Ever get annoyed by, like, those little imperfections you find on plastic products? You know, those sink marks or, like, the ripples that kind of just make things look cheap?

Right.

Yeah. Well, we are diving deep into a technique that's really changing the game here.

Okay.

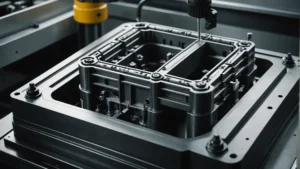

It's called gas assist injection molding, and it's tackling those problems head on.

So gas assist injection molding, huh? It sounds a lot more complicated than it actually is.

It does.

You're basically just injecting gas, actually nitrogen, into the molten plastic while it's still in the mold.

So the real magic is what happens because of that gas. Right. It's not just, like, filling up empty space. It's actually like shaping the plastic from the inside out.

It is. I always think of it like blowing up a balloon inside of, like, cake batter.

Okay.

You know that expanding balloon creates that hollow space.

Right.

And it ends up shaping the cake while it bakes.

I like that. That makes sense. So in gas assist molding, the gas expands inside that molten plastic, pushes it out to the edges of the mold, and then you get those, like, really smooth and flawless surfaces.

Precisely. That's, like, one of the biggest reasons why this is getting so popular right now. Yeah. It just makes the products look so much better.

It's all about quality.

Yeah. And the source, what benefits does gas assist injection molding offer? Really gets into that wow factor.

Okay.

No more sink marks. It's smoother. It just looks so much nicer overall.

You mentioned this source also talked about plastic chairs as an example.

Oh, yeah. Like, picture a chair.

Okay.

With, like, perfectly smooth curves.

Yeah.

No warping or anything. None of those annoying little dimples that you usually see. That's the kind of result that you can get when you use gas assist molding.

So it's not just about making things prettier.

Right.

What other advantages are there? I know the source also talks about saving material.

Oh, yeah, definitely. Like, one of the best things about this is that you could reduce the amount of plastic that you use.

Okay.

By up to 50%.

50%. So, like, half.

Yeah. Imagine using half as much plastic, but the product's still just as strong.

That's huge.

Yeah. Especially now with everybody talking about sustainability.

That's a great point, but how does that even work? How do you use less plastic and keep the same strength?

Remember that balloon analogy? The gas is making those hollow sections inside the product.

Okay.

So you just don't need as much plastic to fill up the mold.

Right.

It's like when they build a bridge with a hollow core. Instead of filling it up with concrete.

Interesting.

You still get that strength.

Yeah.

But you just use way less material.

So it's like Win Win products look better.

Exactly.

And you're using less resources.

Yeah. This source had a visual comparison to the output when you're using these multi cavity molds. I thought that was interesting.

Can you explain that to me?

Yeah. So like, imagine you have a mold with four cavities in it. So with normal injection molding, you might produce like 50 units every hour.

Okay.

If you're using gas assist, you could double that.

Wow.

To almost 100 units every hour.

So you're saving on the material, but you're also boosting production.

Exactly. And it gets even better.

Okay.

Those hollow parts actually help it cool down faster too.

So is that like the cake?

Yes.

Cooling down faster because of the air pockets.

That is a great way to put it.

Okay.

So faster cooling time means less downtime.

Right.

Which means you can make even more products in the same amount of time.

So manufacturers must love this.

Oh, yeah.

Produce more, use, better material, higher quality product.

And don't forget about the cost savings.

Oh, yeah.

This source mentioned that they can use smaller machines.

Yeah. Smaller and less expensive machines.

Yeah. Because you don't need to inject as much plastic.

Okay.

And the pressure requirements are lower.

Right.

So manufacturers can go with smaller injection molding machines.

Yeah.

Which is going to save them money. Makes sense on their initial investment and their operating costs.

So we've covered better quality, less material, faster production.

Yeah.

Potential for cost savings. Yeah. But what about the environment?

Yeah. That's a really important thing to consider. And the good news is that this score is really high when it comes to being environmentally friendly. Well, we've already talked about how it uses less plastic.

Right.

Which is a huge win for the environment.

Right.

But it goes even further than that.

Okay.

They often use nitrogen gas for this. And the best part is you can recycle it.

So you're not just using less, you're being smarter about how you use it.

Exactly.

That's pretty impressive.

Yeah.

What about, like, the energy, though? Is there any impact on the energy used in the process?

That's a good question. And the source did actually say that the shorter cooling time.

Okay.

Means they use less energy during production.

Oh, interesting.

It's kind of like this ripple effect. Less material means faster cooling.

Right.

Which means you need less energy.

It sounds almost too good to be true.

Right.

Are there any downsides or, like, challenges to using gas assist injection molding?

Like any new technology? There are some things to Consider.

Sure.

This source did mention the initial investment as a potential hurdle.

Right. Because it's new.

Yeah. You need special equipment, you need training. And for some companies, that's a big barrier.

Yeah. Especially for smaller companies, I imagine.

Exactly. But it's important to look at the big picture here.

Okay.

While you have those upfront costs.

Right.

The long term benefits often outweigh them.

Okay.

Think about it. You produce more.

Right.

Your material costs are lower, you use less energy.

Yeah.

That all leads to some pretty significant savings over time.

Plus you're making things more sustainable. That's becoming a bigger deal for consumers.

Absolutely. It's not just about the price and how well something works anymore.

Yeah.

People want to buy things that align with their values.

Right.

And as people keep demanding more eco friendly products, companies who use technology like gas assist injection molding.

Right.

Are going to have a big advantage.

It's like us, the consumers.

Yeah.

We're driving that change.

We are.

It's pretty cool.

So apart from that initial investment.

Right.

Are there any other challenges?

One thing that you have to manage really carefully is that gas recycling process.

Okay.

The source mentioned that.

Right.

And they said you need to have good systems to capture and reuse the gas.

So it's not enough to just have the technology.

Right.

You have to implement it properly.

Yeah.

But overall it seems like the good outweighs the bad.

I would agree. I think it's about looking at sustainability as an opportunity.

Okay.

Not an obstacle. It's a chance to come up with new ideas and make things more efficient.

Right.

And that's why gas assist injection molding is so cool. It's so interesting that something so simple like injecting gas into plastic can have such a big impact. I know, it's pretty amazing. What's exciting is that this technique can be used in so many ways.

It can.

I mean, we talked about chairs, but it goes way beyond that.

It does. You could use it for car parts, medical devices. Wow. Even like the cases for electronics.

So many different industries could be changed by this.

Exactly. And that's just the beginning.

Wow.

I think as more companies realize how powerful this is.

Right.

We're going to see even more new and creative ways to use it.

Yeah.

We could be making lighter products, more durable products, things with designs that were impossible before.

All right, so now that we understand the why, let's talk about the what. What products is this technique really changing?

Well, one thing that comes to mind right away is anything that needs to be both strong and lightweight.

Okay.

So like parts for airplanes or cars oh, yeah.

Using less material there would be huge for fuel efficiency.

Exactly.

Right.

And then there's consumer goods where how it looks is really important.

Right.

Products with complicated shapes or things that usually have those sink marks.

Right.

They could be so much better with this.

So things like electronics, casings, toys.

Yep. Yep.

Maybe even furniture.

Exactly.

Okay.

Wow. And don't forget about the medical field.

Oh, right.

This could be huge for making medical equipment lighter and stronger.

Wow.

Imagine if you had a prosthetic limb that was more comfortable and easier to wear.

That would be incredible.

Yeah.

So it really sounds like gas assist injection molding is changing what's possible when it comes to product design and manufacturing.

Definitely.

But what does this all mean for the listeners?

Well, now that you know about it, you can start looking at products a little differently.

Okay.

You might be surprised how many things around you are made using gas assist injection molding.

It's like a secret code now.

Right.

I'll be out and about, and I'll see something with a smooth surface, and I'll think, aha. Yeah, gas assist molding.

I know, right?

Maybe it'll even spark some ideas for our listeners.

That'd be cool.

What products could benefit from this technology or what new things could be invented because of it?

Right. What do you think?

Maybe it's something simple, like a better toothbrush or something super complex, like a lightweight drone that's also really strong.

Yeah.

The possibilities are pretty amazing.

I think so.

It's not just about understanding how things are made now. It's about understanding how those choices affect the world around us.

Exactly.

Well, that's it for our deep dive into the world of gas assist injection molding.

It was fun.

We hope you learned something new and maybe even got inspired.

Definitely.

We'll see you next