All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are Effective Ways to Reduce the Cost of Injection Molding Machine Products?

This article explores effective ways to reduce the cost of injection molding machine products. Key strategies include selecting cost-effective raw materials, optimizing mold designs, enhancing production processes, and managing energy consumption efficiently. By making small adjustments in material choices and ...

OPTIMIZATION

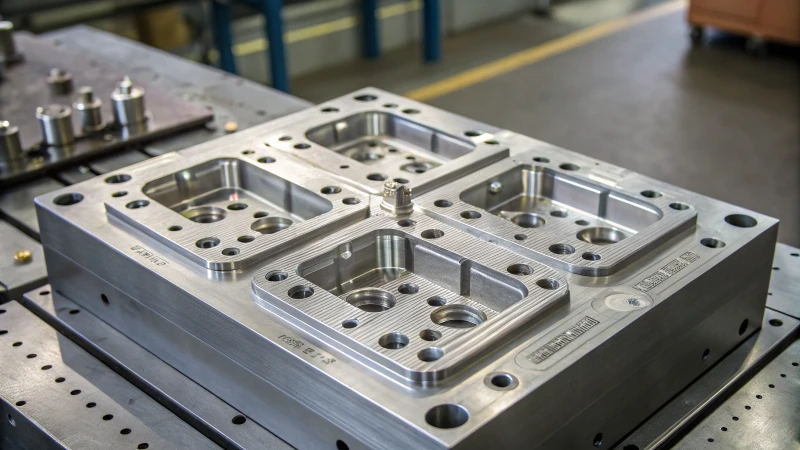

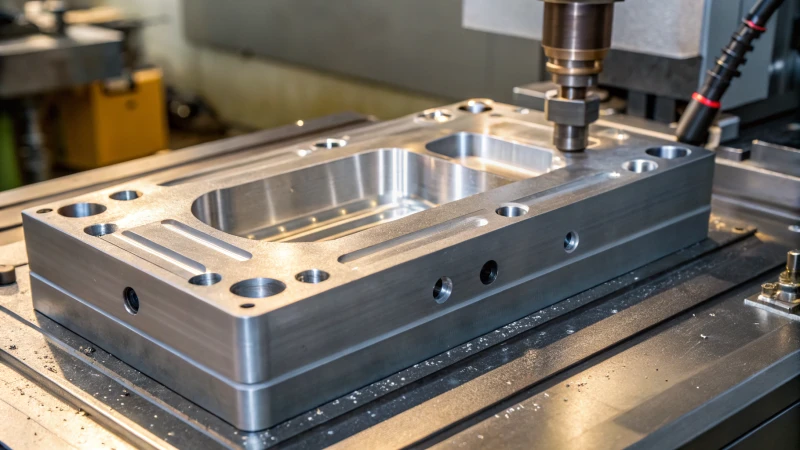

What Are the Pros and Cons of Using Mold Steels with Varying Hardness and Toughness in Injection Molding?

Choosing the right mold steel is crucial in injection molding, as it affects product quality and efficiency. High hardness steels offer excellent wear resistance and dimensional accuracy but can be brittle and challenging to process. Conversely, high toughness steels excel ...

Materials Recommendations

How Can You Solve Warpage Defects in Injection Molded Parts?

Warpage in injection molded parts can significantly impact product quality. This article outlines key strategies for addressing this issue, including optimizing cooling systems to ensure uniform temperature distribution, adjusting gate designs for even melt flow, and carefully selecting materials with ...

OPTIMIZATION

What Are Effective Methods to Solve Sink Mark Defects in Injection Molding?

Sink marks can significantly affect the appearance and strength of injection-molded parts. This article outlines effective methods to address these defects by optimizing product design through uniform wall thickness and rib placement, adjusting injection molding parameters like holding pressure and ...

OPTIMIZATION

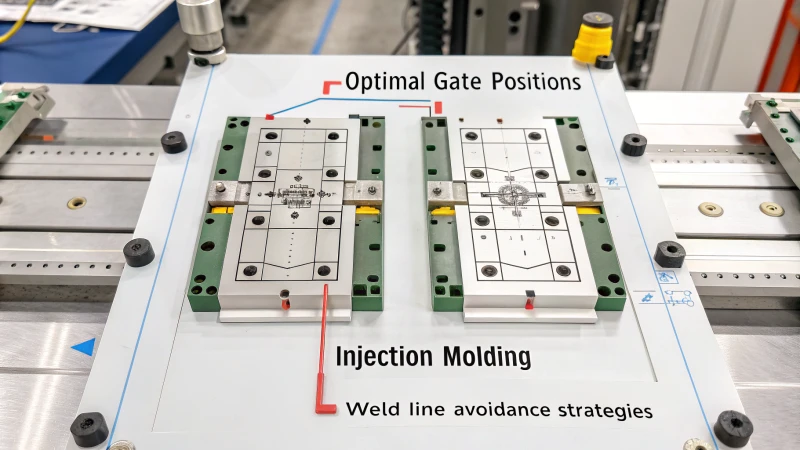

How Can You Prevent Weld Lines by Optimizing Gate Position in Product Design?

Weld lines can significantly affect the appearance and strength of molded products. This article explores how optimizing gate positions during injection molding can prevent these defects. Key strategies include placing gates symmetrically to ensure even melt flow, using sequential gating ...

OPTIMIZATION

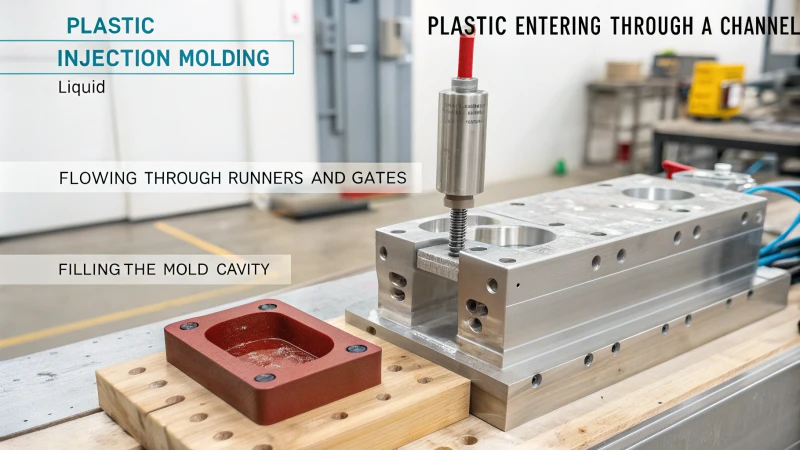

What Happens to Plastic When It’s Injected Into a Mold?

This article explores the intricate journey of plastic during the injection molding process. It details how molten plastic is injected under pressure through the main channel, runners, gates, and finally fills the mold cavity. Each stage is crucial for achieving ...

MANUFACTURING

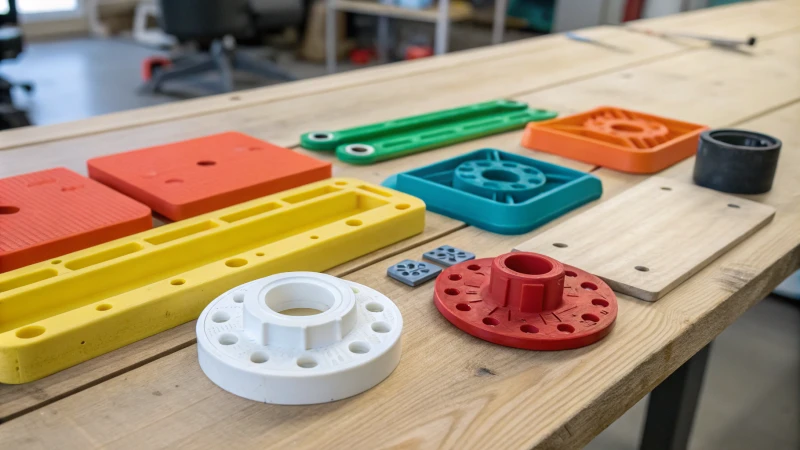

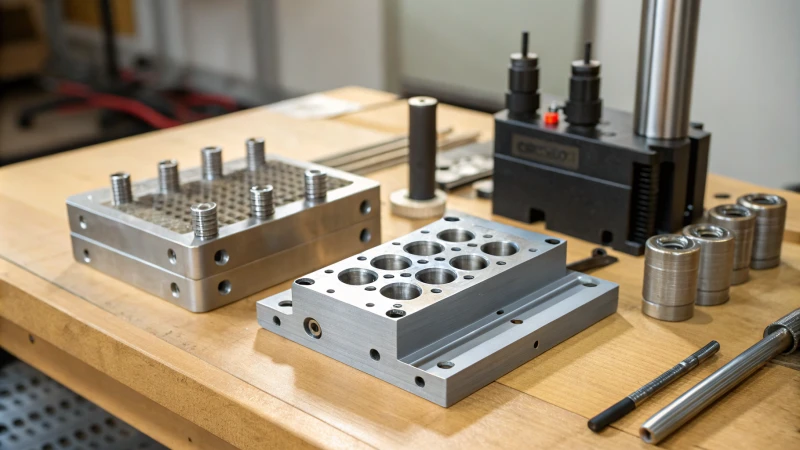

What Are the Essential Standard Parts for Injection Molds?

This article explores the essential standard parts of injection molds, including mold frames, guide parts, ejector systems, gating systems, and cooling components. Each part plays a vital role in ensuring precision and efficiency during the molding process. Mold frames provide ...

MANUFACTURING

How Can You Adjust Injection Pressure for Optimal Plastic Product Performance?

This article explores the importance of adjusting injection pressure in plastic molding to achieve optimal product performance. It highlights how different factors such as mechanical requirements, dimensional accuracy, and appearance quality influence the necessary pressure settings. For high-strength products like ...

OPTIMIZATION

How Do Injection Molding Process Parameters Impact Product Weight?

The injection molding process is a delicate balance of various parameters that directly impact the weight of the final product. Key factors include screw stroke, injection pressure and speed, holding pressure and time, as well as melt and mold temperatures. ...

Quality Inspection

How Do You Choose the Best Reinforcement Materials for Plastic Products?

Selecting the right reinforcement materials for plastic products is crucial for enhancing their mechanical properties. Options like glass fiber, carbon fiber, and aramid fiber offer unique benefits depending on application needs. For automotive parts requiring high strength, glass fiber significantly ...

OPTIMIZATION

What is the Best Way to Determine Optimal Injection Pressure for Plastic Products?

This article explores the best practices for determining optimal injection pressure in plastic molding. It emphasizes the importance of understanding material properties such as viscosity and heat sensitivity, along with product structure considerations like wall thickness and complexity. Mold design ...

OPTIMIZATION

How Does Injection Speed Impact the Quality of Plastic Products?

This article explores how injection speed influences the quality of plastic products in terms of both appearance and internal integrity. Fast injection speeds can lead to surface defects such as flow marks, weld lines, and air entrapment, while slow speeds ...

Quality Inspection

How Do You Calculate the Cost of Injection Molding Machine Products?

This guide provides a comprehensive overview of calculating the cost of injection molding products. It covers essential components such as direct material costs, direct labor costs, and manufacturing expenses including equipment depreciation, energy consumption, and mold allocation. By understanding these ...

Price Evaluation

Why Do Injection Molded Products Lack Sufficient Strength?

Injection molded products frequently fail to meet strength expectations due to various factors including high impurity content, inadequate material drying, incorrect injection parameters, and flawed mold designs. Impurities such as dust or metal chips create weak points in the material, ...

Quality Inspection

How Does Injection Pressure Affect the Performance of Plastic Products?

This article explores how injection pressure affects the mechanical properties, dimensional stability, and physical traits of plastic products. It highlights the importance of proper pressure settings in enhancing strength, toughness, and accuracy in manufacturing processes. Through personal experiences and examples ...

Quality Inspection

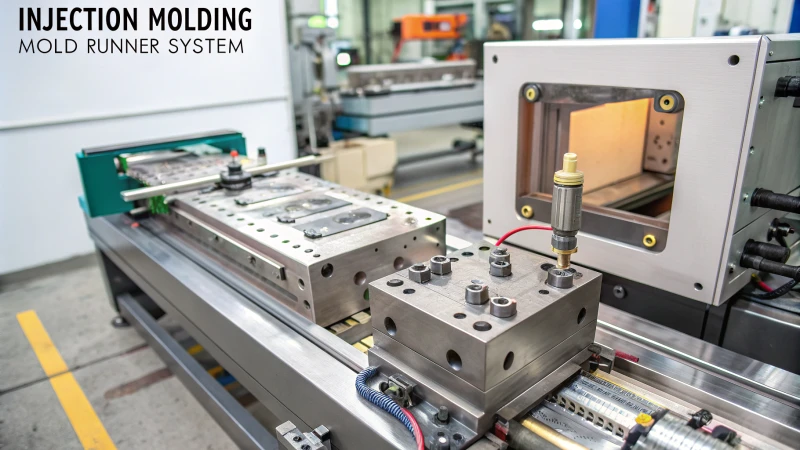

What Factors Should You Consider When Designing a Mold Runner System?

When designing a mold runner system, several critical factors must be considered to ensure efficiency and quality. Key elements include understanding material flow characteristics, which dictate the appropriate size and shape of runners based on the melt flow rate (MFR) ...

DESIGN

How Does Injection Pressure Impact the Dimensional Stability of Plastic Products?

This article explores how injection pressure influences the dimensional stability of plastic products. It highlights the consequences of both excessive and insufficient pressure during molding processes, emphasizing that high pressure can lead to product shrinkage and warping due to internal ...

Quality Inspection

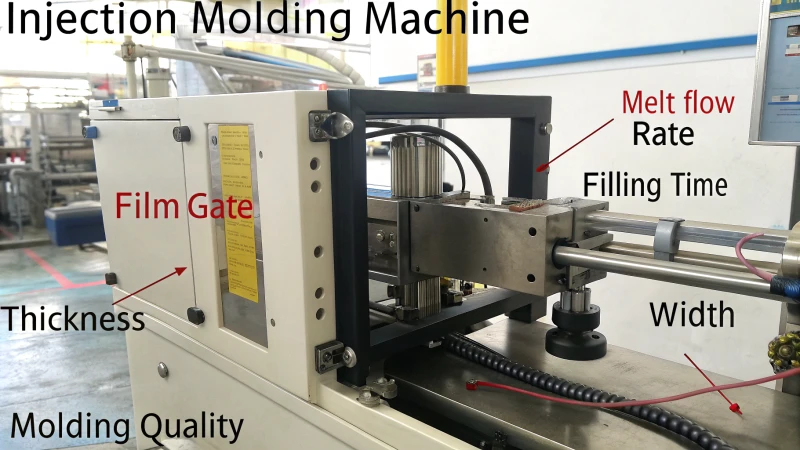

How Does the Thickness and Width of a Film Gate Relate to Each Other?

In injection molding, the dimensions of a film gate—its thickness and width—play a crucial role in determining the flow characteristics of melted materials. Properly sized gates enhance the efficiency of mold filling, improve product quality by ensuring uniform wall thickness, ...

DESIGN

What Tools Can Help Adjust Injection Molding Process Parameters?

This article discusses the critical tools that enhance the injection molding process. Key technologies such as injection molding machine controllers allow precise adjustments of parameters like speed and pressure. Mold temperature controllers ensure optimal heating and cooling for various materials, ...

MANUFACTURING

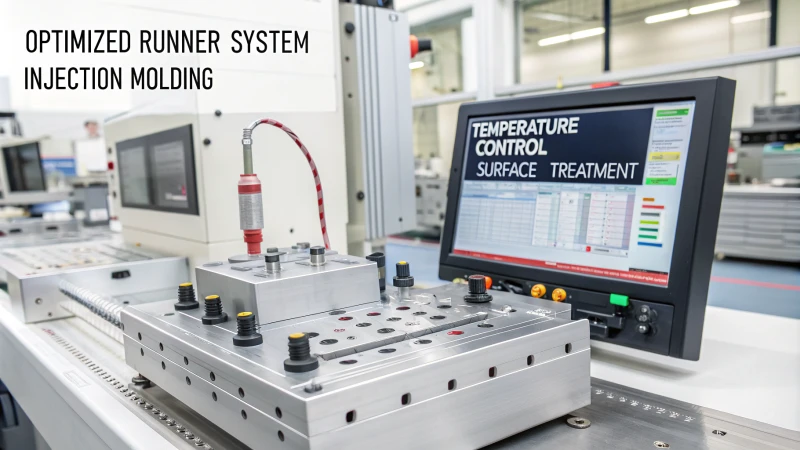

How Can You Optimize a Mold’s Runner System for a Balanced State?

This article discusses how to optimize a mold's runner system for balance in injection molding. Key strategies include maintaining uniform runner sizes, implementing gradual transitions, and utilizing CAE software like Moldflow for simulations. Temperature control is crucial in hot runner ...

OPTIMIZATION

How Does Improper Pretreatment Affect Injection Molded Product Properties?

This article explores the critical impact of improper pretreatment on injection molded products. It highlights how inadequate drying, mixing, and preheating can lead to significant issues such as reduced mechanical strength, deteriorated toughness, uneven hardness distribution, and poor surface quality. ...

Quality Inspection

How Can You Enhance the Precision of Injection Molded Products by Optimizing the Parting Line?

This article explores how optimizing the parting line in injection molding can significantly enhance the precision and aesthetics of molded products. Key strategies include thoughtful mold design, selecting appropriate parting positions to minimize visible seams, utilizing advanced mold structures like ...

OPTIMIZATION

How Does Mold Standardization Impact Production Efficiency?

This article explores how mold standardization significantly impacts production efficiency in manufacturing. By utilizing standardized molds and parts, designers can reduce design time and focus on innovation. Standard mold frames simplify the assembly process, enhance compatibility between different machines, and ...

MANUFACTURING

How Does Main Channel Design Affect Mold Injection Efficiency?

This article explores how the design of the main channel in injection molding affects efficiency. Key factors include the shape (preferably conical), size (ideally 0.5-1mm larger than the nozzle), length (shorter is better to reduce pressure loss), and layout (symmetrical ...

DESIGN

How Can Mold Adjustments Enhance the Strength of Injection Molded Products with Low Injection Pressure?

This article explores how adjusting injection molds can significantly enhance the strength of injection molded products. Key strategies include optimizing gate systems, improving runner designs, enhancing exhaust systems, and controlling mold temperatures. By increasing gate sizes and repositioning them for ...

OPTIMIZATION

What Are the Best Methods to Determine the Appropriate Processing Temperature Range for Materials?

Determining the appropriate processing temperature range for materials is crucial in manufacturing. This article discusses the significance of analyzing material properties such as crystallinity and thermal stability, alongside utilizing reliable supplier data. It emphasizes the need for hands-on experimentation and ...

OPTIMIZATION

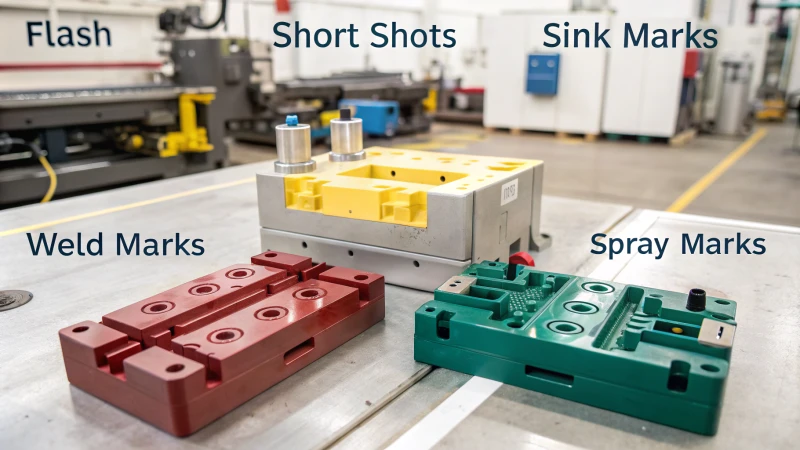

What Defects Arise from Improper Injection Pressure in Molding?

This article explores how improper injection pressure during the molding process can lead to various defects such as flash, short shots, sink marks, weld marks, and spray marks. Each defect arises from either too high or too low injection pressure ...

Quality Inspection

How Can You Adjust the Temperature of an Injection Mold?

Adjusting the temperature of injection molds is crucial for product quality. This article explores various methods such as modifying water or oil temperatures, adjusting heating power based on material needs, optimizing mold structure for uniform heat distribution, utilizing temperature sensors ...

OPTIMIZATION

How Can You Adjust Injection Molding Process Parameters to Enhance Product Quality?

This article explores how to enhance product quality in injection molding by adjusting key parameters such as mold temperature, injection speed, and holding pressure. Higher mold temperatures improve surface gloss while optimizing injection speed reduces defects like flow marks. Proper ...

OPTIMIZATION

How Can You Enhance the Strength of Injection Molded Products?

This article explores effective strategies to enhance the strength of injection molded products. Key factors include careful material selection, optimization of injection molding process parameters such as pressure and speed, and improvements in mold design. Materials like polyamide (PA), polyoxymethylene ...

OPTIMIZATION