Injection molding is a cornerstone of modern manufacturing, enabling the mass production of plastic parts with high precision and efficiency. However, the success of this process hinges on the quality of the mold used. Mold testing is a critical step that ensures the mold performs as expected, producing parts that meet stringent quality standards. In this comprehensive guide, we will explore the top mold testing1 practices for efficient injection molding2, covering everything from basic concepts to advanced technical details.

Mold testing ensures molds produce high-quality parts with minimal defects. Thorough initial inspections and trial runs are critical for success. Optimizing parameters like temperature and pressure improves efficiency. Material compatibility is essential, especially for multi-material molding. Practices vary by industry and material.

Mold testing is only necessary for new molds.False

Even existing molds should be tested periodically to ensure they haven't degraded over time.

Proper mold testing can reduce production costs.True

By identifying and fixing issues early, mold testing prevents defective parts and reduces waste.

Understanding the intricacies of mold testing and its applications is key to leveraging its benefits for your industry. Delve deeper to explore how different materials and parameters affect the final part quality and production efficiency.

- 1. What is Mold Testing in Injection Molding?

- 2. What are the Typical Application Scenarios for Mold Testing?

- 3. What are the Pros and Cons of Injection Molding Compared to Other Technologies?

- 4. What are the Key Steps in the Mold Testing Workflow?

- 5. How Does Material Compatibility Affect Mold Testing?

- 6. What are the Practical Tools for Effective Mold Testing?

- 7. What are the Related Technologies in Mold Testing?

- 8. Conclusion

What is Mold Testing in Injection Molding?

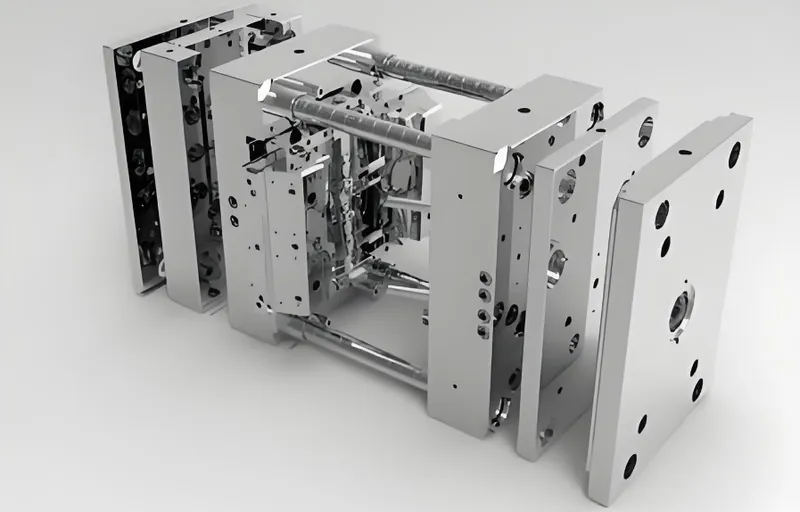

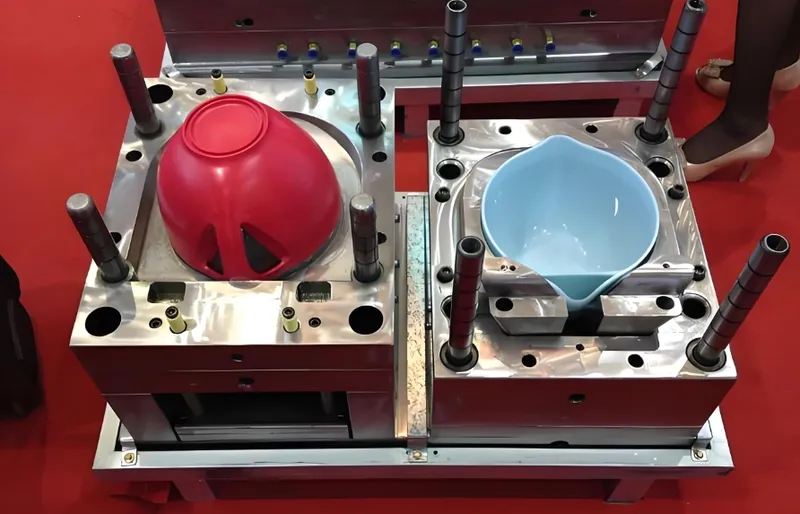

Mold testing in injection molding involves evaluating a mold’s functionality and the quality of the parts it produces before full-scale production. It includes inspecting the mold for issues, running trial injections, and adjusting settings to ensure parts meet standards. This process helps avoid costly production errors.

Injection molding is a manufacturing process where molten plastic is injected into a mold cavity under high pressure, then cooled and solidified to form a part. Mold testing ensures the mold performs as expected, producing parts that meet quality standards.

Definitions

-

Injection Molding: A manufacturing process where molten plastic is injected into a mold cavity under high pressure, then cooled and solidified to form a part.

-

Mold Testing: The process of evaluating a mold’s functionality and the quality of the parts it produces before full-scale production. This includes inspections, trial runs, and parameter optimization.

-

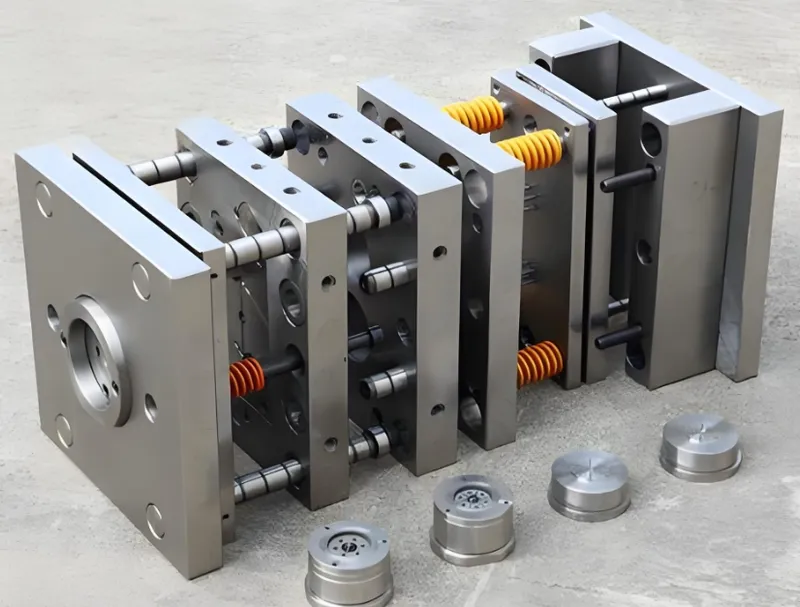

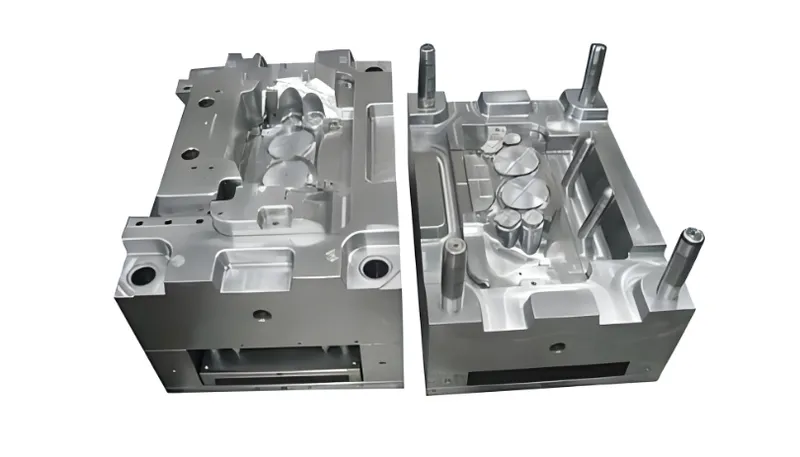

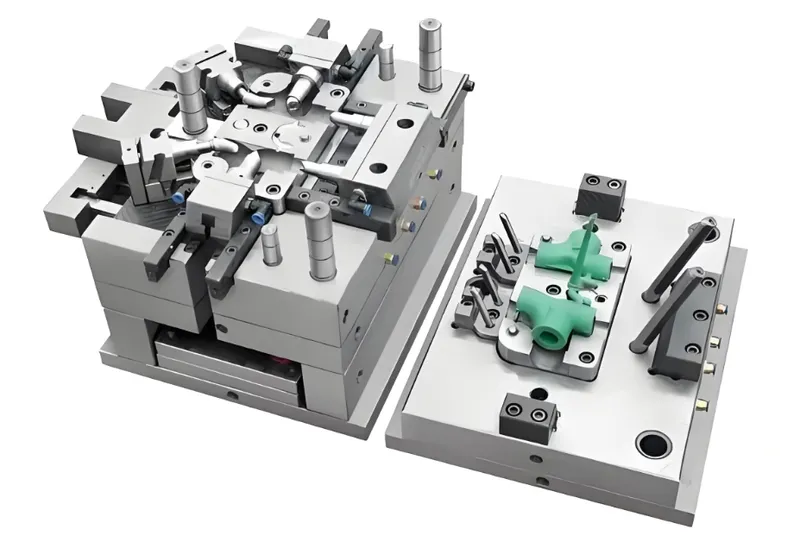

Mold: A tool typically made of steel or aluminum that shapes the plastic part. It consists of two halves: the cavity (which forms the exterior of the part) and the core (which forms the interior).

- Molding Parameters: Variables such as injection pressure, melt temperature, mold temperature, cooling time, and injection speed that affect the quality of the molded part.

Classification

Mold testing can be classified from different perspectives:

-

By Process:

- Initial Mold Inspection: Checking for physical defects, proper assembly, and cleanliness.

- Trial Runs: Producing a small batch of parts to evaluate quality and identify issues.

- Parameter Optimization: Adjusting molding parameters to achieve the best part quality.

-

By Materials:

- Thermoplastics: Most common, require specific temperature and cooling controls.

- Thermosets: Require different processing due to their curing behavior.

- Elastomers: Need special considerations for flexibility and mold release.

-

By Applications:

- Automotive: High precision and durability required.

- Medical: Strict cleanliness and dimensional accuracy.

- Consumer Goods: Focus on aesthetics and cost-effectiveness.

Mold testing practices are the same across all industries.False

Different industries have unique requirements, such as precision in medical devices or durability in automotive parts.

Thermoplastics are the only materials used in injection molding.False

While thermoplastics are common, thermosets and elastomers are also used for specific applications.

What are the Typical Application Scenarios for Mold Testing?

Mold testing is crucial in industries where precision, quality, and efficiency are paramount. It ensures that molds produce parts that meet specific requirements, reducing waste and downtime.

Mold testing is vital in automotive, medical, and consumer goods industries to ensure parts meet safety, precision, and aesthetic standards.

| Industry | Key Testing Focus | Notes |

|---|---|---|

| Automotive | Precision, durability, safety | High standards for fit and function |

| Medical | Cleanliness, dimensional accuracy | Compliance with regulatory standards |

| Consumer Goods | Aesthetics, cost-effectiveness | Focus on minimizing defects |

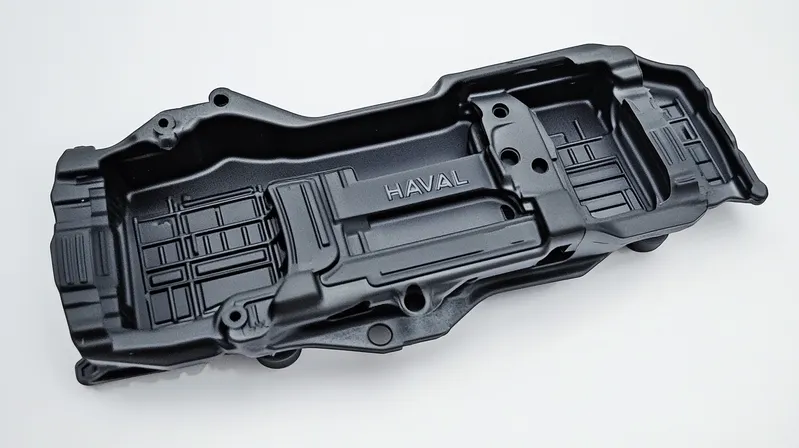

Automotive Industry

In the automotive sector, molds are used to produce complex parts like dashboards, bumpers, and engine components. Mold testing ensures these parts meet safety and performance standards, such as dimensional accuracy for proper fitment and durability under stress.

Medical Devices

For medical devices, mold testing is critical to ensure parts like syringes or surgical tools are sterile, precise, and free from defects. Compliance with FDA regulations often requires rigorous testing protocols.

Consumer Goods

In consumer goods, such as plastic toys or household items, mold testing focuses on aesthetics and efficiency. Testing helps eliminate defects like flash or sink marks, ensuring products are visually appealing and cost-effective to produce.

Mold testing is only necessary for complex parts.False

Even simple parts require testing to ensure quality and efficiency in production.

Mold testing reduces waste and downtime in production.True

By catching issues early, testing prevents defective parts and optimizes the molding process.

What are the Pros and Cons of Injection Molding Compared to Other Technologies?

Injection molding is a widely used manufacturing process, but it has its advantages and disadvantages compared to other technologies like 3D printing or CNC machining.

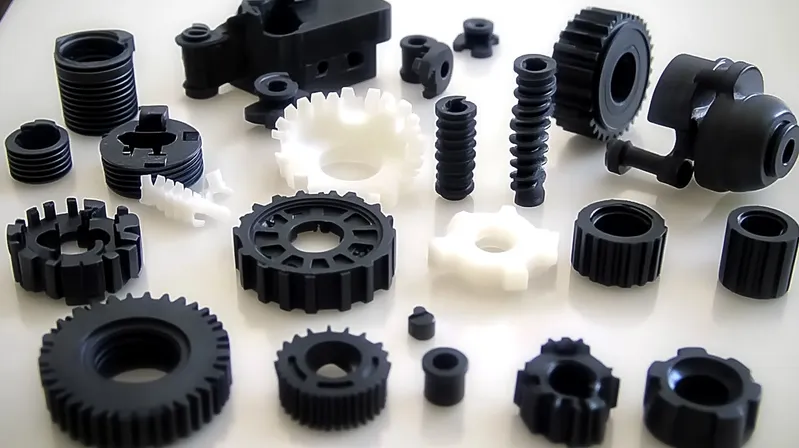

Injection molding is ideal for mass production of complex parts3 with high precision, but it requires high initial tooling costs4 and precise process control.

Pros of Injection Molding

-

High production rates, enabling mass production.

-

Precision for complex geometries, with tolerances as tight as ±0.01 mm.

-

Automation reduces labor costs.

-

Wide material versatility, supporting thermoplastics, thermosets, and elastomers.

Cons of Injection Molding

- High initial tooling costs, often tens of thousands of dollars for complex molds.

-

Requires precise process control to avoid defects like warping or short shots.

-

Material waste from runners in cold runner systems, though mitigated by hot runners.

Comparison with Other Technologies

-

Injection Molding vs. 3D Printing:

- Injection Molding: Better for mass production, higher initial cost but lower per-part cost.

- 3D Printing: Ideal for prototypes or low-volume production, more flexible but slower.

-

Injection Molding vs. CNC Machining:

- Injection Molding: Faster for large volumes, limited to moldable shapes.

- CNC Machining: Can produce complex shapes, but slower and more expensive for mass production.

| Technology | Best For | Precision | Speed | Cost |

|---|---|---|---|---|

| Injection Molding | Complex, precise parts | High | Fast | High initial, low per part |

| 3D Printing | Prototypes, low-volume | Moderate | Slow | High per part |

| CNC Machining | Complex shapes, small batches | High | Moderate | High |

Injection molding is always the most cost-effective option.False

For low-volume production, 3D printing or CNC machining may be more economical.

Injection molding offers the highest precision among manufacturing technologies.True

It can achieve tight tolerances, especially for complex geometries.

What are the Key Steps in the Mold Testing Workflow?

Mold testing follows a structured process to ensure efficiency and quality. Each step is crucial for identifying and resolving potential issues before full production.

The mold testing workflow5 includes inspection, machine setup, trial runs, parameter optimization, and quality control6, ensuring molds produce defect-free parts.

1. Mold Inspection

-

Check for damage, wear, or corrosion.

-

Verify dimensions and tolerances.

-

Ensure moving parts (e.g., slides, ejector pins) function smoothly.

2. Machine Setup

-

Install the mold on the injection molding machine.

-

Set initial parameters based on material and part requirements.

3. Trial Runs

-

Produce a small batch of parts.

-

Inspect parts for defects like short shots, flash, warping, or sink marks.

4. Parameter Optimization

-

Adjust injection speed, pressure, temperature, etc., based on trial results.

-

Use techniques like Design of Experiments (DOE)7 to find optimal settings.

5. Quality Control

-

Measure critical dimensions using tools like calipers or CMM.

-

Perform functional tests if applicable.

-

Document results for future reference.

Mold testing always results in perfect parts on the first trial.False

Multiple trials and adjustments are often needed to optimize the process.

Parameter optimization is crucial for achieving consistent part quality.True

Fine-tuning parameters ensures the process is stable and repeatable.

How Does Material Compatibility Affect Mold Testing?

Material compatibility is vital in mold testing, especially when dealing with different plastics or multi-material molding. Each material has unique properties that influence testing practices.

Material compatibility8 impacts mold design, processing conditions, and part quality, requiring specific testing approaches for different plastics.

Thermoplastics

-

Common materials like ABS, polypropylene, and polycarbonate have varying shrinkage rates (0.5-2%) and melt temperatures (e.g., ABS: 230-260°C; PP: 200-240°C).

-

Testing must account for these properties to prevent defects like warping or incomplete filling.

Thermosets

-

Materials like epoxy or phenolic require precise temperature control due to their irreversible curing process.

-

Overheating can damage the mold or part, making testing critical.

Elastomers

-

Flexible materials like rubber need special attention to mold release and dimensional stability.

-

Testing ensures the part maintains its shape and flexibility.

Multi-Material Molding

- In processes like overmolding, ensuring that different materials bond properly without delamination is crucial.

- Testing verifies material adhesion and compatibility.

| Material Type | Examples | Melt Temp (°C) | Shrinkage (%) | Key Testing Consideration |

|---|---|---|---|---|

| Thermoplastics9 | ABS, Polypropylene | 200-260 | 0.5-2.0 | Check for warping, ensure proper cooling |

| Thermosets | Epoxy, Phenolic | 150-200 | 0.1-0.5 | Control curing to avoid mold damage |

| Elastomers | Rubber, TPE | Varies | Varies | Verify mold release and flexibility |

All plastics can be tested using the same mold testing parameters.False

Different materials require specific temperature, pressure, and cooling settings.

Material compatibility is critical in multi-material molding.True

Incompatible materials can lead to poor bonding or part failure.

What are the Practical Tools for Effective Mold Testing?

Practical tools like checklists and decision-making guides enhance the operability of mold testing, ensuring no critical aspect is overlooked.

A design checklist and process selection decision tree help streamline mold testing and ensure consistent quality.

Design Checklist

A comprehensive checklist ensures thorough evaluation:

-

Mold is clean and free from debris.

-

All moving parts function smoothly.

-

Cooling channels are clear and functional.

-

Ejection system operates correctly.

-

Initial molding parameters are set according to material guidelines.

-

Trial parts meet dimensional tolerances.

-

No visible defects on trial parts.

-

Process is stable and repeatable.

Process Selection Decision Tree

Choosing injection molding and its testing practices depends on several factors:

-

Part Complexity: Is the part complex with tight tolerances? (Yes → Injection Molding)

-

Production Volume: Is high-volume production needed? (Yes → Injection Molding)

-

Material Needs: Does the part require specific plastics or multi-material capabilities? (Yes → Injection Molding)

-

Cost Constraints: Can you afford high initial tooling costs? (Yes → Injection Molding)

A checklist is unnecessary for experienced mold testers.False

Even experienced professionals benefit from a checklist to ensure consistency.

Injection molding is always the best choice for plastic parts.False

For low-volume or highly customized parts, other methods like 3D printing may be more suitable.

Mold testing is part of a broader ecosystem of technologies that support efficient injection molding, from design to quality control.

Related technologies include CAD software for mold design, simulation tools for predicting mold behavior, and automated inspection systems for quality control.

Upstream Technologies

-

CAD Software: Tools like SolidWorks or AutoCAD for designing molds Learn more about CAD tools.

-

Mold Flow Analysis Software: Simulates material flow, cooling, and shrinkage to optimize mold design Explore mold simulation.

Downstream Technologies

-

Quality Control Systems: Coordinate Measuring Machines (CMM) or vision systems for part inspection Discover QC tools.

-

Post-Processing: Trimming, deburring, or surface finishing to finalize parts Learn about post-processing.

Mold flow analysis can eliminate the need for physical mold testing.False

While helpful, simulations cannot fully replace physical testing due to real-world variables.

Automated inspection systems improve consistency in quality control.True

Automation reduces human error and ensures consistent measurement of part dimensions.

Conclusion

Mold testing is an indispensable part of the injection molding process, ensuring that molds produce high-quality parts efficiently. By following the top practices outlined in this guide—from thorough inspections and trial runs to parameter optimization and quality control—manufacturers can minimize defects, reduce costs, and maintain consistent production quality. Whether you’re working with simple consumer goods or complex automotive components, investing time in proper mold testing will pay dividends in the long run.

-

Understanding mold testing practices is crucial for ensuring high-quality production and minimizing defects in manufacturing processes. ↩

-

Exploring injection molding will provide insights into its efficiency and precision in producing plastic parts, essential for modern manufacturing. ↩

-

Learn about the techniques and technologies that enable efficient mass production of intricate components, enhancing your knowledge. ↩

-

This link will provide insights into the financial implications of tooling costs in manufacturing, crucial for decision-making. ↩

-

Understanding the mold testing workflow is essential for ensuring quality and efficiency in production processes. Explore this link to learn more. ↩

-

Quality control is vital for maintaining product standards. Learn about best practices to ensure defect-free production by checking this link. ↩

-

Design of Experiments (DOE) is a powerful tool for optimizing processes. Discover how it can enhance your production efficiency by exploring this resource. ↩

-

Understanding material compatibility is crucial for effective mold testing and ensuring high-quality parts. Explore this link for in-depth insights. ↩

-

Learn about the unique properties of thermoplastics and their impact on mold design and testing practices. This resource will enhance your knowledge. ↩