Plastic injection molding is a cornerstone of modern manufacturing, enabling the production of complex plastic parts with high precision and efficiency. At the heart of this process is the injection molding machine, whose capacity determines the size, complexity, and volume of parts that can be produced. Understanding the capacity of these machines is crucial for manufacturers to select the right equipment for their needs. In this article, we delve into the intricacies of injection molding machine capacity1, exploring its definitions, classifications, applications, and technical details. Whether you’re a seasoned professional or new to the field, this comprehensive guide will equip you with the knowledge to make informed decisions about injection molding technology.

Injection molding machines vary widely in capacity, typically measured by clamping force2 (10 to 2,200 tons) and shot size3 (a few grams to over 10,800 grams), determining the size and volume of parts they can produce.

Understanding machine capacity is essential for optimizing production and ensuring part quality. Delve deeper to explore how different machine types and materials influence capacity and applications.

Injection molding is the most cost-effective process for high-volume plastic part production.True

Due to its high automation and ability to produce complex parts quickly, injection molding reduces per-part costs significantly in large production runs.

All plastic materials can be processed using any injection molding machine.False

Different materials have specific processing requirements, such as temperature and pressure, which may necessitate specialized machines or configurations.

- 1. What is the Capacity of a Plastic Injection Molding Machine?

- 2. What are the Typical Applications of Injection Molding Machines?

- 3. What are the Pros and Cons of Injection Molding Compared to Other Processes?

- 4. What is the Full Workflow of the Injection Molding Process?

- 5. How Do Different Materials Affect Machine Capacity?

- 6. What are the Key Design Considerations for Injection Molding?

- 7. How to Decide if Injection Molding is the Right Process?

- 8. What are the Related Technologies in Injection Molding?

- 9. Conclusion

What is the Capacity of a Plastic Injection Molding Machine?

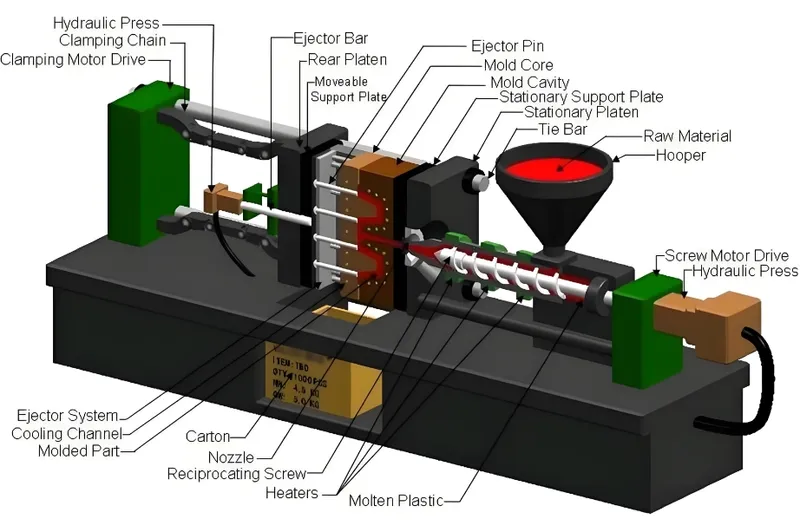

The capacity of a plastic injection molding machine is primarily defined by two key parameters: clamping force and shot size.

-

Clamping Force4: This is the force applied by the machine to keep the mold closed during the injection process. Measured in tons, it determines the maximum size of the mold that can be used. A higher clamping force allows for larger molds and, consequently, larger parts.

-

Shot Size: Also known as injection capacity5, this refers to the maximum amount of plastic that can be injected into the mold in one cycle. Typically measured in ounces or cubic centimeters (though sometimes in grams), it influences the volume and weight of the part that can be produced.

These two factors together define the machine’s ability to produce parts of varying sizes and complexities. For example, a machine with a clamping force of 100 tons and a shot size of 10 ounces might be suitable for small to medium-sized parts, while a machine with 500 tons and 50 ounces could handle larger components.

Classification of Injection Molding Machines

Injection molding machines can be classified based on their capacity and drive system.

-

By Capacity:

-

Small Machines: Typically have a clamping force of up to 100 tons and are used for producing small parts like caps, closures, and medical devices.

-

Medium Machines: Range from 100 to 500 tons and are suitable for medium-sized parts such as automotive components and consumer goods.

-

Large Machines: Have a clamping force above 500 tons and are used for large parts like appliance housings and industrial components.

-

-

By Drive System:

-

Hydraulic Machines6: Use hydraulic pumps to generate clamping force and injection pressure. They are robust and suitable for high-force applications but can be energy-intensive.

-

Electric Machines7: Utilize electric motors for all movements, offering higher precision, energy efficiency, and faster cycle times. They are ideal for clean-room environments and precision molding.

-

Hybrid Machines: Combine hydraulic and electric systems to balance performance and energy efficiency, providing versatility for various applications.

Understanding these classifications helps manufacturers select the appropriate machine for their specific production needs.

Hydraulic machines are more energy-efficient than electric machines.False

Electric machines are generally more energy-efficient due to their precise control and reduced energy consumption during idle times.

Machine capacity directly affects the size and complexity of parts that can be produced.True

Larger clamping force and shot size enable the production of bigger and more intricate parts.

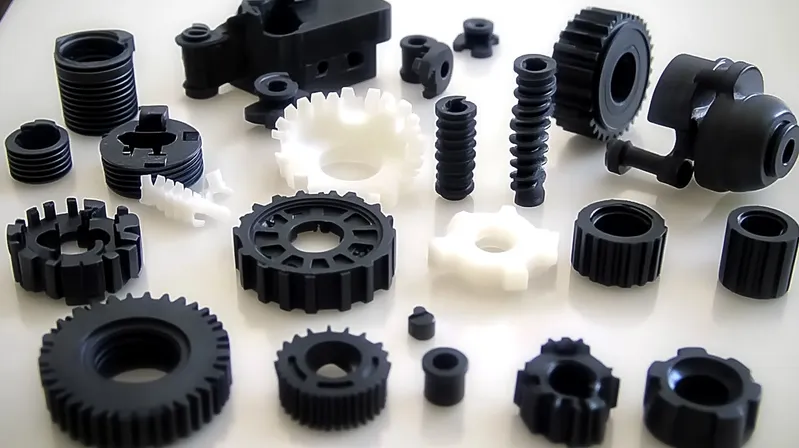

What are the Typical Applications of Injection Molding Machines?

Injection molding is utilized across a wide range of industries, each with unique requirements for machine capacity.

Injection molding is used in automotive, packaging, consumer goods, and medical industries, with machine capacity tailored to part size, complexity, and production volume.

| Industry | Typical Machine Capacity | Notes |

|---|---|---|

| Automotive | Medium to Large (100-2,200 tons) | For parts like dashboards and bumpers |

| Packaging | Small to Medium (10-500 tons) | High-speed production for caps and containers |

| Consumer Goods | Small to Large (10-1,000 tons) | Varies by part size and volume |

| Medical Devices | Small to Medium (10-100 tons) | Precision and cleanliness are critical |

Automotive Industry

Produces parts like dashboards, bumpers, and interior components, often requiring medium to large machines with high clamping force to accommodate large molds and ensure part strength.

Packaging Industry

Manufactures items such as caps, containers, and closures. Small to medium machines are typically used, focusing on high-speed production and precision.

Consumer Goods

Includes products like toys, household items, and electronics housings. Machine capacity varies depending on part size and production volume.

Medical Devices

Requires machines that produce small, precise parts with tight tolerances, often in clean-room settings. Electric machines are preferred for their precision and cleanliness.

For example, a company producing automotive dashboards might use a 500-ton machine with a large shot size, while a medical device manufacturer might opt for a 50-ton electric machine for syringe components.

Injection molding is only suitable for high-volume production.False

While ideal for high volumes, injection molding can also be used for medium-volume runs, especially with cost-effective mold materials like aluminum.

Machine capacity is the sole factor in determining production efficiency.False

Other factors like cycle time, material choice, and mold design also significantly impact efficiency.

What are the Pros and Cons of Injection Molding Compared to Other Processes?

Injection molding offers several advantages over other manufacturing processes, but it also has limitations.

Injection molding excels in high-volume production of complex parts but has high initial costs and longer lead times compared to processes like 3D printing or CNC machining.

Pros

-

High Volume Production8: Ideal for mass production, producing thousands to millions of parts efficiently.

-

Complex Geometries: Capable of creating parts with intricate designs and tight tolerances.

-

Material Versatility9: Can process a wide range of thermoplastics and some thermosets.

- Automation: Highly automated process reduces labor costs and increases consistency.

Cons

-

High Initial Costs10: Mold design and fabrication can be expensive, making it less suitable for low-volume production.

-

Lead Time: Developing and testing molds can take significant time before production begins.

-

Material Limitations: Not all materials are suitable, and some require specialized machines.

-

Defects: Potential for defects like warping, sink marks, and flash if parameters are not optimized.

Compared to 3D printing or CNC machining, injection molding is more cost-effective for large-scale production but less flexible for prototyping or small runs.

Injection molding can produce parts with tighter tolerances than 3D printing.True

Injection molding achieves tolerances as tight as thousandths of an inch, superior to most 3D printing methods.

Injection molding is always the best choice for plastic part production.False

For low-volume or highly customized parts, methods like CNC machining or 3D printing may be more suitable.

What is the Full Workflow of the Injection Molding Process?

The injection molding process consists of several key steps, each requiring precise control.

The injection molding process involves clamping, injection, cooling, and ejection, with each step critical to ensuring part quality.

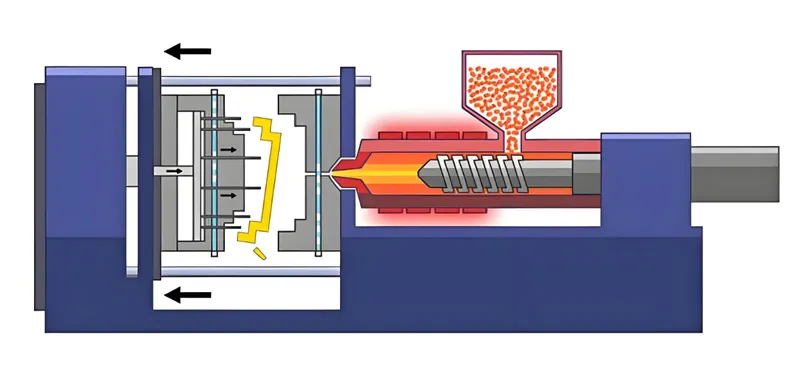

Clamping

The mold is closed and clamped with sufficient force to withstand injection pressure, preventing it from opening during the process.

Injection

Plastic pellets are melted and injected into the mold cavity under high pressure. Key parameters include injection speed, pressure, and temperature.

Cooling

The plastic cools and solidifies within the mold, with cooling time depending on material, part thickness, and mold design.

Ejection

The mold opens, and the solidified part is ejected using pins, requiring full solidification to avoid deformation.

Precise control at each step ensures quality—e.g., inadequate clamping force can cause flash, while improper cooling can lead to warping.

Cooling time is the longest part of the injection molding cycle.True

Cooling typically accounts for the majority of the cycle time, especially for thicker parts.

All injection molding machines have the same cycle time.False

Cycle time varies based on machine size, part complexity, and material used.

How Do Different Materials Affect Machine Capacity?

Material choice significantly impacts the injection molding process and machine capacity requirements.

Materials like polypropylene (PP), polyethylene (PE), polystyrene (PS), and ABS are commonly used, each with unique processing needs that influence machine selection.

| Material Type | Melting Temperature | Notes |

|---|---|---|

| Polypropylene (PP) | ~160-170°C | Low density, chemical resistant |

| Polyethylene (PE) | ~120-130°C | Versatile, used for packaging |

| Polystyrene (PS) | ~240°C | Rigid, used for disposable items |

| ABS | ~220°C | Tough, impact-resistant |

Material Impact

- Melting Temperature: High-melting-point materials like polycarbonate (~260°C) require machines with enhanced heating capabilities.

-

Viscosity: High-viscosity materials like PVC need higher injection pressure, affecting the drive system choice.

-

Shrinkage: Materials shrink variably upon cooling, impacting part dimensions and mold design.

For example, ABS might need moderate capacity, while PVC requires higher pressure capabilities.

All thermoplastics can be processed using the same machine settings.False

Each material requires specific parameters like temperature and pressure.

Material density affects the shot size calculation.True

Shot size is calculated based on volume and density to ensure the correct amount is injected.

What are the Key Design Considerations for Injection Molding?

Designing parts for injection molding requires specific guidelines to ensure manufacturability and quality.

Key considerations include uniform wall thickness, draft angles, avoiding undercuts, and proper gate placement to prevent defects.

Design Checklist

-

Uniform Wall Thickness: Maintain 1-3 mm thickness to prevent warping and sink marks.

-

Draft Angles: Include 1-2 degree angles for easy ejection.

-

Avoid Undercuts: Design without undercuts or use mold features like slides.

-

Rib Design: Use ribs for strength without increasing thickness.

-

Gate Location: Optimize gate placement for even filling and minimal weld lines.

-

Material Selection: Match material to part function and machine capabilities.

These guidelines minimize defects and enhance production efficiency.

Uniform wall thickness is crucial for preventing defects.True

Inconsistent thickness can cause uneven cooling and defects.

Draft angles are unnecessary in injection molding.False

Draft angles are essential for easy part ejection.

How to Decide if Injection Molding is the Right Process?

Consider these criteria to determine if injection molding suits your needs:

Injection molding is ideal for high-volume, complex parts but may not suit low-volume or prototyping needs.

Process Selection Decision-Making

-

Production Volume: High volumes (thousands to millions) favor injection molding.

-

Part Complexity: Complex geometries with tight tolerances are well-suited.

-

Material Requirements: Ensure the material is compatible (thermoplastics or thermosets).

-

Initial Investment: Assess affordability of mold costs.

-

Lead Time: Account for mold development time.

For example, producing 100,000 electronics housings benefits from injection molding’s efficiency.

Injection molding is suitable for prototyping.False

High mold costs make it less economical for prototyping compared to 3D printing.

Injection molding can handle both thermoplastics and thermosets.True

Specialized machines can process thermosets, though thermoplastics are more common.

Injection molding integrates with a broader manufacturing ecosystem.

Related technologies include plastic resin production, mold design, assembly, finishing, and quality control.

Upstream Processes

-

Plastic Resin Production: Creating raw pellets from petrochemicals or bio-based sources.

-

Mold Design and Fabrication: Precision mold-making via CNC, EDM, or additive manufacturing.

Downstream Processes

-

Assembly: Combining molded parts with other components.

-

Finishing: Painting, plating, or texturing for aesthetics or function.

-

Quality Control: Inspecting parts for defects and specifications.

This holistic view optimizes the production chain.

Conclusion

The capacity of a plastic injection molding machine, defined by clamping force and shot size, is critical for its suitability across applications. From small medical parts to large automotive components, the right capacity ensures efficient, high-quality production. By understanding classifications, applications, and technical details, manufacturers can align equipment with production goals. This guide offers valuable insights for navigating injection molding technology, whether designing products or scaling operations.

Table 1: Comparison of Injection Molding Machine Types

| Machine Type | Clamping Force Range | Energy Efficiency | Precision | Typical Applications |

|---|---|---|---|---|

| Hydraulic | 10 – 2,200 tons | Moderate | Good | Automotive, Industrial |

| Electric | 10 – 500 tons | High | Excellent | Medical, Electronics |

| Hybrid | 10 – 1,000 tons | High | Very Good | Consumer Goods, Packaging |

-

Understanding injection molding machine capacity is vital for optimizing production and ensuring quality. Explore this link for in-depth insights. ↩

-

Clamping force is crucial in injection molding. Learn how it affects the quality and efficiency of production by exploring this resource. ↩

-

Shot size directly influences the volume and quality of parts produced. Discover more about its significance in injection molding processes. ↩

-

Understanding clamping force is crucial for optimizing mold design and ensuring quality in injection molding processes. ↩

-

Learning about injection capacity can guide you in choosing the best machine for your manufacturing requirements. ↩

-

Discover the benefits of hydraulic machines in injection molding, which can help you make informed decisions for your production needs. ↩

-

Learn how electric machines enhance efficiency and precision in molding processes, crucial for modern manufacturing. ↩

-

Explore this link to understand how high volume production can enhance efficiency and reduce costs in manufacturing. ↩

-

Discover how material versatility in injection molding can lead to innovative product designs and applications. ↩

-

Learn about the implications of high initial costs in injection molding and how they affect production decisions. ↩