Plastic injection molding is a vital manufacturing process that produces precise, complex plastic parts in large volumes. A critical aspect of this process is determining the capacity of the injection molding machine to ensure it meets production demands efficiently and cost-effectively. Machine capacity is primarily defined by its shot weight1—the maximum amount of plastic it can inject per cycle—and its clamping force2—the force needed to keep the mold closed during injection. These factors, combined with material properties and part design, guide the selection process.

To determine capacity, calculate the shot weight based on part volume and material density, targeting 20–80% of the machine’s capacity for general resins, and ensure the clamping force (2–5 tons per square inch of part area, plus a 10% safety margin) matches the production requirements.

This article explores the key factors, applications, technical details, and practical tools for determining machine capacity3, helping you make informed decisions for your manufacturing needs.

Shot weight is the sole determinant of machine capacity.False

While shot weight is a key factor, clamping force and material properties also play significant roles in capacity determination.

Proper capacity selection improves production efficiency.True

Matching the machine capacity to the part’s requirements reduces waste and downtime, optimizing output.

- 1. What Are the Key Factors in Determining Injection Molding Machine Capacity?

- 2. What Are the Typical Applications of Injection Molding Machines?

- 3. How Does Injection Molding Compare to Other Manufacturing Methods?

- 4. What Are the Steps in the Injection Molding Process?

- 5. What Practical Tools Help Determine Machine Capacity?

- 6. What Technologies Relate to Injection Molding?

- 7. Conclusion

What Are the Key Factors in Determining Injection Molding Machine Capacity?

Determining the right machine capacity involves evaluating several critical parameters that ensure the machine can produce parts effectively.

Key factors include shot weight4, clamping force5, and material properties6, which collectively dictate the machine’s suitability for specific parts and production goals.

| Factor | Description | Notes |

|---|---|---|

| Shot Weight | Amount of plastic injected per cycle, ideally 20–80% of machine capacity. | Depends on material and part size. |

| Clamping Force | Force to hold the mold closed, typically 2–5 tons/in² of projected area. | Requires a 10% safety buffer. |

| Material Properties | Influences flow, shrinkage, and pressure needs, affecting capacity choice. | Varies by resin type. |

Shot Weight

Shot weight refers to the maximum plastic volume (in grams or ounces) the machine can inject per cycle. For general-purpose resins like polyethylene (PE) or polypropylene (PP), the part’s shot weight should fall within 20–80% of the machine’s capacity to ensure proper filling and avoid overloading. For engineered resins like polycarbonate (PC), a narrower range of 30–50% is recommended due to stricter processing needs (Plastics Machinery & Manufacturing).

Clamping Force

Clamping force, measured in tons, keeps the mold closed against the pressure of injected plastic. It’s calculated by multiplying the part’s projected area (in square inches) by 2–5 tons per square inch, depending on material viscosity. For instance, a part with a 50-square-inch area might need 150 tons of clamping force, plus a 10% safety margin, totaling 165 tons (Nicolet Plastics).

Material Properties

The plastic’s characteristics—such as viscosity, melting point, and shrinkage—impact capacity requirements. High-viscosity materials like nylon require higher injection pressures, while materials with significant shrinkage, like ABS, demand precise mold and cooling control.

Clamping force depends only on mold size.False

Clamping force is influenced by part area, material viscosity, and injection pressure, not just mold size.

Material choice affects both shot weight and clamping force needs.True

Different plastics require adjustments in injection and clamping parameters to achieve quality parts.

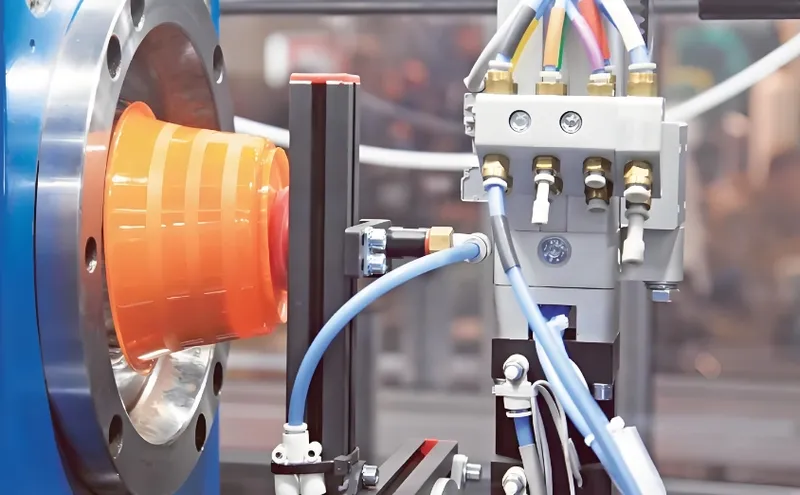

What Are the Typical Applications of Injection Molding Machines?

Injection molding machines support a variety of industries, each with distinct capacity needs based on part size, precision, and production volume.

Common applications include automotive, medical, packaging, and consumer goods, where machine capacity impacts production efficiency and part quality.

Automotive Industry

Automotive parts like bumpers and dashboards require large machines with high clamping forces (often exceeding 1,000 tons) due to their size and structural demands.

Medical Industry

Medical components, such as syringes and implants, need smaller shot weights but high precision, often using machines with advanced control systems for engineered resins.

Packaging Industry

Packaging items like caps and containers favor high-speed machines with moderate clamping forces, optimized for rapid cycle times and high output.

Consumer Goods

From toys to electronics housings, consumer products vary widely, requiring machines ranging from small precision units to larger models for bulkier items.

Injection molding is limited to large-scale production.False

It’s cost-effective for high volumes but can also suit medium runs with proper planning.

Automotive parts often require higher clamping forces than medical parts.True

Larger automotive components need greater force to maintain mold integrity during injection.

How Does Injection Molding Compare to Other Manufacturing Methods?

Injection molding has unique strengths and limitations compared to alternatives, influencing its suitability for specific projects.

Injection molding offers high precision7 and scalability but involves higher initial costs8 than 3D printing or CNC machining.

| Method | Pros | Cons |

|---|---|---|

| Injection Molding | High precision, fast for high volumes9, wide material use | High mold costs, longer lead times |

| 3D Printing | Low setup cost, great for prototypes, complex shapes | Slower, costly for large volumes |

| CNC Machining | Precise, works with metals and plastics | Limited for internal features, costly for high volumes |

| Blow Molding | Good for hollow parts, lower mold costs | Less precise, shape limitations |

Advantages

-

Precision: Tolerances as tight as ±0.005 inches.

-

Speed: Cycle times as low as 10 seconds.

-

Versatility: Supports numerous plastics.

Disadvantages

-

Cost: Molds can cost $2,000–$5,000 or more.

-

Lead Time: Mold-making delays initial production.

Injection molding is always cheaper than 3D printing.False

For low volumes, 3D printing avoids mold costs, making it more economical.

Injection molding provides faster production than CNC machining for high volumes.True

Its automated cycles outpace CNC’s manual processes in large-scale runs.

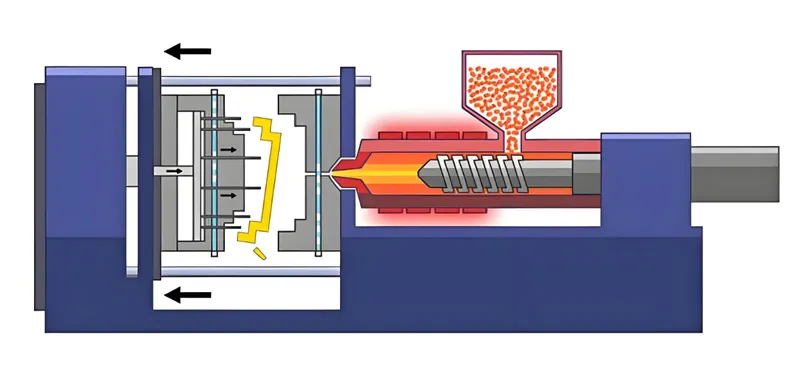

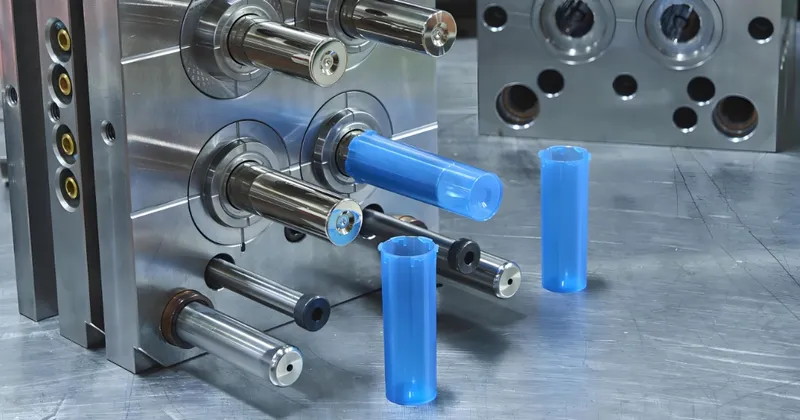

What Are the Steps in the Injection Molding Process?

The injection molding10 process involves multiple stages, each affecting the machine capacity needed for successful production.

Key steps include mold design, material selection, injection, cooling, and ejection, with precise control over pressure and temperature.

Mold Design

Molds are crafted using CAD and CNC machining, incorporating features like draft angles and gates for optimal flow (Wayken RM).

Material Selection

Plastics like PP, ABS, or PC are chosen based on part requirements, influencing machine settings.

Injection Cycle

-

Melting: Plastic is heated in the barrel (e.g., 220°C for ABS).

-

Injection: Molten plastic fills the mold at 100–150 MPa.

-

Cooling: The part solidifies in the mold.

-

Ejection: The mold opens, releasing the part.

Post-Processing

Parts are inspected and may undergo trimming or assembly.

The injection process requires no human intervention.True

Modern machines automate the cycle, minimizing labor.

All materials use identical injection settings.False

Settings vary by material to optimize flow and cooling.

What Practical Tools Help Determine Machine Capacity?

Practical tools streamline the capacity selection process, ensuring compatibility with part and production needs.

Use a design checklist11 and decision-making guide to select the right machine capacity efficiently.

Design Checklist

-

Wall Thickness: 0.04–0.15 inches for uniformity.

-

Draft Angles: 1–2 degrees for easy release.

-

Undercuts: Minimize to simplify molds.

Decision-Making Guide

-

Volume: High → Injection molding; Low → 3D printing.

-

Complexity: High → Injection molding; Simple → Blow molding.

-

Material: Thermoplastics → Injection molding.

A checklist prevents design errors affecting capacity choice.True

It ensures part features align with machine capabilities.

Injection molding suits all production scenarios.False

Other methods may be better for low volumes or simple parts.

What Technologies Relate to Injection Molding?

Injection molding connects to a network of related processes that enhance or complement its use.

Related technologies include mold design, material production, assembly, and alternatives like 3D printing.

Upstream

-

Material Production: Tailoring resins for molding.

-

Mold Making: Precision mold creation.

Downstream

-

Assembly: Joining molded parts.

-

Quality Control: Ensuring part standards.

Alternatives

-

3D Printing: For prototypes.

-

CNC Machining: For precision non-plastics.

Mold design is essential for injection molding success.True

Accurate molds ensure part quality and process efficiency.

Conclusion

Determining the capacity of a plastic injection molding machine involves balancing shot weight, clamping force, and material properties to match production needs. From automotive to medical applications, selecting the right capacity enhances efficiency and quality. By leveraging the tools and insights provided, manufacturers can optimize their injection molding processes for superior results.

-

Understanding shot weight is crucial for optimizing production efficiency and ensuring quality in plastic parts manufacturing. ↩

-

Exploring clamping force helps in selecting the right machine and achieving optimal results in the injection molding process. ↩

-

Learning about machine capacity is essential for maximizing production efficiency and meeting manufacturing demands effectively. ↩

-

Understanding shot weight is crucial for optimizing machine capacity and ensuring quality production. Explore this link for detailed insights. ↩

-

Calculating clamping force accurately is essential for successful molding. This resource provides valuable formulas and examples. ↩

-

Material properties significantly influence production efficiency and quality. Discover more about their impact in this informative article. ↩

-

Understanding the benefits of high precision can help you appreciate why injection molding is preferred for many applications. ↩

-

Exploring the reasons behind higher initial costs can provide insights into the long-term value of injection molding. ↩

-

Learning about the speed of injection molding can help you understand its efficiency in mass production. ↩

-

Explore this link to understand the detailed stages of injection molding and how they impact production efficiency. ↩

-

Discover essential elements of a design checklist that can enhance your injection molding projects. ↩