Biodegradable plastics are revolutionizing the injection molding1 industry by offering a sustainable alternative to traditional plastics. These materials, derived from renewable resources, decompose naturally, reducing environmental impact. In injection molding, they provide versatility, consumer appeal, and eco-friendly solutions across various applications.

Biodegradable plastics in injection molding reduce environmental impact, offer renewable material options, and meet growing consumer demand for sustainable products, though they may require specific processing adjustments.

Understanding the benefits and challenges of biodegradable plastics2 in injection molding is crucial for manufacturers aiming to adopt sustainable practices3. This article explores their advantages, applications, and technical considerations.

Biodegradable plastics reduce plastic waste in injection molding.True

These materials decompose naturally, minimizing long-term environmental pollution.

Biodegradable plastics are always cheaper than traditional plastics.False

While they offer environmental benefits, biodegradable plastics can be more expensive due to production costs.

- 1. What Are Biodegradable Plastics in Injection Molding?

- 2. How Do Biodegradable Plastics Benefit Injection Molding?

- 3. What Are the Steps in Injection Molding with Biodegradable Plastics?

- 4. What Are the Key Considerations for Using Biodegradable Plastics in Injection Molding?

- 5. What Are the Applications of Biodegradable Plastics in Injection Molding?

- 6. How Do Biodegradable Plastics Compare to Traditional Plastics in Injection Molding?

- 7. What Are the Challenges of Using Biodegradable Plastics in Injection Molding?

- 8. How Can Manufacturers Overcome Challenges with Biodegradable Plastics in Injection Molding?

- 9. Conclusion

What Are Biodegradable Plastics in Injection Molding?

Biodegradable plastics are materials that naturally decompose into non-toxic substances, offering a sustainable alternative to traditional plastics in injection molding.

Biodegradable plastics, such as PLA, PHA, and TPS, are used in injection molding for their eco-friendly properties, reducing plastic waste and supporting sustainability in manufacturing.

| Material Type | Common Applications | Notes |

|---|---|---|

| PLA (Polylactic Acid) | Packaging, consumer goods | Made from corn or sugarcane |

| PHA (Polyhydroxyalkanoates) | Medical devices, implants | Biocompatible, produced via fermentation |

| TPS (Thermoplastic Starch) | Disposable items, packaging | Cost-effective, flexible |

Polylactic Acid (PLA)

PLA is a popular biodegradable plastic made from renewable resources like corn starch. It offers high clarity and stiffness, making it ideal for packaging and consumer goods. In injection molding, PLA is valued for its aesthetic appeal and environmental benefits.

Polyhydroxyalkanoates (PHA)

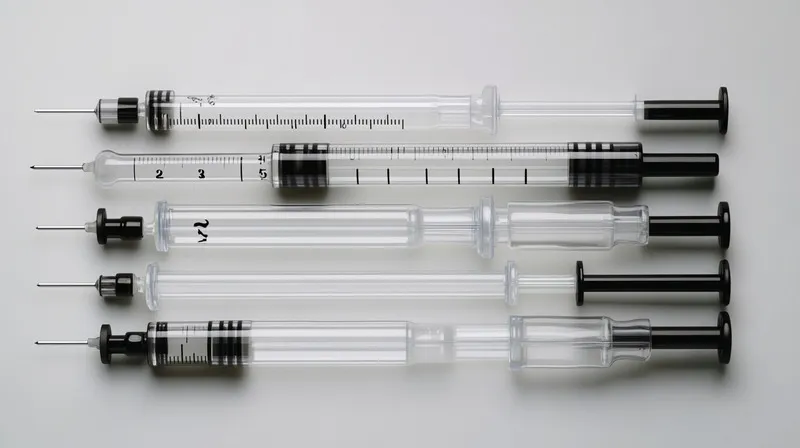

PHA is produced through microbial fermentation and is fully biodegradable. Its biocompatibility makes it suitable for medical applications, such as implants and surgical tools, where traditional plastics may pose risks.

Thermoplastic Starch (TPS)

TPS is derived from starch and is often used for disposable items like cutlery and packaging. It is cost-effective and flexible, though it may require additives to enhance its mechanical properties.

These materials offer unique benefits in injection molding, from reducing environmental impact to meeting specific industry needs. However, their properties can vary, requiring careful selection based on the application.

PLA is the most commonly used biodegradable plastic in injection molding.True

PLA's clarity, stiffness, and renewable sourcing make it a popular choice for sustainable manufacturing.

All biodegradable plastics perform identically in injection molding.False

Different biodegradable plastics have varying properties, affecting their suitability for specific applications.

How Do Biodegradable Plastics Benefit Injection Molding?

Biodegradable plastics offer significant advantages in injection molding, from environmental sustainability to meeting consumer demand for eco-friendly products.

Biodegradable plastics in injection molding reduce environmental impact, support renewable resource use, and enhance brand appeal, though they may require specific processing techniques.

Environmental Impact

Biodegradable plastics decompose naturally, reducing plastic waste and pollution. This is particularly beneficial in industries like packaging, where single-use items are common. By using biodegradable materials, manufacturers can minimize their environmental footprint.

Renewable Resource Use

These plastics are often derived from renewable resources like corn, sugarcane, or cellulose, reducing reliance on fossil fuels. This shift supports sustainable manufacturing practices and contributes to a circular economy.

Consumer Appeal

With growing consumer awareness of environmental issues, products made from biodegradable plastics can enhance brand reputation. Companies that adopt these materials can appeal to eco-conscious consumers, potentially increasing market share.

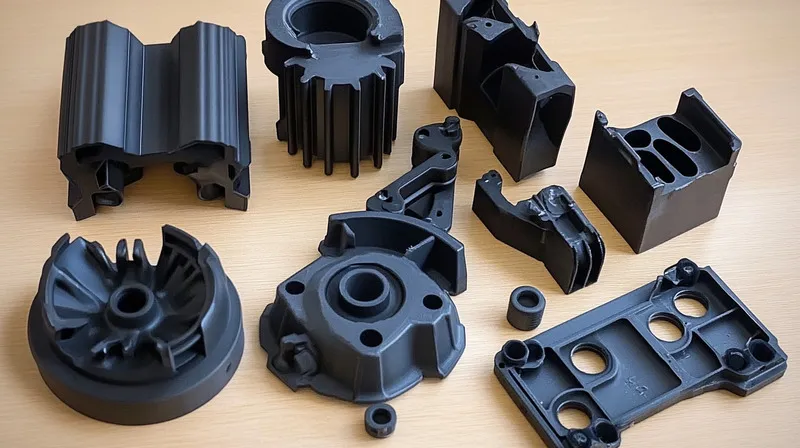

Versatility in Applications

Biodegradable plastics can be used in a wide range of injection molding applications, from packaging and consumer goods to medical devices and automotive parts. Their properties can be tailored to meet specific needs, making them a versatile choice.

Challenges and Considerations

While biodegradable plastics offer many benefits, they can be more expensive than traditional plastics and may require adjustments in processing parameters. Manufacturers must weigh these factors against the environmental and market advantages.

Biodegradable plastics always require new injection molding equipment.False

Many biodegradable plastics can be processed using existing equipment, though some adjustments may be necessary.

Biodegradable plastics reduce the carbon footprint of injection molded products.True

Their production from renewable resources and natural decomposition contribute to lower overall emissions.

What Are the Steps in Injection Molding with Biodegradable Plastics?

Injection molding with biodegradable plastics involves specific steps to ensure optimal material performance and product quality.

The injection molding process for biodegradable plastics includes material preparation4, machine setup, molding, and quality control5, with adjustments for moisture sensitivity and processing temperatures.

Material Preparation

Biodegradable plastics often require pre-drying to remove moisture, as they can be sensitive to hydrolysis. This step is crucial to prevent degradation during molding.

Machine Setup

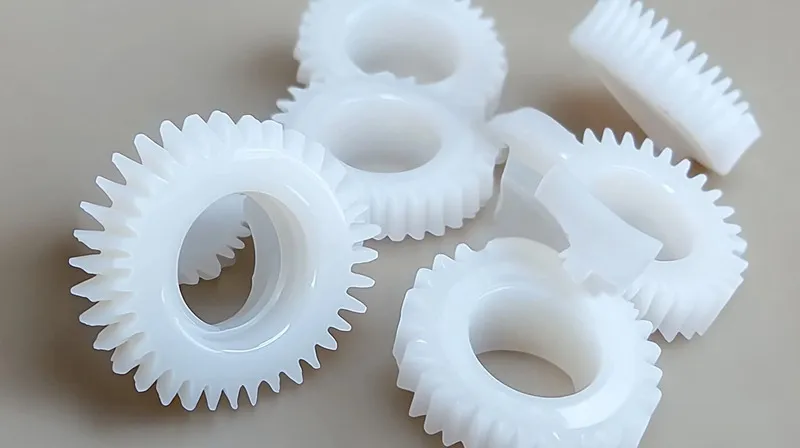

Manufacturers may need to use corrosion-resistant components and specialized screw designs to handle biodegradable materials, which can be more sensitive to shear and heat.

Molding Process

Adjustments to temperature, pressure, and cycle times are often necessary to accommodate the unique properties of biodegradable plastics. For example, PLA typically requires lower processing temperatures than traditional plastics.

Quality Control

Monitoring material viscosity and part dimensions is essential to ensure consistency. Closed-loop systems can help minimize waste and maintain product quality.

These steps ensure that biodegradable plastics are processed effectively, producing high-quality, sustainable products.

Biodegradable plastics require entirely different molding processes than traditional plastics.False

While adjustments are needed, the core injection molding process remains similar.

Pre-drying is a critical step when molding biodegradable plastics.True

Moisture-sensitive materials like PLA and TPS require drying to prevent defects.

What Are the Key Considerations for Using Biodegradable Plastics in Injection Molding?

Using biodegradable plastics in injection molding requires careful consideration of material properties, processing conditions, and end-use requirements.

Key considerations include material selection, processing adjustments, cost implications, and end-of-life disposal options for biodegradable plastics in injection molding.

Material Selection

Choosing the right biodegradable plastic is crucial. Factors like mechanical strength, heat resistance, and biodegradability must align with the product’s intended use. For example, PLA is suitable for packaging, while PHA is better for medical applications.

Processing Adjustments

Biodegradable plastics often require specific processing conditions, such as lower temperatures or specialized equipment. Manufacturers must ensure their machines are compatible or make necessary upgrades.

Cost Implications

Biodegradable plastics can be more expensive than traditional options. However, their environmental benefits and consumer appeal may justify the higher costs, especially in markets where sustainability is valued.

End-of-Life Disposal

Understanding how the product will be disposed of is essential. Biodegradable plastics require proper composting facilities to decompose effectively. Manufacturers should consider the availability of such infrastructure.

These considerations help manufacturers make informed decisions when integrating biodegradable plastics into their injection molding processes.

Biodegradable plastics are always the most cost-effective choice.False

While they offer environmental benefits, their higher material costs can impact overall production expenses.

Proper disposal infrastructure is necessary for biodegradable plastics to decompose effectively.True

Without composting facilities, biodegradable plastics may not break down as intended.

What Are the Applications of Biodegradable Plastics in Injection Molding?

Biodegradable plastics are used in a variety of injection molding applications, offering sustainable solutions across multiple industries.

Biodegradable plastics are applied in packaging, medical devices, consumer goods, and automotive parts, providing eco-friendly alternatives6 to traditional plastics.

Packaging

In packaging, biodegradable plastics are used for items like food containers, bags, and coffee pods. Their ability to decompose reduces waste in landfills and oceans.

Medical Devices

Biocompatible materials like PHA are ideal for medical applications, including implants, surgical tools, and medication containers. These plastics minimize the risk of long-term environmental contamination.

Consumer Goods

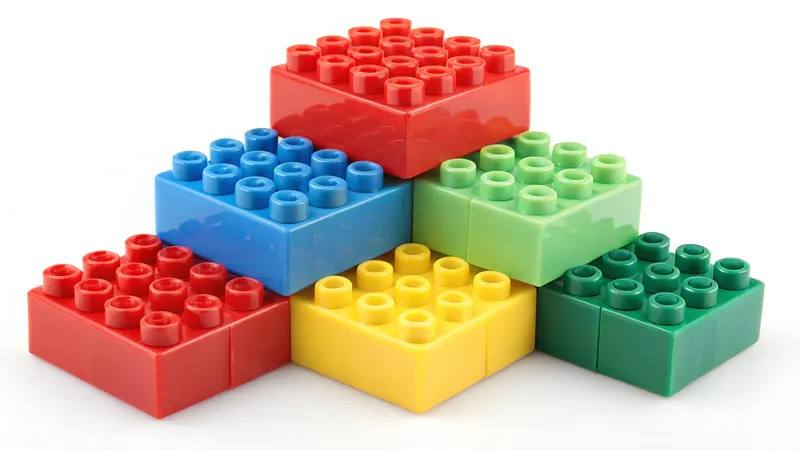

Products like disposable cutlery, toys, and stationery benefit from biodegradable plastics, appealing to environmentally conscious consumers.

Automotive Parts

In the automotive industry, biodegradable plastics are used for interior components, reducing the vehicle’s overall environmental impact.

These applications demonstrate the versatility and growing importance of biodegradable plastics in sustainable manufacturing7.

Biodegradable plastics are only used in packaging applications.False

While packaging is a major application, biodegradable plastics are also used in medical, consumer, and automotive industries.

Biodegradable plastics can replace traditional plastics in most injection molding applications.True

With proper material selection and processing, biodegradable plastics can meet the requirements of many traditional plastic applications.

How Do Biodegradable Plastics Compare to Traditional Plastics in Injection Molding?

Biodegradable plastics offer distinct advantages and challenges compared to traditional plastics in injection molding.

Biodegradable plastics provide environmental benefits and consumer appeal but may require higher costs and specific processing conditions compared to traditional plastics.

| Aspect | Biodegradable Plastics | Traditional Plastics |

|---|---|---|

| Environmental Impact | Decompose naturally, reducing waste | Persist in the environment for centuries |

| Resource Use | Made from renewable resources | Derived from fossil fuels |

| Cost | Generally higher | Lower production costs |

| Processing | May require adjustments | Standard processing parameters |

| Durability | Can be less durable in some cases | Often more durable |

Environmental Benefits

Biodegradable plastics decompose naturally, reducing long-term pollution. Traditional plastics, however, contribute to persistent waste issues.

Resource Sustainability

Biodegradable plastics are often made from renewable resources, supporting sustainable practices. Traditional plastics rely on finite fossil fuels.

Cost Considerations

While biodegradable plastics can be more expensive, their environmental and market benefits may offset these costs for some manufacturers.

Processing Requirements

Biodegradable plastics may require specific processing conditions, such as lower temperatures or specialized equipment, whereas traditional plastics use standard parameters.

Performance

Traditional plastics often offer greater durability, but biodegradable plastics can be engineered to meet specific performance needs.

Understanding these differences helps manufacturers choose the right material for their injection molding projects.

Biodegradable plastics always perform better than traditional plastics.False

Performance depends on the application; traditional plastics may offer superior durability in some cases.

Biodegradable plastics reduce reliance on fossil fuels.True

Their production from renewable resources decreases the need for petroleum-based materials.

What Are the Challenges of Using Biodegradable Plastics in Injection Molding?

While biodegradable plastics offer many benefits, they also present challenges in injection molding that manufacturers must address.

Challenges include higher costs, processing complexities8, limited durability, and the need for proper disposal infrastructure9.

Higher Material Costs

Biodegradable plastics are often more expensive than traditional plastics due to production complexities and lower economies of scale.

Processing Complexities

These materials can be sensitive to moisture and heat, requiring careful handling and specific processing conditions to avoid degradation.

Limited Durability

In some applications, biodegradable plastics may not offer the same level of durability as traditional plastics, potentially limiting their use in high-stress environments.

Disposal Infrastructure

Biodegradable plastics require proper composting facilities to decompose effectively. In regions without such infrastructure, their environmental benefits may not be fully realized.

Addressing these challenges is essential for manufacturers to successfully integrate biodegradable plastics into their injection molding processes.

Biodegradable plastics are always easy to process in injection molding.False

They often require specific handling and processing adjustments to prevent issues like degradation.

The lack of composting facilities can limit the effectiveness of biodegradable plastics.True

Without proper disposal, these materials may not decompose as intended, reducing their environmental benefits.

How Can Manufacturers Overcome Challenges with Biodegradable Plastics in Injection Molding?

Manufacturers can adopt strategies to mitigate the challenges associated with biodegradable plastics in injection molding.

Strategies include optimizing processing parameters, investing in equipment upgrades, and educating consumers about proper disposal.

Optimize Processing Parameters

Adjusting temperature, pressure, and cycle times can help accommodate the unique properties of biodegradable plastics, ensuring high-quality products.

Invest in Equipment Upgrades

Using corrosion-resistant components and specialized screw designs can improve the processing of biodegradable materials, reducing wear and tear on machinery.

Educate Consumers

Providing information on proper disposal methods, such as composting, can help ensure that biodegradable plastics achieve their intended environmental benefits.

Collaborate with Suppliers

Working closely with material suppliers can help manufacturers select the right biodegradable plastic for their application and receive guidance on processing techniques.

These strategies enable manufacturers to harness the benefits of biodegradable plastics while addressing their challenges.

Manufacturers can use standard injection molding equipment without modifications for biodegradable plastics.False

Some equipment upgrades or adjustments are often necessary to handle biodegradable materials effectively.

Consumer education is crucial for maximizing the environmental benefits of biodegradable plastics.True

Proper disposal ensures that these materials decompose as intended, reducing environmental impact.

Conclusion

Biodegradable plastics offer significant benefits in injection molding, from reducing environmental impact to meeting consumer demand for sustainable products. While challenges like higher costs and processing complexities exist, manufacturers can overcome them through careful material selection, process optimization, and consumer education. As the market for eco-friendly products grows, biodegradable plastics will play an increasingly important role in sustainable manufacturing.

Biodegradable plastics are transforming injection molding by providing a greener alternative to traditional plastics. Their use in injection molding supports sustainability goals and offers new opportunities for innovation across industries.

-

Learn how injection molding adapts to biodegradable materials for eco-friendly production methods. ↩

-

Explore the advantages of biodegradable plastics to understand their impact on sustainability and manufacturing processes. ↩

-

Discover various sustainable practices that can enhance your manufacturing processes and reduce environmental impact. ↩

-

Learn why material preparation is critical for the success of injection molding with biodegradable plastics and how it impacts product quality. ↩

-

Discover essential quality control measures that ensure the consistency and quality of products made from biodegradable plastics. ↩

-

Discover various eco-friendly alternatives to traditional plastics and their impact on the environment. ↩

-

Learn about the benefits of sustainable manufacturing practices and their role in reducing environmental impact. ↩

-

This link will provide insights into the specific processing challenges faced by manufacturers when working with biodegradable plastics. ↩

-

Learn about the critical role of disposal infrastructure in maximizing the environmental benefits of biodegradable plastics. ↩