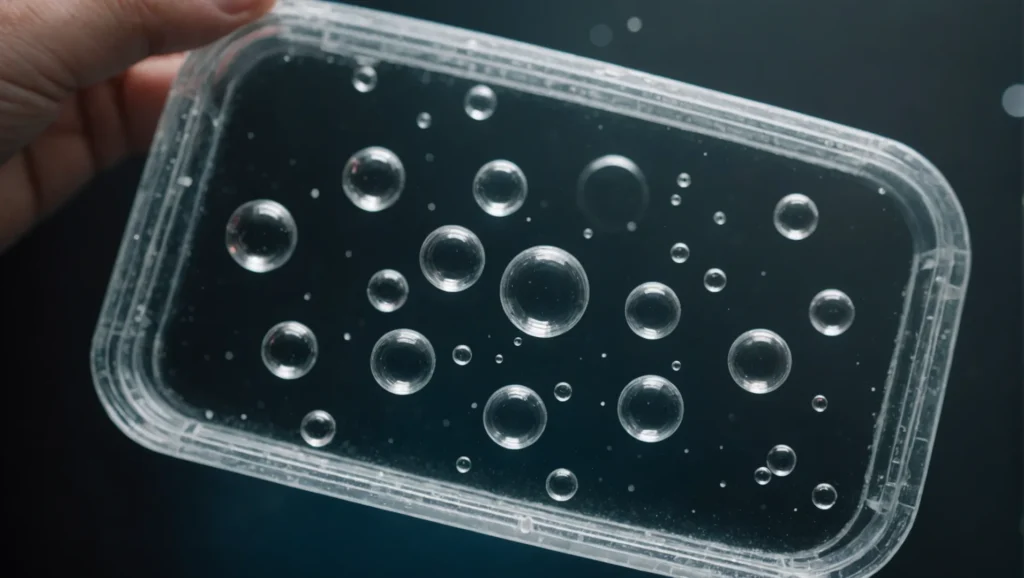

What Are the Causes of Air Bubbles in Injection Molding?

Air bubbles in injection molding can wreak havoc on the quality of plastic parts. Understanding their root causes—such as moisture levels in raw materials, fluid dynamics, injection speed, and equipment settings—is crucial for improving production efficiency and reducing waste.

OPTIMIZATION

What is the Cost to Create an ABS Plastic Injection Mold?

When diving into the world of ABS plastic injection molding, understanding the costs is essential. From product complexity to steel quality, several factors can significantly influence your budget. Let's break it down to help you make informed decisions for your ...

Price Evaluation

What Are the Costs Involved in Producing a Plastic Part?

Understanding the costs involved in producing plastic parts is crucial for anyone in product development or manufacturing. This article delves into the various factors affecting costs, including raw materials, mold complexity, processing efficiency, and post-processing, offering valuable insights for informed ...

Price Evaluation

Where Should You Use Plastic Injection Molds and Why?

Plastic injection molding has transformed the manufacturing landscape. Its ability to produce intricate, high-quality components swiftly makes it a go-to method across numerous sectors. From automotive parts to medical devices, understanding the diverse applications and benefits of injection molding is ...

MANUFACTURING

What Benefits Does Injection Mold Coating Offer?

In the world of plastics manufacturing, where every second counts, injection mold coatings emerge as unsung heroes. They enhance not only the efficiency of production processes but also the durability and longevity of molds. Discover how these coatings can transform ...

MANUFACTURING

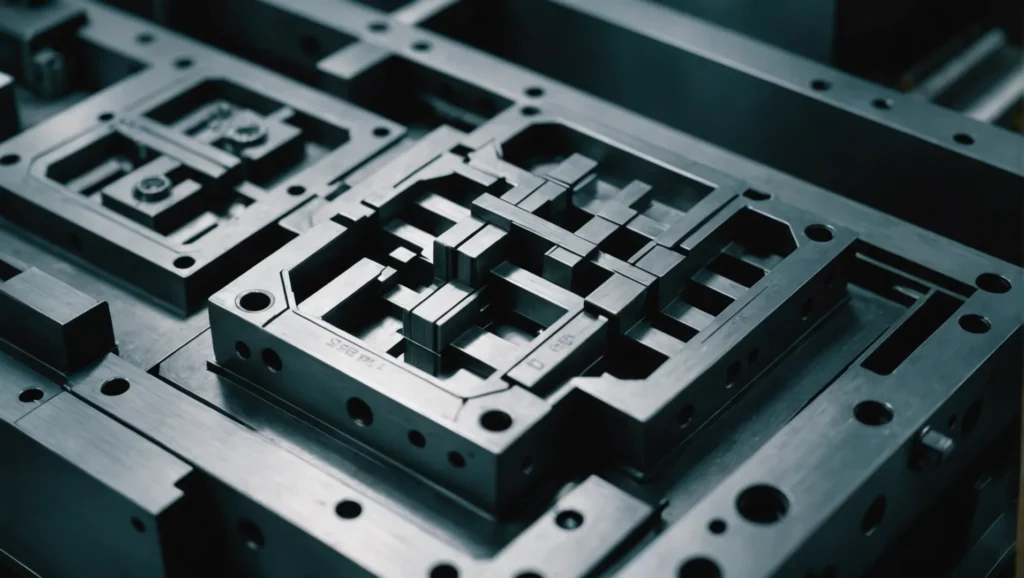

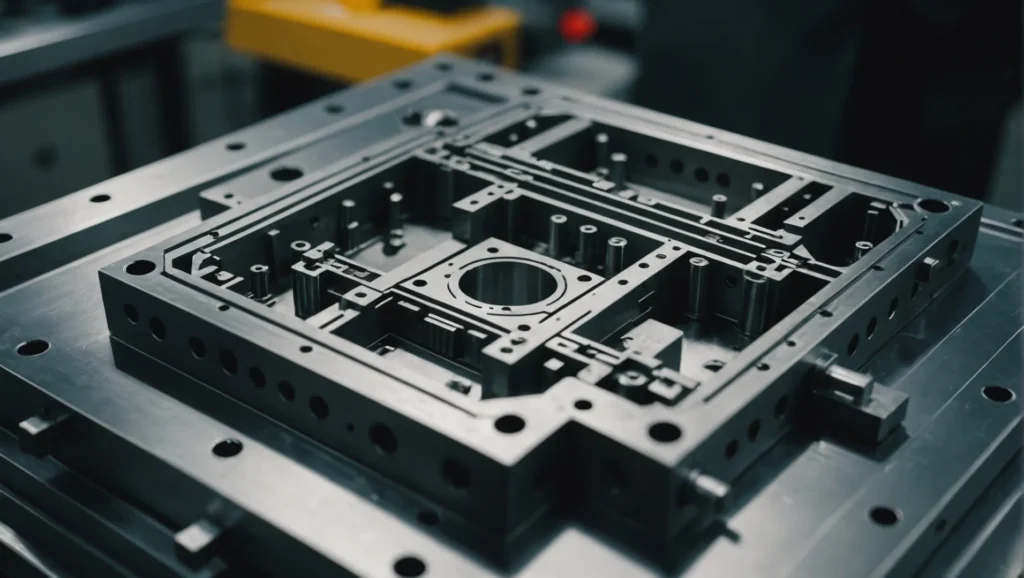

Why Are Injection Moulds So Expensive to Manufacture?

Injection moulds are a cornerstone in the manufacturing of plastic products, yet their cost can be staggering. This article explores the intricate factors contributing to the high costs of injection moulds, including design complexity, material choices, processing technology, and trial/debugging ...

Price Evaluation

How Do Internal Stresses Affect Injection Molded Products?

Injection molding is a cornerstone process in manufacturing plastic products. However, hidden within this process are internal stresses that can undermine product integrity. This article explores the causes and impacts of internal stresses on injection molded products, offering insights into ...

OPTIMIZATION

How Does a Transfer Position Work in Injection Molding?

Injection molding is a complex process, and understanding the transfer position is crucial for ensuring quality in plastic components. This article dives into the significance of the transfer position, its impact on product quality, and common issues that can arise ...

MANUFACTURING

How Does Back Pressure Affect Injection Molding?

Injection molding is a sophisticated process where back pressure plays a crucial role in determining product quality. It impacts material homogeneity, density, and flow characteristics. Understanding and optimizing this parameter is essential for achieving superior manufacturing outcomes.

DEVELOPMENT

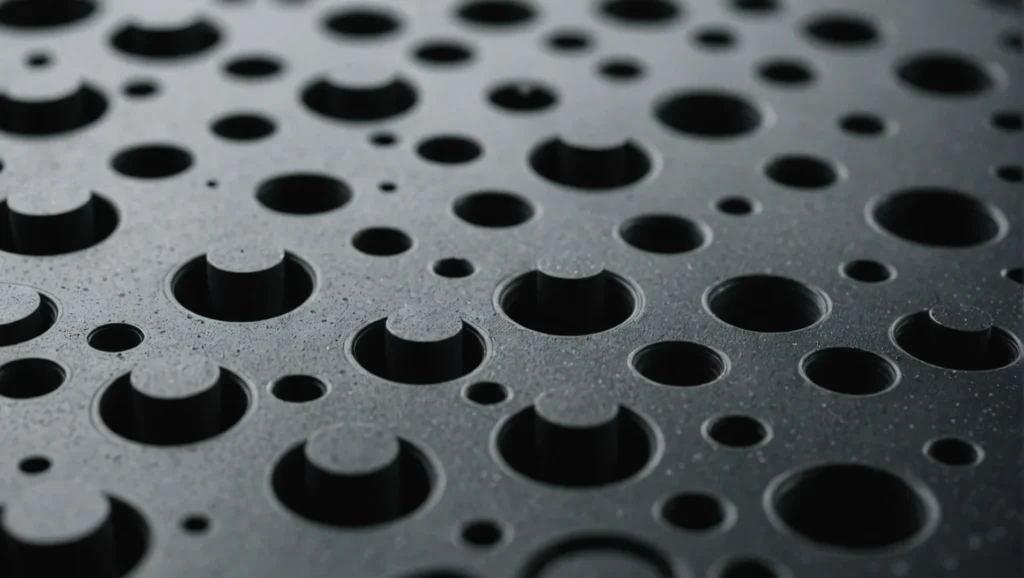

How Does Coring Enhance Injection Molding Efficiency?

Coring plays a pivotal role in injection molding by facilitating the efficient removal of complex parts from molds. By utilizing core pulling mechanisms, manufacturers can reduce material waste, decrease cooling times, and enhance overall product quality. This article delves into ...

DEVELOPMENT

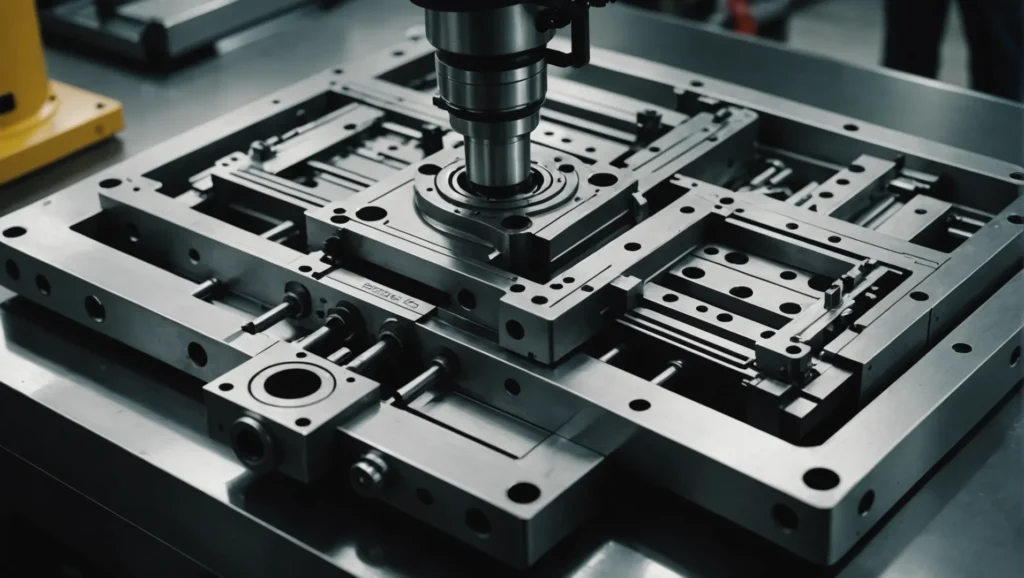

How Does Each Part of an Injection Mold Function?

Injection molding is not just a manufacturing process; it’s an art form that shapes our world. By understanding each component of an injection mold, I can appreciate the precision and efficiency involved in creating everyday plastic products. Join me as ...

MANUFACTURING

How Does Pressure Impact Your Plastic Injection Molded Parts?

In the intricate realm of plastic injection molding, pressure serves as a vital ingredient for ensuring high-quality molded parts. Understanding how different pressures affect everything from filling to mechanical properties is crucial for optimizing your manufacturing process. Join me as ...

MANUFACTURING

How Does the Bakelite Injection Molding Production Process Work?

Bakelite is a trailblazer in thermosetting plastics, renowned for its durability and heat resistance. Understanding the intricate injection molding process— from material preparation to post-processing— is essential for achieving high-quality products. Join me as I explore each stage of this ...

MANUFACTURING

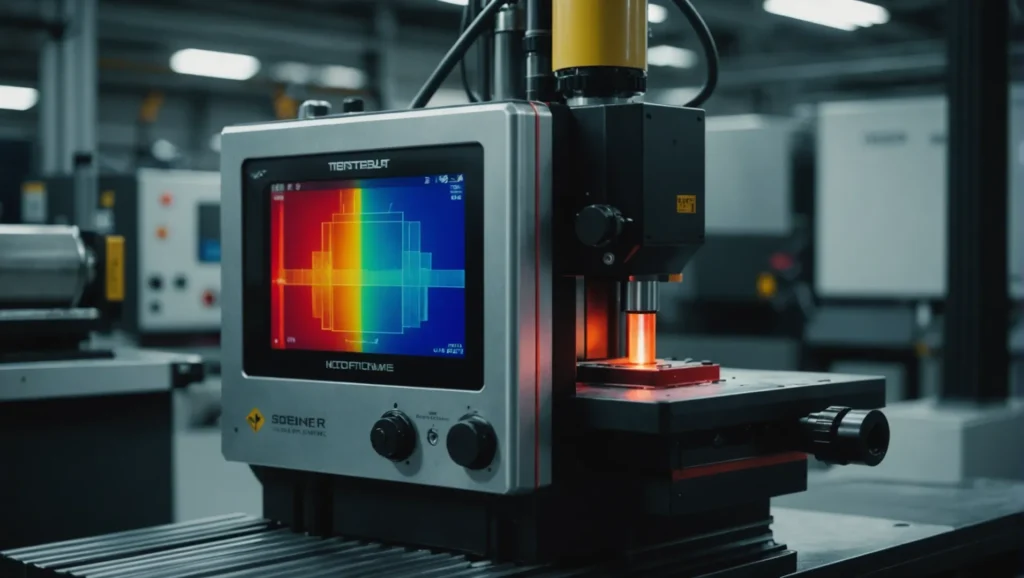

How Does Uneven Mold Temperature Affect Injection Molded Parts?

In the intricate world of injection molding, controlling temperature is essential for producing high-quality parts. However, uneven mold temperatures can lead to a variety of issues, including dimensional inaccuracies and inconsistent surface finishes. Understanding these challenges is crucial for manufacturers ...

Quality Inspection

How is Cycle Time Calculated in Injection Molding?

Understanding how cycle time is calculated in injection molding is crucial for manufacturers aiming to optimize efficiency and reduce costs. By considering key factors like part size, material properties, and mold design, manufacturers can significantly enhance their production processes. Let's ...

MANUFACTURING

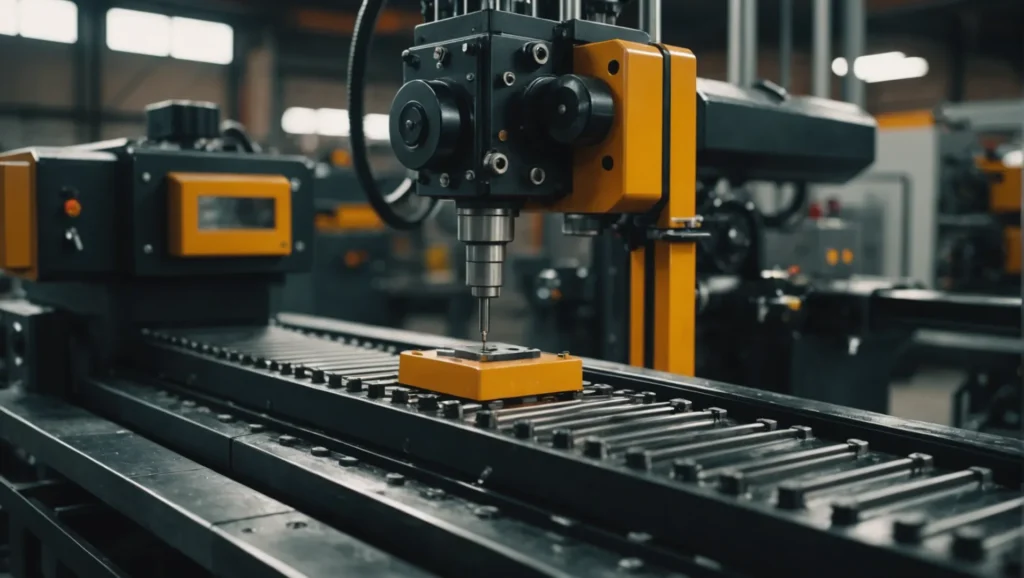

How is Injection Mold Design Standardized?

In the intricate world of manufacturing, standardization in injection mold design plays a crucial role in ensuring that molds are efficient, reliable, and produce high-quality products. This article explores the key elements of standardization and its significance in the industry.

DESIGN

How Should You Prepare for Injection Molding?

Injection molding is a highly efficient manufacturing process that can lead to superior product quality when adequately prepared. In this guide, I will share essential steps to ensure every stage of preparation— from raw material selection to equipment checks— is ...

MANUFACTURING

What Are Effective Solutions for Dark Spots on Injection Molded Products?

Are you frustrated by dark spots marring your injection molded products? These blemishes can be a significant setback, affecting both aesthetics and quality. In this guide, I’ll share effective strategies to tackle these issues, from raw material selection to machine ...

OPTIMIZATION

What Are Injection Speed and Injection Pressure?

Understanding injection speed and injection pressure is vital for anyone involved in injection molding. These parameters significantly influence product quality, manufacturing efficiency, and equipment longevity. In this article, I’ll share insights into how these factors interact and affect the final ...

MANUFACTURING

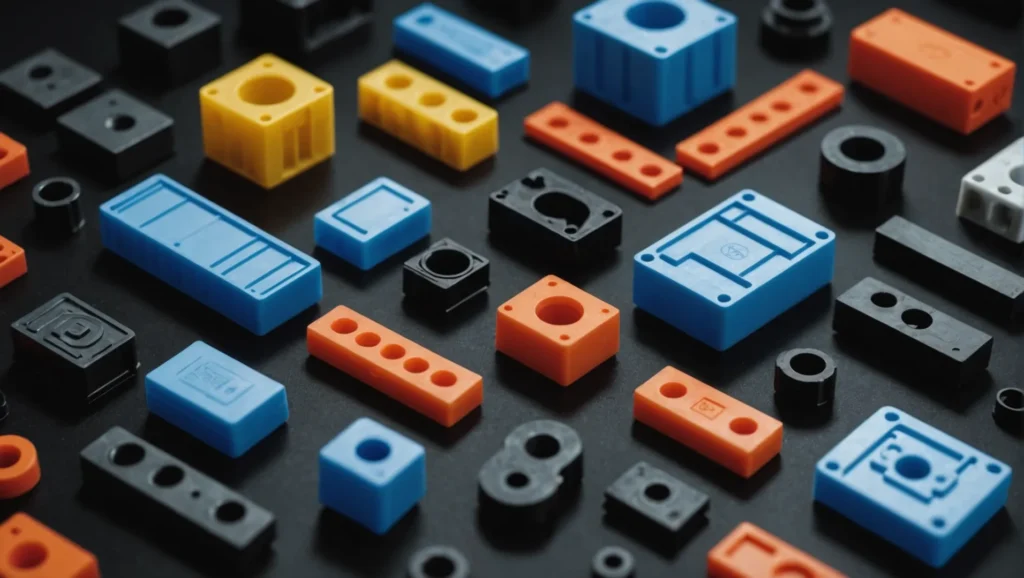

Are Plastic Injection Molded Parts Strong and Durable?

In the world of manufacturing, plastic injection molded parts are a staple due to their adaptability and cost-effectiveness. However, their strength and durability depend on various factors such as plastic type, molding processes, and mold design. This article explores these ...

Materials Recommendations

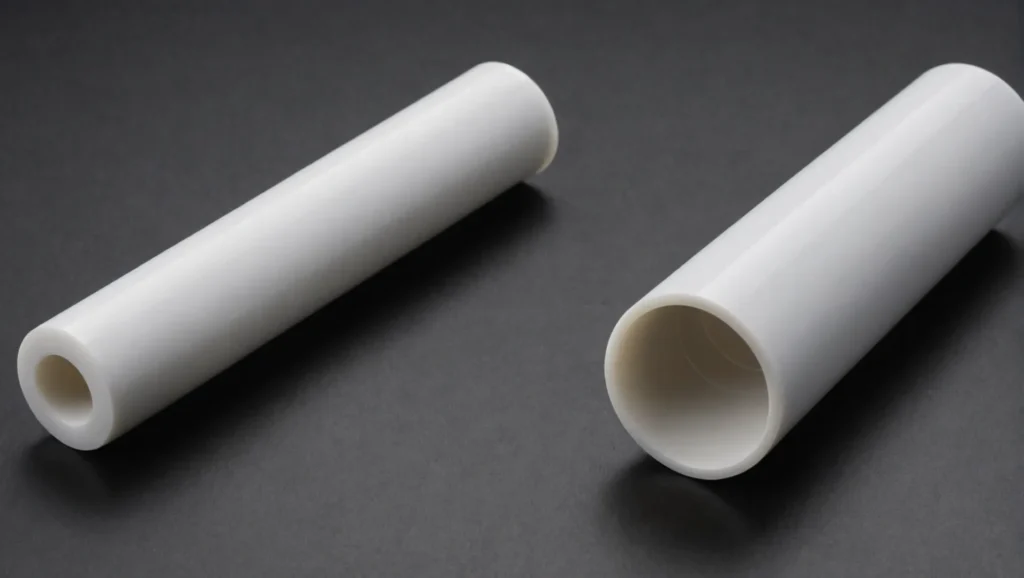

What Are the Key Differences Between Rigid and Plasticized PVC in Injection Molding?

Choosing the right type of PVC for injection molding can significantly impact the performance and durability of your products. In this article, I will explore the key differences between rigid and plasticized PVC, focusing on their physical properties, processing performance, ...

Materials Recommendations

Is Aluminum a Suitable Material for Injection Molds?

As I dive into the world of injection molding, I've found aluminum to be a fascinating option. It boasts unique properties that can significantly enhance production efficiency. Yet, there are crucial aspects to consider before making it your go-to material. ...

Materials Recommendations

How Do ABS, PP, and PVC Differ in Injection Molding?

Understanding the distinctions between ABS, PP, and PVC is crucial for effective injection molding. Each material brings unique properties that influence performance, cost-effectiveness, and suitability for various applications. Dive in to discover what makes each one stand out.

Materials Recommendations

What Causes Porosity in Injection Molded Plastic Products?

Porosity in injection molded plastics can lead to significant quality issues, such as weakened structures and potential failures. Understanding the causes—ranging from material choice to process adjustments and mold design—is crucial for manufacturers looking to enhance product integrity. This article ...

OPTIMIZATION

How Do Injection Molding Machines Produce EVA Products?

The intricate process of crafting EVA products using injection molding machines is both fascinating and essential for many industries. By managing temperature, mold design, and injection parameters carefully, manufacturers can harness EVA's unique properties to create high-quality products that meet ...

MANUFACTURING

How Can You Improve Injection Mold Change Efficiency?

Improving injection mold change efficiency is crucial for manufacturers aiming to boost productivity and minimize downtime. This guide delves into the essential steps, optimization techniques, and collaborative strategies that can transform your operations. Discover how thorough preparation, process optimization, and ...

DEVELOPMENT