Insert molding is a specialized injection molding technique1 that integrates pre-formed inserts—typically metal components2—into plastic parts during the molding process. This method enhances traditional injection molding by producing stronger, more functional, and cost-effective products. By embedding inserts directly into the plastic, manufacturers can reduce assembly steps, improve design flexibility, and create lightweight yet durable components. Widely adopted in industries like automotive, medical, and electronics, insert molding3 leverages the combined properties of metal and plastic to meet diverse application needs.

Insert molding enhances injection processes by integrating metal inserts into plastic parts, reducing assembly steps, improving strength, and enabling complex designs for industries like automotive and medical.

Understanding how insert molding works and its benefits can help you optimize manufacturing processes and product performance. Explore further to see how it compares to other techniques and its practical applications.

Insert molding reduces assembly costs in manufacturing.True

By integrating inserts during the molding process, separate assembly steps are eliminated, leading to significant time and labor savings.

Insert molding is only used in the automotive industry.False

While common in automotive, insert molding is also widely used in medical, electronics, and consumer goods industries due to its versatility.

- 1. What is Insert Molding?

- 2. How Does Insert Molding Enhance Injection Processes?

- 3. What are the Steps in the Insert Molding Process?

- 4. What are the Common Materials Used in Insert Molding?

- 5. What are the Design Considerations for Insert Molding?

- 6. What are the Differences Between Insert Molding and Overmolding?

- 7. Conclusion

What is Insert Molding?

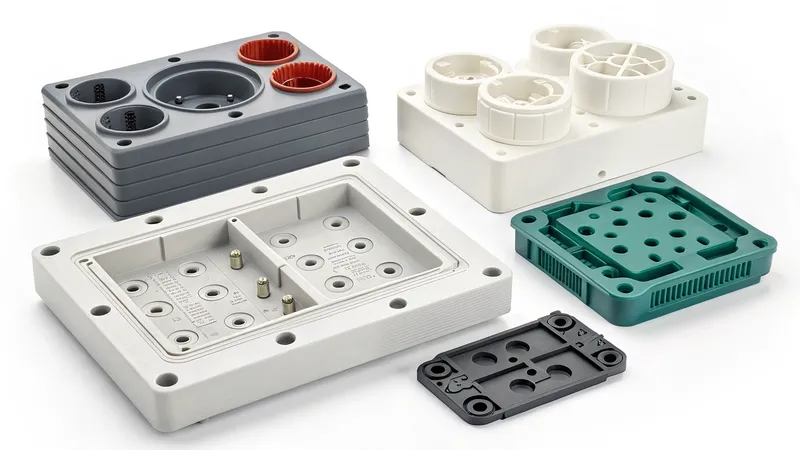

Insert molding involves placing pre-formed inserts, such as metal screws, connectors, or bushings, into a mold cavity before injecting molten plastic. As the plastic cools and solidifies, it bonds with the insert, forming a single, integrated part. This process enhances traditional injection molding by combining the strength and durability of metal with the lightweight and versatile properties of plastic (RapidDirect).

Clear Definitions

-

Insert Molding: A process where pre-formed inserts (e.g., metal, plastic, or electronic components) are embedded into plastic parts during injection molding.

-

Full Technical Name: Insert Injection Molding4

-

Common Aliases: Metal Insert Molding, Insert Molding

-

Core Principles:

- Accurate positioning of inserts in the mold cavity.

- Injection of molten plastic under high pressure to encase the insert.

- Ensuring strong adhesion between the insert and plastic.

- Cooling and ejecting the part without damaging the insert.

Classification

Insert molding can be categorized by process, materials, and applications:

-

By Process:

- Manual Insert Loading: Ideal for low-volume production with hands-on inspection.

- Automated Insert Loading5: Uses robotics for precision and efficiency in high-volume production.

-

By Materials:

- Inserts: Metals (brass, stainless steel, aluminum), plastics, or electronic components (e.g., connectors).

- Plastics:

- Thermoplastics6: Polypropylene (PP), Nylons (PA), Polycarbonate (PC), ABS, Polyethylene (PE), Acetal.

- Thermosets: Polyester, Epoxy, Melamine-Formaldehyde Resins.

- Elastomers: Polyurethane, Natural Rubber.

-

By Applications:

- Automotive: Lightweight structural components.

- Medical Devices: Implants, catheters.

- Electronics: Connectors, switches.

- Consumer Goods: Tools, appliances.

Insert molding is a single-step process.True

It integrates the insert and plastic in one molding cycle, eliminating the need for post-molding assembly.

Insert molding can only use metal inserts.False

While metal is common, inserts can also be plastic or electronic components depending on the application.

How Does Insert Molding Enhance Injection Processes?

Insert molding improves injection molding in several key ways:

-

Multi-Material Integration7: Embeds metal or other inserts into plastic, enhancing strength and functionality (e.g., threaded inserts for fastening).

-

Reduced Assembly8: Combines components in one step, cutting labor costs and production time.

-

Design Flexibility9: Enables complex, multi-material parts tailored to specific needs.

-

Enhanced Performance: Merges plastic’s lightweight nature with metal’s durability, ideal for demanding applications.

Typical Application Scenarios

Insert molding excels in scenarios requiring integrated materials:

-

Automotive Industry: Produces lightweight parts like threaded inserts for fastening, boosting fuel efficiency and reducing assembly time.

-

Medical Devices: Integrates metal components into biocompatible plastics for items like catheters and implants, ensuring strength and functionality.

-

Electronics: Embeds metal contacts into plastic housings for connectors and switches in a single step.

-

Consumer Goods: Combines metal strength and plastic ergonomics in tools and appliances, such as screwdriver handles.

Pros and Cons Comparison

Insert molding offers distinct advantages over other methods, with some trade-offs.

| Aspect | Insert Molding | Traditional Injection Molding | Overmolding |

|---|---|---|---|

| Definition | Integrates pre-formed inserts into plastic. | Molds single-material plastic parts. | Molds one material over another. |

| Pros | – Reduces assembly steps and costs. – Enhances strength and functionality. – Supports complex designs. |

– Simpler process for single-material parts. – Fewer compatibility issues. |

– Strong molecular bonds. – Ideal for textured layers. |

| Cons | – Inserts must endure molding conditions. – Risk of defects if poorly designed. |

– Limited to single materials. – Requires separate assembly. |

– More complex and costly process. |

Comparison Notes:

-

Vs. Traditional Injection Molding: Adds insert integration, reducing assembly needs.

-

Vs. Overmolding: Single-shot process for inserts vs. multi-shot layering (SyBridge Technologies).

Insert molding is more cost-effective than traditional injection molding for multi-material parts.True

It eliminates post-molding assembly, reducing labor and production costs.

Insert molding cannot be used for high-volume production.False

Automated insert loading makes it highly efficient for high-volume runs.

What are the Steps in the Insert Molding Process?

Insert molding follows a precise workflow to integrate inserts and plastic effectively:

-

Insert Loading: Inserts are placed into the mold cavity manually (low-volume) or automatically (high-volume).

-

Injection: Molten plastic is injected under high pressure, surrounding the insert.

-

Cooling and Solidification: The plastic cools and bonds with the insert, maintaining holding pressure to prevent shrinkage.

-

Ejection: The mold opens, and the part is ejected without damage.

-

Post-Molding Operations: Deburring, heat treatment (e.g., 10-20°C below deformation temperature), or humidity control (e.g., 80-100°C hot water bath) may follow.

Key Steps and Parameters

- Insert Positioning: Essential for accuracy; automation improves consistency.

-

Injection Pressure: Ensures even filling and adhesion.

-

Holding Pressure: Prevents shrinkage and maintains dimensions.

-

Cooling Time: Controlled to avoid warping or sink marks.

-

Post-Processing: Enhances final quality through trimming or conditioning.

Automated insert loading improves precision in high-volume production.True

Robotic systems ensure consistent placement, reducing defects and boosting efficiency.

Insert molding always results in perfect adhesion.False

Adhesion depends on material compatibility and process conditions; poor design can cause defects.

What are the Common Materials Used in Insert Molding?

Material choice in insert molding is critical for industries needing lightweight, durable, and functional products.

Insert molding commonly uses metal inserts like brass, steel, or aluminum with thermoplastics such as PP, PA, PC, ABS, or PE for strength and versatility in automotive, medical, and electronics applications.

| Material Type | Recommended Wall Thickness (inches) | Notes |

|---|---|---|

| ABS | 0.045 – 0.140 | Versatile, good finish |

| Acetal | 0.030 – 0.120 | High stiffness, low friction |

| Nylon (PA) | 0.030 – 0.115 | Strong, wear-resistant |

| Polycarbonate (PC) | 0.040 – 0.150 | Transparent, impact-resistant |

| Polypropylene (PP) | 0.035 – 0.150 | Flexible, cost-effective |

Metal Inserts

-

Brass: Corrosion-resistant, ideal for threaded inserts.

-

Stainless Steel: High-strength, used in medical devices.

-

Aluminum: Lightweight, common in automotive parts.

Plastic Materials

- Polypropylene (PP): Flexible and economical, used in consumer goods.

-

Nylons (PA): Strong and wear-resistant, suited for automotive.

-

Polycarbonate (PC): Impact-resistant, used in electronics.

-

ABS: Versatile with good finish, popular in consumer products.

-

Polyethylene (PE): Durable and chemical-resistant, used in packaging.

Material selection hinges on mechanical properties, thermal resistance, and cost (WayKen).

Metal inserts are the only type used in insert molding.False

Plastic and electronic inserts are also used based on application needs.

Material selection is critical for successful insert molding.True

Compatibility between insert and plastic affects performance and durability.

What are the Design Considerations for Insert Molding?

Effective insert molding requires precise design to ensure quality and manufacturability.

Key design considerations include insert selection, tolerances, draft angles, wall thickness, and surface finishes to optimize part performance.

Design Checklist

-

Insert Selection: Use standard inserts (e.g., PEM, Dodge) resistant to molding conditions.

-

Tolerances:

- Substrate molds: ±0.003 in. (0.08mm)

- Resin: ≥0.002 in./in. (0.002mm/mm)

-

Draft Angles:

- Vertical faces: 0.5°

- Most situations: 2°

- Shut-off: 3°

-

Wall Thickness: Varies by material (e.g., ABS: 0.045-0.140 in.).

-

Surface Finishes: Options like PM-F0 (non-cosmetic), SPI-C1 (fine).

Process Selection Decision-Making

-

Use Insert Molding: For parts needing embedded components and fewer assembly steps.

-

Consider Alternatives:

- Overmolding: For layered multi-material parts.

- Traditional Injection Molding: For single-material parts.

-

Moldability Analysis: Validate designs with tools like Protolabs.

Proper insert selection is crucial for part performance.True

The right insert ensures durability under molding conditions.

Insert molding designs do not require draft angles.False

Draft angles aid ejection and prevent damage.

What are the Differences Between Insert Molding and Overmolding?

Insert molding and overmolding enhance injection molding differently.

Insert molding embeds pre-formed inserts in a single shot, while overmolding layers materials in multiple shots for complex designs.

Process Flow

-

Insert Molding: Single cycle embeds inserts into plastic.

-

Overmolding: Multi-shot process layers materials over a base.

Principle

-

Insert Molding: Enhances functionality with embedded inserts.

-

Overmolding: Bonds materials for ergonomic or aesthetic purposes.

Molding Characteristics

-

Insert Molding: Efficient for high-volume, single-shot production.

-

Overmolding: Complex, multi-shot process for layered parts.

Application Scenarios

-

Insert Molding: Automotive fasteners, medical implants.

-

Overmolding: Soft-touch grips, waterproof seals.

Advantages and Disadvantages

-

Insert Molding: Cost-effective, strong parts; requires durable inserts.

-

Overmolding: Flexible designs; higher complexity and cost.

Insert molding and overmolding are interchangeable.False

Insert molding embeds inserts; overmolding layers materials.

Overmolding is more suitable for high-volume production than insert molding.False

Insert molding excels in high-volume with automation.

Conclusion

Insert molding enhances injection processes by integrating metal and plastic in one step, reducing costs, and enabling complex, durable designs. Its versatility spans automotive, medical, electronics, and consumer goods. By mastering its process, materials, and design principles, manufacturers can optimize production and product quality.

-

Learn about the injection molding technique to understand its applications and benefits in various industries. ↩

-

Explore the significance of metal components in insert molding for creating stronger and more functional products. ↩

-

Discover the advantages of insert molding, including cost-effectiveness and design flexibility, to enhance your manufacturing processes. ↩

-

Explore this link to understand the intricacies of Insert Injection Molding and its applications in various industries. ↩

-

Discover how Automated Insert Loading enhances production efficiency and precision in high-volume manufacturing processes. ↩

-

Learn about the various types of Thermoplastics and their applications in manufacturing, which can help in material selection for projects. ↩

-

Explore how Multi-Material Integration can enhance product strength and functionality, making it a game-changer in manufacturing. ↩

-

Learn about the advantages of Reduced Assembly in cutting costs and improving production timelines, crucial for competitive manufacturing. ↩

-

Discover how Design Flexibility allows for innovative and tailored solutions in product design, essential for meeting diverse market needs. ↩