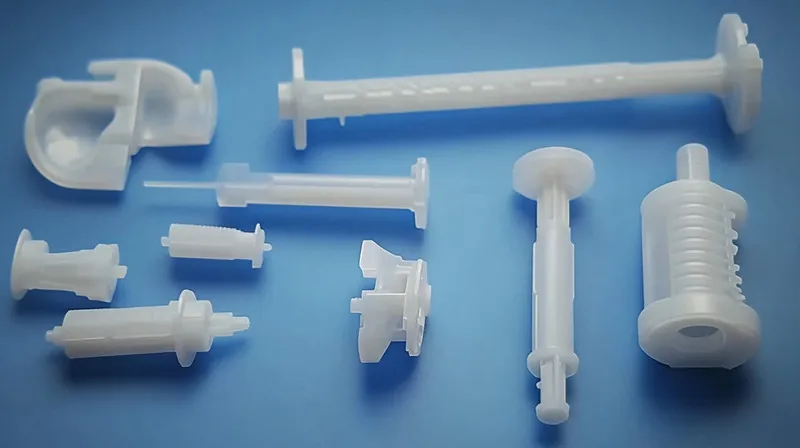

Additives play a crucial role in enhancing the properties of injection-molded parts1, allowing manufacturers to tailor materials for specific applications. From improving strength and durability to enhancing aesthetics and environmental resistance, additives can transform the performance of molded components. However, their impact depends on the type of additive, the base polymer, and the processing conditions used during injection molding.

Additives significantly enhance the properties of injection-molded parts, allowing customization for specific applications. They can improve strength, durability, appearance, and resistance to environmental factors, but their impact depends on the type of additive, base polymer2, and processing conditions.

Understanding how different additives3 affect the final product is essential for optimizing part performance and ensuring cost-effective production. This article explores the various types of additives, their effects on material properties, and practical considerations for their use in injection molding.

Additives always improve the mechanical properties of injection-molded parts.False

While many additives enhance properties like strength or flexibility, some can introduce trade-offs, such as increased brittleness or reduced impact resistance.

Additives are essential for achieving specific performance requirements in injection-molded parts.True

Additives allow for the customization of material properties, making them indispensable for meeting industry-specific demands.

- 1. What Are the Common Types of Additives Used in Injection Molding?

- 2. How Do Additives Affect the Mechanical Properties of Molded Parts?

- 3. What Are the Effects of Additives on Thermal and Chemical Properties?

- 4. How Do Additives Influence the Aesthetics of Molded Parts?

- 5. What Are the Trade-Offs When Using Additives in Injection Molding?

- 6. How to Choose the Right Additives for Your Injection-Molded Parts?

- 7. Conclusion

What Are the Common Types of Additives Used in Injection Molding?

Additives are incorporated into the base polymer to modify specific properties of injection-molded parts. Each type of additive serves a distinct purpose, from enhancing mechanical performance to improving aesthetics.

Common additives in injection molding include reinforcement fillers, functional additives, aesthetic additives, and processing aids, each tailored to improve specific properties like strength, durability, appearance, or processability.

| Additive Type | Purpose | Examples |

|---|---|---|

| Reinforcement Fillers4 | Enhance strength, stiffness, and thermal properties | Glass fibers, carbon fibers, glass beads |

| Functional Additives5 | Improve performance under specific conditions (e.g., heat, UV exposure) | Flame retardants, UV stabilizers, antioxidants |

| Aesthetic Additives | Modify appearance without affecting physical properties | Colorants, pigments, optical brighteners |

| Processing Aids | Facilitate molding by improving flow and reducing cycle times | Lubricants, mold release agents, flow promoters |

Reinforcement Fillers

Reinforcement fillers, such as glass fibers or carbon fibers, are used to increase the mechanical strength and rigidity of molded parts. For example, glass fibers can boost tensile strength but may also make the part more brittle, limiting its use in high-impact applications (Glass Additives).

Functional Additives

Functional additives like flame retardants or UV stabilizers enhance the part’s resistance to environmental factors. UV stabilizers, for instance, are crucial for outdoor applications where prolonged sun exposure could degrade the polymer.

Aesthetic Additives

Colorants and pigments are added to achieve desired visual effects without significantly altering the part’s physical properties. These are commonly used in consumer goods and automotive interiors.

Processing Aids

Processing aids, such as lubricants, improve the flow of the polymer during molding, reducing defects and cycle times. They are particularly useful for complex molds or high-viscosity materials.

All additives improve the processability of injection-molded parts.False

While processing aids specifically enhance flow and mold release, other additives like reinforcement fillers can increase viscosity, making processing more challenging.

Additives can be used to reduce material costs in injection molding.True

Fillers like talc or calcium carbonate can reduce the amount of expensive polymer needed, lowering overall material costs.

How Do Additives Affect the Mechanical Properties of Molded Parts?

Additives can significantly alter the mechanical properties of injection-molded parts, such as tensile strength6, impact resistance, and flexibility7. The choice of additive depends on the desired outcome and the base polymer used.

Additives like glass fibers increase tensile strength and stiffness but may reduce impact resistance8, while plasticizers enhance flexibility at the cost of rigidity.

Strength and Stiffness

Reinforcement fillers like glass or carbon fibers are commonly used to increase the strength and stiffness of parts. For example, adding 30% glass fibers to polypropylene can increase its tensile strength by up to 50% (Material Selection). However, this often comes at the expense of impact resistance, as the part becomes more brittle.

Flexibility and Toughness

Plasticizers are additives that increase the flexibility and toughness of polymers, making them less prone to cracking under stress. They are often used in applications requiring ductility, such as flexible tubing or seals.

Impact Resistance

Impact modifiers, such as rubber particles, can be added to improve a part’s ability to absorb energy without breaking. This is particularly important for parts subjected to sudden forces, like automotive bumpers.

Additives always increase the strength of injection-molded parts.False

While reinforcement fillers boost strength, other additives like plasticizers may reduce it to enhance flexibility.

Additives can tailor mechanical properties to meet specific application needs.True

By selecting the right additive, manufacturers can fine-tune properties like strength, flexibility, and impact resistance.

What Are the Effects of Additives on Thermal and Chemical Properties?

Additives also play a vital role in enhancing the thermal stability and chemical resistance9 of injection-molded parts, making them suitable for demanding environments.

Additives like flame retardants10 and antioxidants improve thermal stability11, while UV stabilizers and chemical-resistant fillers enhance resistance to environmental degradation.

Thermal Stability

Flame retardants are added to reduce the flammability of polymers, making them safer for use in electrical or high-heat applications. Antioxidants, on the other hand, prevent thermal degradation during processing and extend the part’s service life.

Chemical Resistance

Additives such as UV stabilizers protect parts from degradation caused by sunlight, while certain fillers can improve resistance to chemicals or moisture. For example, ceramic fillers can enhance heat resistance in parts exposed to extreme temperatures (Glass Additives).

Additives are necessary for all injection-molded parts to ensure thermal stability.False

While additives can enhance thermal properties, not all applications require them, especially for parts used in low-temperature environments.

Additives can extend the lifespan of injection-molded parts in harsh environments.True

Functional additives like UV stabilizers and antioxidants protect parts from degradation, increasing their durability.

How Do Additives Influence the Aesthetics of Molded Parts?

Aesthetic additives are used to modify the visual appearance of injection-molded parts, including color, transparency, and surface finish.

Colorants, pigments, and optical brighteners are used to achieve desired visual effects, while maintaining the part’s physical properties.

Color and Appearance

Colorants are the most common aesthetic additives, allowing manufacturers to produce parts in a wide range of colors. Pigments can also be used to create metallic or pearlescent effects, enhancing the visual appeal of consumer products.

Transparency and Clarity

For applications requiring transparency, such as optical lenses or packaging, additives like clarifiers can be used to reduce haze and improve light transmission in amorphous polymers like polystyrene or polycarbonate.

Aesthetic additives always affect the mechanical properties of molded parts.False

Most aesthetic additives are designed to alter appearance without significantly impacting physical properties.

Additives are essential for achieving custom colors in injection-molded parts.True

Colorants and pigments allow for precise control over the visual appearance of molded components.

What Are the Trade-Offs When Using Additives in Injection Molding?

While additives offer numerous benefits, they can also introduce trade-offs that must be carefully managed to avoid compromising part quality.

Additives can enhance specific properties but may introduce drawbacks like increased brittleness, higher costs, or processing challenges.

Mechanical Trade-Offs

For example, while glass fibers increase strength, they can make parts more brittle and prone to cracking under impact. Similarly, plasticizers improve flexibility but reduce rigidity, which may not be suitable for load-bearing applications.

Cost Considerations

Some additives, such as high-performance flame retardants or specialty colorants, can increase material costs. Manufacturers must balance the benefits of these additives against their impact on production budgets.

Processing Challenges

Certain additives, like reinforcement fillers, can increase the viscosity of the polymer melt, making it harder to process and potentially leading to defects like incomplete mold filling or surface imperfections.

Additives always make injection molding more expensive.False

While some additives increase costs, others like fillers can reduce material usage and lower overall production costs.

Careful selection of additives is crucial to avoid unintended property changes.True

Manufacturers must consider the full impact of additives on both desired and undesired properties to ensure part performance.

How to Choose the Right Additives for Your Injection-Molded Parts?

Selecting the appropriate additives requires a thorough understanding of the part’s application, the base polymer, and the processing conditions.

Choose additives based on the specific property enhancements needed, ensuring compatibility with the base polymer and processing parameters.

Define Required Properties

Start by identifying the key properties needed for the part, such as strength, flexibility, thermal resistance, or aesthetics. This will guide the selection of the appropriate additive category.

Assess Compatibility

Ensure that the additive is compatible with the base polymer. For example, certain fillers may not disperse well in specific resins, leading to poor performance or processing issues.

Consider Processing Conditions

Some additives require specific processing conditions, such as higher temperatures or longer cycle times. Verify that your injection molding setup can accommodate these requirements.

Test and Validate

Before full-scale production, conduct trials to test how the additive affects the part’s properties and processability. This helps identify any potential issues early on.

All additives are compatible with any base polymer.False

Additives must be carefully matched to the base polymer to ensure proper dispersion and performance.

Testing is essential to confirm the impact of additives on part properties.True

Trials help verify that the selected additives achieve the desired enhancements without introducing defects.

Conclusion

Additives are indispensable in injection molding, offering manufacturers the ability to customize parts for specific applications by enhancing properties like strength, durability, and aesthetics. However, their use requires careful consideration of trade-offs, such as potential brittleness or increased costs. By understanding the types of additives, their effects, and how to select them properly, manufacturers can optimize part performance and meet industry demands effectively.

For those looking to leverage additives in their injection molding processes, start by defining the required properties, ensuring compatibility with the base polymer, and conducting thorough testing to validate performance.

-

Explore this link to understand the advantages and applications of injection-molded parts in manufacturing. ↩

-

Learn about the significance of base polymers in injection molding and how they interact with additives for optimal results. ↩

-

Discover how additives can enhance material properties and performance in various applications, making them essential in manufacturing. ↩

-

Explore how reinforcement fillers enhance the strength and durability of molded parts, crucial for high-performance applications. ↩

-

Learn about functional additives and their role in improving the performance of materials under specific conditions, essential for advanced applications. ↩

-

Understanding tensile strength is crucial for evaluating the performance of materials in various applications. ↩

-

Learning about flexibility in polymers can guide you in choosing the right materials for specific applications. ↩

-

Exploring impact resistance helps in selecting materials that can withstand sudden forces, essential for safety and durability. ↩

-

Learn about chemical resistance to understand how materials withstand harsh environments, ensuring durability and reliability in use. ↩

-

Explore how flame retardants enhance safety in materials, especially in high-heat environments, making them essential for various applications. ↩

-

Understanding thermal stability is crucial for ensuring the longevity and safety of polymer products in various applications. ↩