All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Key Steps in the Plastic Injection Mold Manufacturing Process?

This article delves into the essential steps of plastic injection mold manufacturing, covering mold design, material selection, processing technologies, cooling systems, and quality control practices to ensure high-quality production.

MANUFACTURING

What Are the Most Common Types of Injection Molding Machines?

This article explores the various types of injection molding machines, including hydraulic, electric, and pneumatic options. It highlights their classifications by appearance, power source, plasticization methods, and clamping techniques to aid in selecting the right machine for manufacturing needs.

DEVELOPMENT

What Are the Best Ways to Prevent Resin from Sticking to Molds?

Preventing resin from sticking to molds is essential for smooth crafting. Utilize mold release agents like silicone oil, wax, and PTFE, optimize curing conditions, and consider internal release agents for better results.

OPTIMIZATION

What Is the Best Type of Plastic for Molding: A Comprehensive Guide?

Choosing the right plastic for molding is crucial for product success. This guide explores various plastics, their properties, applications, and how to select the best material for your project.

Materials Recommendations

What Are the Best Techniques for Creating High-Quality Injection Molded Parts?

Creating high-quality injection molded parts requires careful attention to raw material selection, mold design, process parameter control, and rigorous quality monitoring. Each step is crucial for optimal results.

DEVELOPMENT

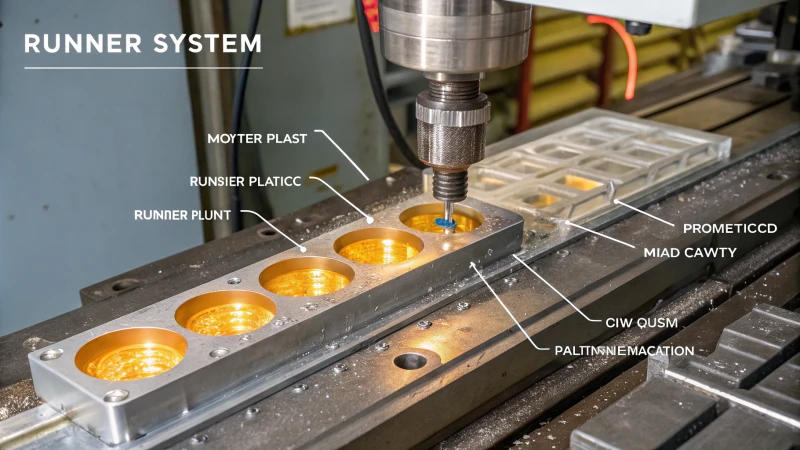

What Role Does the Runner Play in Plastic Molding?

The runner system in plastic molding is crucial for transporting molten plastic from the injection machine to the mold cavity. Its design impacts production efficiency, product quality, and waste reduction.

DEVELOPMENT

How Do Injection Molding Machines Create Plastic Boxes?

This article delves into the injection molding process for creating plastic boxes, covering machine operation, mold design considerations, process parameters, and strategies for improving production efficiency.

MANUFACTURING

What Is Plastic Molding and Why Is It Important?

Plastic molding is a crucial manufacturing process that shapes plastic materials into various forms using techniques like injection, extrusion, and blow molding. It enhances efficiency, reduces waste, and supports diverse industries.

DEVELOPMENT

What Are the Benefits of Plastic Molding Services?

Plastic molding services offer numerous benefits, including efficiency, cost-effectiveness, design flexibility, and strict quality control. These advantages make them ideal for various manufacturing needs and enhance product quality.

DEVELOPMENT

What Are the Best Techniques for Making a Hard Plastic Mold?

This article explores the essential techniques for creating hard plastic molds, covering design, material selection, processing, assembly, trial production, and maintenance to ensure high-quality results.

DEVELOPMENT

What is Tool Life in Injection Molding and Why Does It Matter?

Tool life in injection molding refers to the duration molds and components last before needing replacement. Factors like material quality, design complexity, and process parameters significantly influence tool longevity and production efficiency.

DEVELOPMENT

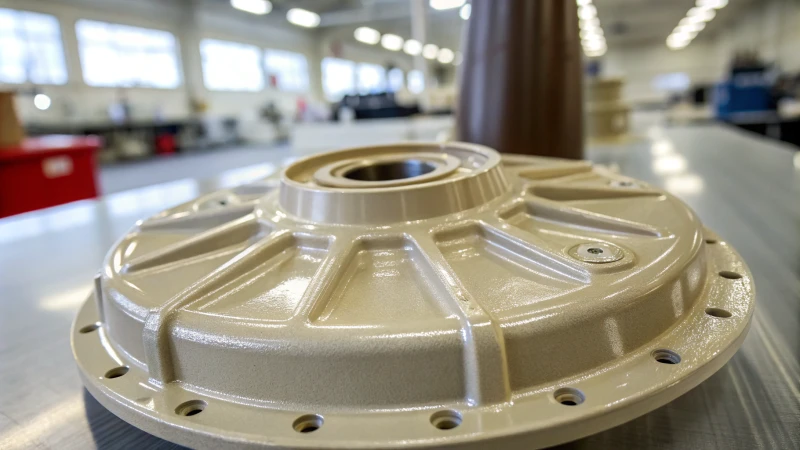

What is the Best Material for Your Mold and How to Choose It?

Choosing the right material for mold making involves considering factors like batch size, precision requirements, complexity, performance characteristics, and cost. Advanced materials enhance durability and efficiency in production.

Materials Recommendations

What Are the Key Limitations of Blow Molding Compared to Injection Molding?

This article explores the limitations of blow molding compared to injection molding, highlighting issues such as limited shape complexity, low dimensional accuracy, and poor appearance quality that affect product design.

DEVELOPMENT

What Are Plastic Mold Products and How Are They Made?

This article explores plastic mold products, detailing their creation through various molding techniques like injection and blow molding. It highlights their applications in packaging, electronics, automotive, and household items.

DEVELOPMENT

What Impact Do Plastic Material Properties Have on Molding Process Selection?

Understanding the impact of plastic material properties, such as flowability, thermal stability, shrinkage rates, toughness, and brittleness, is crucial for selecting appropriate molding processes and ensuring product quality.

Materials Recommendations

What Exactly Is a Preform Mold and How Does It Work?

Preform molds are essential tools in manufacturing, shaping raw materials into precise forms for various industries, including construction and packaging. Understanding their components enhances production efficiency and product quality.

DEVELOPMENT

How Does the Injection Molding Process Work? Discover with Diagrams!

The injection molding process is a crucial manufacturing technique involving raw material preparation, mold installation, parameter setting, and cooling to produce high-quality plastic parts efficiently. Innovations like automation and biodegradable materials enhance its effectiveness.

MANUFACTURING

What Are the Best Plastic Mold Solutions and Tips to Maximize Their Use?

This article explores essential practices for optimizing plastic mold design, cooling systems, and maintenance to enhance product quality and production efficiency in the manufacturing process.

OPTIMIZATION

How Does Injection Molding Effectively Melt Raw Materials?

Injection molding is a sophisticated process that melts thermoplastic materials using an injection system with precise temperature controls, ensuring high-quality production through effective heating and cooling mechanisms.

MANUFACTURING

What Are the Best Surface Finish Options for Injection Molding?

This blog post explores the best surface finish options for injection molding, including paint, electroplating, and texture treatments. It highlights their benefits in enhancing aesthetics, functionality, and cost-effectiveness.

DEVELOPMENT

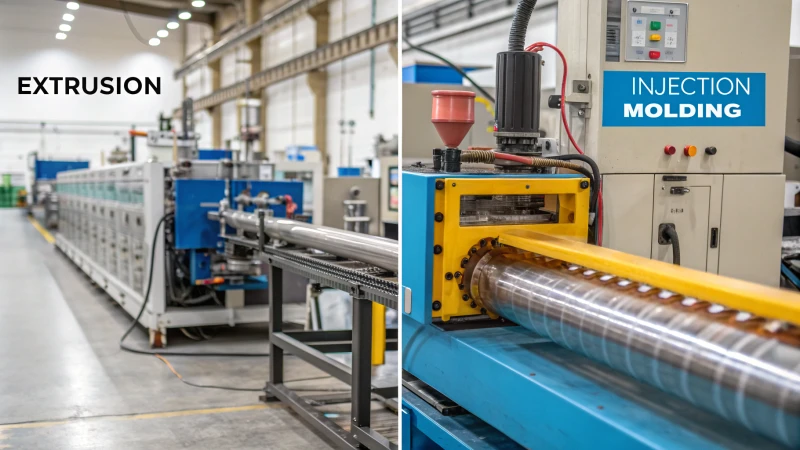

Which Process is More Cost-Effective for Simple Parts: Extrusion or Injection Molding?

This article compares extrusion and injection molding processes, highlighting cost-effectiveness for simple parts. Extrusion generally offers lower equipment costs, better material utilization, and higher production efficiency than injection molding.

Price Evaluation

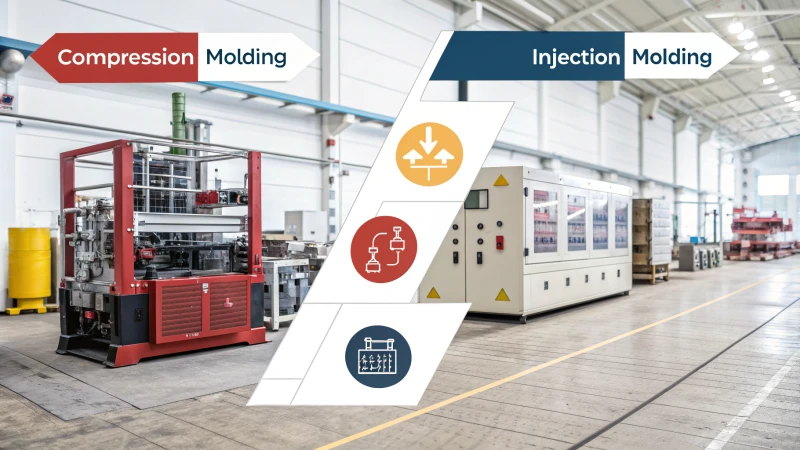

What Are the Key Differences Between Compression Molding and Injection Molding Processes?

This blog post explores the key differences between compression molding and injection molding processes, highlighting their principles, efficiency, costs, and suitability for various applications in plastic manufacturing.

DEVELOPMENT

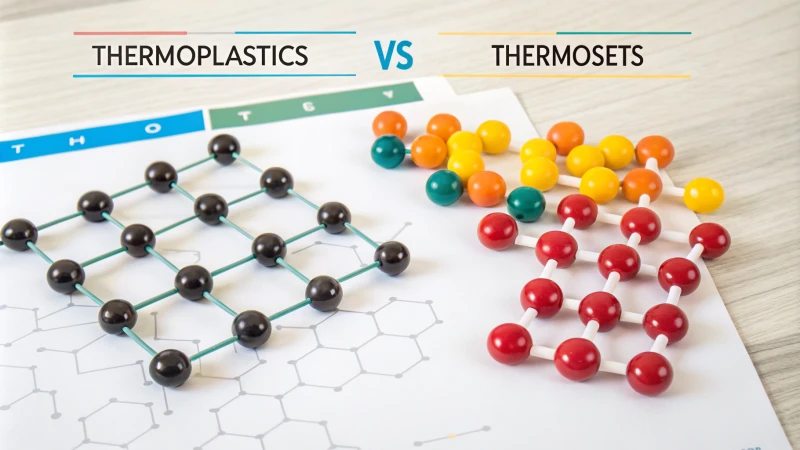

What Are the Key Differences in Material Properties Between Thermoplastics and Thermosets?

This blog post delves into the key differences between thermoplastics and thermosetting plastics, focusing on their molecular structure, mechanical properties, heat resistance, chemical stability, and processing performance. Understanding these distinctions is vital for effective material selection in design and manufacturing.

Materials Recommendations

Is Polyamide More Durable Than Nylon?

This article explores the similarities and differences between polyamide and nylon, focusing on their mechanical, thermal, chemical, and weather-resistant properties to guide material selection for various applications.

Materials Recommendations

When Should You Choose Injection Molding Over Extrusion for Your Project?

This article explores the differences between injection molding and extrusion, highlighting when to choose each method based on product complexity, dimensional accuracy, production batch size, and material flexibility.

DEVELOPMENT

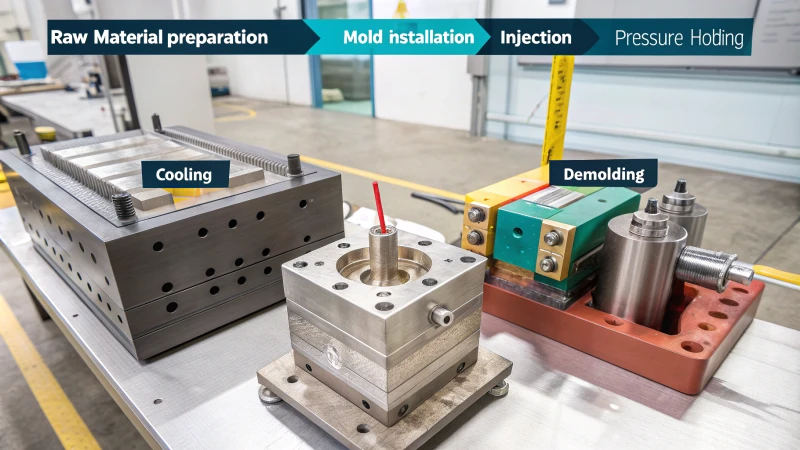

What Are the Key Steps in the Injection Molding Process?

The injection molding process involves several key steps: preparing raw materials, mold installation, injection, pressure holding, cooling, and demolding. Each step is crucial for producing high-quality plastic products.

MANUFACTURING

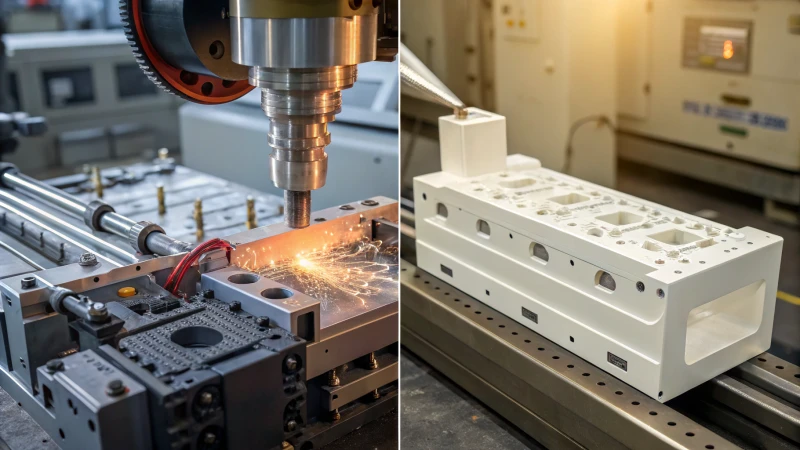

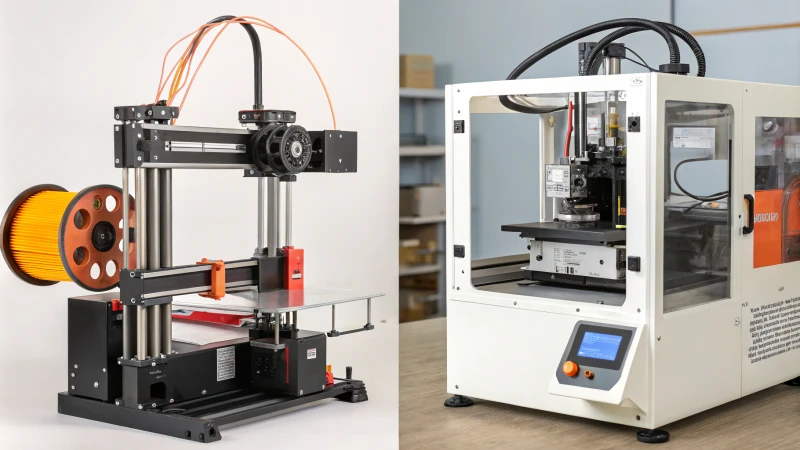

What Are the Key Differences Between 3D Printing and Injection Molding?

This article explores the key differences between 3D printing and injection molding, highlighting their unique strengths in production volume, design complexity, material selection, cost structures, and product quality.

DEVELOPMENT

What Are the Essential Quality Control Considerations for Overmolding?

Overmolding enhances product strength and aesthetics, but requires strict quality control. Key considerations include material compatibility, surface preparation, dimensional stability, and effective bonding techniques to ensure high-quality outcomes.

Quality Inspection

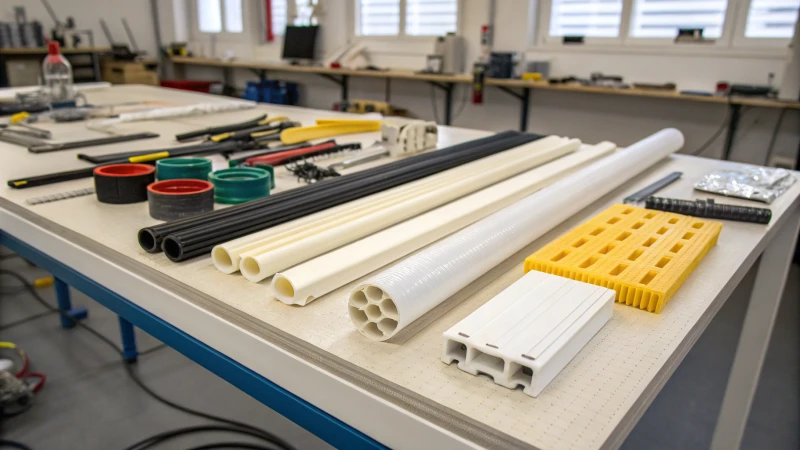

What Shape Can You Expect from the Final Extruded Product?

This article explores the extrusion process, detailing how it produces continuous shapes like pipes, rods, and special profiles. It highlights the benefits of design flexibility, cost-effectiveness, and material selection in manufacturing.

DESIGN

What Are the Production Speeds for Extrusion vs. Injection Molding?

This article compares extrusion and injection molding production speeds, highlighting the continuous efficiency of extrusion versus the cyclical nature of injection molding, along with their respective cost implications.

DEVELOPMENT