All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

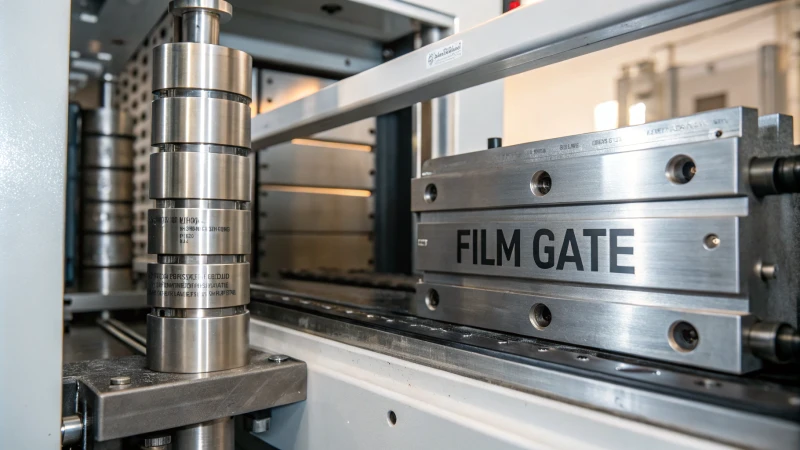

What Are the Key Characteristics and Benefits of a Film Gate?

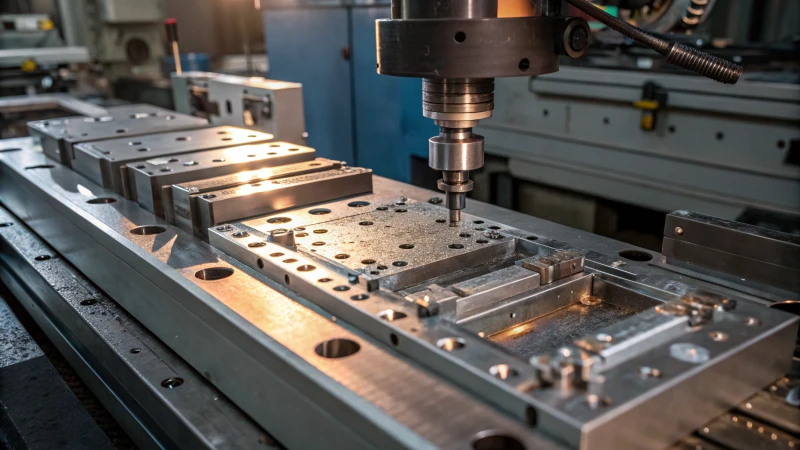

Film gates, also known as thin-sheet or burr gates, play a crucial role in injection molding by providing excellent flow characteristics. They ensure even melt distribution, which is essential for producing large flat or thin-walled plastic parts without defects. The ...

DESIGN

How Do You Optimize Injection Speed and Pressure for Better Performance?

Optimizing injection speed and pressure in molding is essential for achieving high-quality products. Understanding material traits and product designs allows for precise adjustments. Systematic testing helps identify flaws early, ensuring consistent results. Operators should familiarize themselves with machine controls and ...

OPTIMIZATION

What Are Effective Ways to Reduce Appearance Defects in Injection Molded Products?

Injection molding can lead to various defects like flash, shrinkage, weld marks, flow marks, and silver streaks. This article outlines effective methods for reducing these appearance defects through optimized mold design, careful material selection, and precise adjustments in the injection ...

OPTIMIZATION

How Can You Increase Ejection Force by Enhancing Mold Structure?

This article explores effective strategies for increasing ejection force in injection molding. Key methods include optimizing the mold design, enhancing ejector mechanisms, strengthening guiding structures, and adjusting demolding angles. By implementing these techniques, manufacturers can achieve smoother product releases, minimize ...

OPTIMIZATION

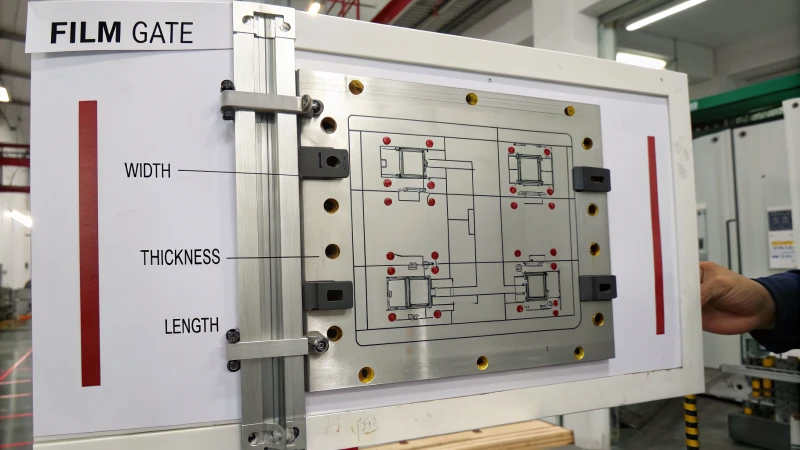

How Can You Determine the Specific Size of a Film Gate?

Determining the correct size of a film gate is crucial in mold design. This article outlines key factors such as product width, wall thickness, material behavior, and gate length. Gate width typically ranges from 25% to 100% of the product ...

DESIGN

What Are the Common Appearance Defects in Injection Molded Products?

Injection molding can lead to various appearance defects that affect both aesthetics and functionality. Common issues include flash (overflow), shrinkage (dent), weld marks, flow marks, silver streaks, poor gloss, and bubbles. Each defect arises from specific causes such as high ...

Quality Inspection

How Can You Adjust Injection Pressure According to Operating Specifications?

This article explores the critical process of adjusting injection pressure in molding operations. It emphasizes the importance of proper training for technicians, thorough equipment inspections, and a deep understanding of material properties. Key steps include starting with lower initial pressure ...

MANUFACTURING

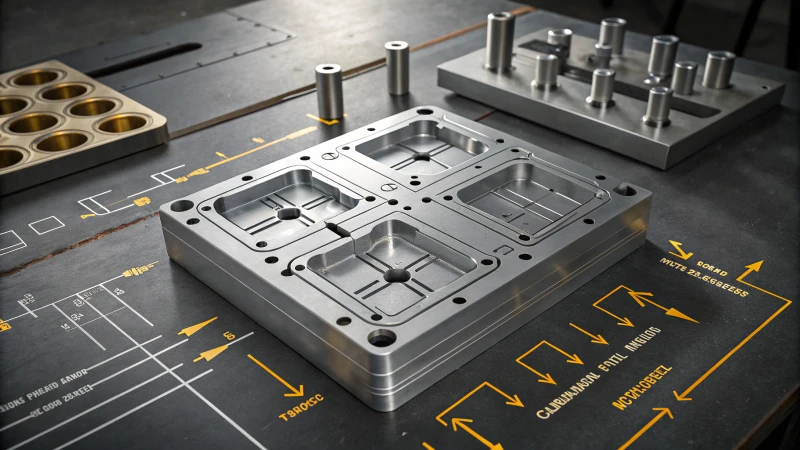

How Does the Design of Main and Branch Channels Influence Mold Production Costs?

This article explores how the design of main and branch channels in mold production affects costs. Key factors include material consumption, processing complexity, and maintenance requirements. Effective channel design can lead to significant savings while maintaining high quality. By understanding ...

DESIGN

What Are the Design Standards for Main and Branch Channels in Mold Design?

In mold design, adhering to specific standards for main and branch channels is crucial for achieving smooth plastic flow. This article delves into the importance of channel shape, size, layout, and material choice. The main runner typically features a conical ...

DESIGN

What is the Typical Gate Length of a Film Gate?

Understanding the typical gate length of a film gate is crucial in injection molding. Ranging from 0.5 to 2mm, this length minimizes pressure and heat loss during the process. Smaller products with thin walls require shorter gates (0.5-1mm) for efficient ...

DESIGN

How Can Mold Design Optimization Reduce Flow Mark Defects in Injection Molded Products?

This article explores how optimizing mold design can effectively reduce flow mark defects in injection molded products. Key strategies include refining runner system shapes and sizes to minimize resistance, selecting appropriate gate types for even melt distribution, and implementing effective ...

DESIGN

How Does Ejection Force Impact Molds and Plastic Products?

Ejection force plays a critical role in injection molding, affecting both the quality of plastic products and the longevity of molds. Excessive ejection force can lead to surface damage, dimensional inaccuracies, and internal structure failures in molded products, while insufficient ...

OPTIMIZATION

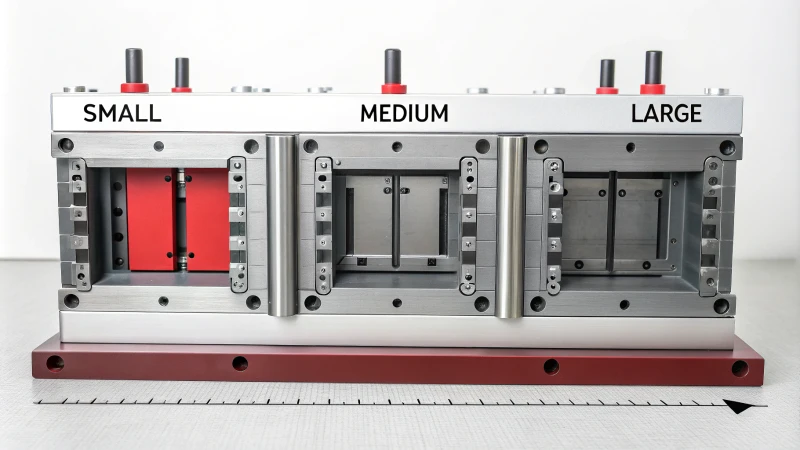

What Is the Best Method to Determine Film Gate Width for Specific Product Size and Wall Thickness?

In injection molding, selecting the correct film gate width significantly impacts product quality and efficiency. This article outlines guidelines based on product size—small (50%-100% of width), medium (30%-70%), and large (20%-50%)—and wall thickness considerations. For thin-wall products, wider gates (40%-80%) ...

OPTIMIZATION

How Do You Choose the Right Processing Temperature for Your Material’s Properties and Application Needs?

Selecting the appropriate processing temperature is essential for achieving desired material properties and product quality. This article explores how factors like crystallinity, thermal stability, flowability, and application requirements influence temperature settings. Crystalline materials require temperatures above their melting points for ...

OPTIMIZATION

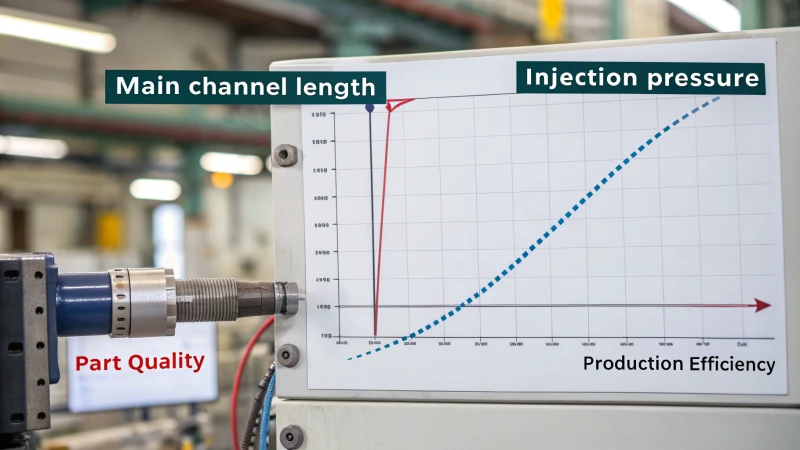

How Does Main Channel Length Design Affect the Quality of Injection Molded Products?

The main channel length in injection molding is crucial for product design, impacting appearance quality, dimensional accuracy, and internal integrity. A well-optimized channel ensures even pressure distribution and melt flow, reducing issues like flash problems and warping deformation. This article ...

MANUFACTURING

How Does the Main Channel Length Affect Mold Injection Pressure?

This article explores how the length of the main channel in injection molding affects injection pressure requirements. Longer channels increase viscous resistance, necessitating higher pressures for proper mold filling. This can lead to challenges such as uneven pressure distribution, which ...

DESIGN

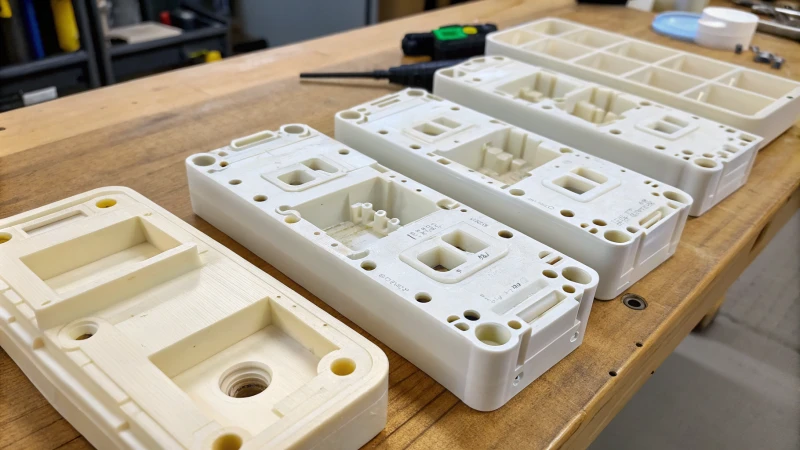

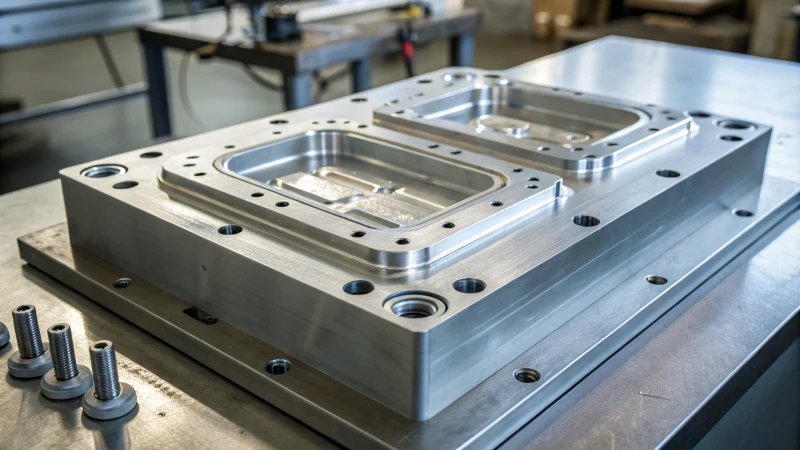

What Are the Key Indicators to Judge the Quality of Injection Molds?

Understanding the quality of injection molds is essential for successful production. Key indicators include evaluating material quality (like P20 and H13 steel), ensuring precise manufacturing accuracy, rational structural design, assessing trial success rates, and monitoring mold service life through wear ...

Quality Inspection

How Does Injection Pressure Influence the Shrinkage of Plastic Products?

This article explores the critical role of injection pressure in plastic molding, detailing how high pressure minimizes shrinkage by compacting the melt, leading to consistent product quality. Conversely, low pressure results in increased shrinkage due to incomplete mold filling. The ...

Quality Inspection

How Does Mold Temperature Impact the Strength of Injection Molded Products?

Mold temperature plays a crucial role in determining the strength and toughness of injection molded products. Proper control of mold temperature enhances melt fluidity, allowing for better filling of complex designs and promoting optimal molecular chain orientation. For materials like ...

OPTIMIZATION

How Can You Choose the Right Injection Molding Machine to Avoid Improper Material Pretreatment?

Selecting the appropriate injection molding machine is crucial for achieving high-quality products. Key factors include an efficient dehumidification and drying system to manage moisture levels, precise temperature control for optimal plasticization, and a suitable screw design tailored to specific materials. ...

OPTIMIZATION

What is the Optimal Injection Pressure Range and How to Determine It?

Understanding the optimal injection pressure range is crucial in injection molding. This article explores how material characteristics like viscosity and flowability, along with product structure and mold design, influence the required pressure settings. Typically ranging between 30 to 150 MPa, ...

OPTIMIZATION

How Can You Minimize the Impact of High Mold Temperature on Injection Molded Product Strength?

High mold temperatures can significantly impact the strength and durability of injection molded products. This article explores strategies to minimize these effects by optimizing cooling systems, adjusting injection molding parameters, and selecting appropriate materials. Key techniques include redesigning cooling channels ...

OPTIMIZATION

What Key Factors Should You Consider When Adjusting Injection Pressure?

This article explores the key factors influencing injection pressure adjustments in molding processes. It emphasizes the importance of product design, material viscosity, wall thickness, and mold characteristics. Understanding how these elements interact can significantly impact the quality of molded products. ...

OPTIMIZATION

How Does Injection Pressure Affect the Properties of Molded Parts?

Injection pressure is a critical factor in injection molding that affects various properties of molded parts. It determines the appearance quality by influencing flash, surface gloss, and weld marks. Dimensional accuracy relies on proper pressure to maintain stability and uniform ...

OPTIMIZATION

How Does Excessive or Insufficient Shrinkage Affect Plastic Product Quality?

This article explores how excessive or insufficient shrinkage impacts the quality of plastic products. It discusses the effects on dimensional accuracy, aesthetic appeal, and internal integrity. Excessive shrinkage can lead to smaller-than-intended parts, causing gaps during assembly and compromising product ...

Quality Inspection

What Is the Best Way to Determine the Optimal Injection Pressure for an Injection Molding Machine?

This article explores the best practices for determining the optimal injection pressure in injection molding. It emphasizes the importance of understanding material characteristics, particularly the melt flow index (MFI), which indicates how easily a polymer flows under pressure. The relationship ...

OPTIMIZATION

How Does Excessive Shrinkage Impact the Strength of Plastic Products?

Excessive shrinkage in plastic products can create internal structural defects, reduce density, and cause warping. These issues lead to decreased tensile strength and overall product reliability. Understanding how shrinkage affects material properties is crucial for designers to ensure the durability ...

MANUFACTURING

How Can You Enhance Dimensional Accuracy in Injection Molded Parts by Optimizing Injection Pressure?

This article explores how optimizing injection pressure can significantly enhance the dimensional accuracy of injection molded parts. It emphasizes the importance of understanding material properties, mold design complexities, and the implementation of advanced techniques such as segmented pressure control and ...

OPTIMIZATION

Should You Choose China or Vietnam for Manufacturing Injection Molds?

Choosing between China and Vietnam for injection mold manufacturing involves weighing various factors. China excels in advanced technology, production efficiency, and quality control, making it a leader in the industry. In contrast, Vietnam offers significant cost advantages due to lower ...

MANUFACTURING

How Can You Effectively Address Flash Problems in Injection Molded Products?

Flash defects in injection molded products can be frustrating and costly. This article outlines practical steps to effectively address these issues by focusing on mold adjustments, optimizing injection molding parameters, and selecting appropriate materials. Key strategies include checking the mold ...

OPTIMIZATION