Alle Beiträge

Blog & Artikel

Lesen Sie unseren neuesten Newsletter

Egal, ob Sie sich für Materialauswahl, Produktdesign, Formenbau, Formenbau und Spritzguss interessieren, Sie können uns gerne alles fragen. Unser Team ist bereit, Ihnen die Beratung und Einblicke zu geben, die Sie benötigen.

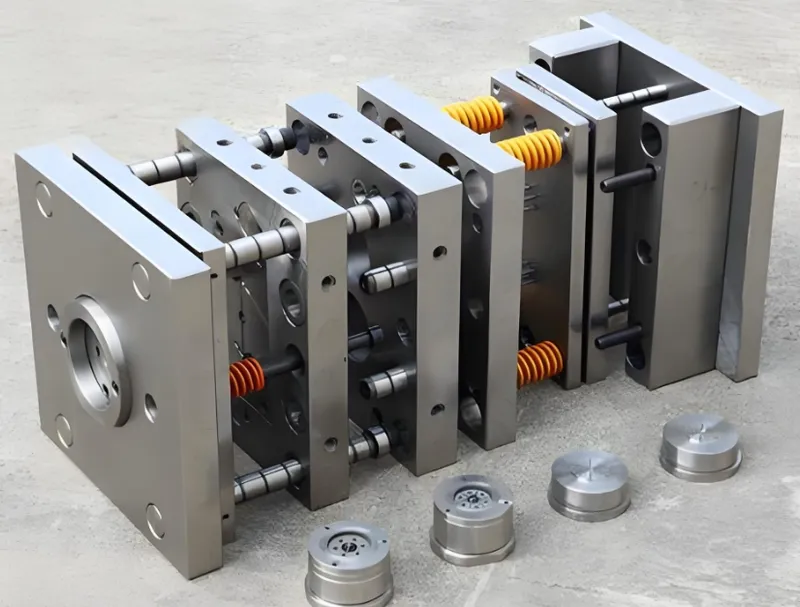

Was sind die besten Praktiken für die Lagerung von Spritzgussformen, um deren Lebensdauer zu verlängern?

Spritzgussformen sind das Rückgrat der Kunststoffherstellung und formen alles von Autoteilen bis hin zu medizinischen Geräten. Diese Präzisionswerkzeuge stellen eine erhebliche Investition dar, die oft Tausende bis Millionen von Dollar kostet. Ihre Langlebigkeit und Leistung hängen jedoch von einem entscheidenden Faktor ab: ...

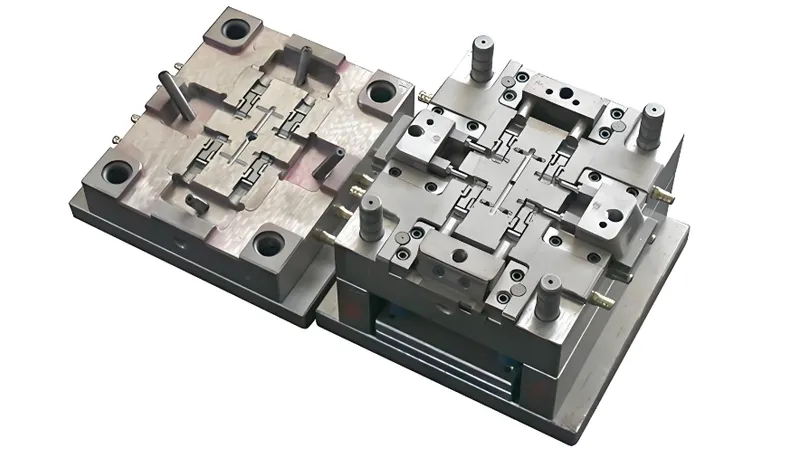

Injektionsform

Welche Vorteile bietet die Verwendung recycelter Materialien beim Spritzgießen?

Wussten Sie, dass die Plastikflasche, die Sie letzte Woche recycelt haben, Teil Ihres nächsten Autos oder Lieblingsspielzeugs werden könnte? Dank der Fortschritte im Spritzgussverfahren1 verändern recycelte Materialien die Fertigungslandschaft2 und bieten eine Win-Win-Situation für beide Seiten ...

Injektionsformung

Die Zukunft im Blick: Neueste Trends bei Spritzgussmaterialien für 2025

Die Spritzgussindustrie entwickelt sich bis 2025 rasant weiter. Neue Materialien werden entwickelt, um den Anforderungen an Nachhaltigkeit, Leistung und Spezialisierung gerecht zu werden. Für Hersteller ist es entscheidend, diesen Trends immer einen Schritt voraus zu sein, um die Produktion zu optimieren, Kosten zu senken und ...

Rohstoffe in Spritzguss

Wie verbessern Kunststoffrippen das Spritzgussdesign?

Kunststoffrippen verbessern das Spritzgussdesign, indem sie den Teilen Festigkeit und Steifigkeit verleihen, den Materialverbrauch minimieren und Defekte wie Verzug oder Einfallstellen verhindern. Das Verständnis der richtigen Konstruktion und Implementierung von Rippen ist der Schlüssel zur Optimierung Ihrer Spritzgussprojekte. In ...

Injektionsformung

Topaktuelle Trends in der Spritzgusstechnologie: Ein umfassender Leitfaden

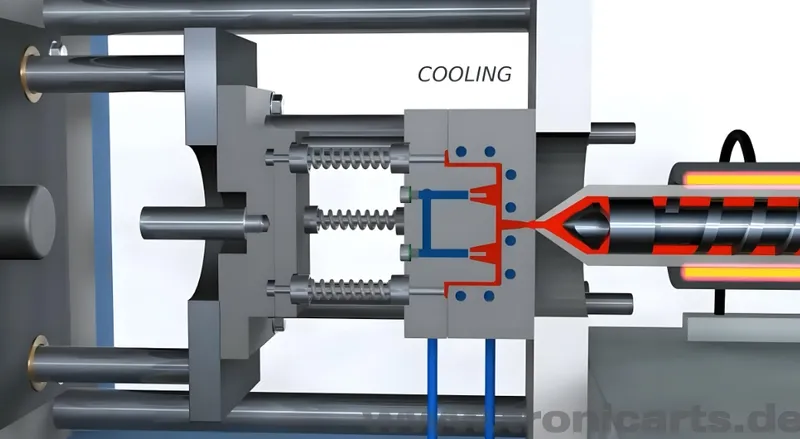

Spritzguss, ein Eckpfeiler der modernen Fertigung, umfasst das Einspritzen von geschmolzenem Material in eine Form, um präzise, hochwertige Teile herzustellen. Dieser Prozess unterliegt einem Wandel, der durch aktuelle Trends wie Nachhaltigkeit1, Automatisierung, Miniaturisierung, fortschrittliche Materialien und On-Demand-Produktion vorangetrieben wird. Diese ...

Injektionsformung

Erreichen enger Toleranzen beim Spritzgießen: Ein umfassender Leitfaden

Das Erreichen enger Toleranzen beim Spritzgießen1 ist entscheidend für die Herstellung hochwertiger, präziser Teile, die strengen Industriestandards entsprechen, beispielsweise in der Medizintechnik, der Automobilindustrie und der Luft- und Raumfahrt. Spritzgießen mit engen Toleranzen erfordert die Optimierung von Design, Materialien, Werkzeugen und Prozessen, um ...

Injektionsformung

Wie wirkt sich die Materialauswahl auf die Spritzgusskosten aus?

Spritzguss ist ein Eckpfeiler der modernen Fertigung und ermöglicht die effiziente Massenproduktion präziser Kunststoffteile. Eine der wichtigsten Entscheidungen in diesem Prozess ist jedoch die Wahl des richtigen Materials. Diese Wahl beeinflusst nicht nur die Leistung von ...

Rohstoffe in Spritzguss

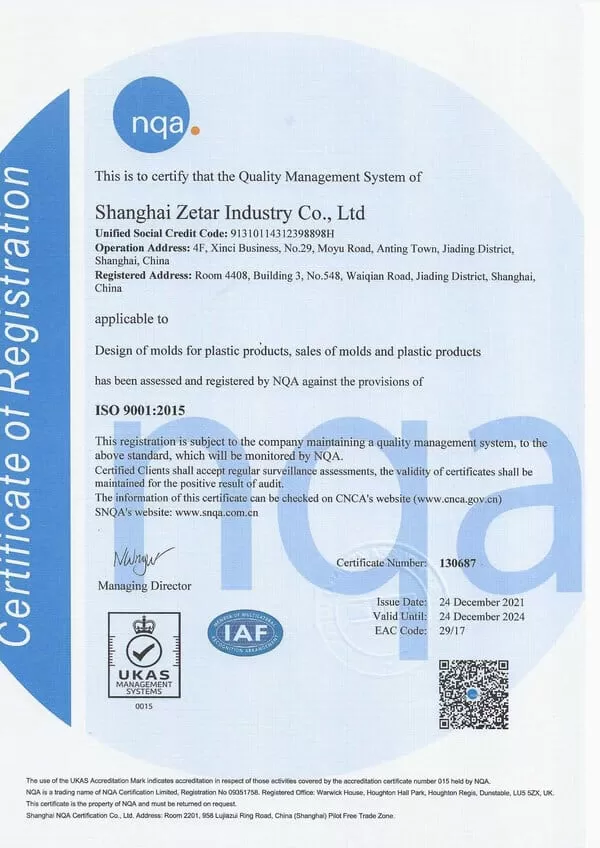

Umfassender Bericht über die Vorteile der ISO 9001-Zertifizierung für Spritzgussbetriebe

Die ISO 9001-Zertifizierung, ein weltweit anerkannter Standard für Qualitätsmanagementsysteme1 (QMS), bietet Unternehmen einen strukturierten Rahmen, um gleichbleibende Qualität sicherzustellen, Kundenerwartungen zu erfüllen und kontinuierliche Verbesserungen voranzutreiben. Für Spritzgussvorgänge – ein Herstellungsverfahren zur Herstellung präziser Kunststoffteile …

Injektionsformung

Was sind die effektivsten Rapid-Prototyping-Techniken für den Formenbau?

Rapid-Prototyping-Techniken1 für den Formenbau haben die Fertigung revolutioniert, indem sie eine schnellere und kostengünstigere Formenproduktion ermöglichen. Diese Methoden sind für Branchen wie die Automobilindustrie, die Medizintechnik und die Konsumgüterindustrie, in denen Präzision und Geschwindigkeit an erster Stelle stehen, unverzichtbar. Rapid Prototyping für den Formenbau2 ...

Injektionsform

Wie senkt die Automatisierung die Arbeitskosten bei Injektionsformungen?

Die Automatisierung im Spritzguss senkt die Arbeitskosten erheblich, indem manuelle Aufgaben durch effiziente, maschinengesteuerte Prozesse ersetzt werden. So können Hersteller mit weniger Personal mehr produzieren und gleichzeitig hohe Qualität und Konsistenz gewährleisten. Die Automatisierung im Spritzguss senkt die Arbeitskosten durch die Automatisierung sich wiederholender ...

Injektionsformung

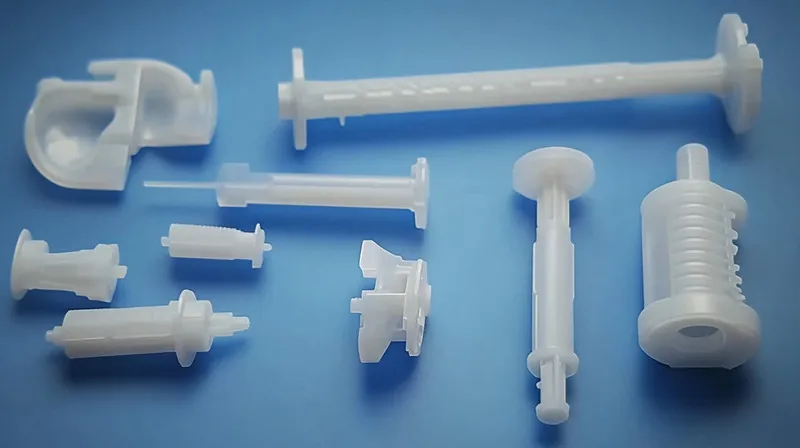

Wie wirken sich Additive auf die Eigenschaften von inspritzgeformten Teilen aus?

Additive spielen eine entscheidende Rolle bei der Verbesserung der Eigenschaften von Spritzgussteilen1 und ermöglichen es Herstellern, Materialien für spezifische Anwendungen anzupassen. Von der Verbesserung der Festigkeit und Haltbarkeit bis hin zur Verbesserung der Ästhetik und Umweltbeständigkeit können Additive die Leistungsfähigkeit von Spritzgussteilen verbessern. Allerdings ...

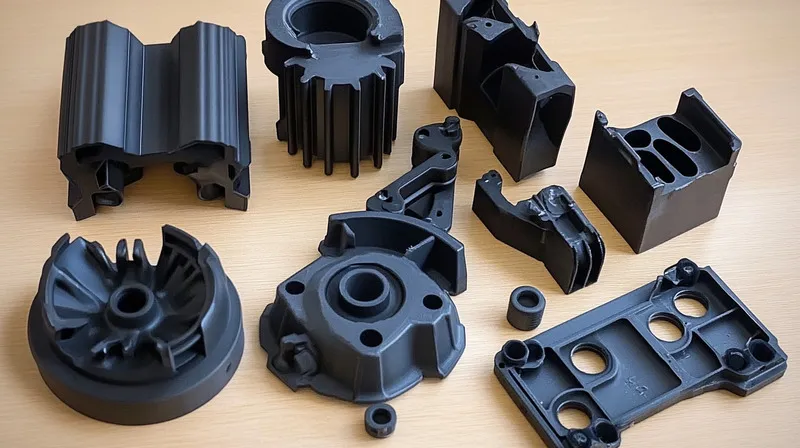

Spritzgussprodukte

Wie können Sie effektive Formen für Dünnwand-Injektionsleisten entwerfen?

Dünnwand-Injektionsformel1 ist ein spezialisiertes Herstellungsprozess, bei dem leichte Kunststoffteile mit Wänden, die häufig weniger als 1 mm dick sind, erzeugt, was es ideal für Branchen wie Verpackungen, Automobiler und Unterhaltungselektronik macht. Das Entwerfen von Formen für diesen Prozess erfordert jedoch Präzision für ...

Injektionsform

Entwerfen von Multi-Cavity-Formen: Ein umfassender Leitfaden

In der Welt des Injektionsformens ist Effizienz alles. Hersteller suchen ständig nach Wegen, um in kürzerer Zeit mehr Teile zu produzieren, ohne die Qualität zu beeinträchtigen. Geben Sie Multi-Cavity-Formen1 ein-diese speziellen Werkzeuge ermöglichen die Erstellung mehrerer identischer Teile in einem einzigen Zyklus, das ...

Injektionsform

Welche Arten und Ursachen gibt es beim Spritzgießen?

Injection -Formteile sind ein weit verbreitetes Herstellungsprozess zur Herstellung präziser Kunststoffteile, erzeugt jedoch häufig verschiedene Formen von Abfällen, die die Kosten erhöhen und die Nachhaltigkeit beeinflussen können. Es ist wesentlich ...

Injektionsformung

Welches Material eignet sich am besten für die Herstellung langlebiger Scharniere?

Erzeugen von dauerhaften lebenden Scharnieren - diese flexiblen Kunststoffverbinder, die wiederholtes Biegen ohne Brechen ermöglichen - wählt das richtige Material aus. In diesem Artikel wird untersucht, warum Polypropylen (PP) 1 die beste Wahl abhängt, es mit Alternativen vergleicht und umsetzbare Einblicke für Design und ...

Rohstoffe in Spritzguss

Welche Auswirkungen haben die Richtlinien von ROHS auf Injektionsformmaterialien?

Die Beschränkung der Richtlinien gefährlicher Substanzen (ROHS) wirkt sich erheblich auf die Injektionsformmaterialien aus, indem sie strenge Grenzen für gefährliche Substanzen durchsetzen und die Hersteller dazu bringen, sicherere, umweltfreundliche Alternativen zu verfolgen1. Diese Verschiebung wirkt sich auf die Materialauswahl, die Produktionskosten und den Marktzugang aus, insbesondere für verkaufte Elektronik ...

Injektionsformung

Welchen Einfluss haben Kristallinitätsniveaus in Polymeren auf die Ergebnisse der Injektionsformung?

Die Kristallinität in Polymeren spielt eine entscheidende Rolle bei der Bestimmung der mechanischen Eigenschaften1, der dimensionalen Stabilität und der Gesamtleistung von inspritzgeformten Teilen. Das Verständnis, wie sich Kristallinität auf den Injektionsformprozess auswirkt2, ist für Ingenieure, Designer und Hersteller von entscheidender Bedeutung, die die Produktqualität optimieren wollen ...

Injektionsformung

Welchen Einfluss haben biologisch abbaubare Kunststoffe auf Spritzgussprozesse?

Biologisch abbaubare Kunststoffe revolutionieren die Injektionsformen-Industrie, indem sie nachhaltige Alternativen zu herkömmlichen Kunststoffbasis-Plastik bieten. Diese Materialien, die aus erneuerbaren Quellen stammen, zersetzen sich auf natürliche Weise und verringern die Auswirkungen auf die Umwelt. Die Integration in Injektionsformprozesse erfordert jedoch spezifische Anpassungen und Überlegungen. Biologisch abbaubar ...

Rohstoffe in Spritzguss

So entwerfen Sie inspritzgeformte Teile für die nahtlose Baugruppe

Das Entwerfen von Injektionsformteilen1 für die nahtlose Baugruppe ist für effiziente Herstellung und qualitativ hochwertige Produkte von wesentlicher Bedeutung. Es stellt sicher, dass Teile perfekt zusammenpassen und die Montagezeit und -kosten reduzieren und gleichzeitig die allgemeine Produktzuverlässigkeit verbessern. Dieser Leitfaden führt Sie durch den Schlüssel ...

Spritzgussprodukte

Wie kann der 3D-Druck Ihren Formenbauprozess revolutionieren?

Der 3D -Druck oder die additive Fertigung1 verändert den Formprozess2, indem sie beispiellose Geschwindigkeit, Kosteneinsparungen und Flexibilität bei der Gestaltung bietet. Diese Technologie ermöglicht die Schaffung von Formen direkt aus digitalen Designs, reduziert die Vorlaufzeiten und ermöglicht komplexe Geometrien, die ...

3D -Druckformen

Ausgleichung von Läufern in Multi-Cavity-Formen: Ein umfassender Leitfaden

Das Ausgleich von Läufern in Multi-Cavity-Molds1 ist ein kritischer Aspekt des Injektionsformens, der sicherstellt, dass jeder Hohlraum gleichmäßig füllt und konsistente, hochwertige Teile erzeugt. In Multi-Cavity-Formen, die so konzipiert sind, dass sie mehrere identische Teile in einem einzigen Zyklus erzeugen, dem Läufersystem-der ...

Injektionsform

Was sind die besten Formentestpraktiken für effizientes Spritzgießen?

Injection -Formteile ist ein Eckpfeiler der modernen Herstellung, die die Massenproduktion von Kunststoffteilen mit hoher Präzision und Effizienz ermöglicht. Der Erfolg dieses Prozesses hängt jedoch von der Qualität der verwendeten Form ab. Schimmelpilze ist ein kritischer Schritt ...

Injektionsform

Was sind die wesentlichen Tipps für ein effektives Formendesign?

Schimmelpilzdesign ist ein kritischer Prozess in der Herstellung, das Materialien wie Kunststoffe, Metalle oder Glas in präzise Teile formuliert, die in Branchen wie Automobil-, Medizin- und Konsumgütern verwendet werden. Eine gut gestaltete Form sorgt für hochwertige Teile1, reduziert Abfall und beschleunigt ...

Injektionsform

Verständnis von Nebenaktionen im Injektionsform: Ein umfassender Leitfaden

Nebenwirkungen im Injektionsform sind spezielle Mechanismen, die die Schaffung komplexer Teilmerkmale wie Undercuts1 ermöglichen, die nicht mit Standardformen erreicht werden können. Diese Funktionen wie Schnapp- oder Gewindelöcher sind für viele Branchen unerlässlich, würden aber ...

Injektionsformung

Ist Injektionsform mit Glasnylon möglich? Ein umfassender Leitfaden

Injection-Formteile sind ein weit verbreitetes Herstellungsprozess für die Erstellung von Kunststoffteilen. Wenn es um Materialien wie mit Glas gefüllter Nylon geht, gibt es einzigartige Überlegungen und Vorteile. Mit Glas gefüllter Nylon, eine Art Nylon, das mit Glasfasern verstärkt wird, bietet eine verbesserte Festigkeit, ...

Rohstoffe in Spritzguss

Wie Injektionsformunternehmen FDA -Konformität erreichen

Injection Moulding ist ein Eckpfeiler der modernen Fertigung und produziert alles, von Lebensmittelverpackungen bis hin zu lebensrettenden medizinischen Geräten. Wenn diese Produkte jedoch mit Nahrung oder dem menschlichen Körper in Kontakt kommen, müssen sie strenge Sicherheitsstandards erfüllen, die von den USA festgelegt sind ...

Injektionsformung

Wie funktioniert das Auswerfersystem beim Spritzgießen?

Das Ejektorsystem bei Injektionsformungen ist ein entscheidender Mechanismus, der die effiziente Entfernung von geformten Teilen aus dem Schimmelpilzhohlraum gewährleistet. Dieses System spielt eine wichtige Rolle bei der Aufrechterhaltung der Produktionsgeschwindigkeit und der Teilqualität11, was es für Hersteller von wesentlicher Bedeutung macht ...

Injektionsformung

Wie verbessert das Umspritzen die Einspritzprozesse?

Das Einsatzformpunkt ist eine spezielle Injektionsformtechnik1, die vorgeformte Einsätze-typisch Metallkomponenten2-in den Kunststoffteilen während des Formprozesses integriert. Diese Methode verbessert das traditionelle Injektionsformwerk, indem sie stärkere, funktionale und kostengünstigere Produkte produziert. Durch Einbettung von Einsätzen direkt in die ...

Injektionsformung

Auswahl der richtigen Kunststoff -B -Seite: Ein umfassender Leitfaden

Bei der Gestaltung von Plastikteilen für die Injektionsformung ist einer der kritischen Aspekte, die zu berücksichtigen sind, die Auswahl der B -Side -Merkmale1. Diese Merkmale, die sich auf der nicht sichtbaren Seite der Rolle befinden, spielen eine wichtige Rolle in der Funktionalität und Montage ...

Rohstoffe in Spritzguss

Wie Biopolymere die Nachhaltigkeit von Injektionsformungen verbessern

Biopolymere transformieren die Injektionsformung1-Industrie, indem sie eine nachhaltige Alternative zu traditionellen Kunststoffen auf Erdölbasis anbieten. Biopolymere sind aus erneuerbaren Ressourcen wie Pflanzen und Mikroorganismen abgeleitet und sind häufig biologisch abbaubar oder kompostierbar, was sie zu einer umweltfreundlichen Wahl für Hersteller macht, die reduzieren möchten ...

Spritzgussprodukte