Mold design is a critical process in manufacturing that shapes materials like plastics, metals, or glass into precise parts used across industries such as automotive, medical, and consumer goods. A well-designed mold ensures high-quality parts1, reduces waste, and speeds up production, while a poorly designed one can lead to defects, delays, and increased costs.

Mold design involves creating tools that shape materials into precise parts, essential for industries like automotive and medical, where quality and efficiency are paramount.

Understanding the essentials of mold design2 is key to leveraging its benefits for your projects. Explore the following sections to learn about the components, materials, processes, and challenges involved in effective mold design.

Mold design is essential for high-volume production.True

Mold design enables efficient, consistent production of large quantities of parts, making it ideal for industries requiring mass production.

Mold design is only used in the plastics industry.False

While common in plastics, mold design is also crucial for metals, glass, and other materials in various industries.

- 1. What are the Key Components of a Mold?

- 2. What Materials are Commonly Used in Mold Design?

- 3. What is the Mold Design Process?

- 4. What are the Common Challenges in Mold Design?

- 5. What are the Applications of Mold Design?

- 6. How Does Mold Design Differ from Other Manufacturing Processes?

- 7. Conclusion

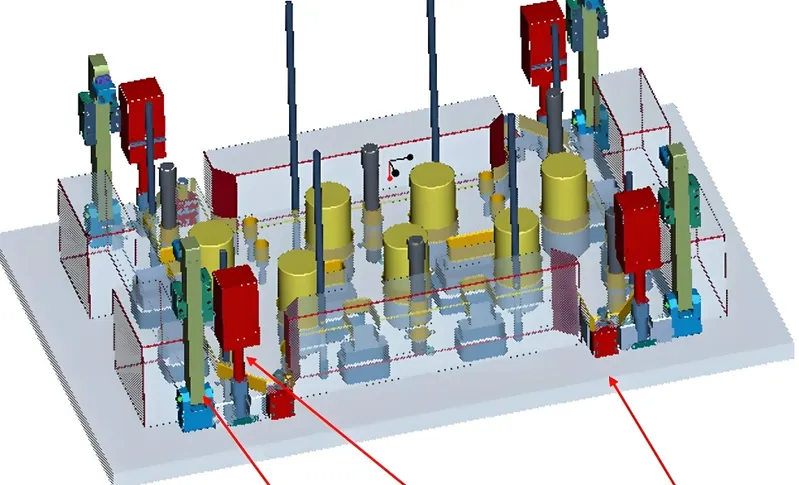

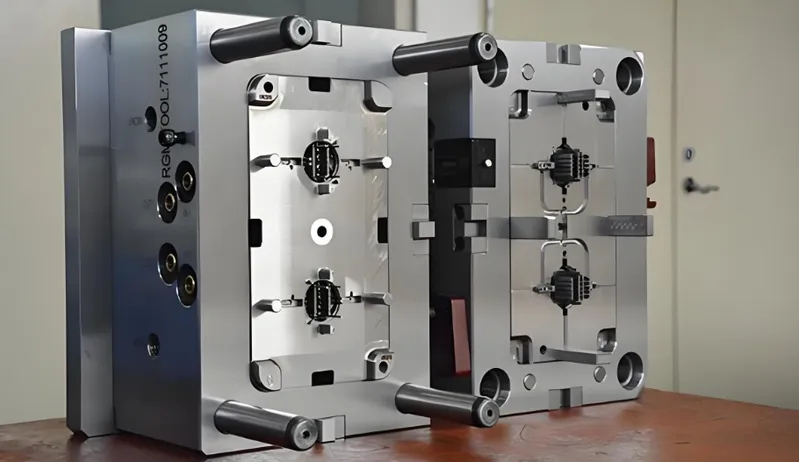

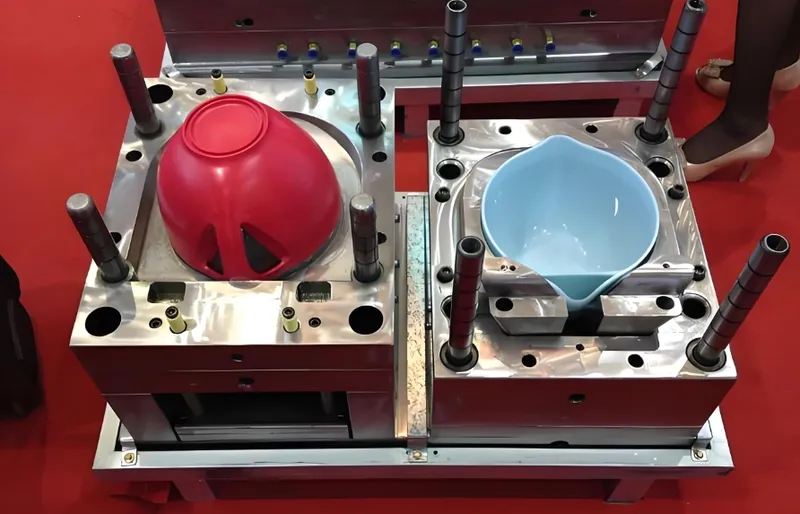

What are the Key Components of a Mold?

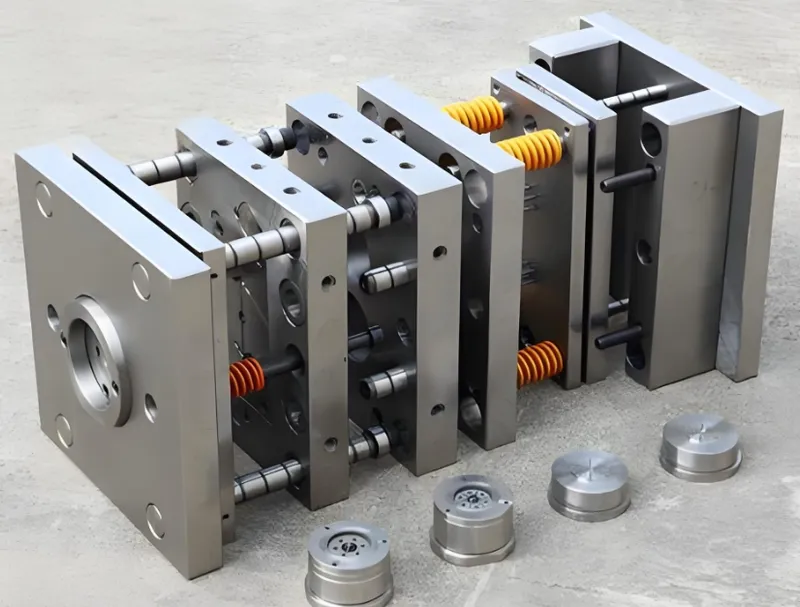

Molds are complex tools made up of several critical components that work together to shape materials accurately and efficiently.

Key mold components include the core and cavity3 for shaping, cooling channels4 for temperature control, ejection system5s for part removal, and gates/runners for material flow.

| Component | Function | Notes |

|---|---|---|

| Core and Cavity | Shape the external and internal features | Must be precisely aligned |

| Cooling Channels | Regulate temperature for uniform cooling | Essential for cycle time |

| Ejection System | Removes the hardened part without damage | Includes pins, air ejection |

| Gates and Runners | Control material flow into the cavity | Affects part quality |

Core and Cavity

The core and cavity are the heart of the mold, defining the shape of the final part. The cavity forms the outer surface, while the core shapes the interior. Precision in their design is crucial for part accuracy.

Cooling Channels

Cooling channels ensure the mold cools uniformly, preventing defects like warping or shrinkage. Advanced designs use conformal cooling for better heat dissipation.

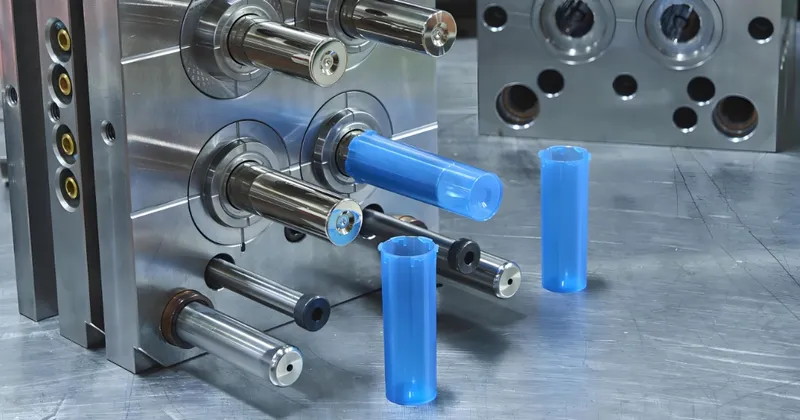

Ejection System

The ejection system, often consisting of pins or air blasts, removes the part without causing damage. Proper placement is key to avoiding marks or deformation.

Gates and Runners

Gates and runners control how material flows into the mold. Poor design can lead to defects like weld lines or air traps.

Cooling channels are optional in mold design.False

Cooling channels are essential for controlling temperature and ensuring part quality, especially in high-volume production.

The core and cavity must be precisely aligned for accurate parts.True

Misalignment can lead to defects like flash or incomplete filling, compromising part quality.

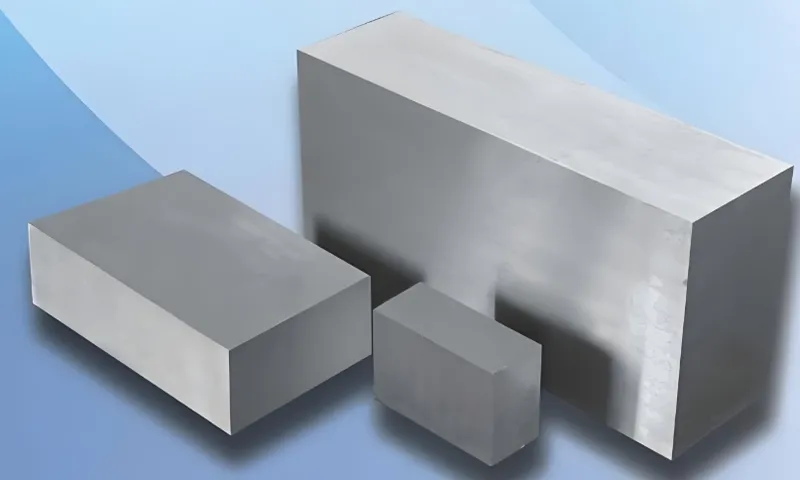

What Materials are Commonly Used in Mold Design?

Choosing the right material for a mold is crucial for durability, cost-effectiveness, and performance, depending on the production volume and part requirements.

Common mold materials6 include steel for durability, aluminum for cost-effective prototyping, and 3D-printed polymers7 for rapid testing.

| Material | Durability | Cost | Best For |

|---|---|---|---|

| Steel | High | High | High-volume production |

| Aluminum | Medium | Low | Prototyping, low-volume runs |

| Beryllium Copper8 | Medium | High | Fast cooling, complex parts |

| 3D-Printed Polymers | Low | Low | Rapid prototyping, testing |

Steel

Steel is the go-to material for high-volume production due to its durability and ability to withstand high temperatures and pressures. However, it is expensive and has lower thermal conductivity.

Aluminum

Aluminum is cost-effective and offers better thermal conductivity, making it ideal for prototyping or low-volume production where speed and cost are priorities.

Beryllium Copper

Beryllium copper is used for molds requiring excellent thermal conductivity, such as those with complex cooling needs. It is more expensive but reduces cycle times.

3D-Printed Polymers

3D-printed molds, often made from photopolymers, are perfect for rapid prototyping. They are less durable but allow for quick design iterations.

Steel is the only material used for molds in high-volume production.False

While steel is common, other materials like beryllium copper are also used for specific high-volume applications requiring fast cooling.

3D-printed molds are suitable for long-term production.False

3D-printed molds are best for prototyping due to their lower durability compared to metal molds.

What is the Mold Design Process?

The mold design process9 is a systematic approach that ensures the mold meets the part’s requirements while optimizing for cost, quality, and production efficiency.

The mold design process involves analyzing the part, selecting materials10, designing the mold layout, simulating performance, and testing the design.

Analyze the Part

Start by assessing the part’s size, shape, tolerances, and material. Identify potential issues like thin walls or undercuts that could complicate molding.

Choose Mold Material

Select the appropriate material based on production volume, part complexity, and budget. Steel is ideal for high-volume runs, while aluminum or 3D-printed polymers suit prototyping.

Design the Mold Layout

Decide on the number of cavities (single or multi-cavity), gate and runner placement, and cooling system design. Use simulation software to optimize the layout.

Simulate and Test

Use simulation tools11 to predict material flow, cooling, and ejection issues. Prototype the mold (e.g., using 3D printing) to validate the design before full production.

Simulation is an optional step in mold design.False

Simulation is crucial for identifying potential issues like poor material flow or uneven cooling before manufacturing the mold.

Multi-cavity molds are always better than single-cavity molds.False

Multi-cavity molds increase production speed but are more complex and expensive, making them unsuitable for low-volume runs.

What are the Common Challenges in Mold Design?

Mold design is not without its challenges, and addressing them early can save time and costs in the long run.

Common challenges in mold design include thermal management, material flow issues, and balancing cost with quality.

Thermal Management

Uneven cooling can cause defects like warping or sink marks. Designing effective cooling channels, especially for complex parts, is critical.

Material Flow

Poor gate and runner design can lead to incomplete filling, air traps, or weld lines. Simulation tools help predict and resolve these issues.

Cost vs. Quality

High-quality molds, especially those made from steel, have high initial costs. Balancing these costs with the need for durability and part quality is essential.

Thermal management is only a concern in plastic molding.False

Thermal management is critical in molding metals and glass as well, as uneven cooling can lead to defects in any material.

Simulation tools can completely eliminate mold design challenges.False

While simulation helps identify issues, real-world factors like material variations or machine settings can still cause problems.

What are the Applications of Mold Design?

Mold design is integral to various industries, enabling the production of precise, high-quality parts at scale.

Mold design is used in automotive, aerospace, medical, and consumer goods industries for producing parts like dashboards, turbine blades, syringes, and packaging.

Automotive

Molds are used to create interior trim, exterior panels, and engine components that require durability and precision.

Aerospace

Lightweight, high-precision parts like turbine blades are produced using molds designed for complex geometries and tight tolerances.

Medical

Sterile, high-precision devices such as syringes and implants rely on molds for consistent quality and safety.

Consumer Goods

Molds are essential for mass-producing items like packaging, electronics casings, and toys with consistent quality.

Mold design is only relevant for large manufacturers.False

Small businesses and startups also use mold design, especially with cost-effective options like 3D-printed molds for prototyping.

Mold design is crucial for ensuring part consistency in mass production.True

Well-designed molds produce identical parts with minimal variation, essential for industries like automotive and medical.

How Does Mold Design Differ from Other Manufacturing Processes?

Mold design is distinct from other manufacturing methods like 3D printing or CNC machining, each with its own advantages and limitations.

Mold design enables high-volume production with consistent quality, while 3D printing is better for prototyping, and CNC machining offers precision for low-volume runs.

| Process | Best For | Pros | Cons |

|---|---|---|---|

| Mold Design | High-volume production | Consistent quality, fast cycles | High initial cost |

| 3D Printing | Prototyping, complex geometries | Low cost for small runs | Slower for large volumes |

| CNC Machining | Precision parts, low-volume | High precision, no mold needed | Slow for mass production |

Mold Design

Ideal for mass production, mold design ensures consistent part quality and fast cycle times but requires significant upfront investment.

3D Printing

Great for rapid prototyping and complex geometries, 3D printing is cost-effective for small runs but not suitable for high-volume production.

CNC Machining

CNC machining offers high precision for low-volume runs without the need for a mold, but it is slower and more expensive per part for large quantities.

Mold design is always more expensive than other manufacturing processes.False

While molds have high initial costs, they become cost-effective for large production runs due to lower per-part costs.

3D printing can fully replace mold design in manufacturing.False

3D printing is excellent for prototyping but lacks the speed and durability needed for high-volume production.

Conclusion

Mold design is a cornerstone of modern manufacturing, enabling the efficient production of high-quality parts across industries. By understanding the key components, materials, processes, and challenges, you can make informed decisions that balance cost, quality, and production efficiency. Whether you’re designing for automotive, medical, or consumer goods, effective mold design is essential for success.

-

Discover how high-quality parts can improve manufacturing outcomes and reduce costs, making your projects more successful. ↩

-

Understanding best practices in mold design can significantly enhance production efficiency and product quality. Explore this link to learn more. ↩

-

Understanding the core and cavity is essential for achieving precision in mold design, which directly impacts part quality. ↩

-

Exploring cooling channels can reveal techniques to enhance mold efficiency and prevent defects during production. ↩

-

Learning about ejection systems can help you optimize part removal processes, ensuring quality and efficiency in manufacturing. ↩

-

Explore this link to understand the various mold materials and their specific applications, ensuring you make an informed choice for your project. ↩

-

Discover the innovative uses of 3D-printed polymers in mold making, which can enhance your prototyping process and speed up production. ↩

-

Learn about the unique benefits of Beryllium Copper in mold making, especially for complex parts requiring fast cooling. ↩

-

Understanding the mold design process is crucial for optimizing production efficiency and ensuring quality in manufacturing. Explore this resource to enhance your knowledge. ↩

-

Choosing the right materials is vital for the success of mold design. This resource will guide you through the selection process for optimal results. ↩

-

Simulation tools are essential for predicting issues in mold design. Discover the top tools that can help streamline your design process. ↩