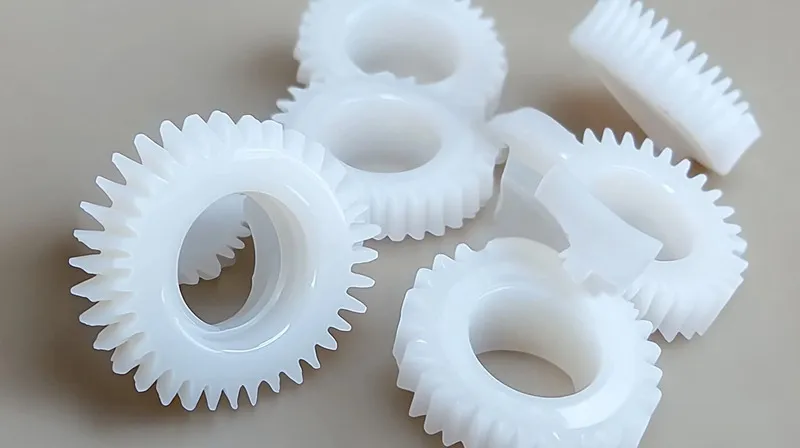

Achieving tight tolerances in injection molding1 is critical for producing high-quality, precise parts that meet stringent industry standards, such as those in medical, automotive, and aerospace applications.

Injection molding with tight tolerances involves optimizing design, materials, tooling, and processes to produce precise parts2 within ±0.002 inches, essential for industries requiring exact fit and function.

This guide explores the methods and considerations necessary to achieve tight tolerances3, offering a detailed resource for manufacturers and engineers aiming for precision.

Tight tolerances in injection molding are achievable with standard processes.False

Achieving tight tolerances requires advanced techniques, high-precision tooling, and rigorous control beyond standard processes.

Material selection significantly impacts achieving tight tolerances.True

Amorphous materials like ABS and PC have lower shrinkage, making them ideal for precision compared to crystalline materials.

What Does Achieving Tight Tolerances Mean in Injection Molding?

Tight tolerances refer to the ability to produce parts with minimal dimensional variation, ensuring consistency and functionality across high-volume production.

Tight tolerances in injection molding mean maintaining dimensional accuracy within ±0.002 inches (±0.05 mm), crucial for parts requiring precise fit, such as medical devices and automotive components.

Definitions and Classifications

-

Injection Molding: A process where molten plastic is injected into a mold under high pressure to form precise parts.

-

Tight Tolerances: Variations typically within ±0.002 inches, ensuring exact specifications.

-

Shrinkage: The reduction in part size as plastic cools, which must be predicted and controlled.

-

Warpage: Distortion from uneven cooling or shrinkage, impacting accuracy.

| Aspect | Description |

|---|---|

| Tooling Precision | High-accuracy molds (e.g., CNC-machined) |

| Process Control | Consistent pressure, temperature, and timing |

| Material Type | Amorphous (e.g., ABS) vs. Crystalline (e.g., PP) |

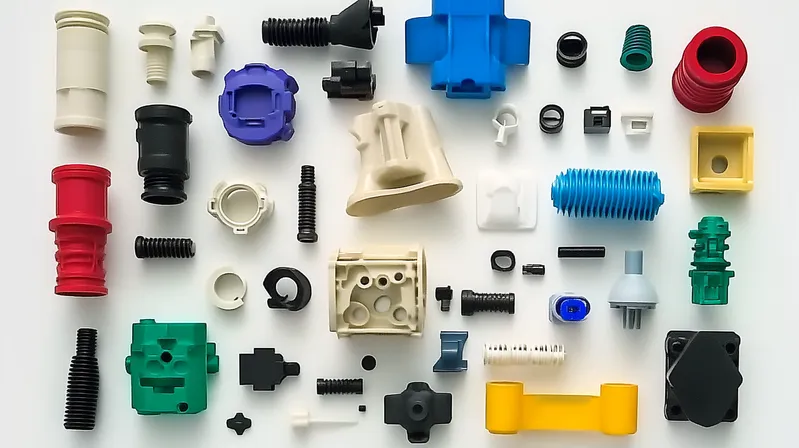

How Are Tight Tolerances Applied in Injection Molding?

Tight tolerances are applied across industries where precision is non-negotiable, balancing performance with production efficiency.

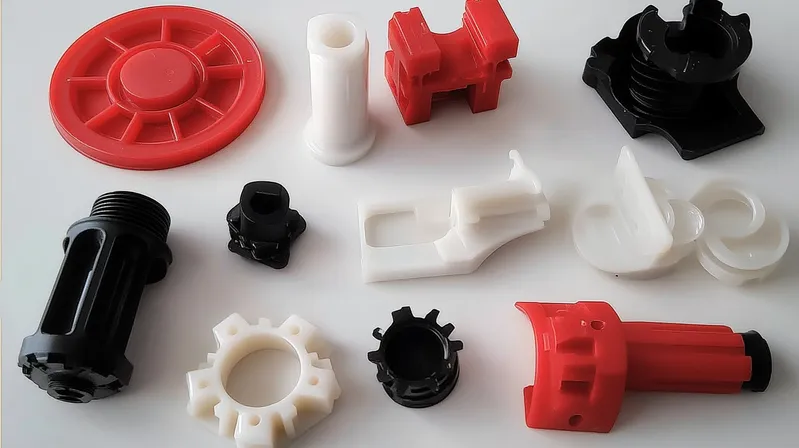

Tight tolerances are applied in injection molding for medical devices4, automotive parts, and aerospace components, requiring careful design and process control to ensure repeatability.

Application Scenarios

-

Medical Devices: Syringes and implants need tolerances as tight as ±0.025 mm for safety Fictiv.

-

Automotive: Connectors and sensors demand precision for assembly reliability.

-

Aerospace: Components require exact dimensions for extreme conditions.

Pros and Cons Comparison

| Method | Pros | Cons |

|---|---|---|

| Injection Molding | High volume, complex shapes | High tooling costs |

| CNC Machining | Tighter tolerances (±0.0005 in) | Slower, costly for volume |

| 3D Printing | Flexible prototyping | Looser tolerances (±0.005 in) |

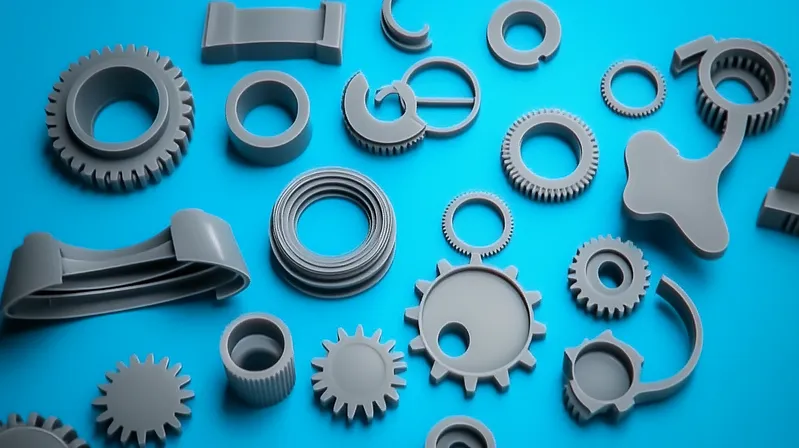

What Are the Key Steps to Achieve Tight Tolerances?

Achieving tight tolerances involves a systematic approach from design to quality control, ensuring every phase supports precision.

The process to achieve tight tolerances includes optimizing design, selecting materials, crafting precise molds, controlling injection parameters, and verifying quality.

Step-by-Step Process

-

Design Optimization:

- Use Design for Manufacturability (DFM) principles Protolabs.

- Ensure uniform wall thickness (1.1-3.5 mm for ABS).

- Add 1-2 degrees of draft for ejection.

-

Material Selection:

- Prefer amorphous materials (e.g., ABS, PC) for lower shrinkage.

- Account for thermal expansion in variable conditions.

-

Mold Design:

- Employ high-precision CNC machining (±0.0508 mm).

- Integrate cooling channels for uniform cooling.

-

Process Control:

- Maintain consistent pressure and temperature.

- Use scientific molding for optimization Xometry.

-

Quality Control:

- Inspect with CMMs and apply SPC for consistency.

| Material | Commercial Tolerance5 | Fine Tolerance6 | Shrinkage Rate7 |

|---|---|---|---|

| ABS | 0.050–0.100 mm | 0.030–0.080 mm | 0.003 in./in. |

| PC | 0.050–0.100 mm | 0.030–0.080 mm | 0.5–0.7% |

| PP | 0.075–0.150 mm | 0.050–0.100 mm | 0.018 in./in. |

What Factors Influence Tight Tolerances?

Several factors determine the success of achieving tight tolerances, from material behavior to equipment precision.

Key factors influencing tight tolerances include material properties8, mold quality9, process parameters, and inspection methods.

Critical Factors

-

Material Shrinkage: Amorphous materials shrink less uniformly.

-

Mold Precision: High-quality tooling reduces variation.

-

Temperature Control: Affects shrinkage and warpage.

-

Pressure Consistency: Ensures uniform fill and pack.

How Can You Ensure Tight Tolerances in Practice?

Practical tools and checklists help translate theory into actionable steps for consistent results.

Ensuring tight tolerances involves using design checklists, process monitoring, and advanced quality control tools.

Design Checklist

- Uniform wall thickness (e.g., 1.1-3.5 mm).

- 1-2 degrees of draft on vertical surfaces.

- Radii instead of sharp corners.

- Specify tolerances only for critical features.

Process Tips

- Conduct mold flow analysis for complex parts.

- Use real-time sensors for parameter monitoring.

Conclusion

Achieving tight tolerances in injection molding demands a holistic approach, integrating optimized design10, precise tooling, suitable materials, and controlled processes11. By mastering these elements, manufacturers can meet the exacting standards of industries like medical, automotive, and aerospace, delivering reliable, high-quality parts.

-

Discover the fundamentals of injection molding, including its processes and applications, to enhance your understanding of this critical manufacturing technique. ↩

-

Learn about the strategies and technologies that ensure the production of precise parts, vital for industries like medical and aerospace. ↩

-

Explore this link to understand the best practices and techniques for achieving tight tolerances in injection molding, crucial for high-quality production. ↩

-

Explore the role of injection molding in creating safe and effective medical devices, highlighting its precision and efficiency. ↩

-

Understanding Commercial Tolerance is crucial for ensuring product quality and compliance in manufacturing processes. ↩

-

Exploring Fine Tolerance helps in achieving precision in engineering, which is vital for high-quality products. ↩

-

Learning about Shrinkage Rate is essential for predicting material behavior during production and use, impacting overall design. ↩

-

Exploring this topic can provide insights into selecting the right materials for your projects. ↩

-

Learning about mold quality can help you improve your production efficiency and reduce defects. ↩

-

Optimized design is key to successful injection molding. Discover insights on how it can improve efficiency and quality. ↩

-

Controlled processes ensure consistency and quality in production. Learn more about their importance in injection molding. ↩