All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Key Steps to Designing Plastic Molded Parts?

Designing plastic molded parts is a blend of art and science, requiring precision and foresight at every step. This guide breaks down the essential phases in the process—from clarifying design requirements to collaborating with manufacturers and optimizing for quality. Join ...

DESIGN

Which Injection Molded Plastic Offers the Highest Strength?

In the ever-evolving world of product design and manufacturing, choosing the right material is pivotal for success. Among various options, polycarbonate (PC) often emerges as a strong contender for its remarkable properties. However, understanding the full spectrum of materials available—including ...

Materials Recommendations

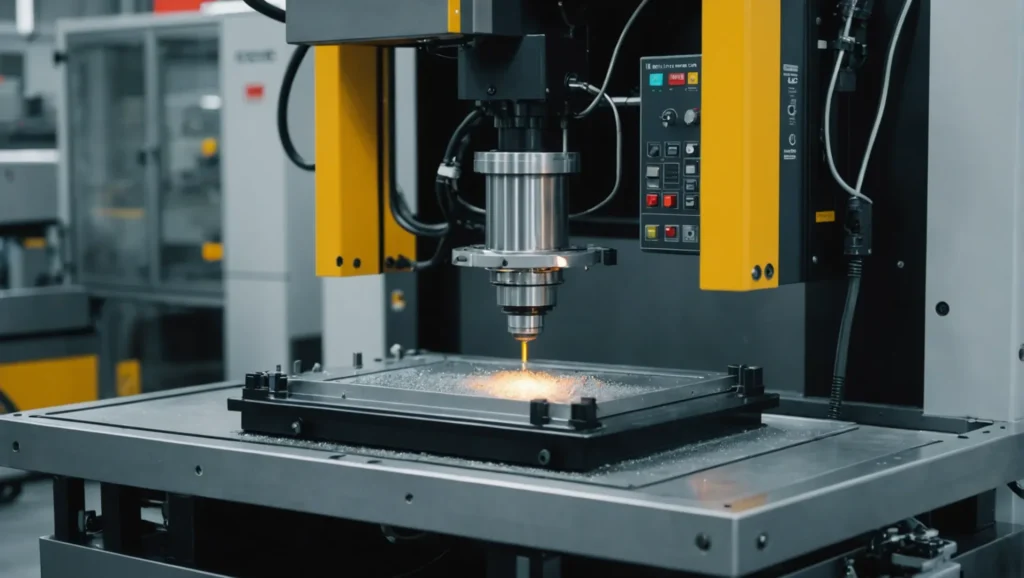

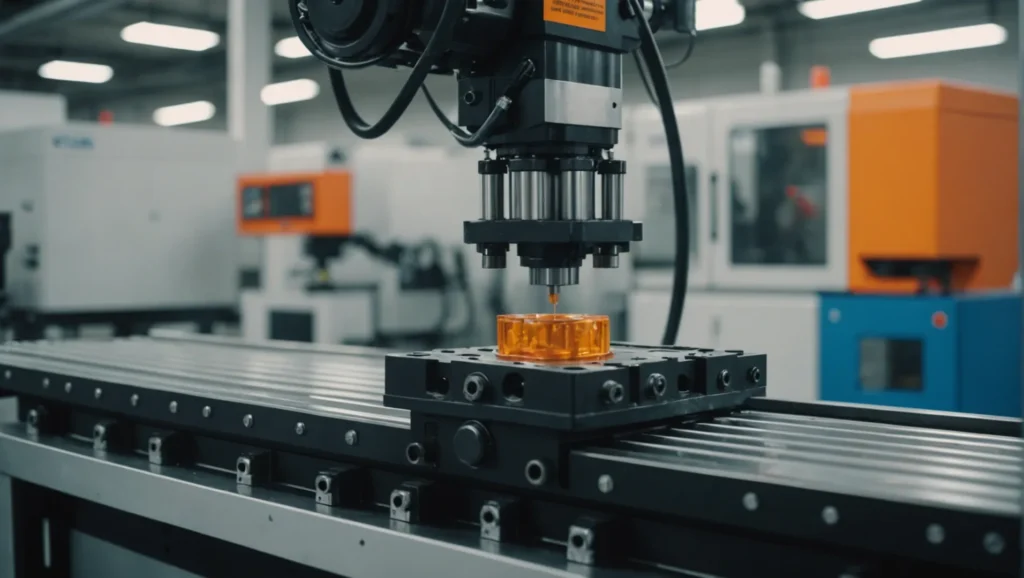

What Is Plastic Injection Molding and How Does It Work?

Plastic injection molding is an essential manufacturing technique that enables the efficient production of complex plastic parts. By injecting molten plastic into molds, this method allows for high precision and rapid production cycles. In this article, we will explore the ...

MANUFACTURING

What Products Can Be Made with Injection Molding?

Have you ever paused to think about the intricate process behind the plastic items we use every day? Injection molding is the backbone of modern manufacturing, transforming simple plastic pellets into everything from sturdy toys to essential medical supplies. In ...

MANUFACTURING

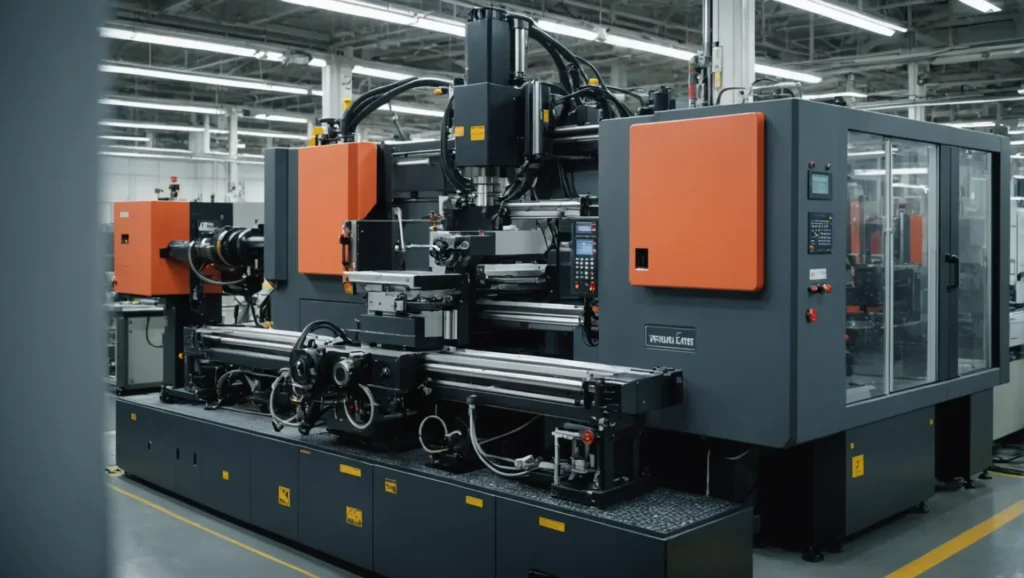

How Does Multiple Injection Molding Enhance Manufacturing Efficiency?

In today’s fast-paced manufacturing landscape, efficiency is the name of the game. Enter multiple injection molding—a groundbreaking process that not only boosts productivity but also opens doors to innovative product designs. This article explores how this technology can revolutionize your ...

MANUFACTURING

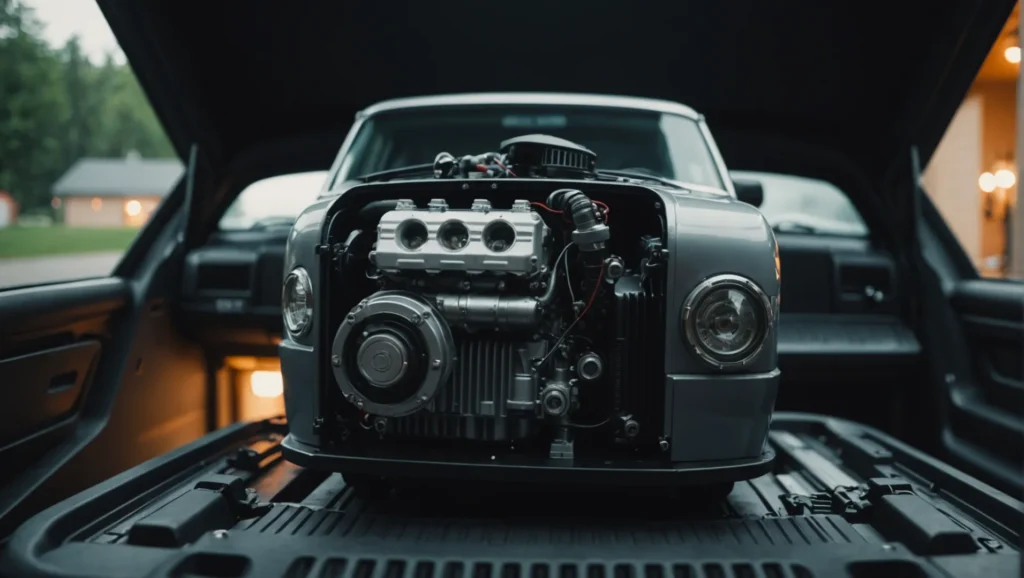

How Does a ‘Dog House’ Function in Automotive Plastic Design?

In the world of automotive engineering, the 'dog house' is more than just a protective structure; it’s a vital player in ensuring the efficiency and comfort of our vehicles. From protecting sensitive components to optimizing space and reducing noise, understanding ...

DESIGN

What Are the Best Strategies to Reduce Injection Molding Costs?

Injection molding is a widely used manufacturing process, but it can be costly. Reducing these costs is key to boosting profitability. By focusing on raw materials, production processes, logistics, and product design, manufacturers can effectively lower expenses while enhancing quality.

DEVELOPMENT

How Does a Hydraulic System Function in an Injection Machine?

Hydraulic systems are the unsung heroes behind the scenes in injection molding machines. They provide the power and precision necessary for creating high-quality plastic products. This article dives into the intricate workings of hydraulic systems, exploring their components, functionality, and ...

MANUFACTURING

What Are the Steps to Achieve High-Quality Injection Molding?

Achieving high-quality injection molding is crucial for creating products that are not only reliable but also visually appealing. This guide explores the essential steps from selecting the right materials to implementing effective quality inspections, ensuring you can produce exceptional results ...

MANUFACTURING

Why is Injection Molding So Fast and Cost-Effective?

Injection molding has become a staple in modern manufacturing due to its remarkable efficiency and affordability. This article delves into the factors that make injection molding a preferred choice for producing intricate designs quickly and economically. We will explore how ...

Price Evaluation

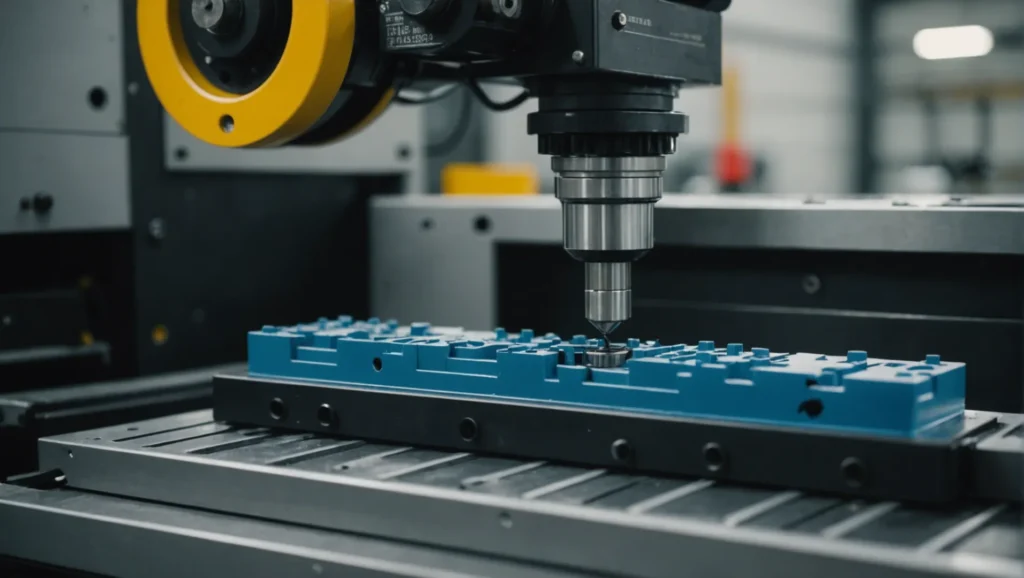

What Is the Timeframe for Creating a Plastic Mold?

Creating a plastic mold is a vital step in manufacturing and product development, but how long does it actually take? Understanding the intricacies behind mold complexity, production technologies, and factory scheduling can help you better manage your timelines and expectations. ...

MANUFACTURING

How Can You Benefit from Cheap Plastic Injection Molding?

In the world of manufacturing, finding a balance between cost and quality is key. Cheap plastic injection molding offers a solution by reducing production costs without sacrificing functionality. This method is especially advantageous for products where precision is not the ...

MANUFACTURING

How Efficient Are Injection Molding Machines at Producing Car Parts?

The automotive industry relies on precision and efficiency for manufacturing. Injection molding machines are at the forefront, revolutionizing how car parts are produced with unmatched quality and cost-effectiveness. This article explores the types of parts best suited for injection molding, ...

MANUFACTURING

What Makes Plastic Injection Molding the Best Option for Manufacturing?

When it comes to manufacturing, the choice of method can make or break your project. Plastic injection molding has emerged as a leading choice due to its efficiency, cost-effectiveness, and ability to create complex designs. In this article, I’ll share ...

MANUFACTURING

What Are the Key Materials Used in Injection Moulding?

Injection moulding is a cornerstone of modern manufacturing, transforming raw materials into complex shapes with precision. The choice of materials can significantly impact the performance and cost-effectiveness of your products. In this article, I’ll share insights on thermoplastics and thermosetting ...

Materials Recommendations

Why Do Car Manufacturers Prefer Using Plastic in Vehicles?

In the fast-evolving world of automotive design, plastics have emerged as a game-changer. Not only do they enhance fuel efficiency and safety, but they also pave the way for innovative designs while keeping costs down. This article explores the multifaceted ...

Materials Recommendations

Which Types of Plastics Can Be Injection-Molded?

Choosing the right plastic for injection molding is crucial for project success. This guide explores the most common types of plastics used in injection molding, including their unique properties and applications, helping you make informed decisions for your projects.

Materials Recommendations

What Are the Key Benefits of Plastic Injection Molding?

Plastic injection molding is a transformative technique that has reshaped various industries with its remarkable efficiency and precision. From automotive to healthcare, this method offers unparalleled benefits that can enhance production processes and product quality. In this article, I explore ...

MANUFACTURING

What Are the Best Practices for Designing Automotive Plastic Parts?

Designing automotive plastic parts involves a careful balance of material selection, structural integrity, and mold design. This article delves into best practices, offering insights on how to optimize performance while keeping costs manageable. Whether you're new to the field or ...

DESIGN

Is It Possible to Inject PP Plastic Resin into an ABS Mold?

Navigating the complexities of injection molding requires a keen understanding of material compatibility. A common question arises: Can PP plastic resin be injected into an ABS mold? While the answer isn't straightforward, exploring methods and considerations can shed light on ...

Materials Recommendations

What Makes Plastics Ideal for Automotive Components?

In today's automotive landscape, plastics have emerged as a cornerstone material for vehicle design and production. Their lightweight nature, design versatility, cost-effectiveness, and functional advantages position them as a key player in enhancing vehicle performance and sustainability. This article explores ...

Materials Recommendations

How Are Plastic Car Toys Made Through Injection Molding?

Plastic car toys are a staple in many children's toy collections, but how exactly are they made? In this article, we explore the injection molding process, its benefits, and other methods used in toy manufacturing. We also take a closer ...

MANUFACTURING

Which Types of Plastics Are Suitable for Injection Molding?

Choosing the right plastic for injection molding is crucial for product quality and manufacturing efficiency. Explore common types such as PE, PP, PVC, PS, ABS, and PC, and learn how their unique properties can enhance your project outcomes.

Materials Recommendations

What Causes Injection Molded Polypropylene Parts to Collapse?

Injection molded polypropylene parts are essential across various industries for their strength and adaptability. However, collapses can disrupt production and impact quality. Understanding the underlying causes—from material properties to mold design—is critical for manufacturers seeking to enhance their processes and ...

Quality Inspection

Which Injection Molded Plastic is the Strongest?

When it comes to selecting the right material for your injection molded project, strength is often a top priority. Polycarbonate, PPS, and PEEK stand out as some of the strongest plastics available, but understanding their specific properties and applications is ...

Materials Recommendations

What Are the Best Materials Used in Injection Moulding?

Injection moulding is a cornerstone of modern manufacturing, enabling the mass production of precise and durable components. Selecting the right material is crucial for optimizing performance and cost-efficiency. In this post, I’ll explore the best materials used in injection moulding, ...

Materials Recommendations

What Are the Key Requirements for Medical Injection Molding?

Medical injection molding is pivotal in manufacturing safe, compliant medical devices. Key elements include biocompatible materials, precise dimensions, and rigorous cleanliness. These factors ensure regulatory compliance and device functionality. Dive deeper to understand material selection, process accuracy, and environmental standards ...

MANUFACTURING

What Are the Best Alternatives to Injection Molding?

Discover the top alternatives to injection molding like 3D printing, blow molding, and more. These methods offer flexibility, cost savings, and suitability for various project needs, from small batch production to complex designs. Explore your options for efficient manufacturing.

MANUFACTURING

What Temperature is Ideal for Molding Plastic?

Molding plastic requires precision, particularly when it comes to temperature settings. The ideal temperature varies based on plastic type: thermoplastics range from 180°C to 250°C, while thermosetting plastics need 200°C to 280°C. Understanding these differences is crucial for producing high-quality ...

MANUFACTURING

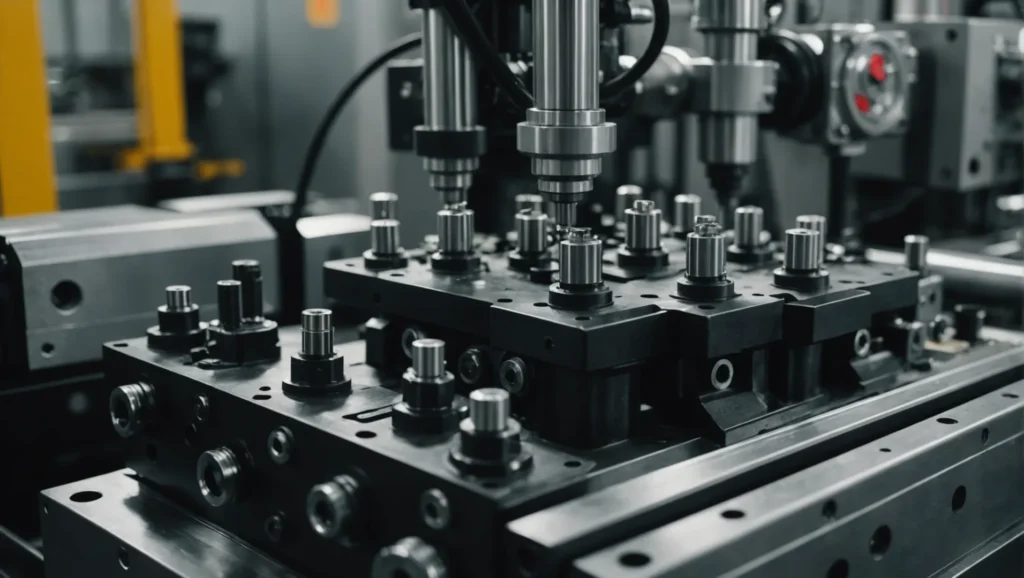

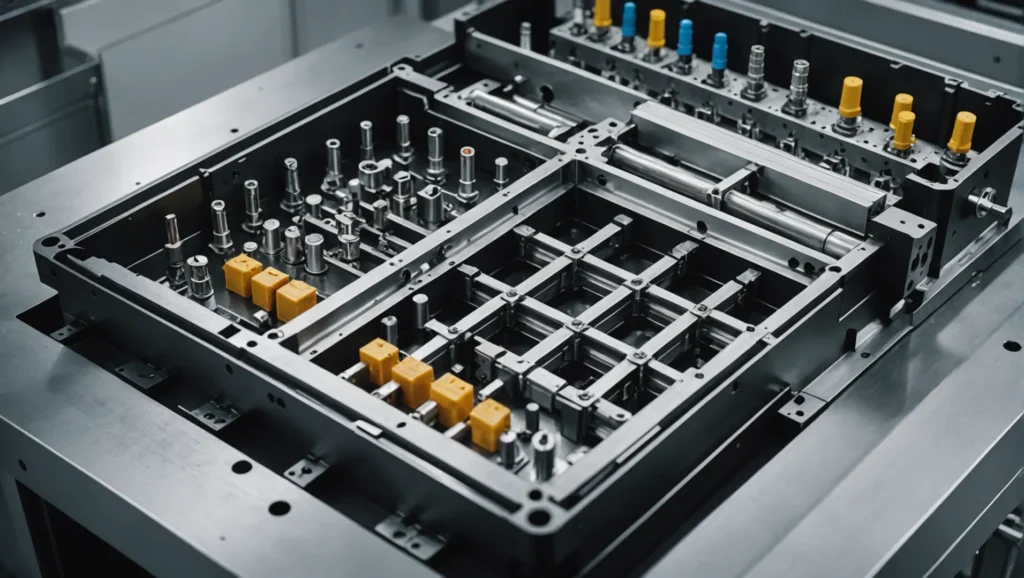

What Are the Seven Essential Components of an Injection Mold?

Explore the seven critical components of an injection mold that ensure the efficient and accurate production of plastic parts. From molding parts to the exhaust system, each element plays a vital role. Discover how these components integrate within the injection ...

MANUFACTURING