Biopolymers are transforming the injection molding1 industry by offering a sustainable alternative to traditional petroleum-based plastics. Derived from renewable resources like plants and microorganisms, biopolymers are often biodegradable or compostable, making them an eco-friendly choice for manufacturers looking to reduce their environmental impact. When used in injection molding—a process where molten material is injected into a mold to create precise parts—biopolymers2 help produce lightweight, durable products while minimizing waste and energy consumption.

Biopolymers enhance the sustainability of injection molding by reducing reliance on fossil fuels, lowering carbon emissions, and offering biodegradable options for products like packaging and medical devices, all while maintaining performance comparable to traditional plastics.

Understanding how biopolymers integrate into the injection molding process is essential for industries aiming to meet sustainability goals3. This article delves into the materials, processes, and applications of biopolymers in injection molding, providing insights into their benefits and challenges.

Biopolymers significantly reduce the carbon footprint of injection molded products.True

Derived from renewable resources, biopolymers have a lower carbon footprint compared to petroleum-based plastics, especially when considering their entire lifecycle.

Biopolymers are always more expensive than traditional plastics.False

While some biopolymers are costlier, advancements in technology and economies of scale are making them increasingly competitive with traditional plastics.

- 1. What are the Common Biopolymers Used in Injection Molding?

- 2. What are the Steps in the Injection Molding Process with Biopolymers?

- 3. What are the Key Factors in Injection Molding with Biopolymers?

- 4. What are the Applications of Biopolymers in Injection Molding?

- 5. What are the Differences Between Injection Molding with Biopolymers and Traditional Plastics?

- 6. Conclusion

What are the Common Biopolymers Used in Injection Molding?

Biopolymers used in injection molding are selected for their sustainability, performance, and compatibility with existing manufacturing processes. These materials offer a range of properties suitable for various applications, from packaging to medical devices.

Common biopolymers in injection molding include Polylactic Acid (PLA)4, Polyhydroxyalkanoates (PHA)5, and starch-based polymers, chosen for their biodegradability, renewability, and versatility in applications like packaging, automotive, and medical products.

| Biopolymer Type | Source | Biodegradability | Typical Applications |

|---|---|---|---|

| Polylactic Acid (PLA) | Corn, sugarcane | Biodegradable | Packaging, disposable items, medical implants |

| Polyhydroxyalkanoates (PHA) | Microbial fermentation | Biodegradable | Medical devices, packaging, agricultural films |

| Starch-based Polymers6 | Corn, potatoes | Biodegradable | Packaging, disposable cutlery, agricultural products |

| Cellulose-based Polymers | Wood, cotton | Biodegradable | Consumer goods, automotive interiors |

Polylactic Acid (PLA)

PLA is one of the most widely used biopolymers in injection molding due to its excellent clarity, strength, and biodegradability. Made from renewable resources like corn starch or sugarcane, PLA is compostable under industrial conditions. It is commonly used for food packaging, disposable cutlery, and medical implants. However, PLA requires specific processing conditions, such as precise temperature control, to prevent degradation during molding (Biopolymers in Injection Molding).

Polyhydroxyalkanoates (PHA)

PHA is produced through microbial fermentation of sugars or lipids, making it fully biodegradable and suitable for sensitive applications like medical devices and agricultural films. PHA offers good mechanical properties and can be processed similarly to traditional plastics, though it may require adjustments in molding parameters to optimize performance (Advanced Injection Molding Review).

Starch-based Polymers

Starch-based biopolymers, derived from corn or potatoes, are often blended with other materials to improve their mechanical properties. These polymers are highly biodegradable and are used in applications like packaging and disposable items. They are particularly popular in the food industry for their compostability and low environmental impact (Bioplastics for Injection).

Cellulose-based Polymers

Cellulose-based biopolymers, sourced from wood or cotton, are used in injection molding for products requiring high strength and durability, such as automotive interiors and consumer goods. While not always fully biodegradable, they are renewable and can be processed using standard injection molding equipment (Biopolymers in Injection Molding).

PLA is the most commonly used biopolymer in injection molding.True

PLA is favored for its balance of performance, cost, and biodegradability, making it a go-to choice for many applications.

All biopolymers are fully biodegradable in any environment.False

Some biopolymers, like PLA, require specific conditions, such as industrial composting, to biodegrade effectively.

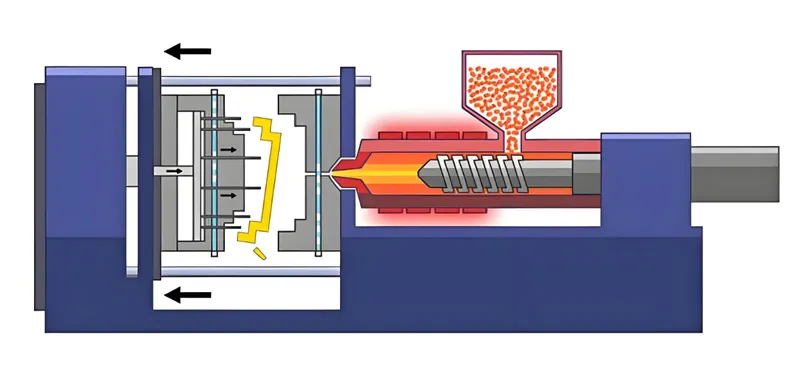

What are the Steps in the Injection Molding Process with Biopolymers?

The injection molding process with biopolymers follows similar steps to traditional plastics but requires careful attention to material preparation and processing conditions to ensure optimal performance and sustainability.

The injection molding process with biopolymers involves material drying, melting, injection, cooling, and ejection, with special care needed for moisture control7 and temperature settings to prevent degradation.

Material Preparation

Biopolymers, especially those like PLA, are sensitive to moisture and must be thoroughly dried before processing to prevent hydrolysis, which can degrade the material during molding.

Melting and Plasticization

The biopolymer is melted in the injection molding machine’s barrel at specific temperatures (e.g., 173-178°C for PLA). Additives like plasticizers may be used to improve flow properties.

Injection

The molten biopolymer is injected into the mold under high pressure (e.g., 25.5 MPa for PLA) to ensure it fills the mold completely and forms the desired shape.

Cooling and Solidification

The mold is cooled to solidify the biopolymer, with cooling times adjusted based on the material and part thickness to prevent warping or shrinkage.

Ejection and Finishing

Once cooled, the part is ejected from the mold, and any excess material is trimmed. The part may undergo additional finishing processes, such as polishing or assembly.

Biopolymers require the same processing conditions as traditional plastics.False

Biopolymers often need specific temperature and moisture controls to prevent degradation during molding.

Injection molding with biopolymers can reduce energy consumption.True

Some biopolymers, like PLA, have lower melting points than traditional plastics, potentially reducing energy use during processing.

What are the Key Factors in Injection Molding with Biopolymers?

Successful injection molding with biopolymers depends on several critical factors that influence the quality, performance, and sustainability of the final product.

Key factors in injection molding with biopolymers include material selection, temperature control, moisture management8, and mold design9, all of which impact the product’s mechanical properties and environmental benefits.

Material Selection

Choosing the right biopolymer is crucial, as different materials offer varying levels of strength, flexibility, and biodegradability. For example, PLA is suitable for rigid parts, while PHA is better for flexible applications.

Temperature Control

Biopolymers have specific melting and processing temperatures that must be carefully managed. For instance, PLA requires a melting temperature of 173-178°C, and exceeding this range can lead to degradation.

Moisture Management

Many biopolymers are hygroscopic, meaning they absorb moisture, which can cause defects during molding. Proper drying and storage are essential to maintain material integrity.

Mold Design

Mold design must account for the unique shrinkage and flow characteristics of biopolymers. Adjustments may be needed to ensure the part meets dimensional tolerances and surface quality standards.

Temperature control is less critical for biopolymers than for traditional plastics.False

Biopolymers often have narrower processing windows, making precise temperature control essential.

Proper mold design can compensate for the unique properties of biopolymers.True

Tailoring mold design to the biopolymer's characteristics can improve part quality and reduce defects.

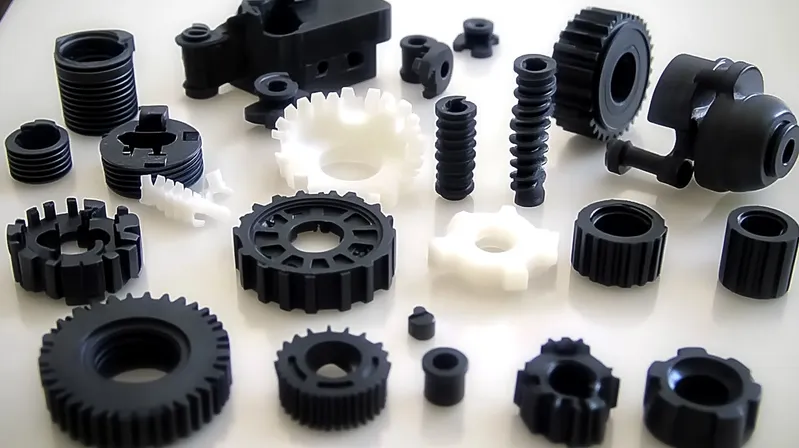

What are the Applications of Biopolymers in Injection Molding?

Biopolymers are used in a wide range of applications across industries, offering sustainable alternatives to traditional plastics without compromising performance.

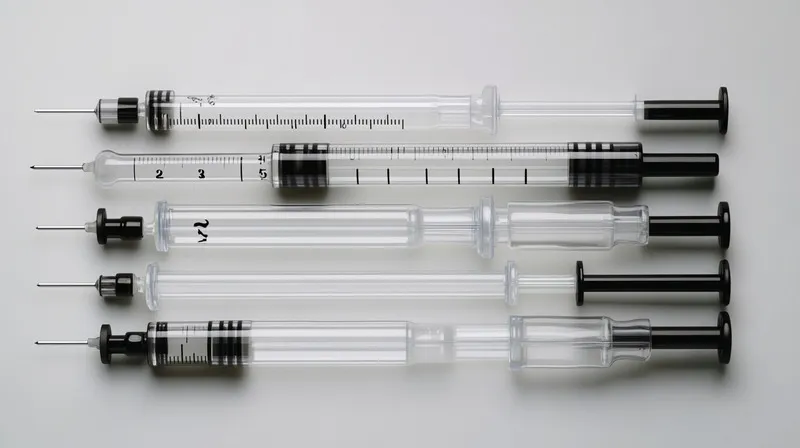

Biopolymers in injection molding are used in packaging, medical devices, automotive components, and consumer goods, providing eco-friendly solutions for products that require durability, biocompatibility10, and biodegradability.

Packaging

Biopolymers like PLA are widely used for food packaging, disposable cutlery, and beverage containers due to their biodegradability and compliance with food safety standards.

Medical Devices

PHA and PLA are used in medical applications such as surgical implants, drug delivery systems, and disposable medical tools, where biocompatibility and biodegradability are critical.

Automotive Components

Biopolymers are increasingly used in automotive interiors, such as dashboards and trim, to reduce vehicle weight and improve sustainability.

Consumer Goods

Products like toys, electronics casings, and household items are made from biopolymers to meet consumer demand for eco-friendly products.

Biopolymers are only suitable for low-performance applications.False

Advances in biopolymer technology have enabled their use in high-performance applications, including medical and automotive sectors.

Biopolymers can be used in food packaging without additional certifications.False

Biopolymers must meet specific food safety standards and certifications, such as FDA approval, for use in food contact applications.

What are the Differences Between Injection Molding with Biopolymers and Traditional Plastics?

While the injection molding process is similar for both biopolymers and traditional plastics, there are key differences in material properties, processing requirements, and environmental impact.

Injection molding with biopolymers differs from traditional plastics in terms of material sourcing, processing conditions, and end-of-life options, offering a more sustainable alternative11 but requiring specific handling and design considerations.

Material Sourcing

Biopolymers are derived from renewable resources, whereas traditional plastics are made from fossil fuels, making biopolymers more sustainable.

Processing Conditions

Biopolymers often require lower processing temperatures and stricter moisture control compared to traditional plastics, which can affect cycle times and energy use.

End-of-Life Options

Biopolymers can be biodegradable or compostable12, reducing landfill waste, while traditional plastics may persist in the environment for hundreds of years.

Performance

While biopolymers can match traditional plastics in many applications, they may have limitations in high-heat or high-stress environments, requiring careful material selection.

Biopolymers always outperform traditional plastics in terms of mechanical properties.False

Biopolymers can match or exceed traditional plastics in some properties but may fall short in others, such as heat resistance.

Injection molding with biopolymers is more energy-efficient than with traditional plastics.True

Some biopolymers have lower melting points, reducing the energy required for processing.

Conclusion

Biopolymers are a game-changer for the injection molding industry, offering a sustainable path forward without sacrificing performance. By leveraging renewable resources and reducing environmental impact, biopolymers help manufacturers meet growing demands for eco-friendly products. However, successful implementation requires careful attention to material selection, processing conditions, and design considerations. As technology advances, biopolymers will continue to play a pivotal role in shaping a more sustainable future for manufacturing.

Biopolymers are the future of sustainable manufacturing.True

With ongoing advancements, biopolymers are becoming increasingly viable for a wide range of applications, driving the shift toward sustainability.

Injection molding with biopolymers is identical to traditional plastics in all aspects.False

While the process is similar, biopolymers require specific adjustments in handling and processing to achieve optimal results.

-

Learn about the injection molding process and how it can be optimized for biopolymer applications to enhance product performance. ↩

-

Explore this link to understand how biopolymers can revolutionize the injection molding industry and contribute to sustainability. ↩

-

This resource will provide valuable insights into achieving sustainability goals through the use of biopolymers in manufacturing. ↩

-

Explore the advantages of PLA in injection molding, including its sustainability and performance benefits for various applications. ↩

-

Learn about PHA’s production process and its suitability for medical devices and packaging, highlighting its biodegradable nature. ↩

-

Discover the versatility of starch-based polymers in various industries, especially their environmental benefits and compostability. ↩

-

Discover the critical role of moisture control in ensuring the quality and performance of biopolymer products during injection molding. ↩

-

Learn about the critical role of moisture management in ensuring the quality and integrity of biopolymer products during injection molding. ↩

-

Discover best practices in mold design that can optimize the performance and quality of biopolymer products in injection molding processes. ↩

-

Discover the significance of biocompatibility in medical applications and its role in patient safety. ↩

-

Learn how biopolymers provide eco-friendly solutions compared to traditional plastics, contributing to a greener future. ↩

-

Discover the differences between biodegradable and compostable materials and their impact on waste management and the environment. ↩