Injection molding is a widely used manufacturing process1 that produces precise plastic parts by injecting molten plastic into a mold. When it comes to creating plastic flowers, this technique is employed to craft detailed components such as petals, stems, and leaves, which are later assembled into realistic artificial flowers. These products find applications in home decor, retail, event planning, and more due to their durability and aesthetic appeal.

Injection molding machines create plastic flowers2 by melting thermoplastic granules, injecting the molten plastic into molds designed as flower parts, and cooling them to form solid, detailed components that are assembled into complete flowers.

This blog post will guide you through the entire process of how injection molding3 machines produce plastic flowers. From the basics of the technology to its practical applications and technical intricacies, you’ll gain a comprehensive understanding of this fascinating manufacturing method.

Injection molding is the most efficient method for producing plastic flowers.True

Its ability to produce large quantities of consistent, intricate parts quickly makes it highly efficient for mass production of plastic flowers.

Injection molding is limited to producing basic shapes.False

The process excels at creating complex, detailed designs like the delicate petals and textured stems of plastic flowers.

- 1. What is Injection Molding and How Does It Work for Plastic Flowers?

- 2. What are the Typical Application Scenarios for Injection Molding in Plastic Flower Production?

- 3. What are the Pros and Cons of Using Injection Molding for Plastic Flowers?

- 4. What is the Full Workflow of the Injection Molding Process for Plastic Flowers?

- 5. How Do Different Materials Affect the Injection Molding Process for Plastic Flowers?

- 6. What are the Key Considerations in Designing Plastic Flowers for Injection Molding?

- 7. How Do You Decide if Injection Molding is Right for Your Plastic Flower Production?

- 8. What are the Related Technologies to Injection Molding for Plastic Flowers?

- 9. Conclusion

What is Injection Molding and How Does It Work for Plastic Flowers?

Injection molding is a cornerstone of modern manufacturing, enabling the creation of precise plastic parts with speed and consistency. For plastic flowers, it involves transforming raw plastic into individual flower components that mimic the look and feel of natural blooms.

Injection molding for plastic flowers entails melting plastic granules, injecting them into molds shaped as petals, stems, or leaves, and cooling them to solidify into detailed parts.

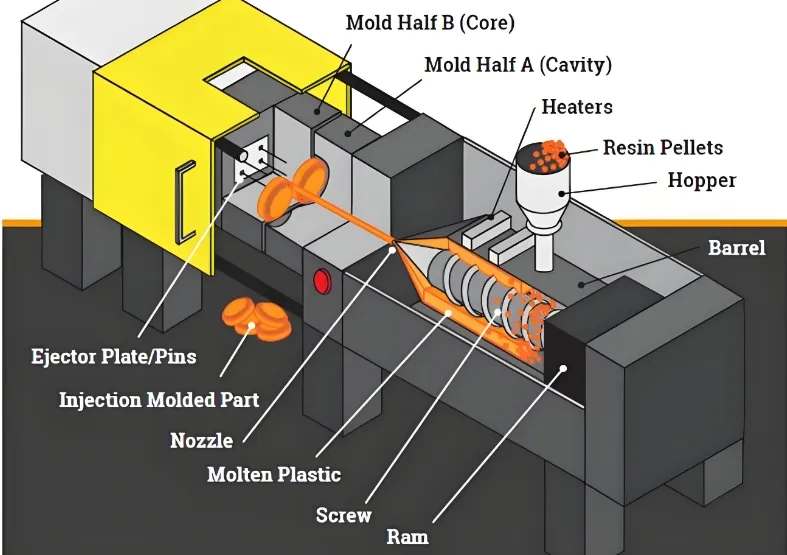

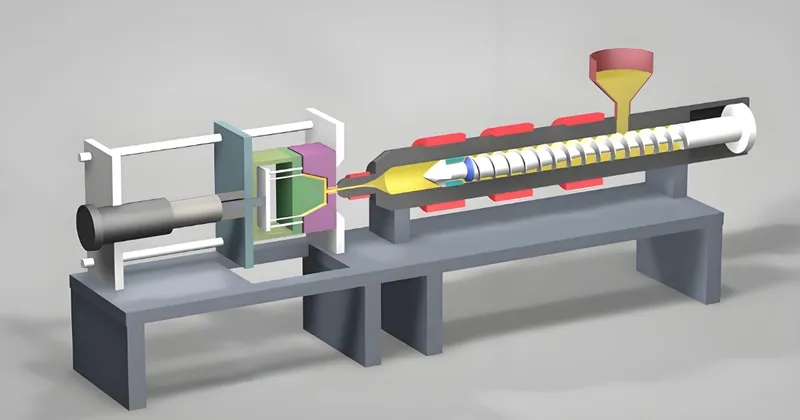

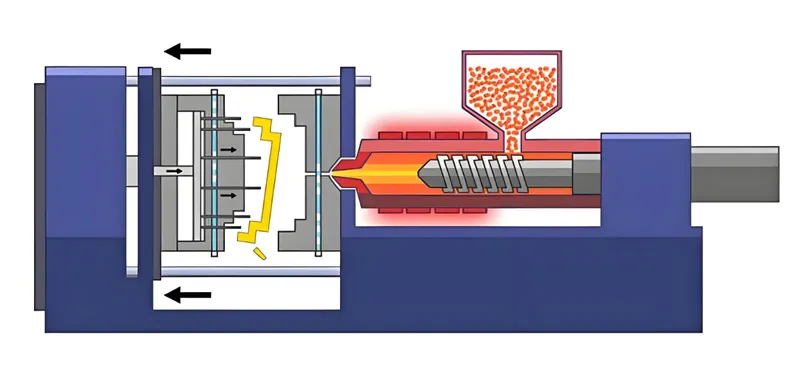

Definitions and Core Principles

At its core, injection molding involves heating thermoplastic granules until they become molten, then injecting this liquid plastic under high pressure into a mold cavity. Once cooled, the plastic hardens into the mold’s shape. For plastic flowers, this means crafting parts with fine details like petal veins or stem textures, which are critical for realism.

The process hinges on three key stages: melting, molding, and cooling. Its efficiency lies in its ability to replicate identical parts rapidly, making it perfect for producing the multiple components needed for artificial flowers.

Classification of Injection Molding

Injection molding can be categorized in various ways:

-

By Process:

-

Standard Injection Molding: The most common method, used for single-material flower parts.

-

Multi-Shot Injection Molding: Enables multi-color or multi-material parts, such as flowers with variegated petals.

-

Gas-Assisted Injection Molding: Useful for hollow or lightweight components, though less common for flowers.

-

-

By Materials:

- Thermoplastics: Materials like polyethylene (PE), polypropylene (PP), and ABS, which can be remelted and reshaped.

- Thermosets: Rarely used for flowers, as they harden permanently after molding.

-

By Applications:

-

Decorative: Plastic flowers for home decor, events, or retail displays.

-

Functional: Parts for toys or educational models.

-

For plastic flowers, standard injection molding with thermoplastics4 is typically employed due to its versatility and cost-effectiveness.

Injection molding is exclusively an industrial process.False

Beyond industrial uses, it’s vital for consumer products like plastic flowers used in decor and retail.

Thermoplastics dominate injection molding for plastic flowers.True

Their ability to be melted and reshaped makes thermoplastics like PE and PP ideal for detailed flower components.

What are the Typical Application Scenarios for Injection Molding in Plastic Flower Production?

Injection molding shines in scenarios requiring high volumes of uniform, high-quality plastic flowers, making it a go-to choice for several industries.

Injection molding is employed in floral decor, retail, and event planning to mass-produce consistent, detailed plastic flowers5 efficiently.

Mass Production for Retail

In retail, plastic flowers are popular for their affordability and longevity. Injection molding enables manufacturers to produce thousands of identical petals, stems, and leaves, ensuring every flower meets the same quality standards—ideal for stores and online sellers.

Event Planning and Decor

Weddings, parties, and corporate events often rely on artificial flowers for decorations that need to look good and last. Injection molding delivers durable, realistic flowers in bulk, capable of withstanding transport and repeated use.

Custom Designs for Niche Markets

While primarily suited for mass production, injection molding can also cater to niche markets with unique flower designs. High-end decor or specialty events might require custom molds6, though this increases initial costs.

Injection molding is cost-effective for small batches.False

High mold costs make it less viable for small runs; it’s most economical for large-scale production.

Injection molding guarantees uniformity in large batches.True

Each cycle produces identical parts, ensuring consistency critical for retail and decor applications.

What are the Pros and Cons of Using Injection Molding for Plastic Flowers?

Injection molding offers distinct advantages for plastic flower production, but it’s not without drawbacks. Here’s a balanced look at its benefits and limitations.

Injection molding provides efficiency, consistency, and high-quality plastic flowers but involves high initial costs and material restrictions.

Advantages

-

High Efficiency7: Capable of producing thousands of parts per hour, perfect for large orders.

-

Consistency: Every part matches the mold exactly, ensuring uniform flowers.

-

Detail Quality: Captures intricate features like petal textures and stem details.

- Cost-Effectiveness: Low per-unit costs in high-volume production.

Disadvantages

- High Upfront Costs8: Mold design and fabrication can be expensive, deterring small runs.

-

Material Limits9: Restricted to thermoplastics, limiting some design options.

-

Design Constraints: Extremely complex shapes may need additional steps like assembly or painting.

Compared to alternatives like 3D printing (better for prototypes) or hand molding (suited for artisanal work), injection molding excels in scalability but lacks flexibility for small or custom projects.

Injection molding is always the cheapest option for plastic flowers.False

It’s cost-effective for large runs, but high mold costs make it less so for small quantities.

Injection molding produces highly detailed flower parts.True

The process accurately replicates mold designs, ideal for realistic flower components.

What is the Full Workflow of the Injection Molding Process for Plastic Flowers?

The journey from raw plastic to finished flower parts involves a series of precise steps, each essential for quality and efficiency.

The injection molding process for plastic flowers includes material preparation, melting, injection, cooling, ejection, and optional post-processing to create detailed, consistent parts.

Step 1: Material Preparation

Plastic granules (e.g., PE, PP, or ABS) are loaded into the machine’s hopper. Material choice depends on the part’s needs—flexibility for petals, rigidity for stems.

Step 2: Melting

The granules are heated in the barrel until molten, with temperatures carefully controlled (typically 180-250°C) to avoid degradation.

Step 3: Injection

Molten plastic is forced into the mold under high pressure (up to 20,000 psi), filling cavities shaped like flower parts and capturing fine details.

Step 4: Cooling

The plastic cools inside the mold, solidifying into the final shape. Cooling time (seconds to minutes) balances speed and quality.

Step 5: Ejection

The solidified part is removed using ejector pins or air, requiring care to preserve delicate features.

Step 6: Post-Processing (Optional)

Painting, texturing, or assembling parts into complete flowers may follow to enhance realism, especially for decorative uses.

| Step | Description | Key Notes |

|---|---|---|

| 1 | Load granules into hopper | Material choice affects part properties |

| 2 | Melt granules in barrel | Temperature control prevents burning |

| 3 | Inject molten plastic into mold | High pressure ensures detail accuracy |

| 4 | Cool plastic in mold | Cooling time impacts cycle speed |

| 5 | Eject solidified part | Gentle ejection preserves delicate shapes |

| 6 | Post-process (e.g., paint, assemble) | Optional for enhanced aesthetics |

Injection molding is entirely manual.False

Modern machines are automated, minimizing labor and boosting efficiency.

Cooling time is the longest step in the process.False

Cooling is quick relative to setup; total cycle time is often under a minute.

How Do Different Materials Affect the Injection Molding Process for Plastic Flowers?

Material choice shapes both the process and the final product, influencing everything from flexibility to appearance.

Common materials like PE, PP, and ABS in injection molding for plastic flowers offer distinct properties such as flexibility, strength, and visual appeal.

Polyethylene (PE)

-

Properties: Flexible, durable, cost-effective.

-

Use: Ideal for petals or leaves needing slight flexibility.

-

Notes: May need painting for vibrant colors.

Polypropylene (PP)

-

Properties: Stiff, chemical-resistant, durable.

-

Use: Great for stems or bases requiring rigidity.

-

Notes: Less translucent, suited for structural parts.

ABS (Acrylonitrile Butadiene Styrene)

-

Properties: Tough, impact-resistant, easily colored.

-

Use: Perfect for detailed, high-quality flower parts.

-

Notes: Offers excellent aesthetics for premium products.

| Material | Key Traits | Best For |

|---|---|---|

| PE | Flexible, durable | Petals, leaves |

| PP | Stiff, resistant | Stems, structural components |

| ABS | Tough, aesthetic | Detailed, premium flower parts |

PP is the most versatile material for all flower parts.False

PP excels for rigid parts, but PE or ABS may suit flexible or detailed components better.

Material choice affects flower durability and look.True

Each material imparts unique traits, tailoring the flower’s function and appearance.

What are the Key Considerations in Designing Plastic Flowers for Injection Molding?

Effective design ensures the process yields high-quality flowers efficiently.

Key design considerations for injection molding plastic flowers include mold precision, material selection, part complexity, and post-processing needs.

Design Checklist

-

Mold Precision: Design molds to capture details like petal veins; optimize gate placement to hide seams.

-

Material Selection: Match materials to part needs (e.g., PE for flexibility).

-

Part Complexity: Simplify designs to avoid undercuts or use multi-part molds if needed.

-

Post-Processing: Plan for painting or assembly if realism is key.

-

Defect Prevention: Avoid thin walls or sharp corners to reduce warping or sink marks.

Mold design dictates final part quality.True

A well-designed mold ensures accurate, defect-free flower parts.

All designs are easily molded without adjustments.False

Complex features like undercuts require special mold features or extra steps.

How Do You Decide if Injection Molding is Right for Your Plastic Flower Production?

Choosing injection molding depends on your project’s scale, complexity, and budget.

Injection molding suits mass production of detailed plastic flowers but may not fit small batches or highly custom designs.

Process Selection Guide

-

Volume: Opt for injection molding for high quantities (thousands+).

-

Complexity: Use it for intricate, repeatable designs.

-

Budget: Accept high initial costs for long-term savings.

-

Alternatives: Consider 3D printing for prototypes or small runs.

Injection molding is ideal for all flower projects.False

It’s best for mass production, not small or custom runs.

Budget impacts process choice significantly.True

High mold costs favor large-scale projects over small ones.

Injection molding connects to a network of technologies that enhance plastic flower production.

Related technologies include 3D printing for prototyping, blow molding for hollow complements, and extrusion for continuous parts.

3D Printing

-

Use: Prototyping or small-batch custom flowers.

-

Benefit: Flexible design testing.

Blow Molding

-

Use: Hollow items like vases for flower displays.

-

Benefit: Complements injection-molded flowers.

Extrusion

-

Use: Continuous stems or bases.

-

Benefit: Pairs with molded parts for full assemblies.

3D printing can fully replace injection molding.False

It’s great for small runs but lacks the speed and scale of injection molding.

Related technologies expand production options.True

Using multiple methods optimizes the entire process.

Conclusion

Injection molding transforms raw plastic into beautiful, durable plastic flowers through a precise, efficient process. Ideal for mass production, it offers unmatched consistency and detail, making it a staple in decor, retail, and event industries. By mastering its workflow, material choices, and design principles, you can harness this technology to create stunning artificial blooms.

-

Learn about the detailed steps involved in the manufacturing process of injection molded products, enhancing your knowledge of production techniques. ↩

-

Discover the process of creating plastic flowers through injection molding, including techniques and benefits of this method. ↩

-

Explore this link to understand the fundamentals of injection molding, its applications, and its significance in manufacturing. ↩

-

Learn about thermoplastics and their advantages in injection molding, crucial for producing high-quality plastic parts like flowers. ↩

-

Learn about the techniques and benefits of mass-producing detailed plastic flowers for various applications. ↩

-

Discover the role of custom molds in injection molding and their effect on production efficiency and costs. ↩

-

Understanding high efficiency in injection molding can help you appreciate its role in large-scale production and cost savings. ↩

-

Exploring the reasons behind high upfront costs can provide insights into the financial considerations of starting an injection molding project. ↩

-

Learning about material limits in injection molding can guide you in selecting the right materials for your production needs. ↩