Injection molded electronic casings1 are plastic housings that protect and support electronic components in devices like smartphones, laptops, and industrial control panels. They are created by injecting molten plastic into a mold, which cools to form precise, durable shapes. These casings must meet strict standards for quality, functionality, and aesthetics to ensure reliability and performance.

Injection molding creates precise, durable plastic casings for electronics, balancing cost, strength, and design flexibility for industries like consumer electronics and automotive.

Understanding the standards and best practices for injection molded electronic casings2 is crucial for designers and manufacturers aiming to produce high-quality products. This guide explores the essential aspects, from material selection to design considerations, helping you make informed decisions for your projects.

Injection molding is the most cost-effective method for producing electronic casings.True

For large production runs, injection molding reduces per-unit costs significantly due to economies of scale.

Injection molded casings can be used in all electronic devices without limitations.False

While versatile, injection molded casings may not be suitable for extremely high-temperature or specialized applications requiring unique materials.

- 1. What Are Injection Molded Electronic Casings?

- 2. What Are the Typical Applications of Injection Molded Electronic Casings?

- 3. What Are the Key Steps in the Injection Molding Process for Electronic Casings?

- 4. How Do Different Materials Affect Injection Molded Casings?

- 5. What Are the Design Considerations for Injection Molded Electronic Casings?

- 6. How Do You Choose Between Injection Molding and Other Technologies?

- 7. What Are the Quality Standards for Injection Molded Electronic Casings?

- 8. What Are the Related Technologies for Injection Molded Casings?

- 9. Conclusion

What Are Injection Molded Electronic Casings?

Injection molded electronic casings are protective enclosures made from plastic, designed to house electronic components. These casings are produced using injection molding, a process where molten plastic is injected into a mold cavity, cooled, and ejected as a solid part. Common aliases include housings, enclosures, or shells. The core principle involves precise control over temperature, pressure, and cooling to achieve the desired shape and properties.

Classification of Injection Molded Casings

-

By Process:

-

Single-Cavity Molds: Used for prototypes or low-volume production.

-

Multi-Cavity Molds: Ideal for mass production, increasing efficiency.

-

Gas-Assisted Injection Molding3: Creates hollow sections for lightweight parts.

-

-

By Materials:

- ABS (Acrylonitrile Butadiene Styrene)4: Cost-effective, durable, moderate heat resistance.

-

Polycarbonate (PC): High impact resistance, transparent options.

-

HDPE (High-Density Polyethylene): Chemical-resistant, low moisture absorption.

-

Polyphthalamide (PPA): High strength for harsh environments.

-

By Applications:

-

Consumer Electronics: Smartphones, laptops, wearables.

-

Industrial Equipment: Control panels, sensors.

-

Automotive Electronics: Dashboards, infotainment systems.

-

- Medical Devices: Diagnostic tools, portable monitors.

-

By Surface Class:

-

Class A: Flawless, high-aesthetic surfaces (e.g., phone exteriors).

-

Class B: Less visible areas (e.g., device sides).

-

Class C: Non-visible, functional surfaces (e.g., internal mounts).

-

ABS is the most commonly used material for electronic casings.True

ABS is favored for its balance of cost, durability, and ease of processing.

All injection molded casings require the same surface finish standards.False

Surface finish standards vary based on the part’s visibility and functional requirements.

What Are the Typical Applications of Injection Molded Electronic Casings?

Injection molded casings5 are essential across various industries, offering protection, durability6, and design flexibility.

Injection molded casings are used in consumer electronics, industrial equipment, automotive, and medical devices for their precision, durability, and cost-effectiveness.

| Industry | Application Examples | Key Requirements |

|---|---|---|

| Consumer Electronics | Smartphones, laptops, wearables | Aesthetics, lightweight, precision |

| Industrial Equipment | Control panels, sensors, IoT devices | Durability, heat resistance |

| Automotive Electronics | Dashboards, infotainment systems | Impact resistance, thermal stability |

| Medical Devices | Diagnostic tools, portable monitors | Biocompatibility, precision |

Consumer Electronics

In consumer electronics, casings must be lightweight, visually appealing, and precise to ensure a snug fit for components. For example, smartphone casings require tight tolerances and high-quality surface finishes to meet user expectations.

Industrial Equipment

Industrial casings need to withstand harsh environments, including exposure to chemicals, heat, and mechanical stress. These casings often prioritize functionality over aesthetics, focusing on durability and reliability.

Automotive Electronics

Automotive casings must endure vibrations, temperature fluctuations, and impacts. Materials like polycarbonate are chosen for their strength and stability in these conditions.

Medical Devices

Medical casings require biocompatible materials and precise dimensions to ensure safety and functionality. These casings often undergo additional sterilization processes.

Injection molded casings are only used in consumer electronics.False

They are widely used across industries, including automotive, industrial, and medical sectors.

Material selection is crucial for meeting application-specific requirements.True

Different industries demand unique properties like heat resistance, impact strength, or biocompatibility.

What Are the Key Steps in the Injection Molding Process for Electronic Casings?

The injection molding process for electronic casings involves several critical steps to ensure precision, quality, and functionality.

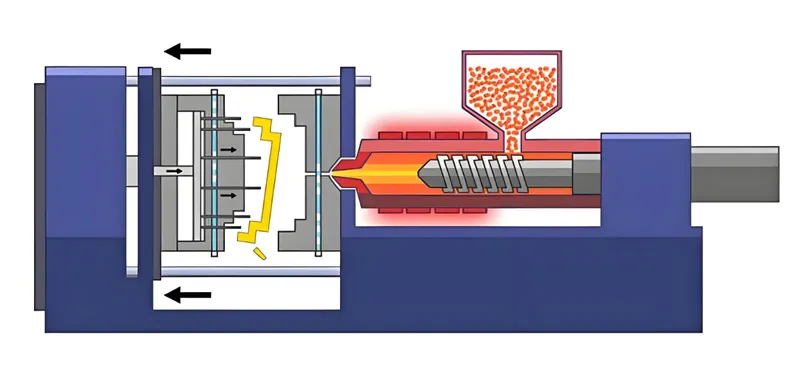

The process includes design, mold creation, material selection7, injection, cooling, ejection, and finishing, with careful control of temperature, pressure, and cooling time.

1. Design

Create a 3D model of the casing, incorporating features like ribs for strength, bosses for mounting, and considerations for thermal management and electromagnetic interference (EMI) shielding.

2. Mold Design and Creation

Develop a mold with precise cavities, cooling channels, and ejector systems. Simulation tools like Moldflow optimize the design to prevent defects.

3. Material Selection

Choose a plastic based on the application’s requirements:

-

ABS: General-purpose, cost-effective.

-

Polycarbonate: High strength, transparency.

-

HDPE: Chemical resistance.

-

PPA: High-performance for extreme conditions.

4. Injection

Melt the plastic and inject it into the mold at controlled temperature (e.g., 200–250°C for ABS), pressure (100–150 MPa), and speed.

5. Cooling

Allow the part to cool in the mold (typically 10–30 seconds) to solidify without warping.

6. Ejection

Remove the part from the mold using ejector pins, ensuring no damage to the surface.

7. Finishing

Apply post-processing like trimming, painting, or polishing to meet surface finish standards.

Key Parameters:

-

Temperature: Affects plastic flow and cooling.

-

Pressure: Ensures complete mold filling.

-

Cooling Time: Balances cycle time and part quality.

-

Injection Speed: Influences surface finish and defect rates.

Cooling time is the most critical factor in injection molding.False

While important, temperature, pressure, and material selection are equally crucial.

Proper mold design reduces defects and improves efficiency.True

Optimized molds minimize issues like warping and sink marks, enhancing production speed.

How Do Different Materials Affect Injection Molded Casings?

Material choice significantly impacts the performance, cost, and manufacturability of electronic casings.

Materials like ABS, polycarbonate, HDPE, and PPA8 offer varying levels of strength, heat resistance, and cost, influencing the casing’s suitability for different applications.

| Material | Strength | Temperature Resistance | Cost | Key Features |

|---|---|---|---|---|

| ABS | High | Moderate | Low | Durable, cost-effective, general-purpose. |

| Polycarbonate] | Very High | High | Moderate | Impact-resistant, transparent, stable. |

| HDPE | Moderate | Very High | Low | Chemical-resistant, low moisture absorption. |

| PPA | Very High | Very High | High | Electrically resistant, durable in harsh conditions. |

Material Properties and Impact

-

ABS: Widely used for its balance of cost and performance. It offers good impact resistance but may not withstand extreme temperatures.

-

Polycarbonate9: Ideal for applications requiring transparency or high impact resistance, such as protective covers or rugged devices.

-

HDPE: Best for environments with chemical exposure or moisture, though less common for aesthetic parts due to its opaque nature.

-

PPA: Used in high-performance applications like automotive or aerospace, where strength and heat resistance are paramount.

Each material also affects shrinkage rates (e.g., ABS: 0.4–0.9%), requiring adjustments in mold design to maintain dimensional accuracy.

Polycarbonate is always the best choice for electronic casings.False

While strong, it’s more expensive and not necessary for all applications.

Material selection impacts both performance and manufacturing costs.True

Choosing the right material ensures the casing meets functional requirements while staying within budget.

What Are the Design Considerations for Injection Molded Electronic Casings?

Designing injection molded casings requires attention to detail to ensure manufacturability, functionality, and aesthetics.

Key design considerations include uniform wall thickness10, draft angles11, tolerances12, and surface finish, all of which affect the part’s quality and production efficiency.

Design Checklist

-

Uniform Wall Thickness: Maintain consistent thickness (e.g., 1.14–3.56 mm for ABS) to prevent warping and sink marks.

-

Draft Angles: Include angles (0.5–2°) to facilitate easy ejection from the mold.

-

Tolerances: Specify tight tolerances (e.g., ±0.05 mm for small parts) for precise fits.

-

Surface Finish: Define finish levels (e.g., SPI-C1 for Class A surfaces) to meet aesthetic or functional needs.

-

Ribs and Bosses: Add ribs (50–60% of wall thickness) for strength and bosses for mounting components.

-

Thermal Management: Incorporate vents or heat sinks for heat dissipation.

- EMI Shielding: Use coatings or inserts to block electromagnetic interference.

Common Design Challenges

-

Undercuts: Minimize or use side actions to avoid complex mold designs.

-

Shrinkage: Account for material-specific shrinkage rates to maintain dimensions.

-

Defects: Prevent issues like sink marks, flash, or warping through careful design and process control.

Uniform wall thickness is crucial for preventing defects.True

Inconsistent thickness can lead to warping, sink marks, and uneven cooling.

All electronic casings require the same design considerations.False

Design requirements vary based on the application, material, and production volume.

How Do You Choose Between Injection Molding and Other Technologies?

Selecting the right manufacturing process depends on factors like production volume, complexity, and cost.

Injection molding is ideal for high-volume production of complex parts, while alternatives like 3D printing or CNC machining are better for prototypes or low-volume runs.

| Criteria | Injection Molding | 3D Printing | CNC Machining |

|---|---|---|---|

| Production Volume | High | Low to Medium | Low to Medium |

| Complexity | High | Very High | Moderate |

| Material Options | Wide | Limited | Wide |

| Cost per Unit | Low (after tooling) | High | High |

| Lead Time | Longer (tooling) | Short | Moderate |

Decision-Making Guide

- Assess Volume: For large quantities (>1,000 units), injection molding is cost-effective.

-

Evaluate Complexity: Injection molding handles intricate designs with ease, while 3D printing excels for highly complex prototypes.

-

Consider Budget: High upfront costs for molds make injection molding suitable for projects with long-term production plans.

-

Check Material Needs: If specific materials are required, ensure the process supports them.

Injection molding is always the best choice for electronic casings.False

For small runs or rapid prototyping, 3D printing or CNC machining may be more suitable.

Injection molding reduces per-unit costs in large production runs.True

The initial mold cost is offset by low per-unit costs in mass production.

What Are the Quality Standards for Injection Molded Electronic Casings?

Quality standards ensure that injection molded casings meet functional, aesthetic, and reliability requirements.

Key quality standards include surface finish grades, dimensional tolerances, and defect limits, varying by the part’s visibility and function.

Surface Finish Standards

-

Class A Surfaces: No visible defects, high gloss or matte finishes (e.g., smartphone exteriors).

-

Class B Surfaces: Minor defects allowed, less visible areas (e.g., device sides).

-

Class C Surfaces: Functional surfaces with no aesthetic requirements (e.g., internal components).

Defect Acceptance Criteria

| Defect Type | Class A | Class B | Class C |

|---|---|---|---|

| Cracks | Not allowed | Not allowed | Allowed if no functional impact |

| Sink Marks | No visible depressions | No visible depressions | Minor, no impact |

| Scratches | ≤8 mm, ≤0.05 mm wide | ≤10 mm, ≤0.1 mm wide | ≤2.5 mm, ≤0.15 mm wide |

| Ejector Marks | Not allowed | Not allowed | Acceptable if no visual impact |

Dimensional Tolerances

- Small Parts (0–10 mm): ±0.05 mm

-

Medium Parts (10–200 mm): ±0.15 mm

-

Large Parts (>200 mm): ±0.25 mm

Inspection involves visual checks under controlled lighting and precise measurement tools to ensure compliance.

Class A surfaces require the highest quality standards.True

These surfaces are highly visible and must be defect-free.

All defects are unacceptable in injection molded casings.False

Acceptance depends on the defect type and the surface class.

Injection molding is part of a broader manufacturing ecosystem, with upstream and downstream technologies enhancing its capabilities.

Related technologies include material science, mold design software, assembly methods, and finishing techniques, all contributing to the final product’s quality.

Upstream Technologies

-

Material Science: Development of advanced plastics like flame-retardant or recycled polymers.

-

Mold Design Software: Tools like Moldflow simulate and optimize mold designs.

Downstream Technologies

- Assembly Methods: Snap fits, ultrasonic welding, or adhesives for joining parts.

- Finishing Techniques: Painting, laser engraving, or pad printing for branding and aesthetics.

Related Processes

-

CNC Machining: Used for creating precise molds or post-processing parts.

-

Additive Manufacturing: Ideal for prototyping or producing complex mold inserts.

-

IoT and Automation: Enhances process monitoring and quality control.

Advancements in material science can improve casing performance.True

New materials offer better strength, heat resistance, or sustainability.

Injection molding is a standalone process without related technologies.False

It integrates with various upstream and downstream technologies for optimal results.

Conclusion

Injection molded electronic casings are vital for protecting and enhancing electronic devices across industries. By understanding the key standards—from material selection and design considerations to quality control and related technologies—manufacturers can produce high-quality, reliable products. Whether for consumer electronics or industrial applications, adhering to these standards ensures that casings meet both functional and aesthetic demands.

-

Explore this link to understand the advantages and applications of injection molded electronic casings in various industries. ↩

-

Discover essential guidelines and practices to ensure high-quality production of electronic casings. ↩

-

Discover the innovative process of gas-assisted injection molding and how it enhances product design and efficiency. ↩

-

Learn about ABS plastic’s unique properties and why it’s a popular choice in manufacturing electronic casings. ↩

-

Explore the advantages of injection molded casings to understand their impact on product design and functionality across industries. ↩

-

Discover how durability influences the reliability and longevity of industrial equipment in demanding environments. ↩

-

Choosing the right material is vital for the performance of electronic casings. This resource will guide you through the selection process. ↩

-

Discover how PPA’s unique properties make it ideal for demanding environments like automotive and aerospace. ↩

-

Learn why polycarbonate is favored for its strength and transparency, crucial for protective applications. ↩

-

Understanding uniform wall thickness is crucial for preventing warping and ensuring quality in injection molded parts. ↩

-

Exploring draft angles can help you learn how to design parts that are easier to eject from molds, improving efficiency. ↩

-

Learning about tolerances will enhance your ability to create precise fits, which is essential for functional designs. ↩