All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Best Practices for Storing Injection Molds to Extend Their Life?

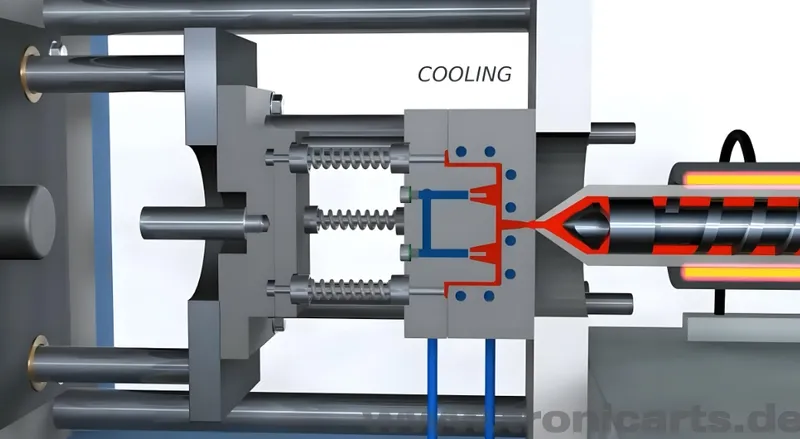

Injection molds are the backbone of plastic manufacturing, shaping everything from automotive parts to medical devices. These precision tools represent a significant investment, often costing thousands to millions of dollars. However, their longevity and performance hinge on one critical factor: ...

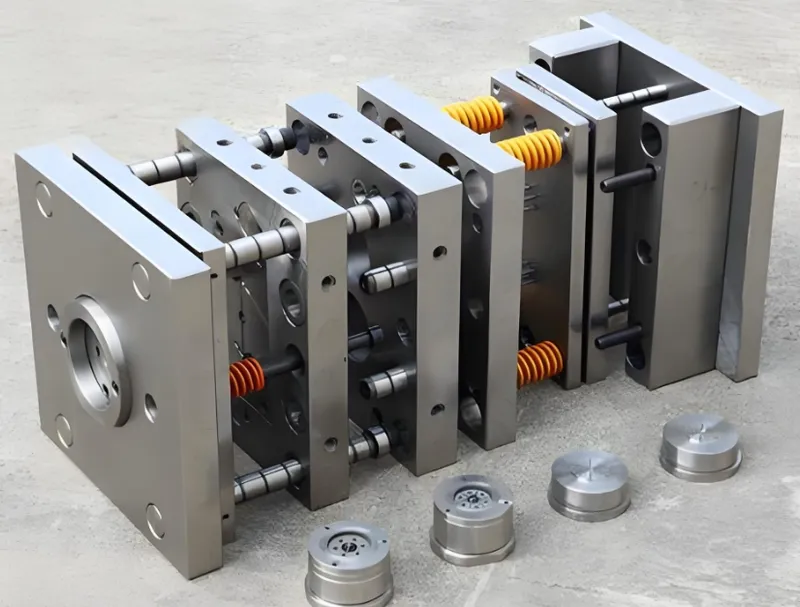

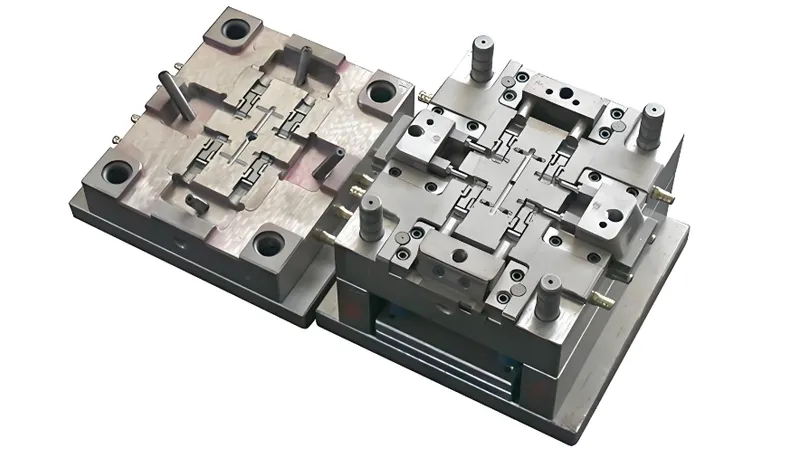

Injection mold

What Are the Advantages of Using Recycled Materials in Injection Molding?

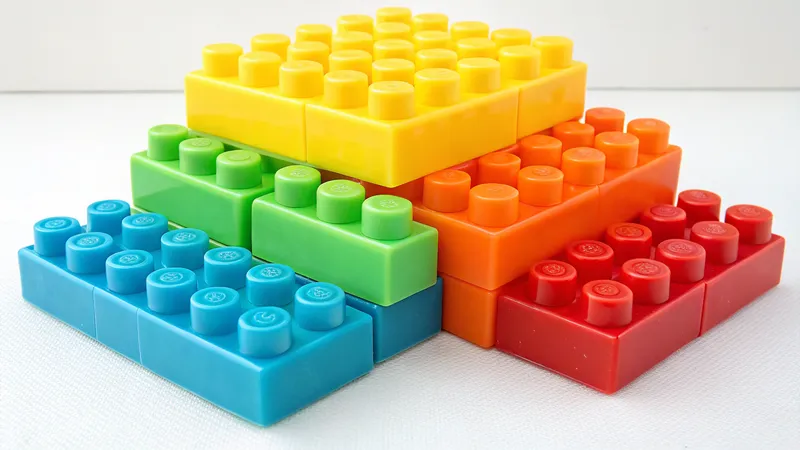

Did you know that the plastic bottle you recycled last week could become part of your next car or favorite toy? Thanks to advances in injection molding1, recycled materials are transforming the manufacturing landscape2, offering a win-win for both the ...

Injection moulding

Navigating the Future: Latest Trends in Injection Molding Materials for 2025

The injection molding industry is evolving rapidly as we approach 2025, with new materials emerging to meet the demands of sustainability, performance, and specialization. For manufacturers, staying ahead of these trends is essential to optimizing production, reducing costs, and aligning ...

Injection molding raw materials

How Do Plastic Ribs Enhance Injection-Molding Design?

Plastic ribs enhance injection-molding design by adding strength and stiffness to parts while minimizing material usage and preventing defects like warpage or sink marks. Understanding how to properly design and implement ribs is key to optimizing your injection-molding projects. In ...

Injection moulding

Cutting-Edge Trends in Injection Molding Technology: A Comprehensive Guide

Injection molding, a cornerstone of modern manufacturing, involves injecting molten material into a mold to produce precise, high-quality parts. This process is undergoing a transformation driven by cutting-edge trends such as sustainability1, automation, miniaturization, advanced materials, and on-demand production. These ...

Injection moulding

Achieving Tight Tolerances in Injection Molding: A Comprehensive Guide

Achieving tight tolerances in injection molding1 is critical for producing high-quality, precise parts that meet stringent industry standards, such as those in medical, automotive, and aerospace applications. Injection molding with tight tolerances involves optimizing design, materials, tooling, and processes to ...

Injection moulding

How Material Selection Affects Injection Molding Costs?

Injection molding is a cornerstone of modern manufacturing, enabling the mass production of precise plastic parts efficiently. However, one of the most pivotal decisions in this process is selecting the right material. This choice influences not just the performance of ...

Injection molding raw materials

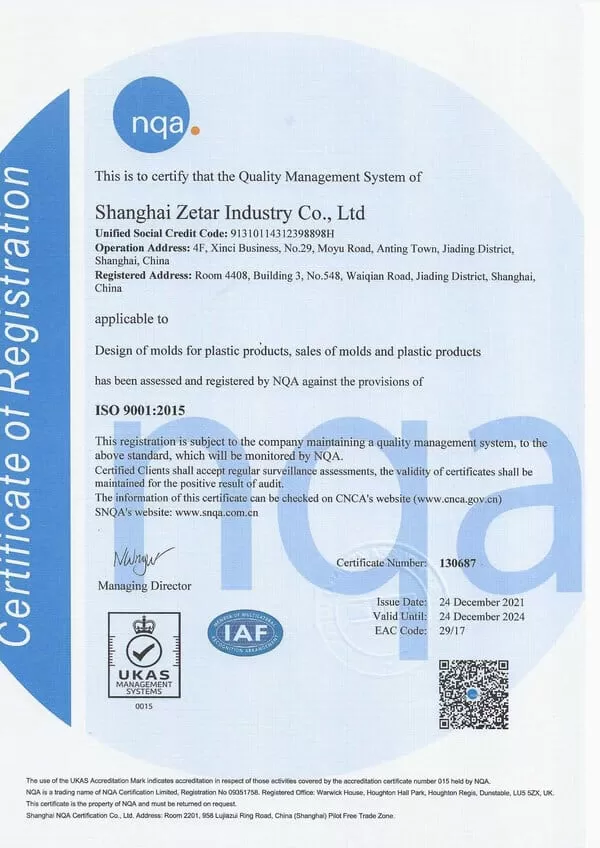

Comprehensive Report on ISO 9001 Certification Benefits for Injection Molding Operations

ISO 9001 certification, a globally recognized standard for quality management systems1 (QMS), provides a structured framework for organizations to ensure consistent quality, meet customer expectations, and drive continuous improvement. For injection molding operations—a manufacturing process that produces precise plastic parts ...

Injection moulding

What Are the Most Effective Rapid Prototyping Techniques for Mold Making?

Rapid prototyping1 techniques for mold making have transformed manufacturing by enabling faster, more cost-effective mold production. These methods are vital for industries like automotive, medical devices, and consumer goods, where precision and speed are paramount. Rapid prototyping for mold making2 ...

Injection mold

How Does Automation Lower Labor Costs in Injection Molding?

Automation in injection molding significantly reduces labor costs by replacing manual tasks with efficient, machine-driven processes, enabling manufacturers to produce more with fewer workers while maintaining high quality and consistency. Automation in injection molding lowers labor costs by automating repetitive ...

Injection moulding

How Do Additives Impact the Properties of Injection-Molded Parts?

Additives play a crucial role in enhancing the properties of injection-molded parts1, allowing manufacturers to tailor materials for specific applications. From improving strength and durability to enhancing aesthetics and environmental resistance, additives can transform the performance of molded components. However, ...

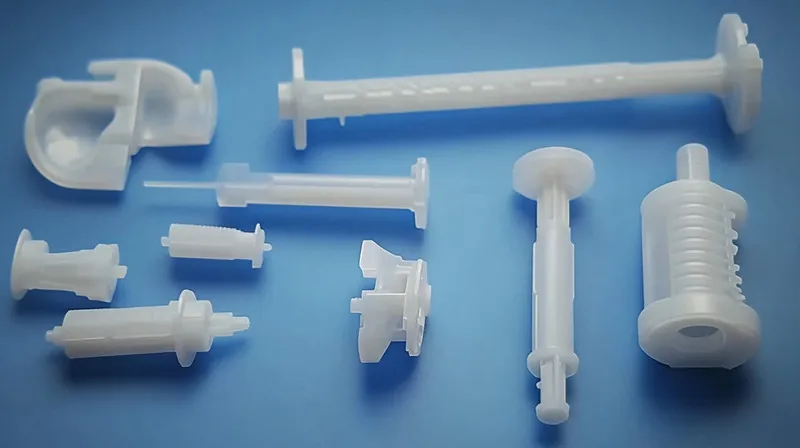

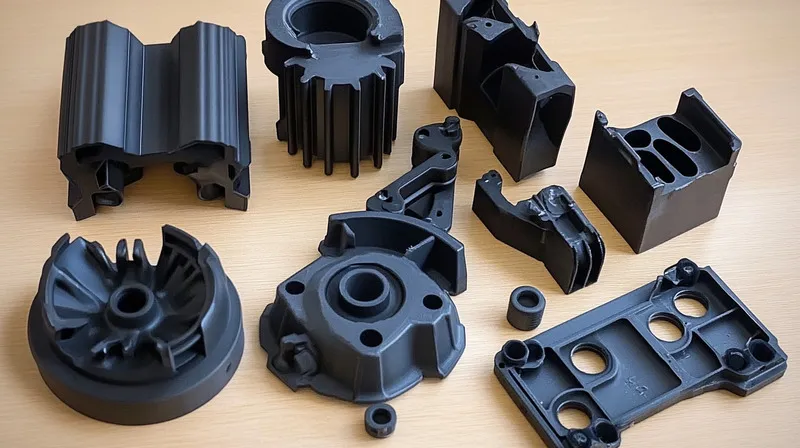

Injection Molded Products

How Can You Design Effective Molds for Thin-Wall Injection Molding?

Thin-wall injection molding1 is a specialized manufacturing process that produces lightweight plastic parts with walls often less than 1mm thick, making it ideal for industries like packaging, automotive, and consumer electronics. However, designing molds for this process requires precision to ...

Injection mold

Designing Multi-Cavity Molds: A Comprehensive Guide

In the world of injection molding, efficiency is everything. Manufacturers constantly seek ways to produce more parts in less time without compromising quality. Enter multi-cavity molds1—these specialized tools allow the creation of multiple identical parts in a single cycle, slashing ...

Injection mold

What Are the Types and Causes of Waste in Injection Molding?

Injection molding is a widely used manufacturing process for producing precise plastic parts, but it often generates various forms of waste that can increase costs and impact sustainability. Understanding the types and causes of waste in injection molding is essential ...

Injection moulding

Which Material is Best for Creating Durable Living Hinges?

Creating durable living hinges—those flexible plastic connectors that allow repeated bending without breaking—requires selecting the right material. This article explores why polypropylene (PP)1 stands out as the best choice, compares it to alternatives, and provides actionable insights for design and ...

Injection molding raw materials

What Impact Do RoHS Directives Have on Injection Molding Materials?

The Restriction of Hazardous Substances (RoHS) directives significantly impact injection molding materials by enforcing strict limits on hazardous substances, driving manufacturers to adopt safer, eco-friendly alternatives1. This shift affects material selection, production costs, and market access, particularly for electronics sold ...

Injection moulding

What Impact Do Crystallinity Levels in Polymers Have on Injection Molding Outcomes?

Crystallinity in polymers plays a crucial role in determining the mechanical properties1, dimensional stability, and overall performance of injection-molded parts. Understanding how crystallinity affects the injection molding process2 is essential for engineers, designers, and manufacturers aiming to optimize product quality ...

Injection moulding

What Impact Do Biodegradable Plastics Have on Injection Molding Processes?

Biodegradable plastics are revolutionizing the injection molding1 industry by offering sustainable alternatives to traditional petroleum-based plastics. These materials, derived from renewable sources, decompose naturally, reducing environmental impact. However, their integration into injection molding processes requires specific adjustments and considerations. Biodegradable ...

Injection molding raw materials

How to Design Injection Molded Parts for Seamless Assembly

Designing injection molded parts1 for seamless assembly is essential for efficient manufacturing and high-quality products. It ensures that parts fit together perfectly, reducing assembly time and costs while improving overall product reliability. This guide will walk you through the key ...

Injection Molded Products

How Can 3D Printing Revolutionize Your Mold Making Process?

3D printing, or additive manufacturing1, is transforming the mold making process2 by offering unprecedented speed, cost savings, and design flexibility. This technology enables the creation of molds directly from digital designs, reducing lead times and allowing for complex geometries that ...

3D Printing Molds

Balancing Runners in Multi-Cavity Molds: A Comprehensive Guide

Balancing runners in multi-cavity molds1 is a critical aspect of injection molding that ensures each cavity fills uniformly, producing consistent, high-quality parts. In multi-cavity molds, which are designed to produce multiple identical parts in a single cycle, the runner system—the ...

Injection mold

What Are the Top Mold Testing Practices for Efficient Injection Molding?

Injection molding is a cornerstone of modern manufacturing, enabling the mass production of plastic parts with high precision and efficiency. However, the success of this process hinges on the quality of the mold used. Mold testing is a critical step ...

Injection mold

What Are the Essential Tips for Effective Mold Design?

Mold design is a critical process in manufacturing that shapes materials like plastics, metals, or glass into precise parts used across industries such as automotive, medical, and consumer goods. A well-designed mold ensures high-quality parts1, reduces waste, and speeds up ...

Injection mold

Understanding Side Actions in Injection Molding: A Comprehensive Guide

Side actions in injection molding are specialized mechanisms that enable the creation of complex part features, such as undercuts1, which cannot be achieved with standard molds. These features, like snap-fits or threaded holes, are essential for many industries but would ...

Injection moulding

Is Injection Molding Possible with Glass-Filled Nylon? A Comprehensive Guide

Injection molding is a widely used manufacturing process for creating plastic parts, but when it comes to materials like glass-filled nylon, there are unique considerations and benefits. Glass-filled nylon, a type of nylon reinforced with glass fibers, offers enhanced strength, ...

Injection molding raw materials

How Injection Molding Companies Achieve FDA Compliance

Injection molding is a cornerstone of modern manufacturing, producing everything from food packaging to life-saving medical devices. However, when these products come into contact with food or the human body, they must meet strict safety standards set by the U.S. ...

Injection moulding

How Does the Ejector System Work in Injection Molding?

The ejector system in injection molding is a crucial mechanism that ensures the efficient removal of molded parts from the mold cavity. This system plays a vital role in maintaining production speed and part quality1, making it essential for manufacturers ...

Injection moulding

How Does Insert Molding Enhance Injection Processes?

Insert molding is a specialized injection molding technique1 that integrates pre-formed inserts—typically metal components2—into plastic parts during the molding process. This method enhances traditional injection molding by producing stronger, more functional, and cost-effective products. By embedding inserts directly into the ...

Injection moulding

Choosing the Right Plastic B Side Features: A Comprehensive Guide

When designing plastic parts for injection molding, one of the critical aspects to consider is the selection of B side features1. These features, located on the non-visible side of the part, play a vital role in the functionality and assembly ...

Injection molding raw materials

How Biopolymers Enhance the Sustainability of Injection Molding

Biopolymers are transforming the injection molding1 industry by offering a sustainable alternative to traditional petroleum-based plastics. Derived from renewable resources like plants and microorganisms, biopolymers are often biodegradable or compostable, making them an eco-friendly choice for manufacturers looking to reduce ...

Injection Molded Products