Warpage in injection molded parts often seems like a never-ending struggle with poor quality.

To solve warping problems in injection molded parts, experts must focus on the cooling system, gate designs and materials. The cooling system needs to work well. A proper gate position matters a lot. Material choice is crucial. Warpage probably reduces this way. Product quality really improves with these steps.

I recall my first experience with warping problems. Watching carefully crafted parts bend out of shape was really frustrating. Initial methods like improving cooling and changing gate layouts help quickly. Looking closely at each detail shows the slight differences that promise lasting success. The next sections explain these methods more clearly. They provide ideas that not only solve warping but also raise your whole injection molding process to higher standards. Very high standards. They give you ways to create top-quality parts without warping.

Optimizing the cooling system reduces warpage in molded parts.True

Efficient cooling minimizes differential shrinkage, reducing warpage.

Using any material will solve warpage defects in injection molding.False

Material selection affects shrinkage rates, influencing warpage outcomes.

How Does Cooling System Optimization Help Reduce Warpage?

Do you know the frustration of a bent item from injection molding? I understand it well. The solution to stop this problem lies in perfecting the cooling system.

Address warping in injection molded parts by optimizing the cooling system, gate design, and material selection. Effective cooling, strategic gate positioning, and choosing suitable materials are crucial steps. These measures help reduce warpage and significantly enhance product quality.

Importance of Cooling Channel Design

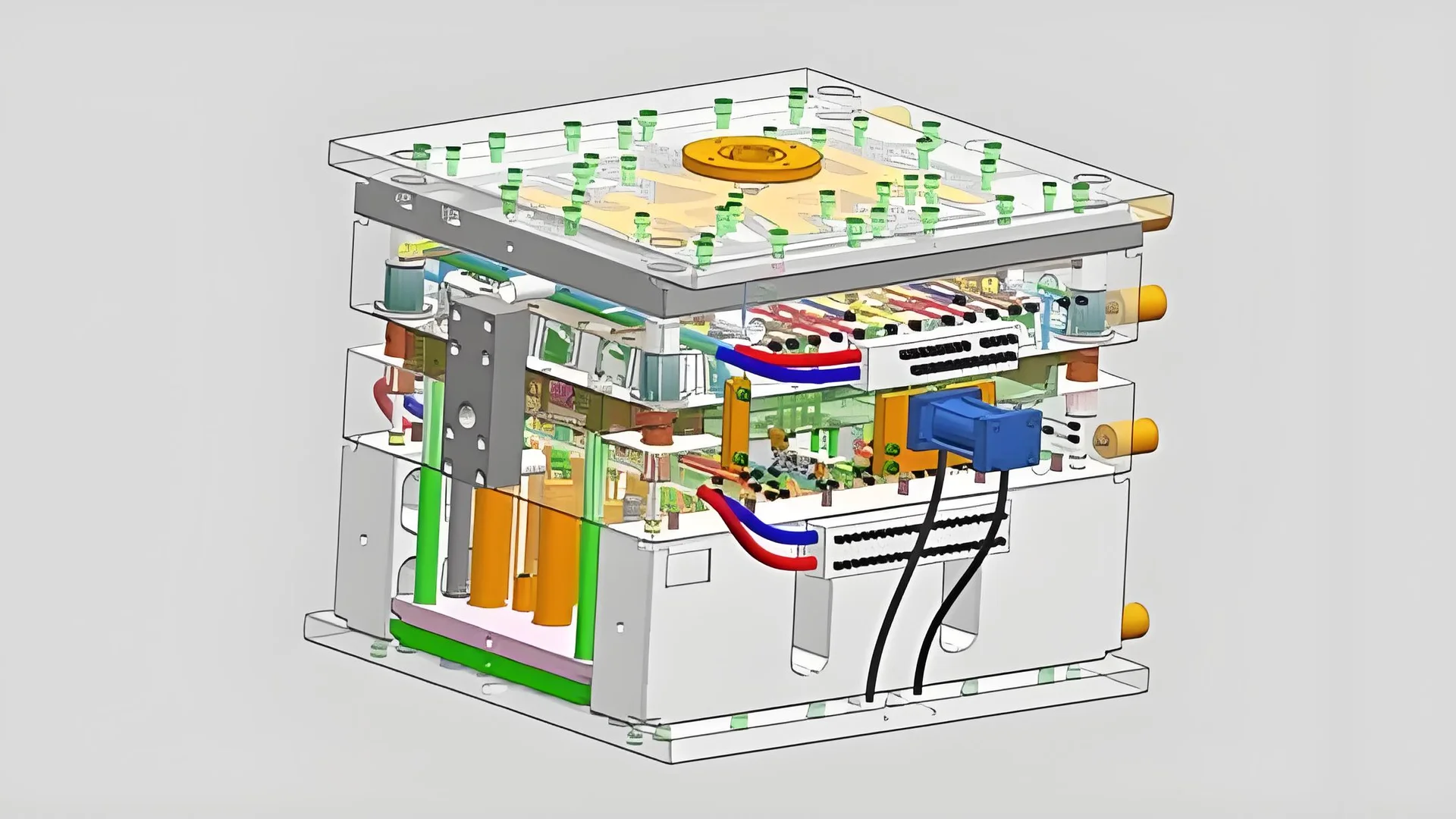

The design of cooling channels1 affects how fast a molded part cools. Properly designed channels ensure uniform cooling, which is essential for minimizing thermal stress and preventing warpage. For complex parts, layered and partitioned channels are beneficial.

For thick-walled parts, a higher density of cooling channels or the use of efficient cooling media can accelerate the process. Conversely, thin-walled parts require controlled cooling to avoid excessive shrinkage.

| Part Type | Cooling Strategy |

|---|---|

| Thick-Walled | Increase channel density |

| Thin-Walled | Control cooling speed |

Regular Maintenance of Cooling Systems

Regular checks and maintenance prevent issues like blockage or leakage in cooling channels. A clogged channel can lead to uneven cooling, which contributes to warpage. Routine inspections and cleanings help maintain optimal performance.

Gate Design Adjustments

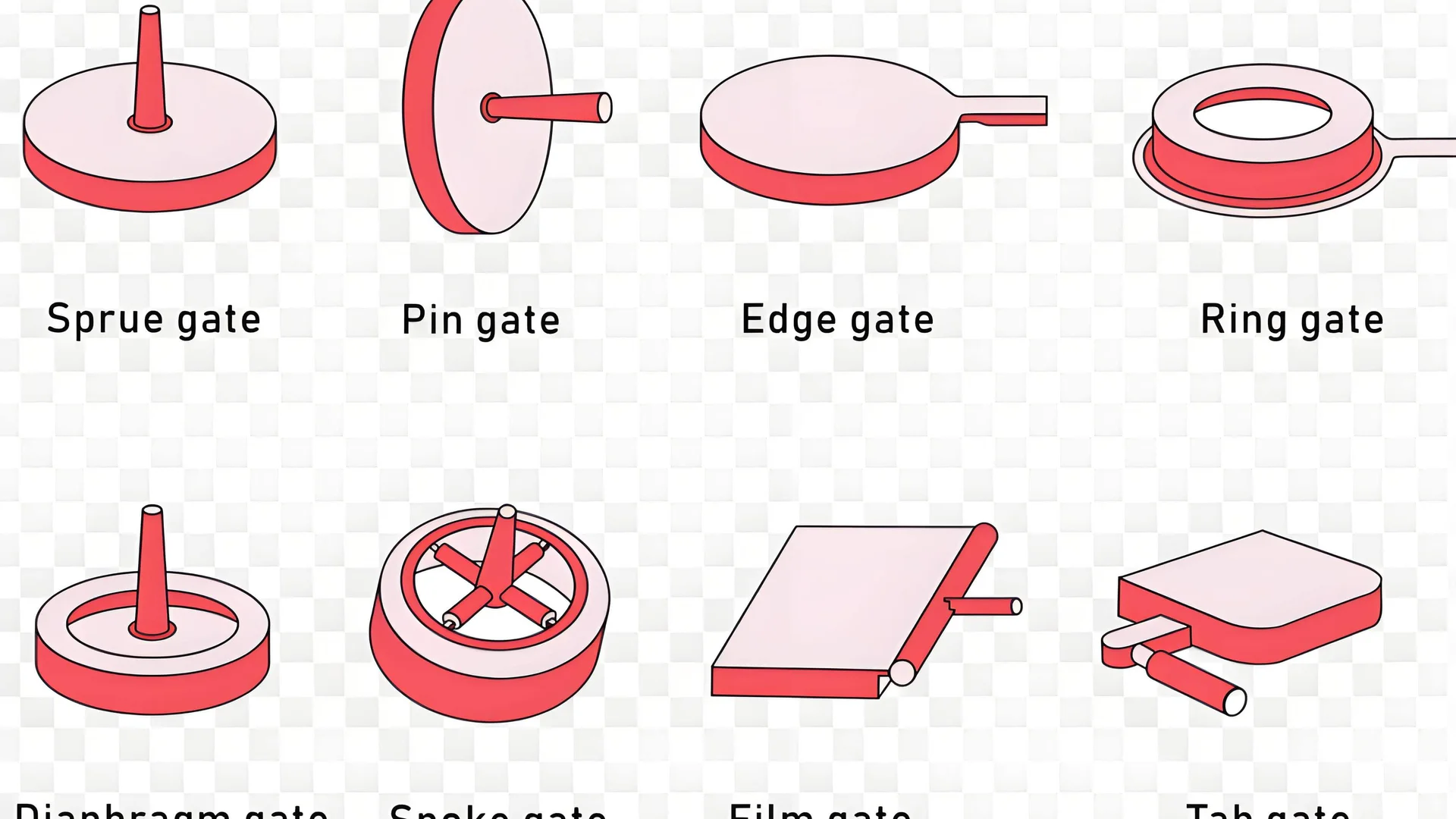

Adjusting the gate design is another way to complement cooling system optimization. By positioning the gate at the thicker section or geometric center, plastic melt fills the cavity more evenly, reducing warpage risks. Different gate types like point gates2 or side gates offer varying benefits depending on part geometry.

Integrating Cooling with Temperature Control

Combining optimized cooling with precise temperature control further enhances warpage reduction. By accurately managing mold temperatures, manufacturers can control crystallization in crystalline plastics, reducing volume shrinkage differences.

Impact on Injection Molding Efficiency

Optimizing cooling systems not only mitigates warpage but also boosts production efficiency. Faster cooling times mean shorter cycle times, leading to increased throughput and cost savings. This optimization is crucial for large-scale production3.

Layered channels reduce warpage in complex parts.True

Layered channels ensure uniform cooling, minimizing thermal stress.

Thick-walled parts need slower cooling to prevent warpage.False

Thick-walled parts require faster cooling to prevent warpage.

How Can Gate Design Adjustments Help Minimize Warpage?

Changing the gate design in injection molding really improves product quality.

Fine-tuning gate design in injection molding reduces warping. Engineers choose the right spot and type for gates. Proper gate placement leads to even flow and cooling. Shrinkage variations decrease. Defects become less likely. Shrinkage variations really drop.

Importance of Gate Design in Injection Molding

I recall the first moment I learned about the role of gate design in injection molding. It was during a late-night study session when I noticed how vital it is to control the path of the molten plastic into a mold. Poor gate placement or incorrect types lead to uneven flow, causing differential shrinkage and warpage. Good gate design is key; it helps maintain steady flow and reduces these flaws.

Optimal Gate Placement

At the factory one day, I saw that placing the gate at the thicker wall or center of a part can lead to smooth melt spread. The melt flows evenly with a central gate, balancing shrinkage, which is essential.

| Part Shape | Recommended Gate Placement |

|---|---|

| Disc-shaped | Center |

| Long-shaped | Along the length |

| Complex shapes | Multiple gates at strategic points |

Choosing the Right Gate Type

Picking the right gate type was a lesson in learning from mistakes. Various types affect flow differently. A point gate, for example, has a fountain-like fill that lessens weld marks and warping. Meanwhile, side gates are ideal for long parts, helping melt flow evenly along its length.

Impact of Gate Design on Cooling

Even cooling is very important as it prevents warpage. Thoughtful gate design ensures that the melt fills evenly, reducing stress and distortion.

Integration with Cooling Systems

Gate design settings work well with optimized cooling systems. Designing cooling paths for uniformity is my goal, especially for complex shapes.

Discover cooling channel strategies5

Material Stability and Gate Design

Lastly, selecting low-shrinkage materials with effective gate designs reduces warping. I often use materials like polystyrene (PS) with fillers for better dimensional stability.

Through these methods, I’ve significantly lowered warping. Gate design is now a vital part of my process improvement toolkit in injection molding.

Central gate placement reduces warpage in disc-shaped parts.True

A central gate ensures even melt flow, reducing shrinkage differences.

Point gates increase warpage due to uneven melt distribution.False

Point gates create a fountain-like fill, reducing weld marks and warping.

Why Is Temperature Control Crucial in the Injection Molding Process?

Have you ever wondered why controlling temperature in injection molding is so important? It’s not only to prevent problems. It’s about finding the right balance for both quality and efficiency.

Controlling temperature is important in injection molding. It helps material flow well and stops defects. Product quality gets better with good temperature control. Crystallization, shrinkage and cooling rates depend on temperature. Products need these things right to be consistent and accurate.

The Role of Temperature in Material Flow

At the start of my work with injection molding, temperature showed its power. Temperature could really make a difference in a project. Think about pouring syrup on a cold day. It doesn’t move well, right? Plastic melts act the same way in molding. Each material flows best at certain temperatures. ABS plastic needs to be between 180-250°C to flow nicely. It’s like finding the right pancake mix – too thick or too thin and it won’t work.

Proper temperature management7 ensures the plastic melt achieves optimal fluidity, reducing internal stresses that lead to defects like warping.

Effects on Crystallization and Shrinkage

My first experience with crystalline plastics was surprising. Adjusting mold temperature for materials like polypropylene (PP) changes crystallization speed and shrinkage greatly. It’s like baking a cake – the wrong temperature makes it flop. Correct temperatures prevent warping and keep parts consistent.

| Material | Barrel Temp. Range (°C) | Effect |

|---|---|---|

| ABS | 180-250 | Ensures fluidity and shrinkage control |

| Polypropylene (PP) | Varies | Controls crystallization and shrinkage |

Cooling System Optimization

Improving a cooling system was like solving a puzzle. Uniform cooling across the mold is crucial. I learned to check for blockages or leaks – imagine a garden hose bent and water stops. This careful check stops uneven cooling and warping, especially in complex parts.

Using layered and partitioned cooling channels8 ensures even distribution of heat, especially in complex-shaped or thick-walled parts.

Impact of Pressure and Speed

Balancing pressure and speed is like driving a car well – too fast or too slow causes trouble. A lot of pressure leads to filling problems and warping. Gentle pressure ensures complete filling, which really lifts the quality of parts.

- Optimal Pressure Settings:

- Injection Pressure: Adjust to lower internal stress.

- Holding Pressure: Often 50%-80% of injection pressure.

Material Selection and Pretreatment

Choosing materials felt like picking ingredients with no room for mistakes. Materials like polystyrene (PS) are great when shrinking is a problem. Removing moisture from materials was another key step – like drying hands before kneading dough; moisture changes everything.

Additionally, pre-treating materials9 to remove moisture is vital, as moisture content affects the thermal characteristics and flow behavior of plastics like nylon (PA).

To sum up, controlling temperature in injection molding isn’t just about numbers; it’s about creating something special with care. By improving mold design, pressure settings, and material selection, you can really get better product consistency—like tuning a musical instrument requiring practice, focus, and maybe a bit of passion for the work.

ABS requires barrel temps between 180-250°C.True

ABS plastic needs specific temperatures for proper viscosity and flow.

Increasing mold temperature for PP reduces warpage.True

Higher mold temperatures enhance crystallization, minimizing warping in PP.

What Material Choices Can Prevent Warpage Defects?

Did a project ever go off course because plastic parts bent in unexpected ways? Choosing the correct material really matters to keep everything moving forward.

Choosing materials that shrink little and stay stable in heat is important. Polystyrene works very well. Glass fiber-reinforced polypropylene is another great choice. These materials help reduce warping in injection-molded parts.

Understanding Material Properties

Warpage problems surprised me the first time. Fixing one issue felt like playing Whac-A-Mole; one resolved, another arose. Uneven shrinkage during cooling caused the trouble. Selecting materials with low shrinkage rates and high thermal stability is crucial. Polystyrene is a preferred choice due to its lower shrinkage, while adding glass fiber10 to polypropylene enhances dimensional stability.

Impact of Fillers and Modifications

Fillers surprised me as both friends and foes. When I mixed talc into polypropylene, the product improved greatly. Incorporating fillers like talc or minerals can alter the material’s shrinkage characteristics. For instance, using talc-filled polypropylene can reduce warpage by stabilizing shrinkage across different part areas.

| Table: Effect of Fillers on Material Properties | Material | Filler | Shrinkage Rate | Warpage Reduction |

|---|---|---|---|---|

| Polypropylene | Glass Fiber | Low | High | |

| Polypropylene | Talc | Moderate | Moderate |

Pretreatment of Materials

Drying materials like nylon is really important. Skipping this once caused moisture-induced warping. Ensuring raw materials are properly dried before processing is vital. Nylon, known for its hygroscopic nature, benefits significantly from drying, preventing moisture-induced uneven shrinkage11 that leads to warping.

Temperature Sensitivity of Materials

Temperature control works wonders against warpage. Different plastics have specific processing temperature ranges. Using ABS plastics, managing temperature precisely keeps fluidity and shrinkage in check. Proper temperature management can mitigate warping issues effectively.

Understanding these details makes me value the mix of art and science in choosing the right materials. Like Jacky12, the skilled designer in consumer electronics, selecting perfect materials brings everything together beautifully.

Polystyrene has a high shrinkage rate.False

Polystyrene is chosen for its lower shrinkage rate, reducing warpage.

Glass fiber reduces polypropylene warpage.True

Adding glass fiber to polypropylene enhances dimensional stability and reduces warpage.

Conclusion

This article discusses effective strategies to reduce warpage in injection molded parts, focusing on cooling system optimization, gate design adjustments, temperature control, and material selection.

-

Exploring best practices in channel design can significantly reduce warpage in molded parts. ↩

-

Understanding point gate benefits can enhance your gate design strategy for improved part quality. ↩

-

Learning about efficiency gains from optimized cooling systems can lead to better production outcomes. ↩

-

Understanding point gates can help designers optimize flow patterns, reducing defects like weld marks and warping. ↩

-

Proper cooling channel strategies enhance uniform cooling, preventing warpage and improving part quality. ↩

-

Choosing the right materials reduces warpage risk, enhancing overall part stability and quality. ↩

-

Discover the specific temperature ranges required for ABS to ensure optimal flow and product quality. ↩

-

Explore how layered cooling channels enhance uniform cooling and prevent defects like warping. ↩

-

Learn about pretreatment steps necessary for nylon to maintain its desired properties during molding. ↩

-

Learn how glass fiber reinforcement enhances polypropylene’s properties, reducing shrinkage and improving stability. ↩

-

Understand why drying nylon is critical to preventing moisture-related defects in injection molding. ↩

-

Explore how product designers like Jacky ensure optimal material choices for functionality and production efficiency. ↩