Injection molds are the backbone of plastic manufacturing, shaping everything from automotive parts to medical devices. These precision tools represent a significant investment, often costing thousands to millions of dollars. However, their longevity and performance hinge on one critical factor: proper storage1. Without it, molds can succumb to rust, corrosion, and physical damage, leading to costly repairs and production delays.

In this guide, we’ll explore the best practices for storing injection molds to maximize their lifespan. From cleaning and rust prevention2 to environmental control3 and regular inspections, these strategies are essential for any manufacturer looking to protect their investment and ensure seamless production.

- 1. Why is Proper Storage Crucial for Injection Molds?

- 2. What are the Best Practices for Cleaning Molds Before Storage?

- 3. How Can Rust and Corrosion Be Prevented During Storage?

- 4. What Environmental Conditions are Ideal for Mold Storage?

- 5. How Should Molds Be Handled and Organized in Storage?

- 6. Why is Regular Inspection Important During Storage?

- 7. What are the Benefits of Following These Storage Practices?

- 8. Conclusion

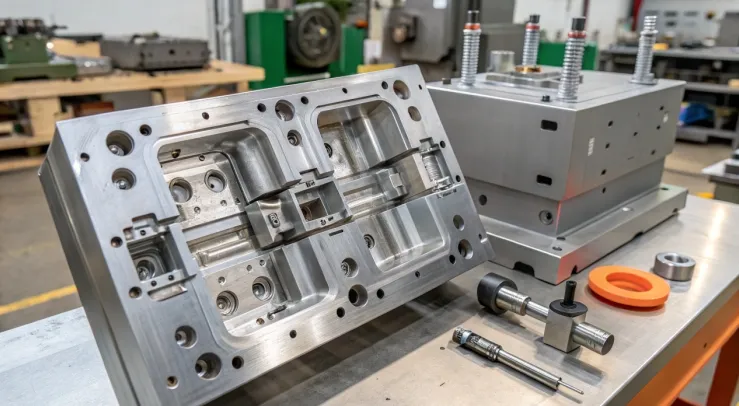

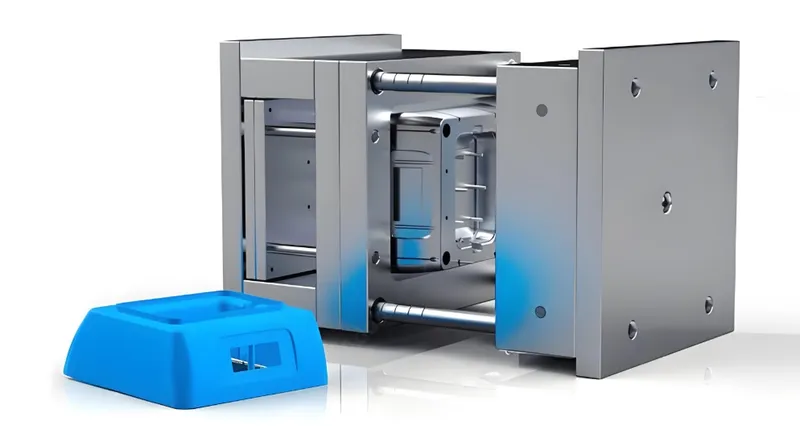

Why is Proper Storage Crucial for Injection Molds?

Injection molds are precision-engineered tools that require careful handling and storage to maintain their functionality. When stored improperly, molds are vulnerable to:

-

Rust and Corrosion4: Moisture and contaminants can cause metal components to deteriorate, especially in steel molds.

-

Physical Damage5: Poor handling or inadequate storage systems can lead to scratches, dents, or misalignment.

-

Contamination6: Dust, debris, or residual plastic can compromise mold surfaces, affecting part quality.

According to industry experts, improper storage can reduce a mold’s lifespan by up to 30%, leading to increased maintenance costs and production downtime. Proper storage practices, on the other hand, can significantly extend mold life and ensure consistent product quality.

Proper mold storage can reduce maintenance costs by up to 30%.True

By preventing rust, corrosion, and damage, manufacturers can avoid frequent repairs and extend the mold’s operational life.

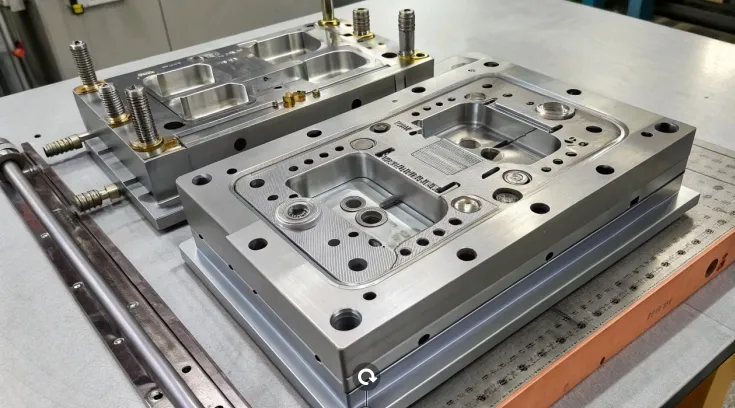

What are the Best Practices for Cleaning Molds Before Storage?

Cleaning is the first and most critical step in preparing molds for storage. Residual plastic7, moisture, or contaminants can trap moisture and accelerate corrosion. The cleaning method depends on the mold material:

| Mold Material | Recommended Cleaning Method |

|---|---|

| Steel | Mild detergent and water |

| Aluminum | Solvent-based cleaners |

| Silicone | Neutral pH soap |

For thorough cleaning, especially in the tool room, use solvent-based degreasers or mold polish8 to remove stubborn residues. Ensure all cavities, cores, and water lines are free of debris.

Cleaning molds before storage is optional if they appear clean.False

Even if molds look clean, microscopic residues can trap moisture and lead to corrosion over time.

How Can Rust and Corrosion Be Prevented During Storage?

Rust and corrosion are the primary enemies of stored molds, particularly for steel molds or those used with acidic plastics like PVC. To prevent this:

-

Apply Rust Preventive Coatings9: Use oil-based coatings for general protection. For molds exposed to gas-emitting plastics, opt for rust preventives that neutralize acidic vapors.

-

Reapply Regularly: For long-term storage or high-risk molds, reapply coatings every 30 days.

-

Seal Water Lines: Ensure water lines are dry and sealed to prevent internal corrosion10.

For molds stored longer than six months, use coatings rated for up to five years11 of indoor protection, as per ASTM testing standards.

Rust preventives are only necessary for steel molds.False

While steel is more prone to rust, aluminum molds can also suffer from corrosion and require appropriate protection.

What Environmental Conditions are Ideal for Mold Storage?

The storage environment plays a pivotal role in preserving mold integrity. Key factors include:

-

Temperature: Maintain a stable range of 20°C–25°C to prevent thermal expansion or contraction.

-

Humidity: Keep humidity between 50%–60% to avoid condensation, which can lead to rust.

-

Ventilation: Ensure good airflow to prevent moisture buildup.

Use hygrometers and dehumidifiers to monitor and control conditions. For molds stored in uncontrolled environments, consider using vapor corrosion inhibitors (VCIs) for added protection.

Temperature control is more important than humidity for mold storage.False

Humidity directly affects moisture levels, which is a key factor in corrosion, making it more critical than temperature.

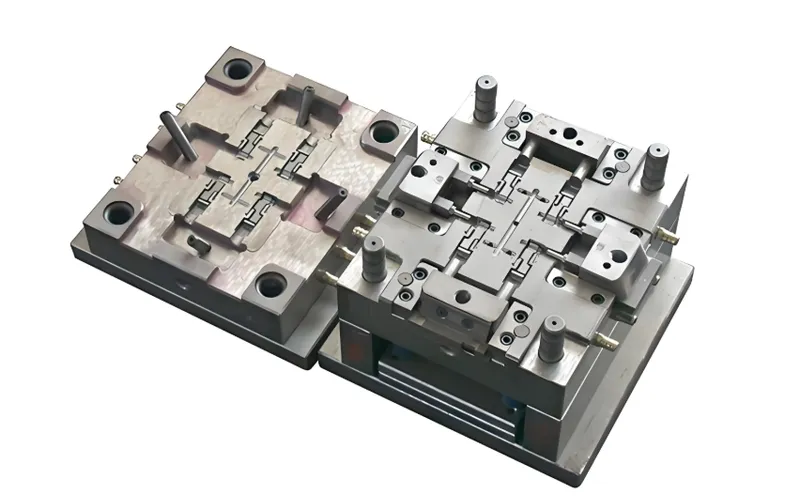

How Should Molds Be Handled and Organized in Storage?

Proper handling and organization prevent physical damage and ensure easy retrieval:

-

Use Sturdy Racks: Store molds on steel racks designed to support their weight and size.

-

Label Clearly: Implement an alphanumeric labeling system (e.g., by customer and mold number) for quick identification.

-

Avoid Stacking: Unless designed for it, avoid stacking molds to prevent pressure damage.

Consider using digital inventory software to track mold locations and storage conditions, enhancing efficiency and reducing retrieval time.

Molds can be stored in any orientation as long as they are secure.False

Molds should be stored in their operational orientation to prevent warping or misalignment of components.

Why is Regular Inspection Important During Storage?

Even with proper preparation, molds can develop issues over time. Regular inspections help catch problems early:

-

Frequency: Inspect molds monthly, logging the date, inspector, findings, and actions taken.

-

What to Check: Look for signs of rust, corrosion, or physical damage. For molds stored over 12 months, crack them open to check internal components.

-

Reapply Coatings: If rust preventive has worn off, reapply immediately.

Regular inspections not only prevent minor issues from becoming major repairs but also ensure molds are production-ready when needed.

Molds in long-term storage do not require inspections if properly prepared.False

Even with proper preparation, environmental changes or coating degradation can lead to issues that require attention.

What are the Benefits of Following These Storage Practices?

Adhering to these best practices offers several advantages:

-

Extended Mold Life: Proper care can increase a mold’s operational lifespan by up to 50%.

-

Reduced Costs: Fewer repairs and less downtime translate to significant cost savings.

- Consistent Quality: Preserved molds produce consistent, high-quality parts.

By investing in proper storage, manufacturers protect their assets and ensure long-term profitability.

Conclusion

Storing injection molds correctly is not just about preservation—it’s about safeguarding your investment and ensuring production efficiency. By following best practices like thorough cleaning, rust prevention, environmental control, and regular inspections, you can extend mold life, reduce costs, and maintain consistent product quality. Whether for short-term or long-term storage, these strategies are essential for any manufacturer looking to optimize their operations.

-

Understanding proper storage techniques can significantly extend the lifespan of injection molds, saving costs on repairs and replacements. ↩

-

Effective rust prevention methods are crucial for maintaining the integrity of injection molds, ensuring they perform optimally over time. ↩

-

Exploring environmental control measures can help manufacturers create ideal storage conditions, preventing damage and enhancing mold longevity. ↩

-

Explore this link to learn effective strategies for preventing rust and corrosion, ensuring the longevity of your injection molds. ↩

-

Discover essential tips to prevent physical damage to your molds, which can save you from costly repairs and downtime. ↩

-

Learn about effective contamination prevention methods to maintain mold quality and enhance production efficiency. ↩

-

Understanding the impact of residual plastic can help you prevent corrosion and ensure mold longevity. ↩

-

Learning about mold polish usage can improve your cleaning techniques and extend the life of your molds. ↩

-

Explore this link to discover effective rust preventive coatings that can protect your molds from corrosion and extend their lifespan. ↩

-

Learn about strategies to prevent internal corrosion in molds, ensuring their durability and functionality over time. ↩

-

Find out about coatings that provide long-lasting protection for molds, crucial for maintaining their integrity during storage. ↩