Injection molding is a versatile manufacturing process, but part weight can be a significant concern, especially in industries like automotive and aerospace where every gram counts. Reducing part weight can lead to cost savings, improved performance, and environmental benefits. In this blog, we’ll explore the most effective ways to achieve this, from design tweaks to advanced techniques.

Reducing part weight in injection molding can be achieved through design optimization, material selection, and advanced techniques like gas-assisted molding1, which are crucial for industries prioritizing lightweight components.

Understanding these methods is essential for manufacturers looking to enhance efficiency and meet industry demands. Delve deeper to explore how each approach can be applied to your specific needs.

Design optimization is the simplest way to reduce part weight.True

By making walls thinner and using ribs, significant weight reduction can be achieved without major changes to the manufacturing process.

Gas-assisted injection molding is only suitable for large parts.False

While often used for large parts, gas-assisted molding can also be applied to smaller components with complex geometries.

- 1. What is Injection Molding and Why is Part Weight Reduction Important?

- 2. How Can Design Optimization Reduce Part Weight in Injection Molding?

- 3. What Materials Are Best for Reducing Part Weight in Injection Molding?

- 4. What Advanced Techniques Can Be Used to Reduce Part Weight?

- 5. How Do Process Parameter Adjustments Affect Part Weight?

- 6. What Are the Pros and Cons of Different Weight Reduction Methods?

- 7. How to Choose the Right Weight Reduction Method for Your Application?

- 8. What Are the Steps in Gas-Assisted Injection Molding for Weight Reduction?

- 9. What Are the Best Practices for Designing Lightweight Injection-Molded Parts?

- 10. Conclusion

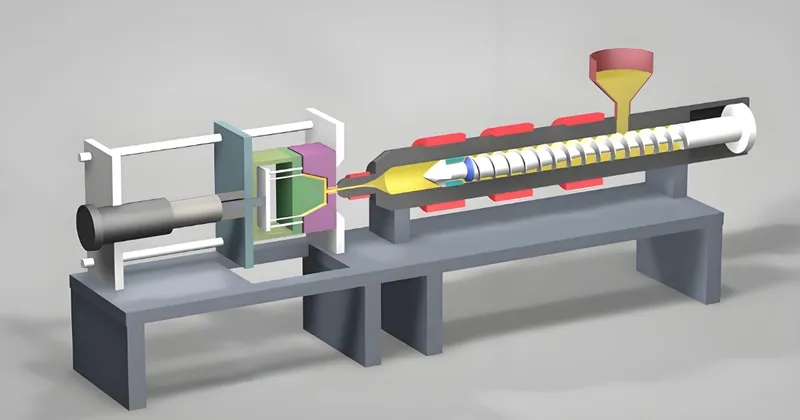

What is Injection Molding and Why is Part Weight Reduction Important?

Injection molding is a widely used manufacturing process, but reducing part weight is critical for enhancing product performance and sustainability.

Injection molding involves injecting molten plastic into a mold to create precise parts, while part weight reduction2 focuses on decreasing mass without compromising functionality, crucial for cost savings and efficiency.

| Concept | Definition |

|---|---|

| Injection Molding | A process where molten plastic is injected into a mold to form parts. |

| Part Weight Reduction | Decreasing the mass of a part while maintaining its required properties. |

What is Injection Molding?

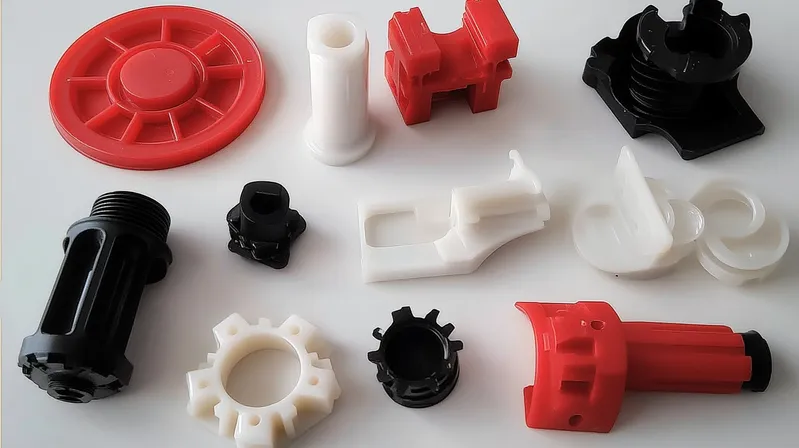

Injection molding is a manufacturing process where molten plastic is injected into a mold to create parts with precise shapes and sizes. It’s widely used for mass production due to its efficiency and repeatability, making it ideal for industries like automotive, consumer electronics, and packaging.

What is Part Weight Reduction?

Part weight reduction involves decreasing the mass of an injection-molded part while maintaining its required mechanical properties, functionality, and aesthetic quality. This is achieved through various methods, including design optimization3, material selection, and advanced molding techniques.

Injection molding is only used for small parts.False

Injection molding can produce parts of various sizes, from tiny components to large automotive parts.

Part weight reduction always compromises part strength.False

With proper design and material selection, weight can be reduced without sacrificing strength.

How Can Design Optimization Reduce Part Weight in Injection Molding?

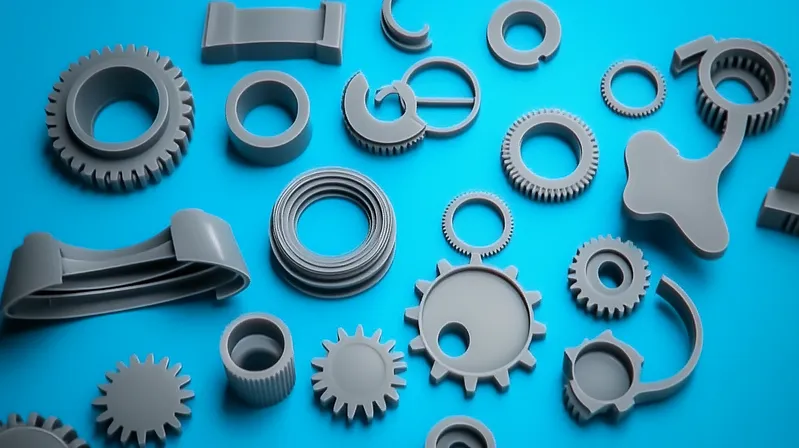

Design optimization is a straightforward yet powerful method to reduce part weight in injection molding, focusing on structural efficiency and material usage.

Design optimization reduces part weight by thinning walls, using ribs for strength, and creating hollow sections4, which is effective across various industries but requires careful analysis.

Thinning Walls and Using Ribs

One of the simplest ways to reduce weight is to make the part’s walls thinner. However, this must be balanced with the part’s structural requirements. Adding ribs can provide the necessary strength without adding significant weight, allowing for thinner walls while maintaining functionality.

Creating Hollow Sections

Designing parts with hollow sections or using techniques like gas-assisted molding to create internal voids can significantly reduce weight. This is particularly useful for larger parts where material savings are substantial.

Part Consolidation

Combining multiple parts into a single component can reduce overall material usage and assembly complexity, leading to lighter and more efficient designs.

Thinning walls always leads to weaker parts.False

When combined with ribs or other reinforcements, thinning walls can maintain or even improve part strength.

Design optimization is cost-effective for existing designs.True

It often requires minimal changes to tooling and can be implemented without significant investment.

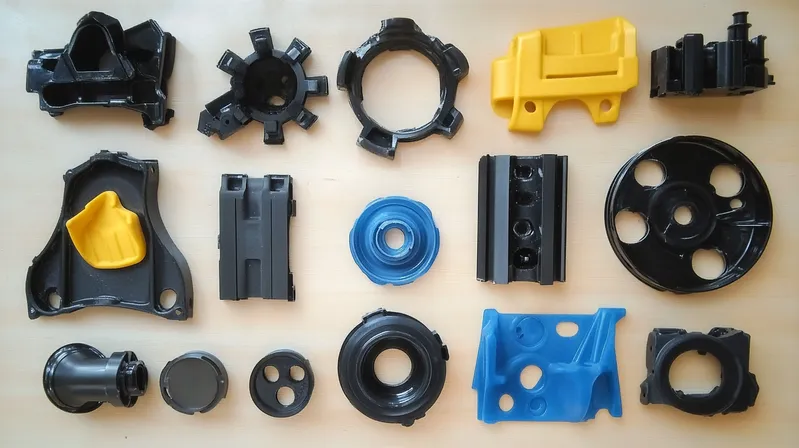

What Materials Are Best for Reducing Part Weight in Injection Molding?

Material selection plays a crucial role in reducing part weight, with certain plastics offering high strength-to-weight ratios ideal for lightweight applications.

High-strength plastics5 like PEEK, PP, and composites are best for reducing part weight, offering significant weight savings but may increase costs or require testing.

| Material Type | Density (g/cm³) | Notes |

|---|---|---|

| Polypropylene (PP) | 0.90 – 0.92 | Lightweight, cost-effective |

| Polyetheretherketone (PEEK) | 1.30 – 1.32 | High strength, heat-resistant |

| Carbon Fiber Composites6 | Varies | Extremely lightweight, strong |

High-Strength Plastics

Materials like polyetheretherketone (PEEK)7 and polypropylene (PP) offer excellent strength-to-weight ratios, making them ideal for weight-sensitive applications. PEEK, for example, is used in aerospace for its lightweight and high-performance properties.

Composites

Incorporating composites, such as carbon fiber-reinforced plastics8, can further reduce weight while enhancing strength. These materials are particularly useful in high-performance applications but may require specialized processing.

Metal-to-Plastic Conversions

Replacing metal parts with plastic ones can lead to significant weight reduction. Plastics are generally lighter than metals and can be engineered to meet similar performance requirements, especially in non-load-bearing applications.

High-strength plastics are always more expensive.False

While some advanced materials are costly, others like PP are affordable and effective for weight reduction.

Composites are only used in aerospace applications.False

Composites are also used in automotive, sports equipment, and consumer goods for their lightweight properties.

What Advanced Techniques Can Be Used to Reduce Part Weight?

Advanced techniques like gas-assisted injection molding9 and microcellular foaming offer innovative ways to reduce part weight while maintaining or improving part quality.

Gas-assisted injection molding and microcellular foaming10 are advanced techniques that reduce part weight by creating hollow sections or cellular structures, ideal for complex or large parts but may require specialized equipment.

Gas-Assisted Injection Molding

This technique involves injecting nitrogen gas into the mold after the plastic, creating hollow sections within the part. It reduces material usage and weight while improving dimensional stability and surface finish.

Microcellular Foaming

Microcellular foaming introduces tiny gas bubbles into the plastic, reducing density without compromising mechanical properties. This process is environmentally friendly and can shorten cycle times.

Structural Foam Molding

Similar to microcellular foaming, structural foam molding creates a foam core within the part, reducing weight and improving rigidity. It’s particularly useful for large, thick-walled parts.

Gas-assisted molding always results in better surface finish.True

The gas pressure helps eliminate sink marks and improves surface quality.

Microcellular foaming is only suitable for small parts.False

It can be applied to parts of various sizes, depending on the equipment and process parameters.

How Do Process Parameter Adjustments Affect Part Weight?

Adjusting process parameters like injection speed, pressure, and temperature can lead to minor weight reductions without changing the part design or material.

Process parameter adjustments11 can reduce part weight by optimizing material flow and packing, but the impact is limited compared to design or material changes.

Optimizing Injection Speed and Pressure

By fine-tuning injection speed and pressure, manufacturers can reduce the amount of material used while ensuring complete mold filling. This can lead to slight weight reductions, especially in thin-walled parts.

Temperature Control

Controlling the mold and melt temperatures can influence material density and flow, potentially allowing for lighter parts. However, this method requires precise control and may not yield significant weight savings.

Process parameter adjustments can achieve the same weight reduction as design changes.False

While helpful, parameter adjustments typically offer smaller weight reductions compared to design or material optimizations.

Temperature control is crucial for reducing part weight.True

Proper temperature management ensures optimal material flow and can contribute to weight savings.

What Are the Pros and Cons of Different Weight Reduction Methods?

Understanding the advantages and disadvantages of each weight reduction method12 is essential for selecting the right approach for your application.

Each weight reduction method has unique pros and cons, from cost-effectiveness and simplicity to the need for specialized equipment and expertise.

| Method | Pros | Cons |

|---|---|---|

| Design Optimization | – Simple and widely applicable – Significant weight reduction possible – Cost-effective |

– May require redesign – Could affect part strength – Needs careful analysis |

| Material Selection | – Significant weight reduction – Improved properties possible – Enables metal-to-plastic conversions |

– Material properties might not meet requirements – Higher cost for advanced materials – Requires testing |

| Process Parameter Adjustment | – Can be done without changing design or material – Cost-effective for minor adjustments |

– May not lead to substantial weight reduction – Requires precise control |

| Gas-Assisted Injection Molding | – Reduced weight through hollow sections – Improved dimensional stability and surface finish |

– Higher setup costs – Requires specialized expertise |

| Microcellular Foaming Processes | – Reduces density without mechanical property loss – Environmentally friendly |

– Requires modified tooling and equipment – May have limitations on part design |

| Metal-to-Plastic Conversions | – Significant weight reduction – Potential cost savings in production |

– Design and process implications – Not suitable for high-load applications |

Design optimization is always the best method for weight reduction.False

The best method depends on the specific application, part complexity, and industry requirements.

Advanced techniques like gas-assisted molding are too expensive for most manufacturers.False

While initial costs are higher, the long-term benefits in weight reduction and part quality can justify the investment.

How to Choose the Right Weight Reduction Method for Your Application?

Selecting the appropriate weight reduction method requires considering factors like part complexity, industry requirements, and cost constraints.

Choose the right weight reduction method by evaluating part size, complexity, cosmetic requirements, and budget, using a decision-making framework.

Decision-Making Framework

-

Is the part large or complex? If yes, consider gas-assisted molding for significant weight reduction and improved finish.

-

Does the part require high cosmetic quality? If yes, gas-assisted molding or microcellular foaming may be suitable.

-

Are cost constraints tight? If yes, prioritize design optimization and process parameter adjustments.

All weight reduction methods are equally effective.False

Each method has its strengths and is suited to different applications and constraints.

A decision-making framework can simplify the selection process.True

By considering key factors, manufacturers can quickly identify the most appropriate method.

What Are the Steps in Gas-Assisted Injection Molding for Weight Reduction?

Gas-assisted injection molding is a powerful technique for reducing part weight, particularly for large or complex components.

Gas-assisted injection molding reduces part weight by injecting gas to create hollow sections, involving steps like partial plastic injection, gas injection, pressure holding, and venting.

Process Workflow

-

Inject Molten Plastic: A short shot of molten plastic (typically 70-80% of the mold volume) is injected.

-

Inject Gas: Pressurized nitrogen gas is injected through channels, creating hollow sections and reducing material density.

-

Hold Gas Pressure: The gas pressure is maintained during cooling to ensure dimensional stability.

-

Venting and Ejection: After the part solidifies, the gas is vented, and the part is ejected.

Key parameters include gas pressure, injection speed, and mold temperature, which must be optimized to prevent defects.

Gas-assisted molding always requires specialized molds.True

Molds must be designed with gas channels to accommodate the process.

This technique can be used with any plastic material.False

Material compatibility is crucial; materials like PA6, PA66, and PP are commonly used.

What Are the Best Practices for Designing Lightweight Injection-Molded Parts?

Designing lightweight parts13 requires a strategic approach, focusing on structural efficiency and material usage.

Best practices for designing lightweight parts include minimizing wall thickness, using ribs, selecting appropriate materials, and considering manufacturing constraints.

Design Checklist

-

Minimize Wall Thickness: Use the thinnest possible walls while ensuring structural integrity.

-

Optimize Shape: Use ribs and gussets for strength and avoid unnecessary material.

-

Material Selection: Choose materials with high strength-to-weight ratios.

-

Hollow Sections: Design parts with hollow sections or use gas-assisted molding.

-

Part Consolidation: Combine multiple parts into a single component to reduce material usage.

-

Manufacturing Constraints: Account for injection molding limitations like draft angles and gate locations.

Thinner walls always lead to faster cycle times.True

Thinner parts cool faster, reducing cycle times and increasing production efficiency.

Part consolidation is only beneficial for weight reduction.False

It also reduces assembly time and complexity, leading to cost savings.

Conclusion

Reducing part weight in injection molding is a multifaceted challenge that requires a strategic approach. By understanding the various methods—design optimization, material selection, advanced techniques, and process adjustments—you can choose the best strategy for your application. Whether you’re in automotive, aerospace, or consumer electronics, these techniques can help you achieve lighter, more efficient parts. Explore the links provided to delve deeper into each method and start optimizing your injection molding processes today.

-

Discover the benefits of gas-assisted molding in reducing part weight and improving manufacturing efficiency in various industries. ↩

-

Explore effective strategies for reducing part weight in injection molding, enhancing performance and sustainability in manufacturing. ↩

-

Learn how design optimization can significantly improve injection molding processes and reduce costs while maintaining quality. ↩

-

Discover the advantages of hollow sections in injection molding, including significant weight reduction and material savings for larger parts. ↩

-

Learn about high-strength plastics like PEEK and PP, which are crucial for achieving lightweight designs without compromising strength. ↩

-

Discover how composites, such as carbon fiber, can significantly lower weight while maintaining strength in various applications. ↩

-

Explore the unique properties of PEEK and its critical role in aerospace applications, enhancing performance and reducing weight. ↩

-

Explore the advantages of carbon fiber-reinforced plastics, including weight reduction and enhanced strength, for high-performance applications. ↩

-

Learn about gas-assisted injection molding, a technique that reduces weight and improves part quality, ideal for complex designs. ↩

-

Discover how microcellular foaming creates lightweight, strong plastic parts while being environmentally friendly and efficient. ↩

-

Explore how adjusting process parameters can optimize production efficiency and reduce material usage effectively. ↩

-

Discover various weight reduction methods and their pros and cons to make informed decisions for your projects. ↩

-

Discover effective strategies for designing lightweight parts that maintain structural integrity while reducing material costs. ↩