Plastic injection molding is a cornerstone of modern eyeglass manufacturing, enabling the efficient production of lightweight, durable, and stylish frames. This process involves melting thermoplastic materials1 and injecting them into precision molds to create intricate designs with consistent quality. While lenses require separate manufacturing methods, plastic injection molding2 is the go-to technique for producing eyeglass frames3 at scale.

Plastic injection molding machines create eyeglass frames by melting thermoplastics like polycarbonate4, injecting them into molds, cooling to solidify, and ejecting the frames, ideal for mass production due to efficiency and design flexibility5.

Plastic injection molding is used to create both eyeglass frames and lenses.False

Plastic injection molding is primarily used for frames; lenses require separate processes like casting or grinding for optical precision.

Plastic injection molding is the most cost-effective method for small production runs.False

The high initial mold costs make it less economical for small quantities; methods like CNC machining or 3D printing are better suited.

- 1. What are the Common Materials Used in Plastic Injection Molding for Eyeglasses?

- 2. What are the Steps in the Plastic Injection Molding Process for Eyeglasses?

- 3. What are the Applications of Plastic Injection Molding in Eyeglass Manufacturing?

- 4. What are the Differences Between Plastic Injection Molding and Other Eyeglass Manufacturing Methods?

- 5. Conclusion

What are the Common Materials Used in Plastic Injection Molding for Eyeglasses?

The choice of material in plastic injection molding significantly impacts the performance, aesthetics, and cost of eyeglass frames. Each material offers unique properties tailored to specific applications.

Common materials include polycarbonate6 for durability, cellulose acetate7 for aesthetics, nylon8 for flexibility, and ABS for cost-effectiveness, each suited to different eyewear needs.

| Material | Properties | Applications |

|---|---|---|

| Polycarbonate (PC) | Lightweight, high impact resistance, UV protection | Safety glasses, sports eyewear |

| Cellulose Acetate | Traditional look, customizable colors | Fashion frames |

| Nylon | Flexible, stress-resistant | Sports eyewear |

| ABS | Cost-effective, good impact resistance | Industrial eyewear |

Polycarbonate (PC)

Polycarbonate is a popular choice for eyeglass frames due to its exceptional durability and lightweight nature. It offers high impact resistance, making it ideal for safety glasses and sports eyewear. Additionally, polycarbonate provides excellent clarity and UV protection, which is why it is commonly used in sunglasses.

Polycarbonate is the most commonly used material for eyeglass frames.True

Polycarbonate is favored for its lightweight, impact resistance, and clarity, making it ideal for various eyewear applications.

Nylon

Nylon is prized for its flexibility and resistance to stress, making it perfect for sports eyewear that needs to withstand active use. It can endure varying environmental conditions, ensuring long-lasting performance.

Cellulose Acetate

Cellulose acetate is known for its traditional aesthetic and ability to be customized with various colors and patterns. While heavier than polycarbonate, it is often chosen for fashion frames where style is a priority. This material also requires careful mold design due to its unique flow properties.

ABS

ABS (Acrylonitrile Butadiene Styrene) is a cost-effective material with good impact resistance. Although it has lower clarity compared to polycarbonate, it is sometimes used in industrial eyewear where functionality outweighs aesthetics.

All materials used in plastic injection molding for eyeglasses offer the same level of durability.False

Materials like polycarbonate and nylon offer higher impact resistance and flexibility compared to others like ABS or cellulose acetate.

What are the Steps in the Plastic Injection Molding Process for Eyeglasses?

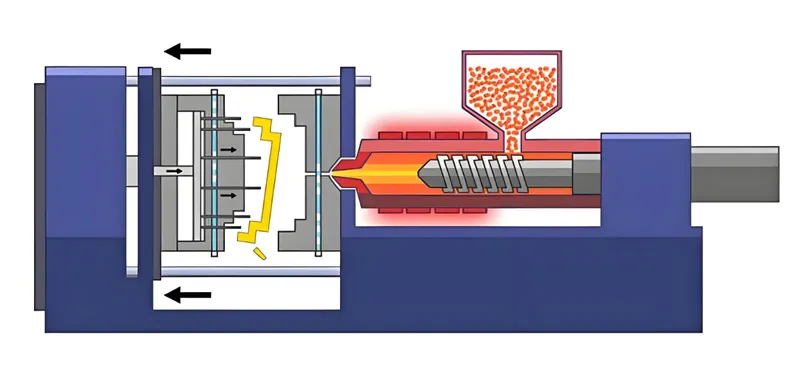

The plastic injection molding process9 for eyeglass frames is a precise, multi-step procedure that ensures high-quality, consistent results. Each step requires careful control of parameters like temperature, pressure, and cooling time.

The process involves material preparation10, heating and melting, injection, cooling and solidification11, ejection, and post-processing, with each step critical to achieving the desired frame quality.

1. Material Preparation

Plastic pellets, such as polycarbonate or nylon, are fed into the hopper of the injection molding machine. Additives like pigments or UV stabilizers may be included to enhance specific properties of the frames.

2. Heating and Melting

The plastic pellets are heated in the machine’s barrel to a molten state, typically between 200-300°C, depending on the material. An extrusion screw mixes and plasticizes the material to ensure uniformity.

3. Injection

The molten plastic is injected into the mold cavity under high pressure (100-200 MPa) to fill all the intricate details of the frame design, such as rims and temples.

4. Cooling and Solidification

The plastic cools and solidifies inside the mold, taking the shape of the eyeglass frame. Cooling is facilitated by water channels in the mold, with the cooling time carefully optimized to prevent defects like warping.

5. Ejection

Once solidified, the mold opens, and ejector pins gently push the frame out of the mold, ensuring no damage to delicate features.

6. Post-Processing

Excess material, such as flash, is trimmed, and the frame is polished to achieve a smooth, mirror-like surface. Additional steps like hinge attachment and lens insertion complete the assembly.

The injection molding process always results in perfect frames without any defects.False

Defects like warping or sink marks can occur if parameters like temperature and cooling time are not properly controlled.

Cooling time is a critical factor in preventing frame defects.True

Proper cooling ensures the frame solidifies evenly, reducing the risk of warping or internal stresses.

What are the Applications of Plastic Injection Molding in Eyeglass Manufacturing?

Plastic injection molding is versatile, enabling the production of a wide range of eyeglass frames for various uses. Its ability to handle complex designs and maintain tight tolerances makes it indispensable in the eyewear industry.

Applications include fashion frames, sunglasses, sports eyewear, and safety glasses, each benefiting from the process’s efficiency and design flexibility.

Fashion Frames

For fashion-forward designs, plastic injection molding allows for intricate details, customizable colors, and unique shapes that appeal to style-conscious consumers.

Sunglasses

Lightweight and durable, injection-molded sunglasses frames12 offer UV protection and impact resistance, making them ideal for outdoor use.

Sports Eyewear

Flexible and stress-resistant materials like nylon are used to create frames that can withstand the rigors of active sports while providing comfort and durability.

Safety Glasses

Polycarbonate frames offer high impact resistance, making them essential for industrial and protective eyewear applications.

Plastic injection molding is only used for fashion eyeglass frames.False

It is also used for sunglasses, sports eyewear, and safety glasses, among others.

What are the Differences Between Plastic Injection Molding and Other Eyeglass Manufacturing Methods?

While plastic injection molding is ideal for mass production, other methods like CNC machining and 3D printing offer alternatives for different production needs. Understanding their differences helps manufacturers choose the right approach.

Plastic injection molding excels in high-volume production with complex designs, while CNC machining and 3D printing are better for prototyping and small runs.

| Method | Pros | Cons |

|---|---|---|

| Plastic Injection Molding | High production rates, low labor costs, complex designs | High initial mold costs, not for small runs |

| CNC Machining | Flexible for prototyping, small quantities | Slower production, higher labor costs |

| 3D Printing | Rapid prototyping, highly customized designs | Not cost-effective for high volumes, less durable |

Plastic Injection Molding

Best for large-scale production, this method offers efficiency and precision but requires significant upfront investment in molds.

CNC Machining

Ideal for prototyping or small batches, CNC machining provides flexibility but is slower and more labor-intensive.

3D Printing

Perfect for rapid prototyping and custom designs, 3D printing lacks the speed and cost-effectiveness needed for mass production.

Plastic injection molding is the most flexible method for prototyping.False

CNC machining and 3D printing offer greater flexibility for small-scale prototyping.

Conclusion

Plastic injection molding is a vital process in eyeglass manufacturing, offering unparalleled efficiency and design flexibility for producing high-quality frames. By selecting the right materials and carefully controlling each step of the process, manufacturers can create durable, stylish, and functional eyewear for a variety of applications. While it may not be suitable for small production runs due to high initial costs, its benefits make it indispensable for large-scale production.

-

Learn about thermoplastic materials and their importance in producing lightweight and durable eyeglass frames. ↩

-

Explore this link to understand the significance of plastic injection molding in creating high-quality eyeglass frames. ↩

-

Discover the manufacturing process of eyeglass frames and the advantages of using plastic injection molding. ↩

-

Learn about thermoplastics and their applications, which are crucial for understanding material choices in production. ↩

-

Discover insights on how efficiency and design flexibility enhance mass production processes, vital for manufacturers. ↩

-

Explore the advantages of polycarbonate, a top choice for eyeglass frames, known for its durability and UV protection. ↩

-

Discover why cellulose acetate is favored for its aesthetic appeal and customization options in eyewear design. ↩

-

Learn about nylon’s flexibility and stress resistance, making it ideal for active lifestyles in sports eyewear. ↩

-

Explore this link to understand the intricacies of the plastic injection molding process, crucial for high-quality eyeglass frames. ↩

-

Learn about the essential steps in material preparation that ensure the quality and durability of eyeglass frames. ↩

-

Discover the importance of cooling and solidification in the molding process to prevent defects and ensure frame integrity. ↩

-

Learn about the materials used in sunglasses frames and how they enhance performance and style for outdoor activities. ↩