MANUFACTURING

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Pros and Cons of Nitriding Injection Molds?

Nitriding is a surface heat treatment process that significantly increases the hardness and wear resistance of injection molds. With surface hardness reaching HV1000-1200 (HRC70), nitrided molds exhibit improved fatigue strength and anti-seize performance while also enhancing corrosion resistance. However, the ...

MANUFACTURING

How Does Nitriding Treatment Enhance Mold Durability?

Nitriding treatment significantly improves mold durability by adding nitrogen to the surface layer, resulting in increased hardness, reduced wear, and enhanced fatigue resistance. The process involves careful preparation of molds through inspection, cleaning, pre-treatment like tempering and de-stressing, followed by ...

MANUFACTURING

What Are the Applications and Benefits of Nitriding Treatment for Molds?

Nitriding treatment significantly improves the durability and efficiency of molds used in manufacturing. By forming a hard nitride layer on the surface, it enhances wear resistance and extends mold life. This process is particularly beneficial for die-casting aluminum and zinc ...

MANUFACTURING

What Is the Lead-Time for a Plastic Injection Mold?

Navigating the intricacies of plastic injection mold timelines can make or break a manufacturing project. Understanding the lead-time is crucial as it varies significantly based on mold complexity, design requirements, and the manufacturer’s capabilities. This article delves into how these ...

MANUFACTURING

What Makes Precision Injection Molding the Best Choice?

Precision injection molding stands out in manufacturing due to its high dimensional accuracy and consistent quality. It's ideal for industries like electronics, medical, automotive, and aerospace. Explore why this technology is increasingly indispensable across these sectors, offering high efficiency and ...

MANUFACTURING

What Are the Most Effective Surface Treatments for Injection Molds?

In the competitive world of manufacturing, ensuring the longevity and efficiency of injection molds is paramount. Discover the most effective surface treatments available, including polishing, sandblasting, electroplating, and PVD titanium plating, to enhance mold durability and product quality.

MANUFACTURING

Why Is Temperature Control Crucial in Plastic Injection Molding?

Temperature control is a pivotal aspect of plastic injection molding, influencing every phase of the process from fluidity to final product quality. Understanding the significance of temperature can lead to improved production efficiency, better product integrity, and ultimately, customer satisfaction.

MANUFACTURING

What Are the Key Process Points in Thin-Wall Injection Molding?

Thin-wall injection molding is pivotal for producing lightweight, high-strength components efficiently. Mastering its key process points can elevate your production quality. This article explores critical areas including material selection, mold design, process parameters, and equipment choice, offering insights into achieving ...

MANUFACTURING

What Are the Applications and Benefits of Low-Pressure Injection Molding?

Low-pressure injection molding is a transformative manufacturing process that offers exceptional product protection, cost efficiency, and rapid production cycles. It’s particularly beneficial in industries like automotive, electronics, and medical devices where delicate components require careful handling. This article explores how ...

MANUFACTURING

What Are the Manifestations and Adjustment Methods for Insufficient Clamping Force in Injection Molding Machines?

In the world of injection molding, precision is key. Yet, one common issue that can disrupt the process is insufficient clamping force. This article explores the manifestations of this problem and offers practical adjustment methods to enhance product quality and ...

MANUFACTURING

What Are the Essential Steps for Effective Injection Mold Maintenance?

Effective injection mold maintenance is vital for manufacturing success, ensuring both product quality and equipment longevity. This article explores the essential steps and practices that enhance mold performance, from routine inspections to proper documentation. Read on to discover how to ...

MANUFACTURING

What is Silicone Injection Molding and How Does It Work?

Silicone injection molding is a transformative process that enhances precision in creating silicone products. By understanding this method, engineers and designers can innovate in product development while leveraging the unique advantages of silicone material. Dive into the intricacies of this ...

MANUFACTURING

What Are the Standard Tolerances for Injection Molded Parts?

Navigating the world of injection molded parts can be complex, especially when it comes to tolerances. Understanding these standards not only helps ensure quality but also assists in making informed decisions about material and design choices. In this guide, we’ll ...

MANUFACTURING

How Does Decompression Work in Injection Molding?

Understanding decompression in injection molding is essential for producing high-quality plastic components efficiently. This critical operation directly impacts product integrity and manufacturing precision. By mastering decompression techniques, manufacturers can significantly enhance product quality, reduce defects, and optimize production processes.

MANUFACTURING

What Are the Steps to Add Luminous Powder in Plastic Injection Molding?

Incorporating luminous powder into plastic injection molding can significantly enhance product appeal and functionality. Whether you're in manufacturing or product design, understanding this process is crucial. This blog offers a comprehensive guide on selecting materials, mixing techniques, and adjusting injection ...

MANUFACTURING

What Is the Best Steel for PET Preform Injection Molds?

When it comes to manufacturing PET preforms, selecting the right steel for injection molds is crucial. The right material not only ensures durability and performance but also impacts the quality of the final product. In this guide, I’ll explore the ...

MANUFACTURING

What Benefits Does Gas Assist Injection Molding Offer?

In today's competitive manufacturing landscape, every edge counts. Enter gas assist injection molding, a technique that promises to revolutionize how products are made. This method not only enhances product quality but also optimizes material use and boosts production efficiency—all while ...

MANUFACTURING

How Can an Injection Molding Machine Produce PET or PLA Cups?

The world of sustainable packaging is rapidly evolving, and injection molding machines play a crucial role in this transformation. Understanding how these machines produce PET and PLA cups is essential for optimizing production efficiency and ensuring high-quality results. This article ...

MANUFACTURING

How Can You Accurately Estimate the Injection Molding Cycle?

Estimating the injection molding cycle is essential for enhancing production efficiency and reducing manufacturing costs. By understanding key factors like cooling time, injection time, and holding time, manufacturers can optimize their processes for improved outcomes.

MANUFACTURING

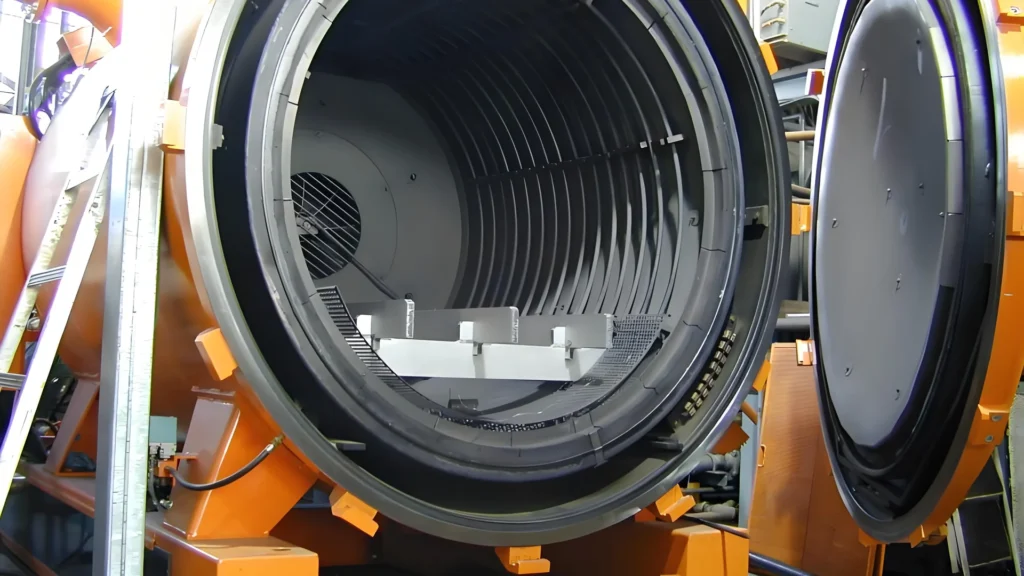

How Do Injection Molding Machines Create Hollow Parts?

Are you fascinated by the world of manufacturing? Join me as I explore how injection molding machines create hollow parts. From blow molding to gas-assisted techniques, discover the magic behind these processes and how they shape our everyday products.

MANUFACTURING

Can Injection Molding Machines Effectively Inject Threaded Molds?

Injection molding is a cornerstone of modern manufacturing, but can it handle the complexity of threaded molds? The answer is yes! By carefully considering mold design, process parameters, and material selection, manufacturers can create high-quality threaded components. In this article, ...

MANUFACTURING

What Are the Key Four Elements of Injection Molding Processing?

Injection molding is a pivotal process in manufacturing, where precision and quality are paramount. In this article, we'll explore the four key elements that define injection molding: plastic materials, injection molding machines, molds, and process parameters. Understanding these components is ...

MANUFACTURING

What Are the Seven Essential Components of Injection Molding?

Injection molding is a fascinating and complex process that shapes our everyday lives. From the toys we play with to the containers we use, this manufacturing technique is everywhere. Understanding the seven essential components—molding parts, gating system, guide mechanism, ejector ...

MANUFACTURING

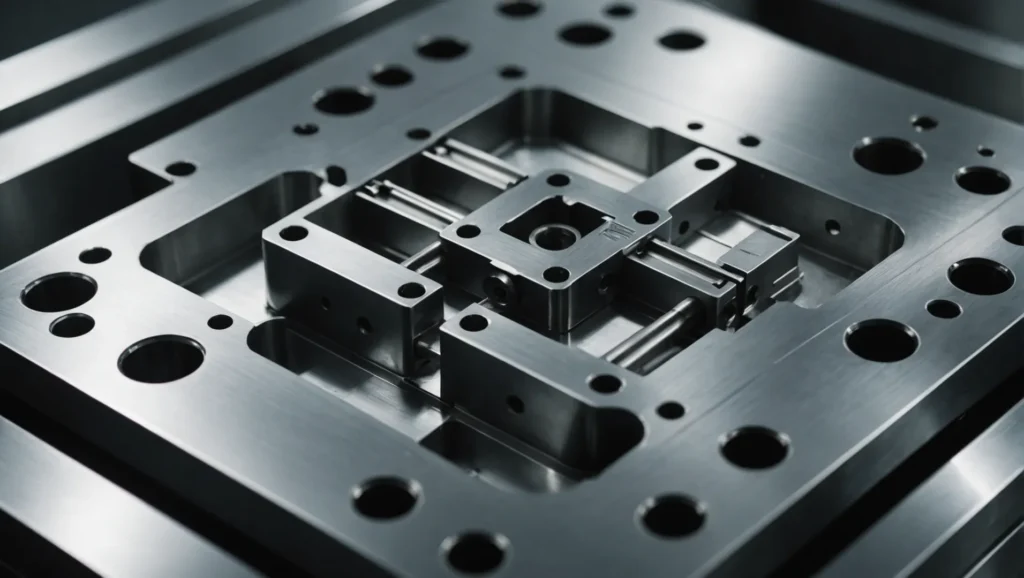

What Are the Steps to Create High-Quality Injection Molding?

Creating high-quality injection molded parts involves several critical steps, including careful selection of raw materials, meticulous mold design, precise process control, effective post-processing, and stringent quality management. Each phase plays a crucial role in ensuring that the final products meet ...

MANUFACTURING

Where Should You Use Plastic Injection Molds and Why?

Plastic injection molding has transformed the manufacturing landscape. Its ability to produce intricate, high-quality components swiftly makes it a go-to method across numerous sectors. From automotive parts to medical devices, understanding the diverse applications and benefits of injection molding is ...

MANUFACTURING

What Benefits Does Injection Mold Coating Offer?

In the world of plastics manufacturing, where every second counts, injection mold coatings emerge as unsung heroes. They enhance not only the efficiency of production processes but also the durability and longevity of molds. Discover how these coatings can transform ...

MANUFACTURING

How Does a Transfer Position Work in Injection Molding?

Injection molding is a complex process, and understanding the transfer position is crucial for ensuring quality in plastic components. This article dives into the significance of the transfer position, its impact on product quality, and common issues that can arise ...

MANUFACTURING

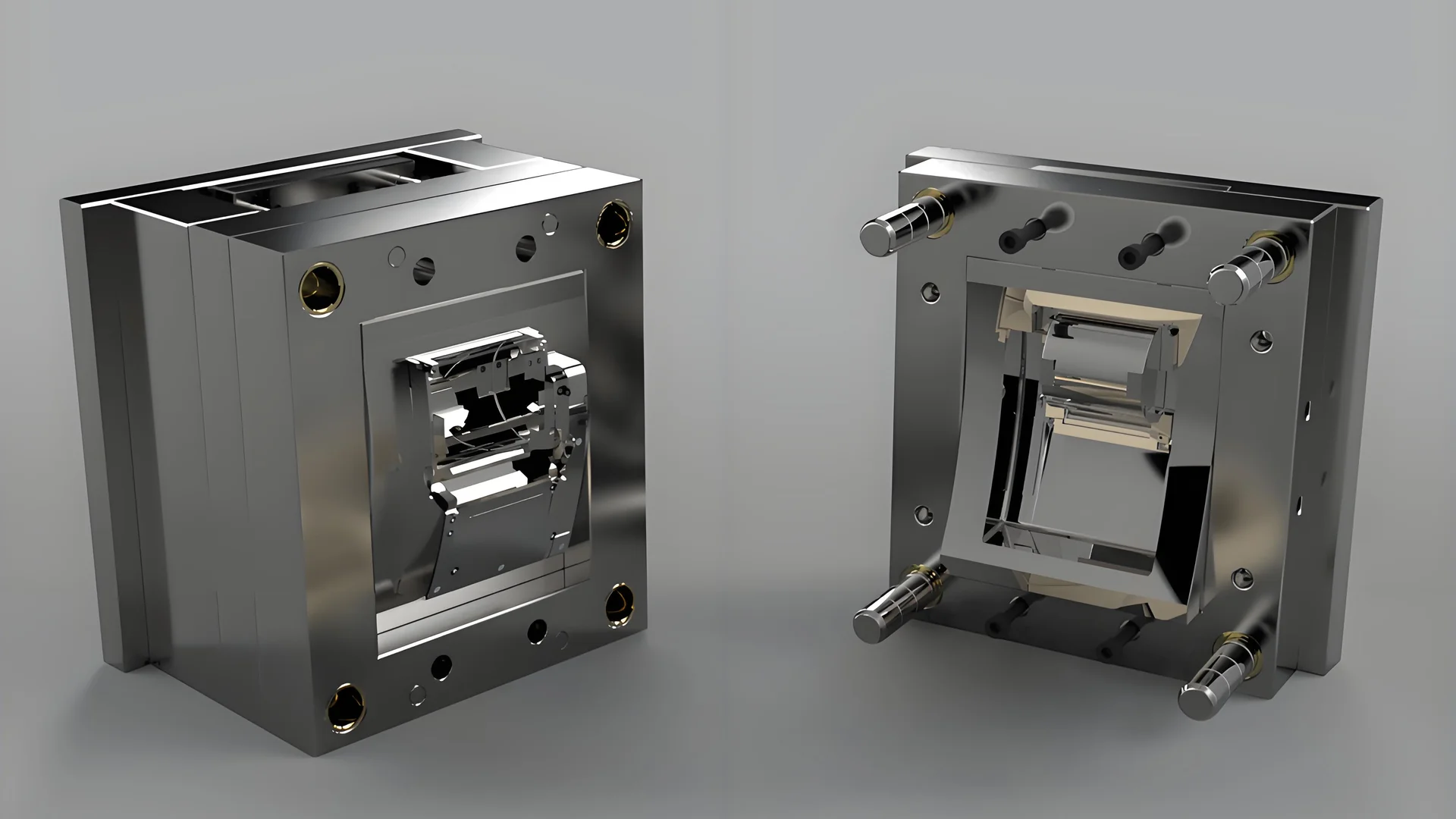

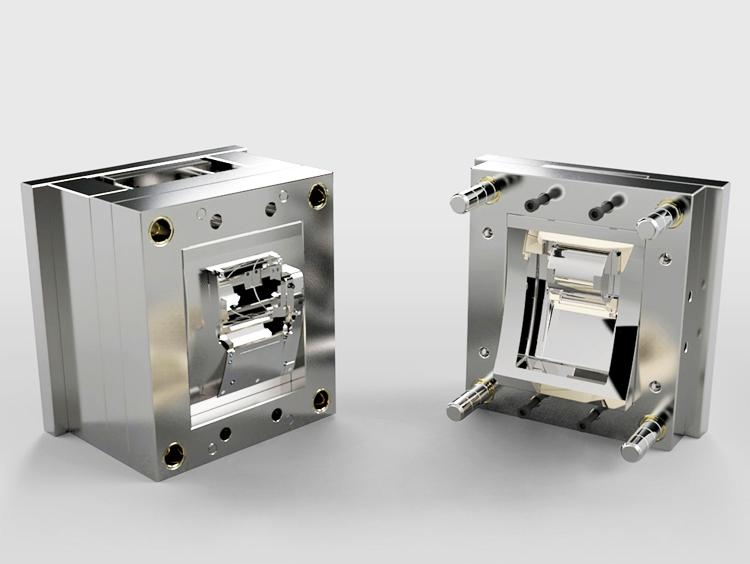

How Does Each Part of an Injection Mold Function?

Injection molding is not just a manufacturing process; it’s an art form that shapes our world. By understanding each component of an injection mold, I can appreciate the precision and efficiency involved in creating everyday plastic products. Join me as ...

MANUFACTURING

How Does Pressure Impact Your Plastic Injection Molded Parts?

In the intricate realm of plastic injection molding, pressure serves as a vital ingredient for ensuring high-quality molded parts. Understanding how different pressures affect everything from filling to mechanical properties is crucial for optimizing your manufacturing process. Join me as ...

MANUFACTURING

How Does the Bakelite Injection Molding Production Process Work?

Bakelite is a trailblazer in thermosetting plastics, renowned for its durability and heat resistance. Understanding the intricate injection molding process— from material preparation to post-processing— is essential for achieving high-quality products. Join me as I explore each stage of this ...

MANUFACTURING