![]()

The injection molding industry is evolving rapidly as we approach 2025, with new materials emerging to meet the demands of sustainability, performance, and specialization. For manufacturers, staying ahead of these trends is essential to optimizing production, reducing costs, and aligning with market expectations. This blog post explores the latest developments in injection molding materials, providing a comprehensive guide to help you make informed decisions for your manufacturing processes.

Injection molding is adapting to 2025 with sustainable materials1 like bio-based and recycled plastics, high-performance polymers2 for demanding applications, and specialized materials for industries3 such as medical and aerospace.

Understanding these material trends is crucial for manufacturers aiming to balance cost, performance, and environmental impact. Dive deeper to explore how these materials can transform your production processes and product offerings.

Injection molding materials in 2025 focus heavily on sustainability.True

Bio-based and recycled plastics are gaining popularity due to environmental regulations and consumer demand for eco-friendly products.

High-performance polymers are only used in aerospace applications.False

While common in aerospace, high-performance polymers like PEEK are also used in automotive, medical, and electronics industries for their strength and heat resistance.

- 1. What Are the Key Materials Used in Injection Molding for 2025?

- 2. What Are the Typical Applications of These Materials?

- 3. What Are the Pros and Cons of Injection Molding Compared to Other Technologies?

- 4. What Is the Injection Molding Process Workflow?

- 5. How Do Different Materials Affect the Injection Molding Process?

- 6. What Are the Design Considerations for Injection Molding?

- 7. How to Choose the Right Process for Your Project?

- 8. What Are the Related Technologies in Injection Molding?

- 9. Conclusion

What Are the Key Materials Used in Injection Molding for 2025?

Injection molding materials are evolving to meet the needs of industries focused on sustainability, performance, and precision, offering new possibilities for product development.

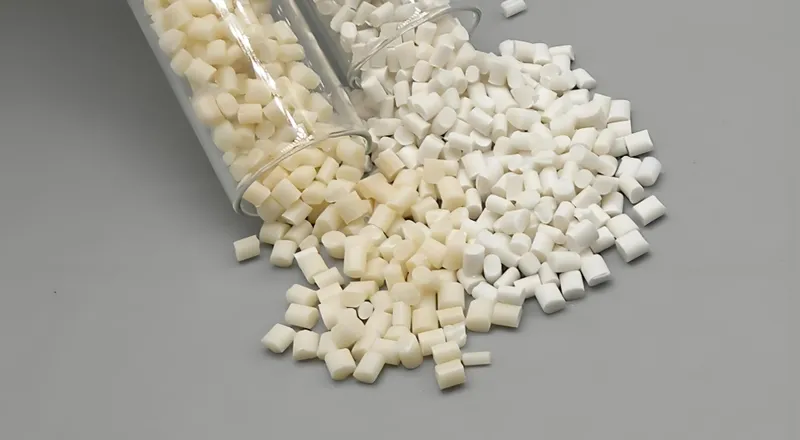

Key materials for injection molding in 2025 include bio-based plastics4 like PLA and PHA, recycled resins5, high-performance polymers such as PEEK, and specialized materials like LCP and Nitinol for medical applications.

| Material Type | Examples | Key Properties | Applications |

|---|---|---|---|

| Bio-Based Plastics | PLA, PHA, Algae-derived | Biodegradable, eco-friendly | Packaging, consumer goods |

| Recycled Plastics | Post-consumer PET composites | Sustainable, cost-effective | Automotive, consumer goods |

| High-Performance Polymers | PEEK, PEI | Heat resistance, high strength | Aerospace, automotive, medical |

| Specialized Materials | LCP, Nitinol | Precision, shape memory | Medical devices, electronics |

Bio-Based Plastics

Bio-based plastics like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are gaining traction due to their biodegradability and reduced environmental impact. These materials are ideal for industries like packaging and consumer goods, where sustainability is a priority. For example, algae-derived bioplastics offer HDPE-grade tensile strength (28 MPa) and marine degradability within 18 months (Jaycon).

Recycled Plastics

Recycled resins, such as post-consumer PET composites, are increasingly used in automotive and consumer goods to reduce waste and lower material costs. These materials can contain up to 40% recycled content while maintaining performance standards (Plastic Moulds).

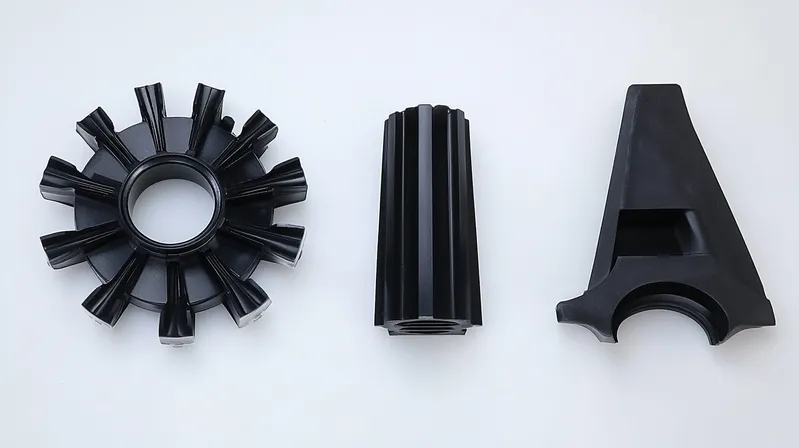

High-Performance Polymers

Materials like polyether ether ketone (PEEK) and polyetherimide (PEI) are essential for applications requiring high strength and heat resistance, such as aerospace components and automotive parts. These polymers are also used in medical devices due to their biocompatibility and durability.

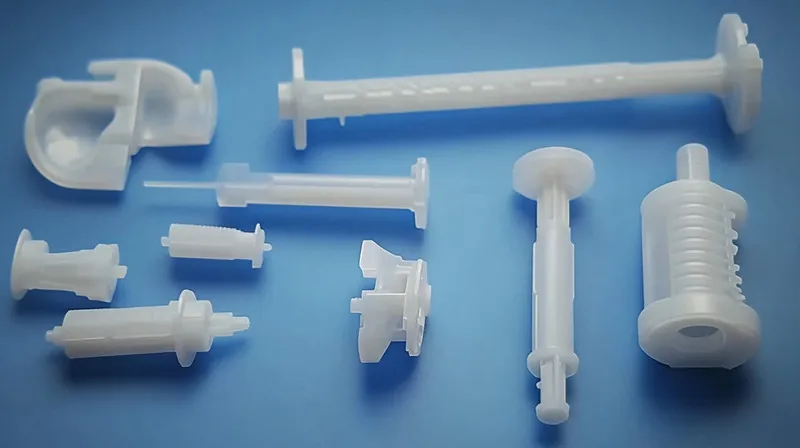

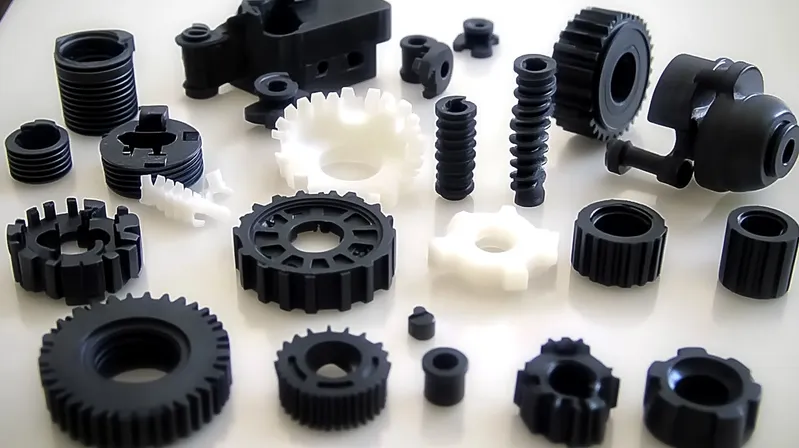

Specialized Materials

Liquid Crystal Polymer (LCP) and nickel-titanium alloys (Nitinol) are used in precision applications like micro-molded medical components and shape-memory stents. LCP allows for parts as small as 0.03g with tolerances of ±5μm, while Nitinol is ideal for self-expanding medical implants (Jaycon).

Bio-based plastics are suitable for all injection molding applications.False

While eco-friendly, bio-based plastics may not meet the performance requirements of high-stress or high-temperature applications.

High-performance polymers like PEEK are essential for lightweighting in electric vehicles.True

PEEK's high strength-to-weight ratio makes it ideal for reducing vehicle weight while maintaining durability.

What Are the Typical Applications of These Materials?

Injection molding materials are selected based on industry needs and product characteristics, with each material offering unique benefits for specific applications.

Typical applications include automotive components, packaging, consumer goods, medical devices, and aerospace parts, each requiring materials tailored to their performance and regulatory demands.

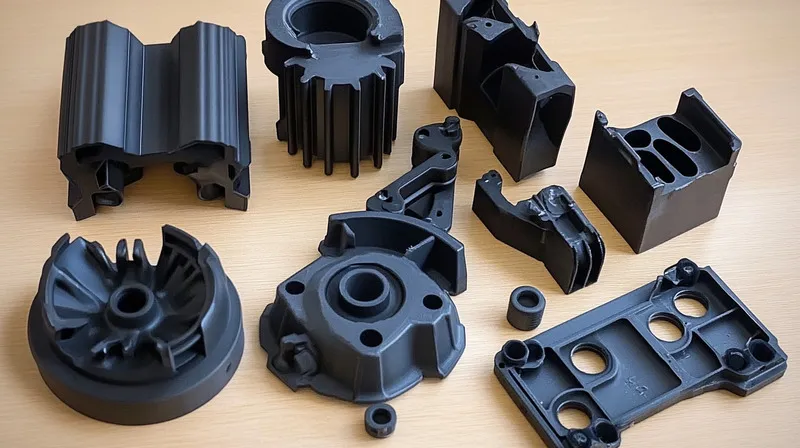

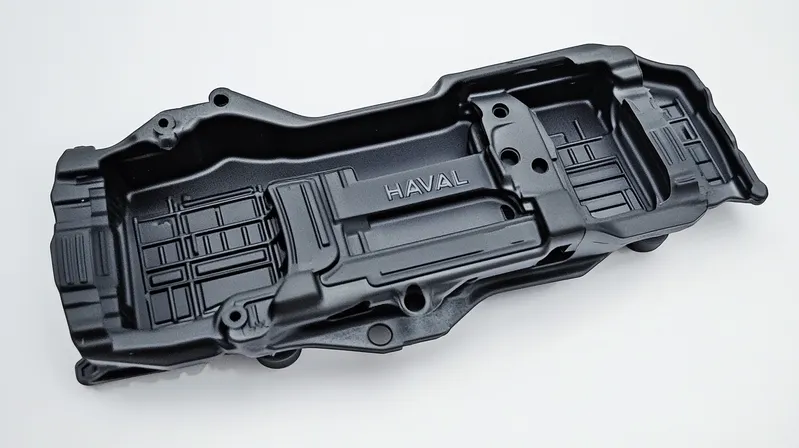

Automotive Industry

Lightweight plastics, such as recycled resins and high-performance polymers, are used for electric vehicle components like battery housings and interior panels. The rise of electric vehicles is driving demand for these materials, with new factories like Hyundai’s in Georgia set to open in 2025 (Grand View Research).

Packaging

Sustainable materials like bio-based plastics are increasingly used for food and beverage containers, caps, and closures. These materials help reduce environmental impact while meeting regulatory standards for safety and durability (Prototool).

Consumer Goods

Durable thermoplastics and recycled resins are used for electronics housings, toys, and appliances, offering a balance of cost, performance, and sustainability.

Medical Devices

High-precision materials like LCP and Nitinol are essential for medical implants, syringes, and diagnostic equipment. These materials must meet strict biocompatibility and performance standards (Jaycon).

Aerospace

High-performance polymers like PEEK are used for lightweight, heat-resistant components in aircraft and spacecraft, where reducing weight without compromising strength is critical.

Injection molding is only used for plastic parts.False

While plastics are common, injection molding is also used for metals (MIM), ceramics, and elastomers.

Bio-based plastics are ideal for medical applications.False

Bio-based plastics may not always meet the stringent biocompatibility and sterilization requirements of medical devices.

What Are the Pros and Cons of Injection Molding Compared to Other Technologies?

Injection molding offers distinct advantages for high-volume production but comes with trade-offs compared to other manufacturing methods.

Injection molding excels in high production rates6, low labor costs, and minimal waste, but requires high initial tooling costs7 and has design constraints8 compared to 3D printing or CNC machining.

| Aspect | Injection Molding | 3D Printing | CNC Machining |

|---|---|---|---|

| Pros | High production rates, low labor costs, minimal waste, complex shapes possible. | Flexible for prototyping, no tooling costs, customizable designs. | High precision, suitable for small batches, wide material range. |

| Cons | High initial tooling costs, material limitations, design constraints (e.g., draft angles). | Slower for high volumes, higher per-part cost, limited material strength. | Slower for large batches, higher labor costs, material waste. |

When to Choose Injection Molding

- High-Volume Production: Ideal for producing large quantities of parts quickly and cost-effectively.

-

Complex Geometries: Capable of producing intricate shapes with tight tolerances.

-

Material Variety: Supports a wide range of materials, from plastics to metals.

When to Consider Alternatives

-

Prototyping: 3D printing offers faster iteration without tooling costs.

-

Small Batches: CNC machining is better for low-volume, high-precision parts.

-

Large, Hollow Parts: Blow molding is more suitable for containers or bottles.

Injection molding is the most cost-effective method for all production volumes.False

For low-volume production, the high tooling costs of injection molding may not be justified compared to 3D printing or CNC machining.

Injection molding produces less waste than CNC machining.True

Injection molding generates minimal waste since excess material can often be recycled, whereas CNC machining produces significant material waste.

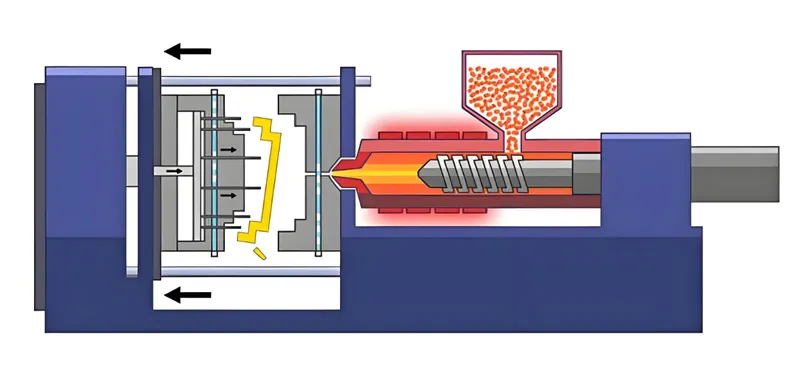

What Is the Injection Molding Process Workflow?

The injection molding process9 is a precise, multi-step operation that requires careful control of parameters to ensure part quality.

The process involves clamping the mold, injecting molten material, cooling it to solidify, and ejecting the finished part, with key parameters10 like pressure, temperature, and cooling time11 affecting the outcome.

Process Steps

-

Clamping: The mold is closed and secured under high pressure to withstand injection forces.

-

Injection: Molten material is injected into the mold cavity at controlled pressure and speed.

-

Cooling: The material solidifies as heat is dissipated, with cooling time impacting part quality.

-

Ejection: The mold opens, and the part is ejected using pins or plates.

Key Parameters

-

Injection Pressure: Typically 10,000–20,000 psi to ensure complete mold filling.

-

Temperature: Varies by material (e.g., 200–300°C for thermoplastics, higher for metals).

-

Cooling Time: Ranges from seconds to minutes, affecting cycle time and part integrity.

-

Cycle Time: Total time per part, often 10–60 seconds for plastics.

Higher injection pressure always leads to better part quality.False

Excessive pressure can cause defects like flash or warping, so optimal pressure is material-specific.

Cooling time is the most critical factor in cycle time reduction.True

Cooling typically accounts for the majority of the cycle time, so optimizing it can significantly improve production speed.

How Do Different Materials Affect the Injection Molding Process?

Material selection is crucial in injection molding, as each material type has unique properties that influence processing conditions and part performance.

Thermoplastics are versatile and recyclable, thermosets offer high heat resistance, metals provide strength, and bio-based plastics reduce environmental impact, each requiring specific processing adjustments.

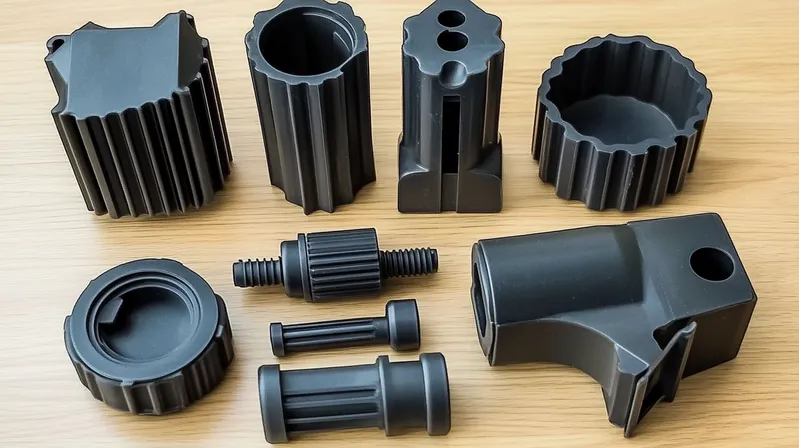

Thermoplastics

-

Properties: Can be remelted and reshaped, making them recyclable.

-

Processing: Require precise temperature control to avoid degradation.

-

Applications: Widely used in automotive, packaging, and consumer goods.

Thermosets

-

Properties: Permanently set after molding, offering high heat and chemical resistance.

-

Processing: Require careful control of curing time and temperature.

- Applications: Used in electrical components and high-temperature environments.

Metals (MIM)

-

Properties: High strength and durability, ideal for small, complex parts.

-

Processing: Involves debinding and sintering post-injection, adding complexity.

-

Applications: Aerospace, medical, and automotive components.

Bio-Based Plastics

-

Properties: Biodegradable, with varying mechanical properties.

-

Processing: Often require lower processing temperatures to prevent degradation.

-

Applications: Packaging, disposable products, and eco-friendly consumer goods.

All thermoplastics can be used interchangeably in injection molding.False

Each thermoplastic has unique properties, requiring specific mold designs and processing conditions.

Bio-based plastics always have lower mechanical strength than traditional plastics.False

Some bio-based plastics, like algae-derived bioplastics, can match the tensile strength of conventional plastics like HDPE.

What Are the Design Considerations for Injection Molding?

Designing for injection molding requires attention to detail to ensure part quality and manufacturability, with specific guidelines for wall thickness, draft angles, and material selection.

Key design considerations include maintaining uniform wall thickness, incorporating draft angles, and selecting materials based on application requirements to avoid defects and ensure efficient production.

Design Checklist

-

Uniform Wall Thickness: Keep walls between 1–3 mm to prevent warping or sink marks.

-

Draft Angles: Include 1–2° angles to facilitate part ejection.

-

Material Selection: Choose materials based on mechanical, thermal, and regulatory needs (e.g., biocompatibility for medical devices).

-

Avoid Undercuts: Use side actions or redesign to simplify mold complexity.

Common Design Mistakes

- Inconsistent Wall Thickness: Leads to uneven cooling and defects.

-

Sharp Corners: Cause stress concentrations; use radii instead.

-

Insufficient Draft: Makes part ejection difficult, risking damage.

Uniform wall thickness is critical for preventing defects in injection molded parts.True

Inconsistent thickness can cause warping, sink marks, and internal stresses due to uneven cooling.

Draft angles are unnecessary for simple parts.False

Even simple parts benefit from draft angles to ensure smooth ejection and reduce wear on the mold.

How to Choose the Right Process for Your Project?

Selecting the appropriate manufacturing process depends on production volume, part complexity, and material requirements, with injection molding being ideal for high-volume, complex parts.

For high-volume production of complex parts, injection molding is the go-to process, while 3D printing suits prototyping, and CNC machining is best for small batches of high-precision parts.

| Scenario | Recommended Process | Reason |

|---|---|---|

| High-volume production | Injection molding | Cost-efficient, scalable, fast cycle times. |

| Prototyping or low-volume | 3D printing | No tooling costs, rapid iteration. |

| Large, hollow parts | Blow molding | Better for containers or bottles. |

| Small, complex metal parts | Metal injection molding | High precision, strength. |

Decision-Making Tips

- Evaluate Production Volume: Injection molding becomes cost-effective at higher volumes.

-

Consider Part Complexity: Injection molding handles intricate designs well, but may require complex molds.

-

Assess Material Needs: Ensure the chosen process supports the required material properties.

Injection molding is always the best choice for plastic parts.False

For low-volume or highly customized parts, 3D printing or CNC machining may be more suitable.

Metal injection molding (MIM) is ideal for large metal parts.False

MIM is typically used for small, complex parts due to cost and process limitations.

Injection molding is part of a broader manufacturing ecosystem, with upstream and downstream technologies that enhance its capabilities and efficiency.

Related technologies include material science for developing new polymers, mold design software for optimizing tooling, and automation for improving production efficiency.

Upstream Technologies

-

Material Science: Development of bio-based polymers, composites, and alloys.

-

Mold Design Software: Tools like SolidWorks for creating precise mold geometries.

Downstream Technologies

- Assembly Techniques: Joining molded parts via welding, adhesives, or fasteners.

-

Finishing Processes: Painting, coating, or texturing for aesthetics and functionality.

-

Quality Control: Non-destructive testing and dimensional inspection.

Complementary Technologies

-

3D Printing: For rapid prototyping and hybrid manufacturing.

-

Automation: Robotics and AI for process optimization and predictive maintenance (MakerVerse).

Automation in injection molding reduces production costs.True

Automation minimizes labor costs and improves consistency, leading to higher efficiency.

3D printing will replace injection molding in the future.False

While 3D printing is growing, injection molding remains superior for high-volume production due to speed and cost advantages.

Conclusion

The injection molding materials landscape in 2025 is defined by sustainability, performance, and specialization. Bio-based and recycled plastics address environmental concerns, while high-performance polymers and specialized materials like LCP and Nitinol meet the needs of advanced applications. By understanding these trends and leveraging the right materials and processes, manufacturers can enhance efficiency, reduce environmental impact, and stay competitive in a dynamic market.

-

Explore the latest sustainable materials to enhance your production processes and meet environmental standards. ↩

-

Discover how high-performance polymers can improve your product quality and performance in demanding applications. ↩

-

Learn about specialized materials that can give your products a competitive edge in niche markets like medical and aerospace. ↩

-

Explore the advantages of bio-based plastics, including their sustainability and performance in various applications. ↩

-

Learn how recycled resins contribute to sustainability and cost-effectiveness in the injection molding industry. ↩

-

Understanding the benefits of high production rates can help you optimize manufacturing processes and reduce costs. ↩

-

Exploring the reasons behind high tooling costs can aid in budgeting and decision-making for manufacturing projects. ↩

-

Learning about design constraints can help you make informed choices when selecting manufacturing techniques for your projects. ↩

-

Understanding the injection molding process is crucial for optimizing production and ensuring high-quality parts. Explore this resource for in-depth insights. ↩

-

Learning about key parameters like pressure and temperature can significantly enhance your understanding of injection molding and improve product outcomes. ↩

-

Cooling time is critical in the injection molding process; exploring this topic can help you grasp its impact on part integrity and production efficiency. ↩