Automation in injection molding significantly reduces labor costs by replacing manual tasks with efficient, machine-driven processes, enabling manufacturers to produce more with fewer workers while maintaining high quality and consistency.

Automation in injection molding lowers labor costs by automating repetitive tasks like part removal, inspection, and packaging, reducing the need for manual labor and increasing production efficiency.

Understanding how automation impacts labor costs is crucial for manufacturers looking to optimize their operations. This blog explores the key ways automation reduces labor expenses, the types of automation used, and the benefits and challenges of implementation.

Automation always reduces labor costs in injection molding.True

By automating tasks previously done manually, manufacturers can reduce the number of workers needed, directly lowering labor costs.

Automation is only beneficial for large-scale production.False

While particularly advantageous for high-volume production, automation can also improve efficiency and consistency in smaller-scale operations.

- 1. What is Injection Molding and How Does Automation Fit In?

- 2. How Does Automation Reduce Labor Costs in Injection Molding?

- 3. What Types of Automation Are Used in Injection Molding?

- 4. What is the Process of Implementing Automation in Injection Molding?

- 5. What are the Benefits and Challenges of Automation in Injection Molding?

- 6. How Do Automated and Manual Processes Compare in Injection Molding?

- 7. Conclusion

What is Injection Molding and How Does Automation Fit In?

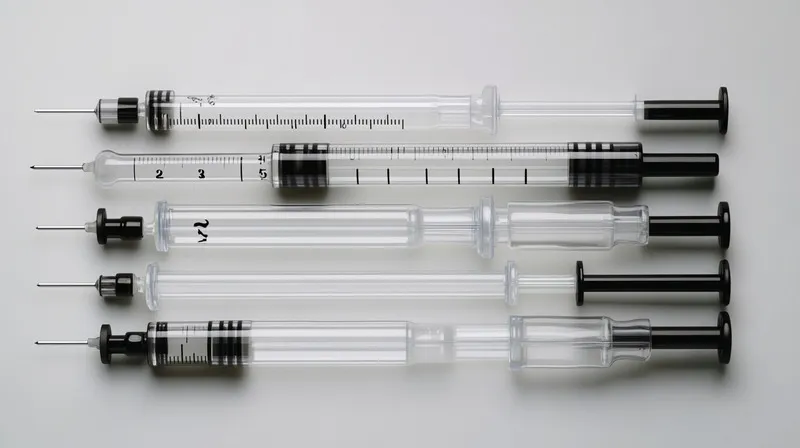

Injection molding1 is a manufacturing process where molten plastic is injected into a mold to create parts with precise shapes and sizes, commonly used in industries like automotive, medical, and consumer goods.

Injection molding involves melting plastic pellets, injecting them into a mold, and cooling them to form parts. Automation enhances this process by handling tasks like part removal, inspection, and packaging, reducing manual labor.

| Process Step | Manual Task2 | Automated Task3 |

|---|---|---|

| Part Removal | Worker removes part from mold | Robotic arm removes part |

| Inspection | Worker visually inspects part | Automated system inspects part |

| Packaging | Worker sorts and packages parts | Automated system sorts and packages |

| Material Handling | Worker loads pellets and removes waste | Automated system handles materials |

The Role of Automation in Injection Molding

Automation in injection molding refers to the use of machines, such as robotic arms and conveyor systems, to perform repetitive tasks. This reduces the need for human intervention, lowering labor costs and increasing production speed.

For example, robotic arms can remove parts from molds faster and more consistently than human workers, allowing for continuous operation without breaks.

Automation eliminates all manual labor in injection molding.False

While automation reduces the need for manual labor, some tasks like maintenance and troubleshooting still require human intervention.

Automation increases production speed and consistency.True

Automated systems perform tasks faster and with greater precision, reducing cycle times and defects.

How Does Automation Reduce Labor Costs in Injection Molding?

Automation reduces labor costs4 by minimizing the need for workers in repetitive and time-consuming tasks, allowing manufacturers to allocate human resources to more complex roles.

Automation lowers labor costs by replacing manual tasks like part removal, inspection, and packaging with machines, reducing the workforce needed for production.

Key Ways Automation Reduces Labor Costs

-

Part Removal: Robotic arms5 can remove parts from molds quickly and consistently, eliminating the need for workers to perform this repetitive task.

-

Inspection: Automated quality control systems6 use cameras and sensors to inspect parts, reducing the need for manual inspection.

-

Packaging: Automated systems sort, count, and package parts, minimizing manual labor in the final stages of production.

-

Material Handling: Automated feeders and waste removal systems handle raw materials and scrap, reducing the need for workers to manage these tasks.

By automating these tasks, manufacturers can operate with fewer workers, directly lowering labor costs.

Automation only reduces labor costs in high-volume production.False

Automation can reduce labor costs in both high- and low-volume production by improving efficiency and reducing manual intervention.

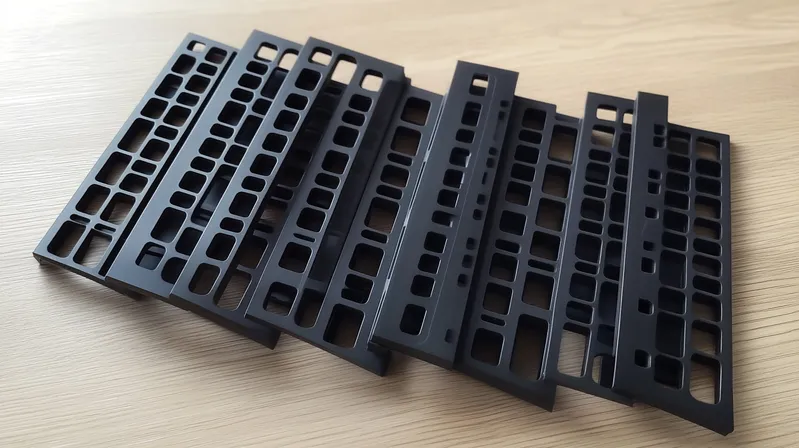

What Types of Automation Are Used in Injection Molding?

Various types of automation are employed in injection molding to streamline production and reduce labor costs, each suited to specific tasks within the process.

Common types of automation in injection molding7 include robotic arms8, conveyor systems, automated quality control9, and material handling systems, each reducing manual labor in different stages.

Robotic Arms

Robotic arms are widely used for tasks like part removal, stacking, and assembly. They can operate continuously, increasing production speed and reducing the need for manual labor.

For instance, robotic automation can handle multiple tasks simultaneously, such as removing parts and placing them on conveyors for further processing.

Conveyor Systems

Conveyor systems transport parts between different stages of production, such as from the molding machine to inspection or packaging areas, reducing the need for workers to manually move parts.

Automated Quality Control

Automated inspection systems use cameras, sensors, and software to detect defects, ensuring consistent quality without manual checks.

Material Handling Systems

These systems automate the loading of plastic pellets into the machine and the removal of waste material, minimizing manual handling.

Robotic arms are the only type of automation used in injection molding.False

While robotic arms are common, other automation types like conveyor systems and automated quality control are also essential.

Automated quality control systems can completely replace human inspectors.False

While highly effective, automated systems may still require human oversight for complex inspections or troubleshooting.

What is the Process of Implementing Automation in Injection Molding?

Implementing automation in injection molding involves careful planning, installation, and training to ensure seamless integration and optimal performance.

The implementation process includes assessment, planning, installation, training, and testing, requiring investment and expertise but leading to long-term cost savings.

Steps in the Implementation Process

-

Assessment: Evaluate current processes to identify tasks suitable for automation.

-

Planning: Select the appropriate automation technology and design the system for integration with existing equipment.

-

Installation: Install and integrate the automation equipment with the injection molding machines.

-

Training: Train workers to operate and maintain the new systems.

- Testing and Optimization: Test the system and make adjustments to ensure efficiency and reliability.

While the process can be complex, the reduction in labor costs and increased efficiency often justify the investment.

Implementing automation in injection molding is a quick and easy process.False

Implementation requires careful planning, installation, and training, making it a complex but worthwhile endeavor.

What are the Benefits and Challenges of Automation in Injection Molding?

Automation offers significant benefits in reducing labor costs and improving efficiency but also presents challenges like high initial costs and the need for specialized training.

Benefits include reduced labor costs, increased efficiency, improved consistency, and enhanced safety. Challenges involve high upfront costs, complexity, and the need for worker training.

Benefits of Automation

-

Reduced Labor Costs10: Fewer workers are needed for production, lowering overall labor expenses.

-

Increased Efficiency11: Automation speeds up production cycles and reduces downtime.

-

Improved Consistency: Automated systems ensure uniform quality, reducing defects and waste.

- Enhanced Safety: Automation handles dangerous tasks, reducing workplace injuries.

Challenges of Automation

-

Initial Costs12: The upfront investment in automation equipment can be substantial.

-

Complexity: Integrating and maintaining automated systems requires technical expertise.

-

Training: Workers must be trained to operate and troubleshoot the new systems.

-

Flexibility: Automated systems may be less adaptable to changes in production than manual labor.

Despite these challenges, the long-term benefits of automation often outweigh the initial hurdles.

Automation in injection molding has no downsides.False

While automation offers many advantages, it also comes with challenges like high costs and the need for specialized training.

Automation improves workplace safety by reducing manual handling of dangerous tasks.True

Automated systems can perform hazardous tasks, minimizing the risk of injuries to workers.

How Do Automated and Manual Processes Compare in Injection Molding?

Automated processes in injection molding offer clear advantages over manual processes in terms of labor costs, efficiency, and consistency, though they require higher initial investment.

Automated processes reduce labor costs, increase efficiency, and improve consistency compared to manual processes, but they involve higher upfront costs and less flexibility.

| Aspect | Manual Process | Automated Process |

|---|---|---|

| Labor Costs | Higher due to more workers needed | Lower due to reduced need for workers |

| Efficiency | Slower, with more downtime | Faster, with less downtime |

| Consistency | Variable, depending on worker skill | High, with consistent quality |

| Initial Investment | Lower, as less equipment is needed | Higher, due to cost of automation equipment |

| Flexibility | Higher, as workers can adapt to changes | Lower, as systems are programmed for specific tasks |

Automated processes are always more efficient than manual processes in injection molding.True

Automation reduces cycle times and minimizes downtime, leading to greater overall efficiency.

Manual processes are more cost-effective for small-scale production.True

For low-volume production, the high initial costs of automation may not be justified, making manual processes more economical.

Conclusion

Automation in injection molding is a powerful tool for reducing labor costs by minimizing the need for manual intervention in repetitive tasks like part removal, inspection, and packaging. While the initial investment and implementation process can be challenging, the long-term benefits—such as increased efficiency, improved consistency, and enhanced safety—make automation a valuable strategy for manufacturers.

As technology continues to advance, automation is likely to become even more accessible and integral to injection molding operations. Manufacturers considering automation should carefully assess their needs, plan the implementation process, and invest in worker training to maximize the benefits.

-

Explore this link to understand the fundamentals of injection molding and its applications across various industries. ↩

-

Learn about the limitations and challenges faced in manual tasks during the injection molding process, and how they can be addressed. ↩

-

Discover how automation in injection molding improves efficiency and reduces labor costs, enhancing production quality. ↩

-

Explore how automation can significantly cut costs and improve efficiency in manufacturing processes. ↩

-

Discover how robotic arms can streamline production and lower labor costs through efficiency and precision. ↩

-

Learn about the advantages of automated quality control systems in enhancing product quality and reducing labor needs. ↩

-

Explore how automation enhances efficiency and reduces costs in injection molding processes. ↩

-

Learn about the role of robotic arms in increasing production speed and efficiency in manufacturing. ↩

-

Discover how automated quality control ensures product quality and consistency in production. ↩

-

Understanding how reduced labor costs can enhance profitability is crucial for businesses considering automation. ↩

-

Exploring the impact of increased efficiency can help businesses optimize their operations and boost productivity. ↩

-

Knowing the initial costs can help businesses budget effectively and make informed decisions about automation investments. ↩