ISO 9001 certification, a globally recognized standard for quality management systems1 (QMS), provides a structured framework for organizations to ensure consistent quality, meet customer expectations, and drive continuous improvement. For injection molding operations—a manufacturing process that produces precise plastic parts by injecting molten material into molds—ISO 9001 certification2 offers significant benefits. This report explores these advantages in depth, covering definitions, classifications, applications, technical details, practical tools, and related technologies.

ISO 9001 certification enhances injection molding3 by improving product quality, operational efficiency, and customer satisfaction, making it a valuable asset for manufacturers.

ISO 9001 certification ensures zero defects in injection molded products.False

While ISO 9001 improves quality and reduces defects, it does not guarantee zero defects. It provides a framework for continuous improvement and risk management.

- 1. What is ISO 9001 and How Does It Apply to Injection Molding?

- 2. What are the Key Benefits of ISO 9001 for Injection Molding Operations?

- 3. How Does ISO 9001 Integrate into the Injection Molding Process?

- 4. What Practical Tools Does ISO 9001 Provide for Injection Molding?

- 5. What Technologies Complement ISO 9001 in Injection Molding?

- 6. Conclusion

What is ISO 9001 and How Does It Apply to Injection Molding?

ISO 9001 certification establishes a systematic approach to quality management, while injection molding creates precise plastic parts for various industries. Together, they ensure consistency and excellence in manufacturing.

ISO 9001, a quality management standard, integrates with injection molding to standardize processes, reduce defects, and meet industry-specific requirements like automotive and medical manufacturing.

Clear Definitions

-

ISO 9001: Officially titled "ISO 9001:2015 – Quality Management Systems – Requirements," this standard outlines criteria for a QMS based on seven principles: customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision-making, and relationship management. Certification is achieved through external audits (ISO 9001 Overview).

-

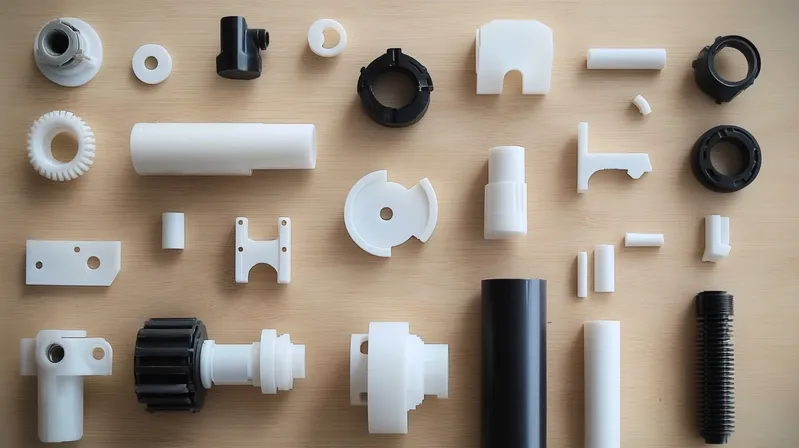

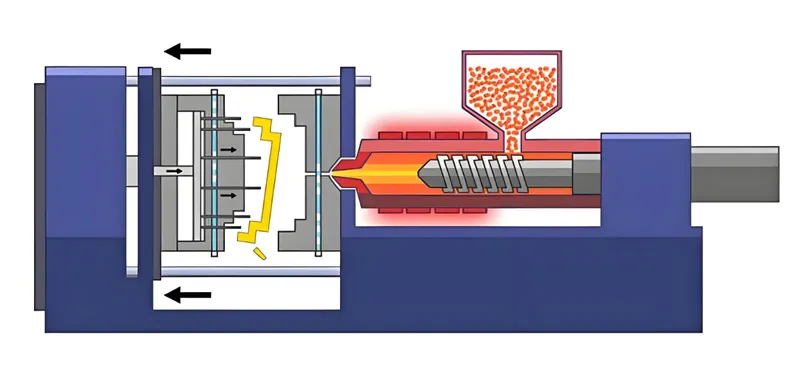

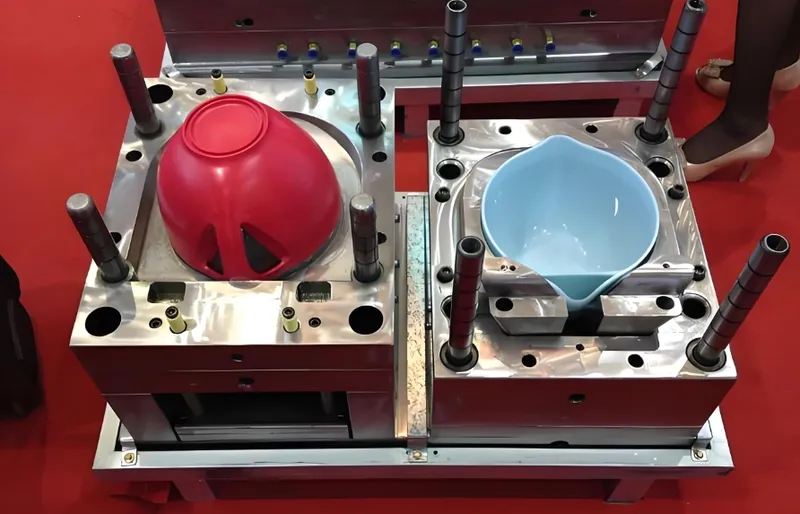

Injection Molding: A process where molten plastic (thermoplastics or thermosets) is injected into a mold cavity, cooled, and solidified to form parts. Known as plastic injection molding, it’s widely used in automotive, medical, and consumer goods industries.

Classification

-

By Material: Includes thermoplastics (e.g., ABS, polypropylene) and thermosets (e.g., epoxy).

-

By Mold Type: Single-cavity or multi-cavity molds.

-

By Application: Automotive (e.g., bumpers), medical (e.g., syringes), and consumer products (e.g., toys).

What are the Key Benefits of ISO 9001 for Injection Molding Operations?

ISO 9001 certification offers practical advantages for injection molding, addressing quality, efficiency, and market needs across industries.

ISO 9001 improves injection molding by enhancing quality control, reducing waste, and boosting competitiveness in regulated and global markets.

Typical Application Scenarios

-

Regulated Industries: Essential for medical devices and automotive parts, ensuring compliance with strict standards.

-

Global Market Access: Certification meets customer and regulatory requirements for international trade.

-

Efficiency Gains: Reduces defects and optimizes processes in high-volume production.

Pros and Cons Comparison

| Aspect | ISO 9001 Certification | Six Sigma4 |

|---|---|---|

| Focus | Comprehensive QMS | Process improvement5 |

| Scope | Organization-wide | Project-specific |

| Certification | Yes | No |

| Key Benefits | Consistency, customer trust, market access | Defect reduction, statistical analysis |

ISO 9001 certification is more comprehensive than Six Sigma for injection molding.True

ISO 9001 addresses the entire quality management system, while Six Sigma focuses on specific process improvements.

How Does ISO 9001 Integrate into the Injection Molding Process?

ISO 9001 enhances every stage of injection molding, from material selection to quality control, ensuring consistent outcomes.

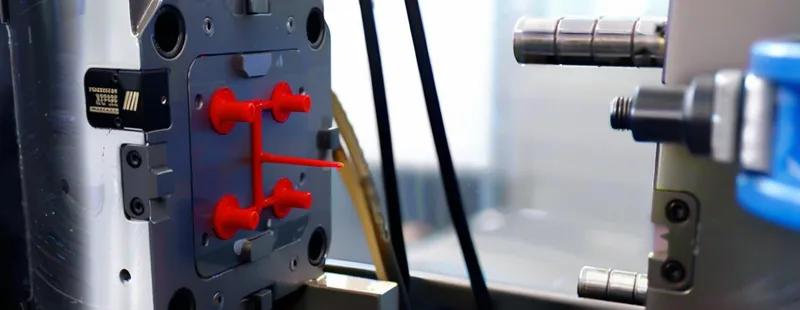

ISO 9001 integrates into injection molding by standardizing material handling, process control, and inspection, minimizing errors and improving efficiency.

Process Workflow Breakdown

-

Material Selection: Standardized procedures ensure material traceability and quality.

-

Injection Process: Controlled parameters (e.g., temperature, pressure) reduce variability (Molding Parameters).

-

Quality Inspection: Documented testing ensures compliance with specifications.

Material Compatibility

- Thermoplastics: Requires precise temperature control, managed under ISO 9001 to prevent defects.

- Thermosets: Standardized curing processes ensure consistency.

What Practical Tools Does ISO 9001 Provide for Injection Molding?

ISO 9001 offers actionable tools to maintain quality and streamline decision-making in injection molding operations.

ISO 9001 provides checklists and decision-making frameworks to ensure quality and guide certification implementation in injection molding.

Design Checklist

-

Verify material specifications.

-

Ensure mold maintenance schedules.

-

Conduct regular quality audits (Mold Design Checklist).

Decision-Making Framework

| Step | Question | Action |

|---|---|---|

| Assess Current QMS | Meets requirements? | Evaluate certification need6 |

| Identify Gaps | Defects or inefficiencies present? | Document and prioritize fixes7 |

| Evaluate Costs | Benefits outweigh costs? | Plan implementation if justified8 |

What Technologies Complement ISO 9001 in Injection Molding?

ISO 9001 connects with upstream and downstream technologies, enhancing its impact on injection molding.

ISO 9001 works with mold design software, automation, and quality control systems to optimize injection molding processes.

- Upstream: CAD/CAM tools and advanced materials.

- Downstream: Automated inspection and assembly systems.

Conclusion

ISO 9001 certification transforms injection molding operations by improving quality, efficiency, and market competitiveness. Benefits include reduced defects, enhanced customer trust, and cost savings, making it a strategic investment for manufacturers. Explore how ISO 9001 can elevate your operation further (ISO 9001 Benefits).

-

This link will help you learn about the essential elements of quality management systems and their importance in various industries. ↩

-

Exploring this resource will provide insights into how ISO 9001 certification can enhance business operations and quality management. ↩

-

Understanding injection molding is crucial for grasping its applications and benefits in manufacturing processes. ↩

-

This link will help you understand the methodologies of Six Sigma and its impact on reducing defects and improving processes. ↩

-

Discover various strategies and tools for process improvement that can lead to significant operational efficiencies. ↩

-

Understanding the certification process is crucial for ensuring compliance and enhancing your QMS effectiveness. ↩

-

Learn best practices for documenting and prioritizing fixes to improve your QMS and operational efficiency. ↩

-

Explore effective strategies for planning QMS implementation to ensure successful outcomes and resource allocation. ↩