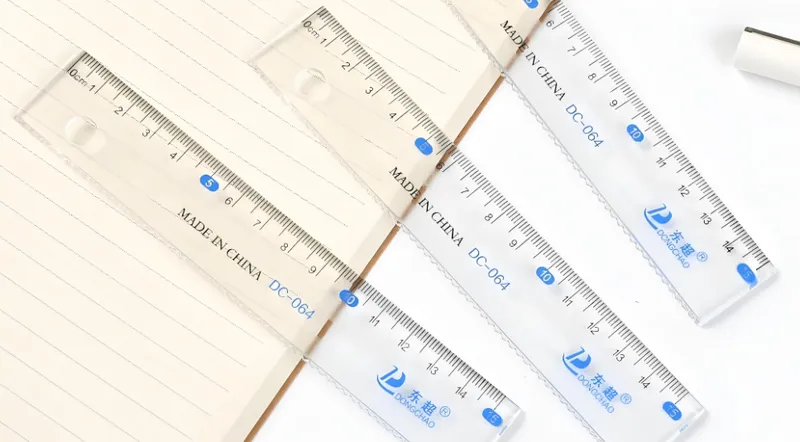

Injection molding is a cornerstone of modern manufacturing, widely employed to produce precise plastic parts, including everyday tools like rulers. This process involves melting plastic materials, injecting them into a mold, and allowing them to cool and solidify into the desired shape. For rulers, injection molding1 ensures accurate engravings and consistent quality, making it a preferred method for mass production in industries such as stationery and education.

Injection molding machines manufacture rulers by melting thermoplastics like ABS or polypropylene2, injecting them into precision molds, cooling, and ejecting the finished product, enabling efficient mass production of detailed and consistent rulers3 for stationery and educational use.

Understanding the injection molding process for rulers offers a window into advanced manufacturing techniques and their practical applications. Dive deeper to learn how material choices and process parameters shape the quality and functionality of these essential tools.

Injection molding is the most cost-effective method for producing rulers in large quantities.True

The high initial mold costs are offset by low per-unit costs in mass production, making it economical for large volumes.

Injection molding can only be used for plastic rulers.False

While commonly used for plastics, injection molding can also be adapted for other materials like metals or composites, though it’s less common for rulers.

- 1. What are the Common Materials Used in Injection Molding for Rulers?

- 2. What is the Process of Injection Molding for Rulers?

- 3. What are the Key Factors in the Injection Molding Process for Rulers?

- 4. What are the Applications of Injection-Molded Rulers?

- 5. How Does Injection Molding Compare to Other Manufacturing Methods for Rulers?

- 6. Conclusion

What are the Common Materials Used in Injection Molding for Rulers?

Injection molding for rulers relies heavily on thermoplastics4, chosen for their ease of processing and robust properties. The most prevalent materials include:

-

ABS (Acrylonitrile Butadiene Styrene)5: Valued for its hardness, durability, and impact resistance, ABS is perfect for rulers that endure frequent handling.

-

Polypropylene (PP)6: Known for flexibility, chemical resistance, and light weight, PP suits rulers used in diverse settings, from classrooms to outdoors.

Occasionally, materials like polycarbonate (PC) are used for specialized rulers requiring high impact strength or transparency, though their higher cost limits widespread adoption.

| Material | Properties | Common Applications |

|---|---|---|

| ABS | Hard, durable, impact-resistant | General-purpose rulers |

| PP | Flexible, chemical-resistant, lightweight | Rulers for educational or outdoor use |

| PC | High impact strength, transparent | Specialty rulers requiring transparency or extra durability |

For more on material properties, explore Protolabs’ Material Guide.

ABS is the most commonly used material for injection-molded rulers.True

ABS strikes a balance of durability, cost, and processability, making it a top choice for standard rulers.

Injection molding cannot use biodegradable materials.False

Biodegradable plastics like PLA can be molded, though they’re less common for rulers due to cost and property trade-offs.

What is the Process of Injection Molding for Rulers?

The injection molding process for rulers is a streamlined sequence of steps tailored to produce precise, high-quality tools:

-

Material Selection: Choosing a thermoplastic based on the ruler’s intended properties.

-

Mold Design: Crafting a mold with exact cavities and measurement engravings.

-

Injection: Melting the plastic and injecting it into the mold under high pressure.

-

Cooling: Allowing the plastic to solidify within the mold.

-

Ejection: Removing the finished ruler from the mold.

-

Post-Processing: Smoothing edges, refining markings, or polishing as needed.

Each step ensures the ruler meets stringent quality standards. Learn more about the process at Moldall’s Injection Molding Guide.

The mold design is the most critical step in injection molding for rulers.True

The mold dictates the ruler’s precision and markings, with any imperfections replicated across all units.

Injection molding requires no post-processing for rulers.False

Post-processing, like edge smoothing or marking enhancement, is often needed for a polished finish.

What are the Key Factors in the Injection Molding Process for Rulers?

Several variables influence the success of injection molding rulers:

-

Injection Pressure: Must be optimized to fill the mold fully without defects like air pockets.

-

Cooling Time: Balances cycle speed and part integrity—too short risks warping, too long slows production.

-

Mold Temperature: Affects plastic flow and engraving clarity.

-

Material Properties: Dictates the ruler’s durability, flexibility, and appearance.

Fine-tuning these factors ensures efficiency and quality. For a deeper dive, see Essentra’s Injection Molding Guide.

Cooling time is the most significant factor affecting production speed.True

Cooling often dominates the cycle time, directly influencing output rates.

All thermoplastics behave identically in injection molding.False

Each thermoplastic has unique melting, flow, and cooling traits, requiring specific adjustments.

What are the Applications of Injection-Molded Rulers?

Injection-molded rulers serve a variety of purposes:

-

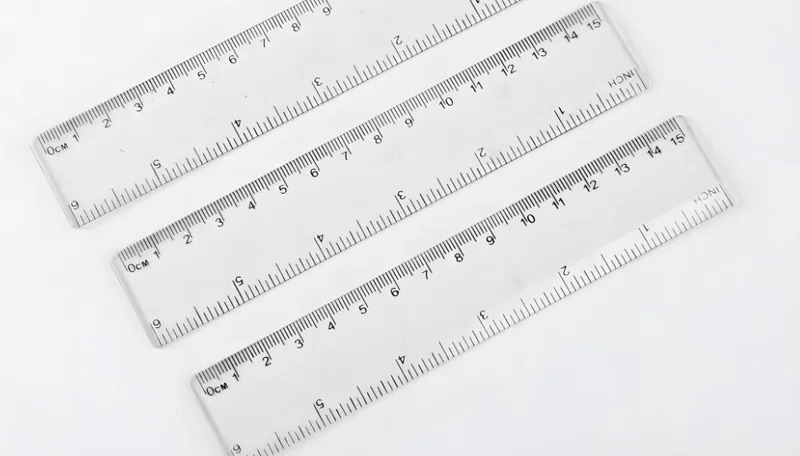

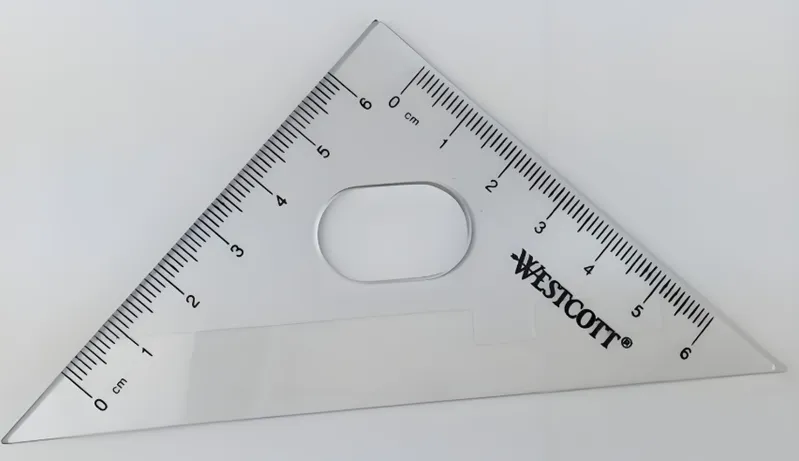

Stationery: Essential in schools and offices for their precision and durability.

-

Educational Tools7: Used in classrooms to teach measurement and geometry.

-

Measuring Instruments8: Employed in construction and engineering for accurate readings.

Their reliability stems from the precision of injection molding.

Injection-molded rulers are only used in educational settings.False

Beyond education, they’re vital in professional and industrial contexts requiring precision.

Injection molding enables rulers with complex designs.True

The process supports detailed engravings, multi-color options, and added features.

How Does Injection Molding Compare to Other Manufacturing Methods for Rulers?

Injection molding stands out among alternatives:

-

Machining: Ideal for small batches but costly and slow for mass production.

-

3D Printing: Great for prototypes, yet too slow and limited for large-scale ruler production.

-

Extrusion: Suits continuous profiles but struggles with flat, engraved rulers.

Injection molding shines in high-volume scenarios, balancing cost, speed, and quality. Compare methods further at Protolabs’ Manufacturing Guide.

Injection molding is the fastest method for producing rulers.False

Initial mold setup takes time, making it slower than some methods for small runs.

Injection molding offers the highest precision for rulers.True

It achieves tight tolerances and consistency critical for measurement tools.

Conclusion

Injection molding is a vital process for crafting plastic rulers with unmatched precision and efficiency. By mastering material selection, process steps, and key variables, manufacturers meet diverse industry needs. As technology progresses, injection molding promises even more innovative ruler designs and applications.

For additional insights, visit Wikipedia’s Injection Moulding Page.

-

Explore this link to understand the fundamentals of injection molding and its significance in producing high-quality plastic parts. ↩

-

Learn about the properties and applications of thermoplastics, crucial for understanding their role in injection molding. ↩

-

Discover the techniques behind mass production that ensure quality and precision in ruler manufacturing. ↩

-

Understanding thermoplastics can enhance your knowledge of material selection in manufacturing processes. ↩

-

Exploring ABS properties will help you appreciate its role in durable product design, especially in everyday items like rulers. ↩

-

Learning about Polypropylene’s benefits can inform your choices in materials for various applications, enhancing product functionality. ↩

-

Discover innovative educational tools that enhance learning in measurement and geometry, making lessons more engaging. ↩

-

Learn about the critical role measuring instruments play in construction and engineering for accuracy and efficiency. ↩