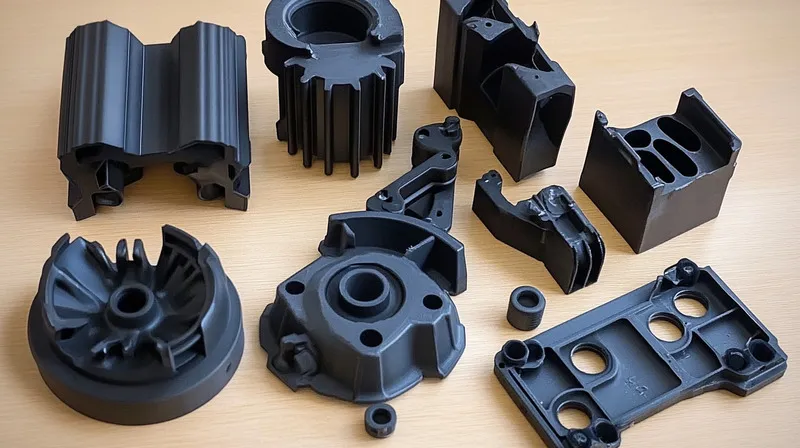

Plasticizers play a crucial role in enhancing the flexibility of injection-molded parts1 by modifying the physical properties of polymers. This blog post explores the definitions, classifications, applications, advantages, disadvantages, and technical considerations of using plasticizers in injection molding.

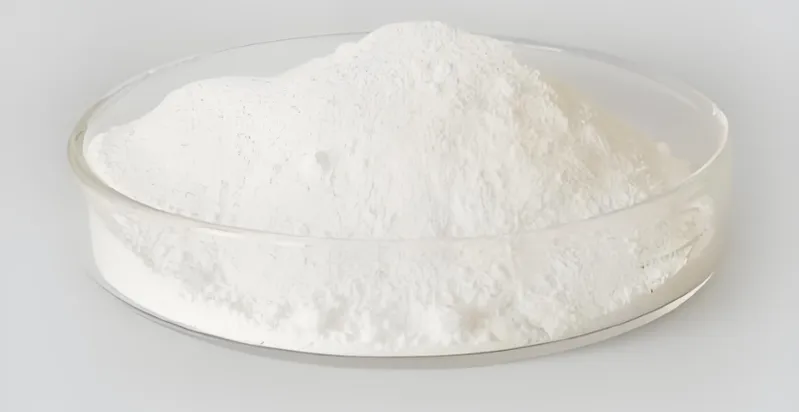

Plasticizers are additives that increase the flexibility and workability of polymers, particularly in injection molding2, by reducing intermolecular forces and enhancing molecular mobility.

Understanding how plasticizers3 function can help manufacturers optimize the performance of their injection-molded products. Read on to discover their types, effects on the molding process, and practical applications.

Plasticizers always improve the durability of injection-molded parts.False

While plasticizers enhance flexibility, they can sometimes reduce mechanical strength or durability, depending on the type and amount used.

Plasticizers are only used in flexible PVC applications.False

Plasticizers are used in various polymers beyond PVC, including polyolefins and engineering plastics, to enhance flexibility and processability.

- 1. What are Plasticizers and How Do They Work?

- 2. How Do Plasticizers Affect the Injection Molding Process?

- 3. What are the Applications of Plasticizers in Injection-Molded Parts?

- 4. How Do Plasticizers Compare to Other Flexibility-Enhancing Methods?

- 5. What are the Key Considerations When Using Plasticizers?

- 6. Conclusion

What are Plasticizers and How Do They Work?

Plasticizers are chemical additives that increase the flexibility, workability, or distensibility of plastics. They work by embedding themselves between polymer chains, reducing intermolecular forces, and allowing the chains to move more freely, thus making the material less rigid and more pliable.

Plasticizers reduce the glass transition temperature of polymers, enhancing molecular mobility and making injection-molded parts more flexible.

| Plasticizer Type | Common Polymers Used With | Notes |

|---|---|---|

| Phthalates4 | PVC, Polyolefins | Cost-effective but under regulatory scrutiny |

| Adipates | PVC, Polyurethanes | Excellent low-temperature flexibility |

| Citrates5 | Medical-grade PVC | Biocompatible and non-toxic |

Phthalates

Phthalates are widely used plasticizers, particularly with PVC, due to their affordability and ability to impart flexibility. However, concerns over health and environmental impacts are reducing their popularity.

Adipates

Adipates excel in applications requiring flexibility at low temperatures, such as automotive interiors and food packaging.

Citrates

Citrates are favored in medical and food-contact applications for their non-toxic and biocompatible properties.

Phthalates are the only plasticizers used in injection molding.False

While phthalates are common, adipates and citrates are also used for specific properties or regulatory compliance.

Plasticizers can be used with any polymer.False

Plasticizers are most effective with polar polymers like PVC; their efficacy varies with non-polar polymers like polyolefins.

How Do Plasticizers Affect the Injection Molding Process?

Plasticizers influence the injection molding process by altering melt viscosity, processing temperatures, and cycle times, which can improve efficiency but require careful management.

Plasticizers lower melt viscosity6, enabling easier mold filling and potentially reducing processing temperatures and cycle times7.

Mixing and Compounding

Plasticizers are blended with the polymer during compounding. Precise control over the type and amount ensures the desired flexibility without sacrificing other properties.

Melt Viscosity

By weakening intermolecular forces, plasticizers reduce melt viscosity, facilitating smoother flow during molding and potentially lowering energy costs.

Molding Parameters

Plasticizers can allow for lower processing temperatures and pressures, reducing thermal degradation risks, though adjustments depend on the polymer-plasticizer combination.

Plasticizers always reduce processing temperatures.False

The effect on temperature varies with the specific polymer and plasticizer used.

Excessive plasticizer use can cause defects.True

Overuse can lead to surface blooming, reduced strength, or dimensional instability.

What are the Applications of Plasticizers in Injection-Molded Parts?

Plasticizers enhance flexibility in injection-molded parts across multiple industries, making them indispensable in specific applications.

Plasticizers are used in automotive, medical, consumer goods, and packaging industries to produce flexible components8 like seals, tubing, and films.

Automotive Industry

Plasticizers enable the production of flexible seals, gaskets, and interior trim components that withstand mechanical stress and temperature variations.

Medical Devices

In medical applications, plasticizers like citrates are used in flexible tubing, IV bags, and catheters, where biocompatibility9 is critical.

Consumer Goods

Flexible toys, footwear, and household items benefit from plasticizers, improving user comfort and product longevity.

Plasticizers are essential for all injection-molded parts.False

Many parts require rigidity or strength, where plasticizers are unnecessary.

Plasticizers can improve impact resistance.True

Increased flexibility can enhance a part’s ability to absorb impact without fracturing.

How Do Plasticizers Compare to Other Flexibility-Enhancing Methods?

Plasticizers are one of several techniques to increase polymer flexibility, each with distinct advantages and trade-offs.

Plasticizers provide a cost-effective flexibility solution, but copolymerization or elastomer blending may offer superior performance in some cases.

Copolymerization

Copolymerization introduces flexible segments into the polymer structure, offering inherent flexibility without additives, though it’s more complex and costly.

Blending with Elastomers

Blending polymers with elastomers enhances flexibility but may compromise clarity or processability, unlike plasticizers.

Plasticizers are the only way to enhance flexibility.False

Copolymerization and elastomer blending are viable alternatives with different benefits.

Plasticizers are always the cheapest option.False

Cost-effectiveness depends on the application and performance requirements.

What are the Key Considerations When Using Plasticizers?

Using plasticizers effectively in injection molding requires careful planning to balance flexibility with other properties.

Key considerations include plasticizer type, amount, polymer compatibility, processing conditions, and regulatory compliance.

Design Checklist

| Consideration | Details |

|---|---|

| Type and Amount | Select based on desired flexibility; avoid overuse |

| Polymer Compatibility | Match plasticizer to polymer type |

| Processing Conditions | Adjust temperature and pressure as needed |

| Regulatory Compliance | Ensure safety for medical or food use |

All plasticizers are safe for medical use.False

Only specific plasticizers, like citrates, meet biocompatibility standards.

Plasticizer amount doesn’t affect properties.False

Excessive amounts can degrade mechanical properties or cause surface issues.

Conclusion

Plasticizers are vital for creating flexible injection-molded parts, offering a practical solution for industries like automotive, medical, and consumer goods. However, their use requires careful consideration of type, compatibility, and processing parameters to avoid drawbacks like reduced strength or regulatory issues.

- Learn about the specific ways plasticizers enhance flexibility, vital for optimizing product performance. ↩

- Gain insights into the injection molding process, essential for understanding the role of plasticizers in manufacturing. ↩

- Explore how plasticizers enhance flexibility and performance in injection-molded products, crucial for manufacturers. ↩

- Learn about the potential risks of phthalates and why their use is being scrutinized in many applications. ↩

- Discover the advantages of citrates in ensuring safety and compliance in sensitive applications like food and healthcare. ↩

- Understanding how plasticizers lower melt viscosity can enhance your knowledge of injection molding efficiency and product quality. ↩

- Learning about the effects of plasticizers on cycle times can help optimize production efficiency and reduce costs. ↩

- Discover how flexible components enhance comfort and longevity in consumer products, making them more appealing and functional for users. ↩

- Understanding biocompatibility is crucial for ensuring safety and effectiveness in medical applications, especially for devices in direct contact with patients. ↩