All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Products Are Best Suited for Injection Molding Over Blow Molding?

This article explores the advantages of injection molding over blow molding for producing precision electronic parts, automotive interiors, small plastic toys, and medical devices, emphasizing accuracy and efficiency.

DEVELOPMENT

How Are Advances in Materials Science Transforming Extrusion and Injection Molding Capabilities?

Advancements in materials science are revolutionizing extrusion and injection molding by expanding material options, enhancing product quality, improving efficiency, and promoting sustainability in manufacturing processes.

DEVELOPMENT

What Are the Key Differences Between Blow Molding and Injection Molding Shapes?

This article explores the key differences between blow molding and injection molding, highlighting their unique characteristics, advantages, production costs, and material choices to guide designers in selecting the right method for their projects.

DEVELOPMENT

What Shape Does the Final Extruded Product Take?

The extrusion process transforms raw materials into continuous profiles like pipes, rods, and special shapes. Key factors include material properties, die design, cooling methods, and application requirements for optimal functionality.

DEVELOPMENT

What Are the Best Materials for Blow Molding and Injection Molding Processes?

Choosing the right materials for blow molding and injection molding is essential for product design success. Key materials include PE, PP, PVC for blow molding; PC, Nylon, ABS for injection molding.

Materials Recommendations

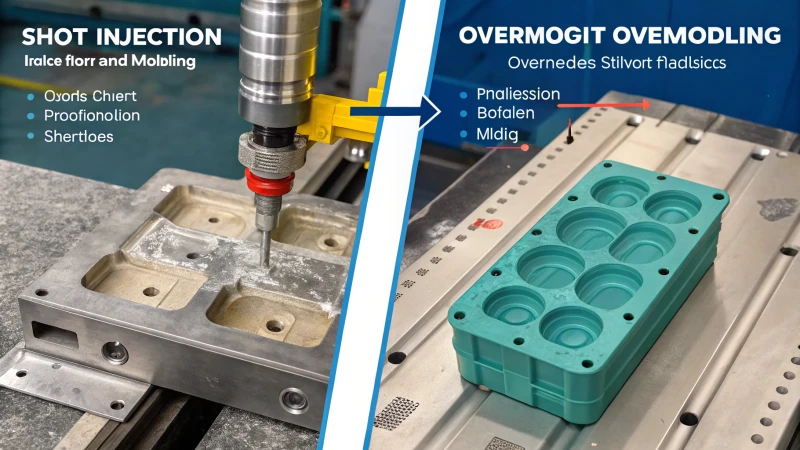

What Are the Key Differences Between Two-Shot Injection Molding and Overmolding?

This article explores the key differences between two-shot injection molding and overmolding, highlighting their processes, advantages, applications, and cost implications to help designers choose the right method for their projects.

DEVELOPMENT

What Are the Key Differences in Surface Finishes Between Extruded and Injection Molded Parts?

This article explores the differences in surface finishes between extruded and injection molded parts, highlighting factors like mold quality, process parameters, and post-processing techniques that influence product aesthetics and functionality.

DEVELOPMENT

What Shape Does the Final Product Take in Injection Molding?

Injection molding creates diverse product shapes, including three-dimensional designs, thin-walled structures, and products with inserts. Each shape serves specific functions while balancing aesthetics and practicality in design.

MANUFACTURING

What Are the Key Differences in Material Feeding Between Extrusion and Injection Molding?

This article explores the key differences in material feeding between extrusion and injection molding, highlighting their methods, efficiency, production rates, and suitability for various product designs.

DEVELOPMENT

What Are the Top Applications for Two-Shot Molding Products?

Two-shot molding revolutionizes product design by combining aesthetics and functionality across various industries, including electronics, automotive, and healthcare. This innovative technique enhances user experience while improving production efficiency.

DEVELOPMENT

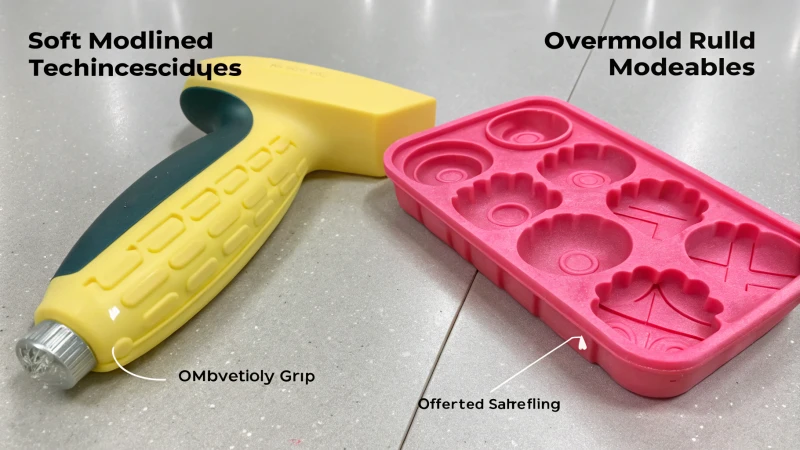

When Should You Choose Overmolding Over Two-Shot Injection Molding?

This article explores the advantages of overmolding versus two-shot injection molding, emphasizing its benefits in enhancing surface performance, accommodating complex shapes, and being cost-effective for small batch production.

MANUFACTURING

When Should You Choose Injection Molding Over Extrusion?

Choosing between injection molding and extrusion depends on factors like shape complexity, accuracy, production volume, and material flexibility. Injection molding excels in intricate designs, while extrusion suits simpler shapes.

DEVELOPMENT

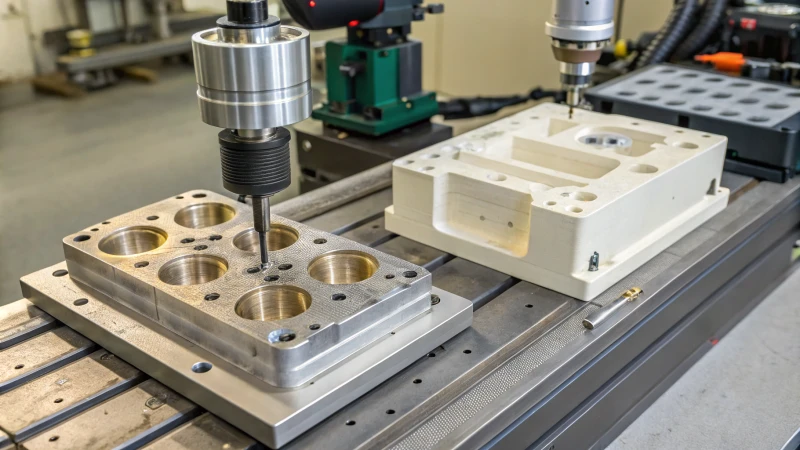

What Are the Key Differences Between Injection Molding and Other Manufacturing Processes?

This article explores the key differences between injection molding and other manufacturing processes, including cost, efficiency, precision, and material utilization, helping manufacturers choose the best method for their projects.

DEVELOPMENT

What Are the Key Differences Between Plastics for Extrusion and Injection Molding?

This article explores the key differences between extrusion and injection molding processes in plastics manufacturing, focusing on melt viscosity, thermal stability, shrinkage rates, and material toughness. Understanding these factors is crucial for optimizing product design and production efficiency.

MANUFACTURING

Which Factors Should You Consider When Choosing Between Two-Shot Injection Molding and Overmolding for Your Project?

Choosing between two-shot injection molding and overmolding involves considering design complexity, material performance, production costs, efficiency, and joining quality. Each method offers unique advantages for specific project needs.

DEVELOPMENT

Which Materials Are Most Commonly Used in Injection Molding?

This article explores the most commonly used materials in injection molding, including polyethylene, polypropylene, and engineering plastics like ABS and polycarbonate. It highlights their properties, applications, and selection criteria for effective product design.

Materials Recommendations

What Are the Size Limits for Parts Produced by Injection Molding?

This article explores the size limits of injection molded parts, focusing on machine specifications, mold manufacturing precision, and material performance. Understanding these factors is crucial for effective design and production.

DEVELOPMENT

What Are the Most Common Applications for Two-Shot Molding Products?

Two-shot molding, or two-color injection molding, combines materials to enhance product aesthetics and functionality across various industries like electronics, automotive, medical, and home appliances. This method improves efficiency and reduces waste.

DEVELOPMENT

What Are the Size Limits for Parts Produced by Extrusion?

This article explores the size limitations in extrusion molding, focusing on width, thickness, length, and shape complexity. It highlights the importance of mold design and material properties in production.

DEVELOPMENT

What Materials Are Commonly Used in Extrusion Molding?

This blog post explores the common materials used in extrusion molding, including thermoplastics, thermosetting plastics, rubber, and composites. Each material's unique properties enhance product design and manufacturing efficiency.

Materials Recommendations

What Are the Limitations of Injection Molding and How Can They Be Overcome?

This article explores the limitations of injection molding, including challenges with complex shapes, material constraints, size restrictions, production inefficiencies, and high costs. It also offers strategies to overcome these issues.

DEVELOPMENT

Which Is More Energy Efficient: Extrusion or Injection Molding?

This article compares the energy efficiency of extrusion and injection molding processes, highlighting that extrusion typically offers more stable energy consumption and lower overall costs compared to the variable demands of injection molding.

DEVELOPMENT

What Common Defects Occur in Extrusion and Injection Molding, and How Can They Be Prevented?

This article explores common defects in extrusion and injection molding, their causes, and preventive measures to enhance product quality. Key insights include material purity, mold design, and process monitoring.

Quality Inspection

What Makes Blow Molding Ideal for Producing Bottles and Containers?

Blow molding is a cost-effective and efficient manufacturing process for creating hollow plastic bottles and containers. It offers flexibility in design, uniform material distribution, and high production efficiency.

MANUFACTURING

Blow Molding vs Injection Molding: Which Process is Best for Creating Lightweight Products?

This article explores the differences between blow molding and injection molding, highlighting their unique advantages for creating lightweight products. Blow molding excels in producing hollow items, while injection molding offers precision for complex designs.

DEVELOPMENT

What Are the Key Advantages of Injection Molding for Your Projects?

Injection molding is a highly efficient manufacturing process that offers excellent product quality, design flexibility, and low production costs. It is ideal for creating complex shapes with diverse materials.

DEVELOPMENT

Extrusion vs Injection Molding: Which Process is Best for Mass Production and Small Batches?

This article compares extrusion and injection molding processes, highlighting their efficiency, cost-effectiveness, and suitability for mass production versus small batches. Understanding these differences aids in selecting the right manufacturing method.

DEVELOPMENT

How Do High Mold Accuracy Requirements Impact Costs?

Achieving high mold accuracy is crucial but comes with significant costs. Manufacturers face increased expenses from acquiring precision equipment, maintaining it, using specialized materials, and implementing complex machining processes. Testing and debugging further inflate budgets as they require skilled labor ...

Price Evaluation

How Can You Test and Ensure the Accuracy of Injection Molds?

Ensuring the accuracy of injection molds is crucial in manufacturing. This article discusses various testing methods such as appearance inspection, surface roughness detection, linear dimension measurement, and assembly accuracy checks. Techniques like using roughness meters for surface quality assessment and ...

Quality Inspection

How Can You Enhance the Toughness of Injection Molded Products?

This article explores effective strategies for enhancing the toughness of injection molded products. Key methods include selecting high-toughness materials like polycarbonate, modifying plastics with rubber elastomers or nanoparticles, and optimizing injection molding parameters such as melt temperature and speed. Additionally, ...

OPTIMIZATION