All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Causes of Cold Slug in Injection Molding?

Cold slugs are a common issue in injection molding that can compromise product quality. They typically form due to material temperature inconsistencies, inadequate nozzle designs, or improper mold cooling. This blog explores the causes of cold slug formation and offers ...

OPTIMIZATION

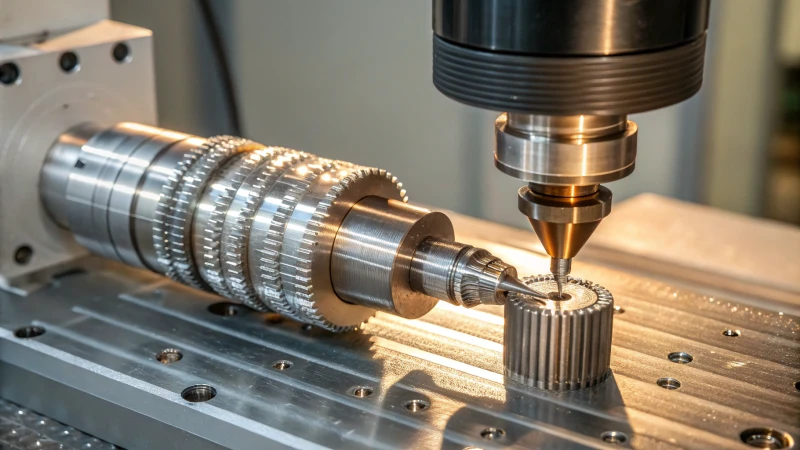

How Can You Successfully Injection Mold Threads?

Successfully injection molding threads involves a comprehensive approach that includes optimizing mold design for thread alignment, selecting appropriate materials, maintaining precise temperature control, and implementing effective venting techniques. Each factor plays a crucial role in achieving high-quality threaded components. Proper ...

MANUFACTURING

What Are the Best Design Techniques for Injection Mold Parting Surfaces?

Designing effective parting surfaces in injection molding is crucial for product quality. Key considerations include the shape of the plastic product, aesthetic requirements, processing ease, and venting needs. Simple shapes allow straightforward parting line placement, while complex shapes may require ...

DESIGN

What Are the Key Advantages of Hot Runner Mold Design?

Hot runner molds revolutionize plastic manufacturing by significantly boosting production efficiency. They reduce cycle times from 20-30 seconds to 10-15 seconds, minimize material waste, and enhance product quality through consistent melt flow and temperature control. By selecting the right hot ...

DESIGN

What Are the Best Practices for Designing the Ejection Mechanism of an Injection Mold?

Designing an effective ejection mechanism for injection molds involves understanding the product's shape and material properties, choosing suitable ejection methods like push rod or push plate, calculating necessary ejection forces, and ensuring proper positioning to avoid damage. Key considerations include ...

DESIGN

What Are the Applications and Benefits of Gas-Assisted Injection Molding Technology?

Gas-assisted injection molding technology revolutionizes manufacturing by using high-pressure gas to create hollow sections in plastic parts. This process reduces material usage by up to 40%, improves product strength and surface finish, and allows for intricate designs that traditional methods ...

DEVELOPMENT

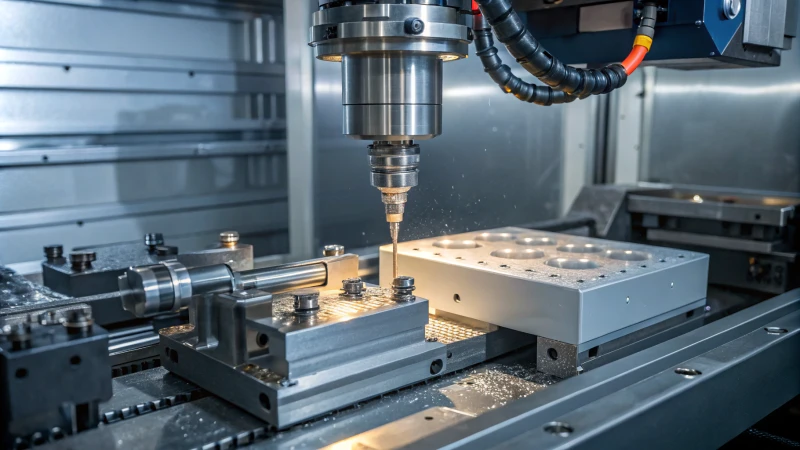

How Is EDM Revolutionizing Injection Mold Manufacturing?

Electrical Discharge Machining (EDM) is transforming injection mold manufacturing by allowing for the precise creation of complex shapes and handling hard materials post-quenching. This technology enhances efficiency and product quality through its ability to maintain dimensional accuracy and surface integrity. ...

MANUFACTURING

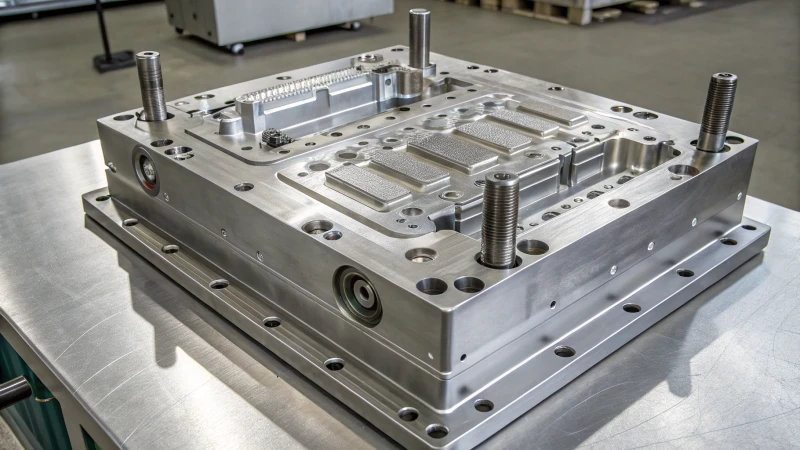

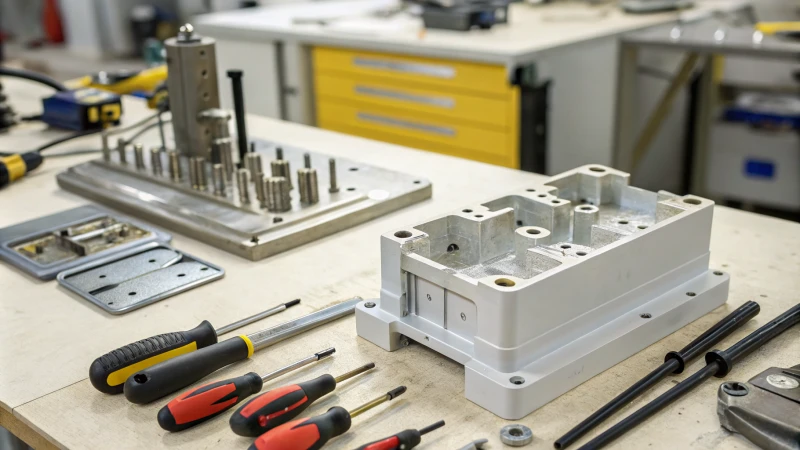

How Are Mold Inserts Designed and What Are Their Applications?

Mold inserts are crucial components in manufacturing that improve product quality and efficiency. Designed with precision, they enhance mold functionality by allowing intricate shapes and features without compromising the overall structure. Material selection plays a significant role in durability and ...

DESIGN

How Does the Core Pulling Mechanism in Injection Molds Work?

Core pulling mechanisms play a vital role in injection molding by allowing the creation of intricate designs such as side holes and undercuts. These mechanisms retract cores during or after mold opening to facilitate smooth demolding without damaging the product. ...

DEVELOPMENT

How Does Uneven Product Wall Thickness Impact the Injection Molding Process?

Uneven wall thickness in injection molding leads to issues like imbalanced melt flow, fusion marks, and warping, affecting product quality. Understanding these effects is crucial for improving design and manufacturing processes.

MANUFACTURING

What Are the Key Differences Between Injection Molding and Vacuum Forming?

This article explores the key differences between injection molding and vacuum forming, two popular manufacturing techniques. Injection molding is ideal for high-volume production of intricate designs due to its efficiency and precision. In contrast, vacuum forming offers a more budget-friendly ...

MANUFACTURING

What Are the Best Ways to Prevent Cracks in Injection Molded Products?

This article explores effective strategies to prevent cracks in injection molded products, emphasizing the importance of product design optimization, process control, and mold maintenance for enhanced durability and quality.

DEVELOPMENT

What Are the Best Methods to Prevent Silver Grain Defects in Injection Molded Products?

Silver grain defects in injection molded products can be minimized by focusing on raw material management, precise parameter settings, effective mold design, and process optimization to enhance product quality.

OPTIMIZATION

What Are the Key Advantages of Injection Molding Compared to Other Plastic Manufacturing Processes?

Injection molding offers significant advantages over other plastic manufacturing processes, including high production efficiency, superior product quality, design flexibility, material adaptability, and cost-effectiveness in mass production.

DEVELOPMENT

How Can You Effectively Reduce the Manufacturing Costs of Injection Molded Plastic Products?

This article explores effective strategies to reduce manufacturing costs in injection molding, focusing on optimizing raw materials, streamlining production processes, managing equipment efficiently, and implementing robust quality control measures.

OPTIMIZATION

What Are the Best Ways to Prevent Fusion Marks on Injection Molded Products?

This article explores effective strategies to prevent fusion marks in injection molded products, emphasizing the importance of mold design, process parameter adjustments, and material selection for improved quality.

OPTIMIZATION

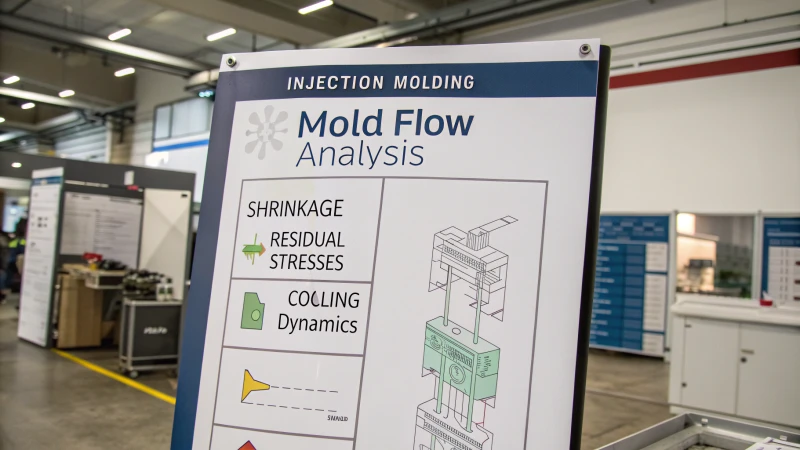

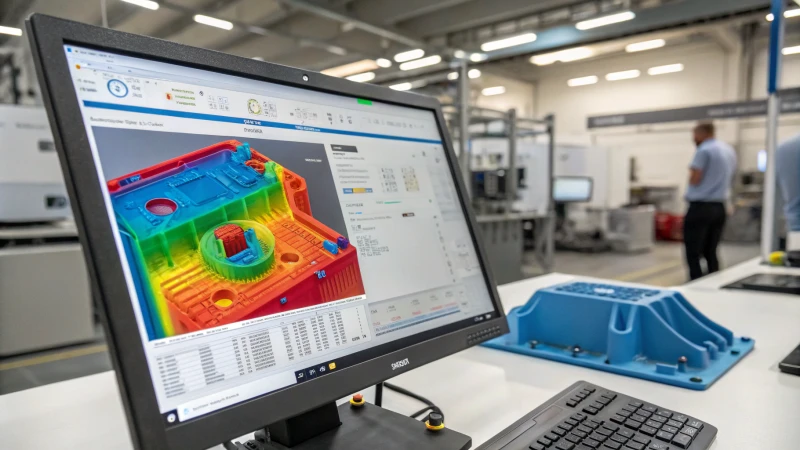

What Is Mold Flow Analysis and How Does It Predict Warpage in Injection Molded Parts?

Mold flow analysis is crucial in injection molding, predicting warpage by assessing shrinkage, residual stresses, and cooling patterns. This software enhances design accuracy and manufacturing efficiency, ensuring high-quality molded parts.

DEVELOPMENT

How Can You Ensure Uniform Wall Thickness in Your Injection Mold Design?

Ensuring uniform wall thickness in injection mold design is crucial for product quality. Key factors include gate design, runner systems, cooling layouts, and mold cavity adjustments to minimize defects.

DESIGN

What Parameters Can Be Optimized by Mold Flow Analysis in Injection Molding?

Mold Flow Analysis (MFA) optimizes injection molding parameters such as gate location, runner systems, injection pressure, and cooling times to enhance production efficiency, reduce defects, and improve product quality.

OPTIMIZATION

What Factors Influence the Duration of Plastic Injection Molding?

This article explores the key factors influencing the duration of plastic injection molding, including cycle composition, material properties, part size and shape, process parameters, and mold design. Understanding these elements can enhance efficiency and product quality.

DEVELOPMENT

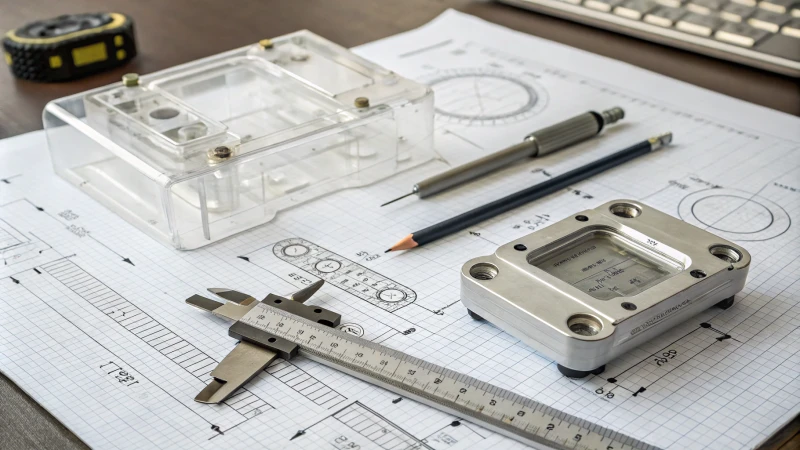

What Key Factors Should You Consider When Designing an Injection Mold?

Designing an injection mold requires careful consideration of product shape, size, wall thickness, precision needs, cooling system design, and cost management to ensure efficient production and high-quality outputs.

DESIGN

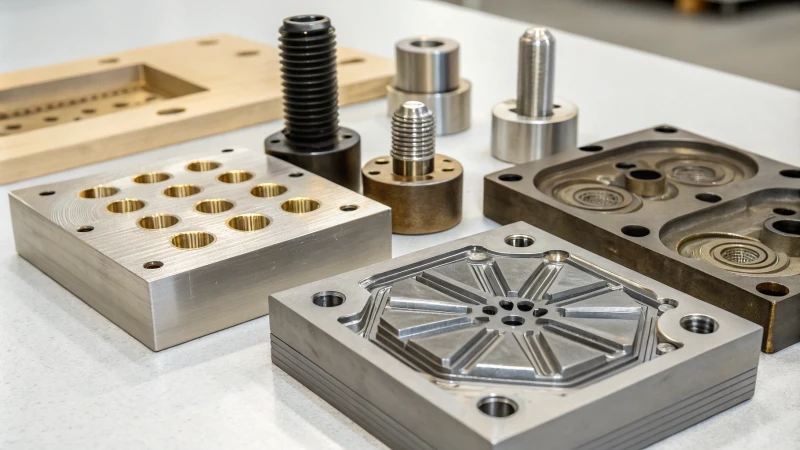

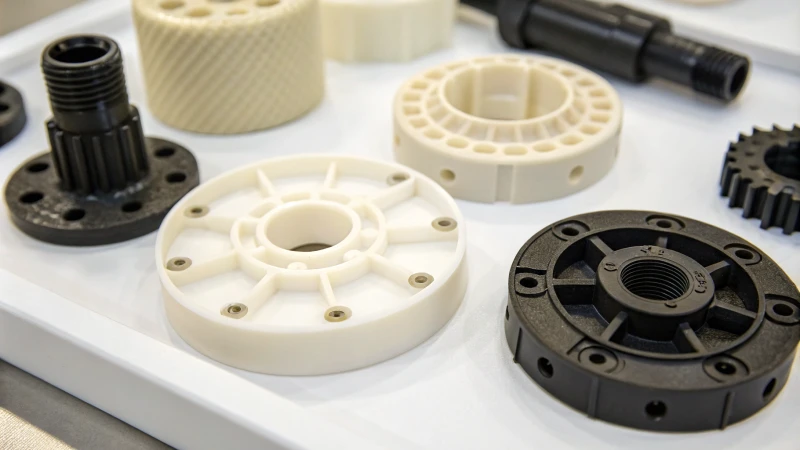

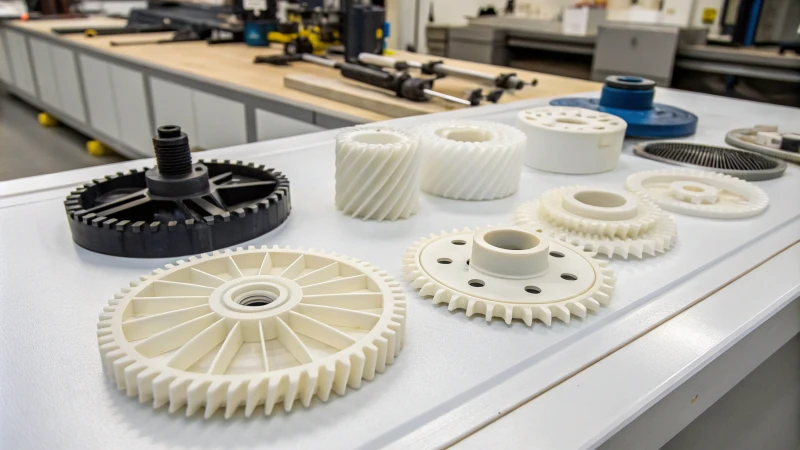

What Are Injection Molded Plastic Parts and Why Are They Important?

Injection molded plastic parts are essential in modern manufacturing, offering high precision, complex shapes, and efficiency. This versatile process is crucial for industries like automotive and consumer electronics.

DEVELOPMENT

What Role Does Injection Molding Play in Manufacturing?

Injection molding revolutionizes manufacturing by enabling the efficient production of complex, high-quality plastic parts across various industries. Its precision, speed, and innovative mold designs enhance product quality and efficiency.

DEVELOPMENT

How Do Mold Flow Analysis Results Guide Injection Mold Design?

Mold flow analysis is essential for optimizing injection mold design, influencing gate placement, runner systems, and cooling channels. It enhances production efficiency and product quality by predicting potential defects.

DESIGN

What Are the Best Ways to Adjust Melt Temperature in Injection Molding to Minimize Fusion Marks?

This article explores the importance of adjusting melt temperature in injection molding to minimize fusion marks. It discusses material properties, mold design, cooling systems, and process parameter coordination for optimal results.

OPTIMIZATION

What Are the Key Benefits of Mold Flow Analysis?

Mold Flow Analysis is a vital tool in injection molding that simulates the process to optimize mold design, predict defects, enhance product quality, and improve production efficiency.

DESIGN

How Do Injection Molding Machines Create Plastic Balls?

Injection molding machines create plastic balls through a detailed process involving mold design, material selection, and precise control of injection parameters. Each step is crucial for producing high-quality products.

MANUFACTURING

What are the Best Techniques for Removing Gates After Injection Molding?

Removing gates from injection molded parts requires careful consideration of methods such as manual, mechanical, chemical, and ultrasonic removal. Factors like gate size, material type, and production efficiency influence the best choice.

DEVELOPMENT

Why is Injection Molding Considered Fast and Cost-Effective?

Injection molding is a fast, cost-effective manufacturing process driven by automation. It features short cycle times and high material utilization, making it ideal for large-scale production across various industries.

DEVELOPMENT

What Makes a High Speed Injection Molding Machine Essential for Efficient Production?

High-speed injection molding machines significantly enhance manufacturing efficiency by reducing cycle times and improving product quality. Their advanced technology allows for rapid injection, optimizing material flow and minimizing defects.

DEVELOPMENT