Injection molding is a manufacturing process where molten plastic, such as polyvinyl chloride (PVC), is injected into a mold to create precise, complex shapes like PVC fittings. These fittings are vital components in plumbing, construction, and irrigation systems. Known for its ability to produce large quantities of identical parts with high precision, injection molding is a cornerstone of modern manufacturing. But how efficient is it for producing PVC fittings? This blog post explores the process, its efficiency metrics, and its practical applications.

Injection molding1 efficiently produces PVC fittings by injecting molten PVC into molds, enabling high-volume production with precision, though initial mold costs can be significant.

Understanding the efficiency of injection molding is key to determining its suitability for your production needs. Read on to discover how factors like production rate, energy consumption2, and material waste contribute to its effectiveness.

Injection molding is the most efficient method for producing PVC fittings.True

For large-scale production, injection molding offers high precision, automation, and reduced per-part costs, making it highly efficient.

Injection molding is only suitable for large production runs.False

While cost-effective for high volumes, it can be adapted for smaller runs with careful planning, though initial costs may be higher.

- 1. What are the Key Efficiency Metrics in Injection Molding for PVC Fittings?

- 2. What Materials are Used in Injection Molding for PVC Fittings?

- 3. What are the Steps in the Injection Molding Process for PVC Fittings?

- 4. What are the Key Factors Affecting Injection Molding Efficiency for PVC Fittings?

- 5. What are the Applications of Injection Molding for PVC Fittings?

- 6. How Does Injection Molding Compare to Other Methods for Producing PVC Fittings?

- 7. Conclusion

What are the Key Efficiency Metrics in Injection Molding for PVC Fittings?

Efficiency in injection molding hinges on several measurable factors, including production rate, energy use, and material waste3. These metrics determine the process’s cost-effectiveness and scalability.

Injection molding efficiency for PVC fittings is driven by cycle time, energy consumption, material waste, and automation, enabling high output with optimized processes.

| Efficiency Metric | Impact on Production | Notes |

|---|---|---|

| Cycle Time4 | Shorter cycles increase output | Optimized for each part |

| Energy Consumption | Lower energy use reduces costs | Modern machines enhance efficiency |

| Material Waste | Minimized waste improves cost-effectiveness | Achieved through precise control |

| Automation | Reduces labor costs and errors | Key for large-scale production |

Production Rate

The production rate measures how many fittings an injection molding machine can produce per hour. With optimized cycle times, modern machines can churn out hundreds of fittings hourly, making them ideal for mass production. Learn more at Injection Molding for PVC Fittings.

Energy Consumption

Energy efficiency5 is critical for keeping costs down. Advances in machine design, like servo motors, reduce energy use per part, enhancing overall efficiency and sustainability.

Material Waste

Injection molding generates minimal waste when properly controlled. Precise mold design and injection parameters ensure that excess material is kept to a minimum, as highlighted in Efficiency in Injection Molding.

Injection molding always results in minimal material waste.False

Waste can increase if process parameters or mold designs are not optimized.

Automation in injection molding reduces production costs.True

Automation minimizes labor costs and human error, boosting efficiency and consistency.

What Materials are Used in Injection Molding for PVC Fittings?

The materials chosen for injection molding directly influence both efficiency and the quality of PVC fittings, with PVC being the star player due to its versatility.

PVC (Polyvinyl Chloride)6 is the primary material for injection-molded fittings, often enhanced with additives like stabilizers and plasticizers for better performance.

Polyvinyl Chloride (PVC)

PVC is a durable, chemical-resistant thermoplastic that can be rigid or flexible based on plasticizer use. It’s the go-to material for fittings in various applications. Check out PVC Material Properties for more details.

Additives

Additives like stabilizers7 (to prevent degradation), lubricants (to aid flow), and pigments (for color) are mixed with PVC to optimize its molding properties and final performance.

PVC is the only material used in injection molding for fittings.False

While PVC dominates, materials like polypropylene or ABS can also be used depending on the application.

Additives in PVC improve the efficiency of the injection molding process.True

Lubricants and stabilizers reduce friction and enhance flow, speeding up cycle times.

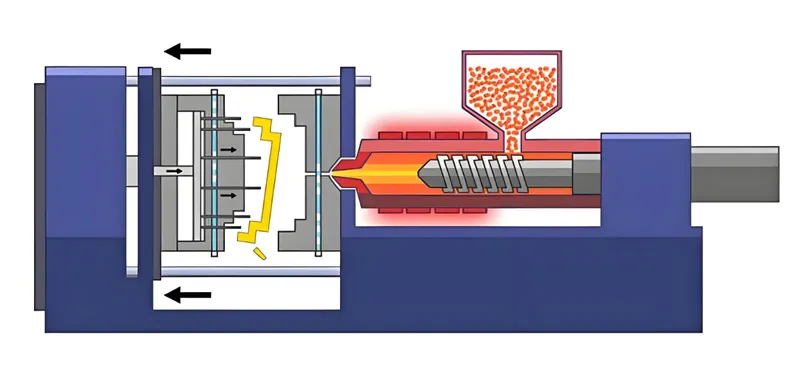

What are the Steps in the Injection Molding Process for PVC Fittings?

The injection molding process for PVC fittings is a series of precise steps, each optimized to ensure efficiency and quality.

The injection molding process for PVC fittings includes material feeding, melting, injection, cooling, and ejection, with each step fine-tuned for maximum efficiency.

Material Feeding

PVC pellets are loaded into the machine’s hopper, setting the stage for the molding process.

Melting

The pellets are melted in a barrel at 170°C to 200°C, using heat and a reciprocating screw. Special screw designs prevent PVC degradation, as noted in PVC Injection Molding Guide8.

Injection

Molten PVC is injected into the mold under high pressure, filling the cavity to form the fitting.

Cooling

The mold is cooled to solidify the PVC, with cooling time being a key factor in cycle efficiency.

Ejection

The mold opens, and the finished fitting is ejected, ready for use or further processing.

The injection step is the most time-consuming part of the process.False

Cooling typically takes longer, as it ensures proper solidification before ejection.

Proper control of melting temperature is crucial for PVC to prevent degradation.True

PVC’s sensitivity to heat requires precise temperature management to maintain material integrity.

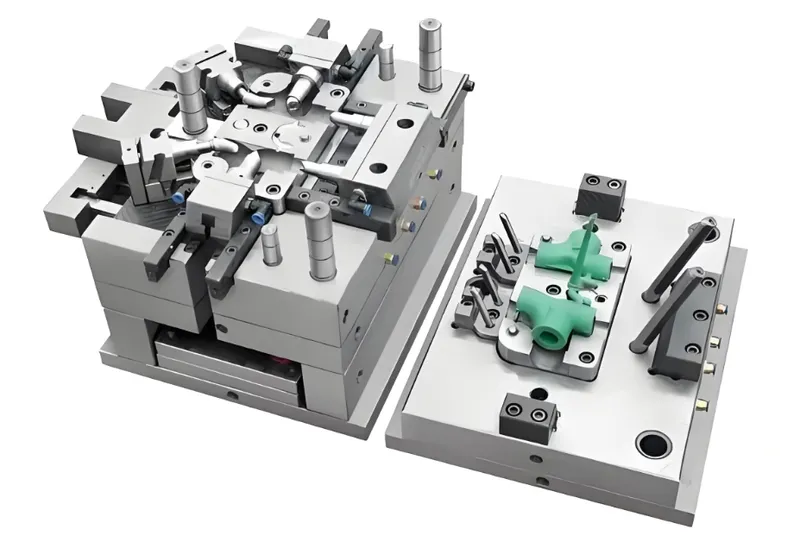

What are the Key Factors Affecting Injection Molding Efficiency for PVC Fittings?

Several factors determine how efficiently an injection molding machine produces PVC fittings, from machine settings to mold design.

Key factors affecting efficiency include machine settings, mold design, material properties, and automation, all of which impact production speed and cost.

Machine Settings

Temperature, pressure, and cycle time must be optimized. For PVC, precise temperature control prevents degradation, while pressure ensures uniform mold filling.

Mold Design

A well-crafted mold with features like cooling channels reduces cycle times and defects. See Mold Design for Injection Molding9 for more insights.

Material Properties

PVC’s viscosity and thermal stability affect processing. Additives can tweak these properties for better efficiency.

Automation

Automation reduces labor costs and ensures consistency, making it a game-changer for large-scale production.

Mold design has no impact on injection molding efficiency.False

Poor mold design can increase cycle times and defects, lowering efficiency.

Automation is essential for efficient injection molding.True

It cuts labor costs and enhances consistency, driving efficiency.

What are the Applications of Injection Molding for PVC Fittings?

Injection molding shines in producing PVC fittings for a range of industries, thanks to its precision and scalability.

PVC fittings made via injection molding are used in plumbing, construction, and irrigation for their durability and cost-effectiveness10 in high-volume production.

Plumbing

PVC fittings11 are staples in water supply and drainage systems, valued for their chemical resistance.

Construction

In building frameworks and piping, these fittings offer reliable, easy-to-install connections.

Irrigation

For agricultural water systems, PVC fittings ensure efficient distribution with minimal leaks.

Injection molding is only used for plumbing fittings.False

It’s also widely used in construction and irrigation, among other fields.

Injection molding allows for the production of complex fitting shapes.True

It creates intricate designs with tight tolerances, perfect for complex fittings.

How Does Injection Molding Compare to Other Methods for Producing PVC Fittings?

Injection molding stands out against alternatives like extrusion or fabrication, especially for complex, high-volume needs.

Injection molding is more efficient than extrusion or fabrication for complex PVC fittings12 in large volumes, despite higher initial costs.

Comparison with Extrusion

Extrusion suits continuous shapes like pipes but struggles with discrete, complex parts. Injection molding excels at detailed fittings.

Comparison with Fabrication

Fabrication, involving cutting and assembling PVC, is labor-intensive and less efficient for large runs but offers flexibility for small batches.

Injection molding is always more cost-effective than fabrication.False

For small or custom batches, fabrication may be cheaper due to lower upfront costs.

Injection molding produces higher precision parts than extrusion.True

It offers tighter tolerances and complex geometries compared to extrusion.

Conclusion

Injection molding is a powerhouse for producing PVC fittings, especially in large-scale, standardized production. Its high production rates, energy efficiency, and minimal material waste make it a top choice for industries like plumbing, construction, and irrigation. While initial mold costs can be steep, the process’s scalability and precision often outweigh this drawback for high-volume needs13. For smaller or custom runs, alternatives like fabrication might be more practical.

Optimizing machine settings, mold design, and material properties can unlock the full potential of injection molding, delivering high-quality PVC fittings efficiently and cost-effectively.

-

Explore this resource to gain a deeper understanding of injection molding, its processes, and applications in manufacturing. ↩

-

This link will provide insights into how energy consumption impacts the efficiency and cost-effectiveness of injection molding processes. ↩

-

Discover effective strategies to reduce material waste in injection molding, enhancing sustainability and cost savings. ↩

-

Understanding cycle time’s role can help optimize production processes and increase output efficiency. ↩

-

Exploring this resource will provide insights into how energy efficiency can significantly reduce costs and enhance sustainability in manufacturing. ↩

-

Understanding PVC’s properties will help you appreciate its versatility and why it’s the preferred material for fittings in various applications. ↩

-

This link will explain how additives improve the performance and longevity of injection-molded products, crucial for quality manufacturing. ↩

-

Explore this guide to understand the intricacies of PVC injection molding and improve your production efficiency. ↩

-

Discover essential mold design practices that can enhance your injection molding process and reduce defects. ↩

-

Discover the factors that contribute to the cost-effectiveness of injection molding in producing durable PVC fittings for various applications. ↩

-

Explore the advantages of PVC fittings in various industries, including plumbing and construction, to understand their importance and applications. ↩

-

Learn about the manufacturing techniques for complex PVC fittings and how injection molding plays a crucial role in their production. ↩

-

Discover the industries that thrive on high-volume manufacturing and how injection molding meets their demands effectively. ↩