Imagine a plastic so tough it can outlast steel in harsh conditions, yet so versatile it can be shaped into intricate parts for medical devices or industrial machinery. That’s Ultra High Molecular Weight Polyethylene1, or UHMWPE. Molding this super-plastic isn’t easy—it’s like trying to pour honey through a straw. Only a few manufacturers have mastered the process, using injection molding to create parts that are stronger, lighter, and more precise than ever before.

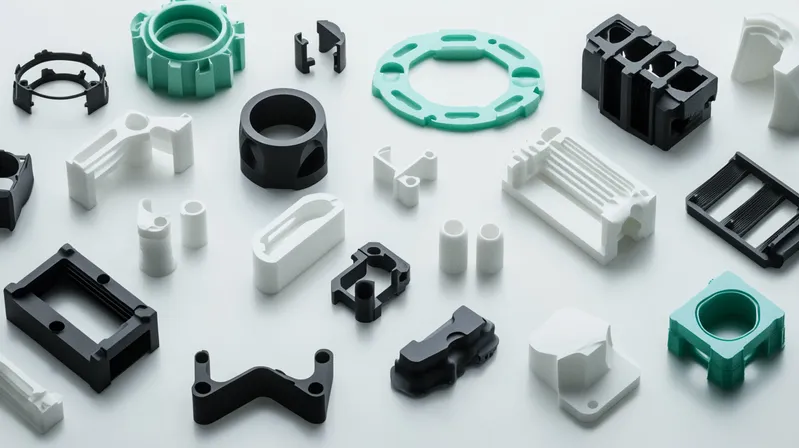

Injection molding UHMWPE involves melting Ultra High Molecular Weight Polyethylene and injecting it into a mold to create durable, wear-resistant parts2 for medical, industrial, and other high-performance applications.

This blog dives into the world of injection molding3 UHMWPE, exploring what it is, why it’s special, its applications, challenges, and how it stacks up against other methods. Whether you’re a manufacturer or just curious about advanced materials, read on to discover the ins and outs of this remarkable process.

Injection molding UHMWPE requires specialized equipment.True

Due to its high viscosity, standard injection molding machines can’t generate the necessary pressure, requiring custom high-pressure machines.

Injection molding UHMWPE is the cheapest method for all production runs.False

While cost-effective for large volumes, the high initial equipment and tooling costs make it less economical for small batches compared to machining.

What is Injection Molding UHMWPE?

Injection molding UHMWPE is a bit like baking a cake, but instead of flour and sugar, you’re working with a plastic engineered for incredible strength. The process starts by heating UHMWPE until it’s soft and pliable, then injecting it into a mold under high pressure to form precise shapes. Once cooled, you’ve got a durable, high-performance part. UHMWPE’s high molecular weight—millions of atomic mass units—gives it exceptional strength, wear resistance4, and low friction, but it also makes it tricky to mold (UHMWPE Properties).

Why is Injection Molding UHMWPE Special?

UHMWPE is a diva in the molding world. Its high molecular weight makes it thick and syrupy when melted, resisting the easy flow of other plastics. This means you need specialized machines capable of handling extreme pressure and temperature demands. It’s like squeezing toothpaste back into the tube—challenging, but doable with the right expertise and tools. Only a handful of manufacturers have cracked this code, making it a standout process in the plastics industry (Injection Molding Overview).

What are the Applications of Injection Molding UHMWPE?

From artificial joints to industrial gears, injection-molded UHMWPE shines in applications requiring durability and precision.

UHMWPE is used in medical implants, industrial components, and more, thanks to its biocompatibility5, wear resistance, and low friction.

Medical Devices

In the medical field, UHMWPE is a star player in joint replacements like hips and knees. Its biocompatibility and wear resistance6 ensure these implants last for decades, while injection molding delivers the precision needed for a perfect fit.

Industrial Uses

Factories rely on UHMWPE for gears, bearings, and conveyor parts. Its low friction and high durability make it ideal for components that endure constant wear, with injection molding enabling complex shapes that other methods struggle to achieve.

What are the Challenges of Injection Molding UHMWPE?

Injection molding UHMWPE isn’t without its hurdles—its unique properties demand careful handling.

The high viscosity and narrow processing window7 of UHMWPE pose significant challenges, including incomplete mold filling and potential defects.

The biggest headache is its viscosity—think of pouring cold molasses. This can lead to incomplete parts or defects like air bubbles or warping. Plus, UHMWPE’s sensitivity to temperature means too much heat can degrade it, while too little leaves it unmoldable. Manufacturers overcome these issues with high-pressure equipment and precise temperature control, but it’s a delicate balance (Specialized Techniques).

Injection molded UHMWPE parts are more precise than those made by other methods.True

Injection molding allows for tighter tolerances and complex designs, crucial for applications like medical implants, unlike compression molding or machining.

Injection molding UHMWPE is a simple process with no challenges.False

The material’s high viscosity and temperature sensitivity create significant hurdles, requiring advanced equipment and expertise.

How Does Injection Molding UHMWPE Compare to Other Methods?

Injection molding isn’t the only way to shape UHMWPE—let’s see how it stacks up against compression molding8 and machining9.

| Method | Pros | Cons |

|---|---|---|

| Injection Molding | High precision, complex shapes, efficient for large volumes | High equipment cost, challenging for UHMWPE, risk of defects |

| Compression Molding | Simpler process, lower cost, good for basic shapes | Less precise, limited geometries, slower production |

| Machining | No mold needed, flexible for small batches, complex shapes | High waste, time-consuming, costly per part |

Injection molding excels in precision and scalability, but its upfront costs and complexity make it best for high-volume, intricate parts. Compression molding suits simpler, cheaper projects, while machining offers flexibility for small runs at the expense of waste and time.

Conclusion

Injection molding UHMWPE is a game-changer for creating tough, precise parts that stand up to the harshest conditions. While its challenges—high viscosity, specialized equipment, and a tricky processing window—require expertise, the payoff is worth it: efficient production of complex, durable components for medical, industrial, and beyond. If you’re looking to push the limits of manufacturing, UHMWPE injection molding might just be your next big move.

-

Explore the unique properties and advantages of UHMWPE that make it a game-changer in various industries. ↩

-

Discover the importance of wear-resistant parts in different industries and how they enhance product longevity. ↩

-

Learn about the injection molding process specifically for UHMWPE and its significance in creating high-performance parts. ↩

-

Learn about wear resistance and its significance in enhancing the longevity and performance of industrial components. ↩

-

Understanding biocompatibility is crucial for ensuring the safety and effectiveness of medical implants like joint replacements. ↩

-

Exploring this topic reveals why these properties are crucial for the longevity and safety of medical devices. ↩

-

Understanding these challenges can help manufacturers improve their processes and product quality. ↩

-

Explore this link to understand the benefits and limitations of compression molding, a key method for shaping materials like UHMWPE. ↩

-

Discover the intricacies of machining, its applications, and how it compares to other manufacturing methods for better decision-making. ↩